High-density cotton carding metallic card clothing

A metal card clothing and carding technology, which is applied in the field of carding machines, can solve the problems of fiber sinking into the gap depth and increase carding resistance, etc., to achieve increased carding and fiber support, increased carding output, and increased tooth density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

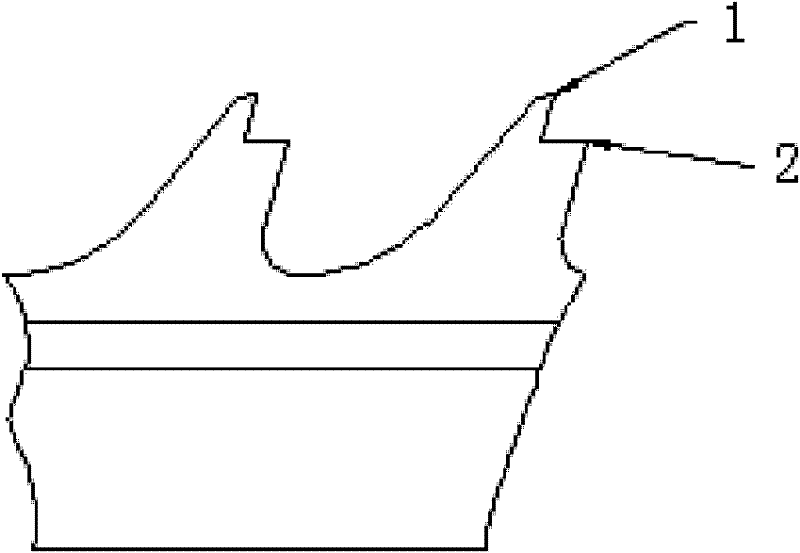

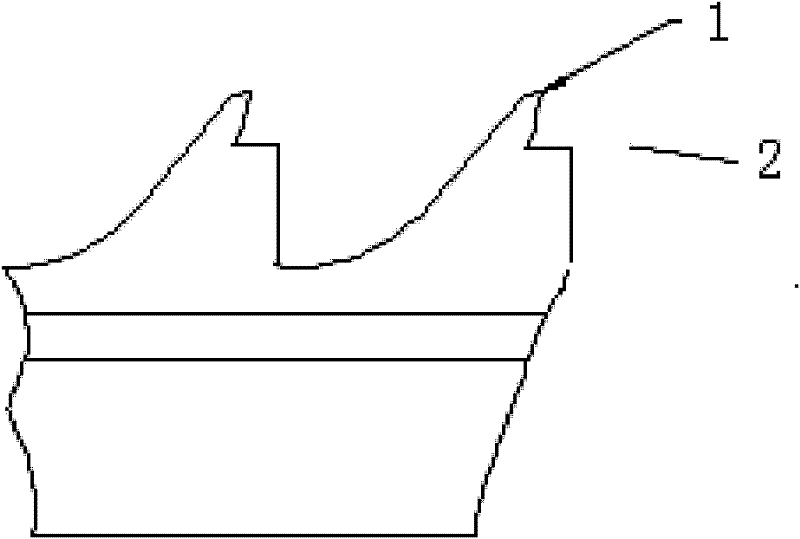

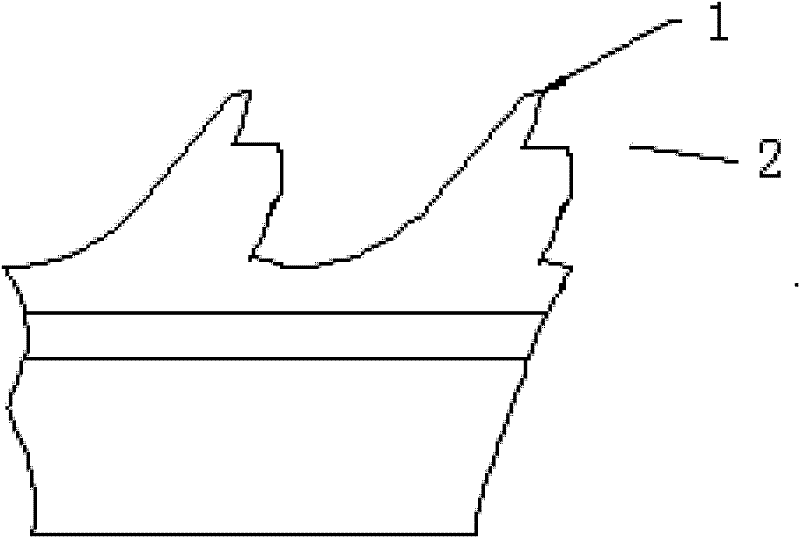

[0009] The basic structure of the high-density carding metal card clothing disclosed in the application of the present invention is: there are several main comb teeth 1 protruding along the strip-shaped base. metal card clothing, each main comb tooth 1 facing the fiber carding direction protrudes side teeth 2, the tooth height of the side teeth 2 is lower than the tooth height of the main comb teeth 1, the side teeth 2 and the main comb teeth 1 The tooth height difference range is preferably 0.15-0.2mm. Such as figure 1 , figure 2 , image 3 and Figure 4 In the specific implementation structure shown, the tooth tops of the side teeth 2 are all horizontal tooth tops, such as Figure 5 , Figure 6 and Figure 7 In the structure of the shown embodiment, the tooth tops of the side teeth 2 are upward tooth tops from the root to the tooth tip. remove figure 2 According to the structure of the embodiment, the tooth top of the side tooth 2 intersects with the tooth side to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com