Single-tooth-body multi-tooth-tip cylinder card clothing and application thereof

A tip and single-tooth technology, which is applied in the field of single-tooth and multi-tooth tip cylinder clothing, can solve the problems of low fiber impurity removal rate, high fiber short-lint rate, and reduced work efficiency, so as to improve carding effect and improve The ability to hold fibers and the effect of reducing neps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

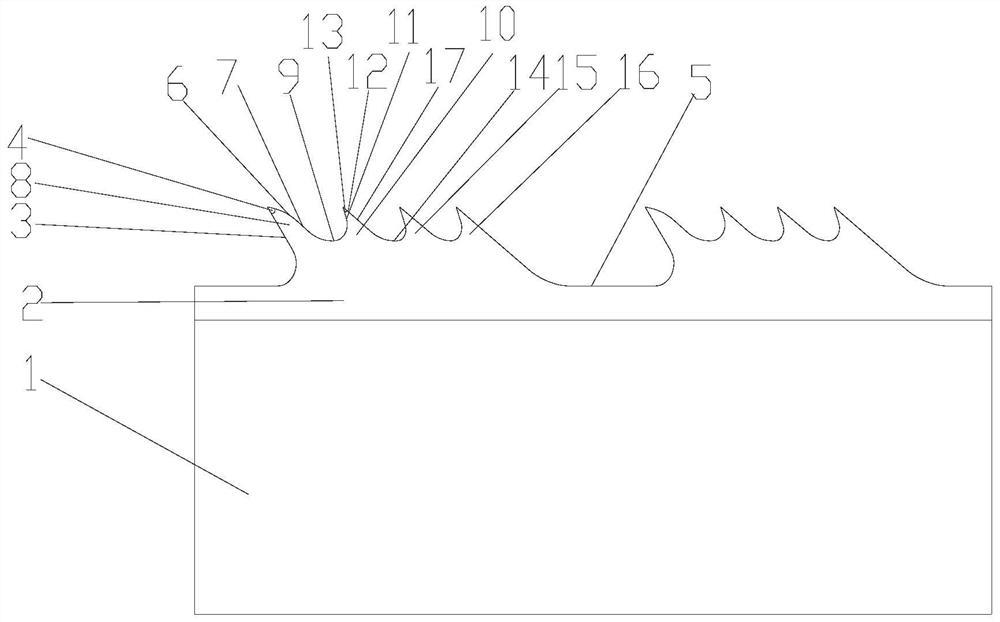

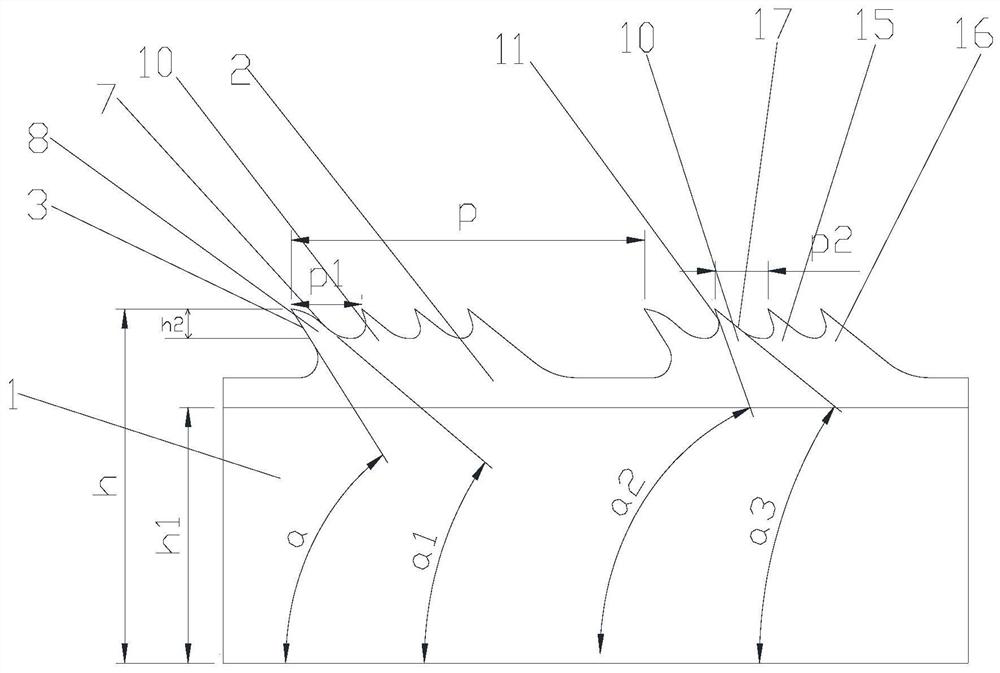

[0050] Such as figure 1 and figure 2 As shown, this embodiment provides a single-tooth multi-toothed cylinder card clothing, including a base 1, a plurality of needle teeth 2 all arranged on the base 1, and the two adjacent needle teeth 2 They are connected together by the first smooth concave arc line 5. The needle tooth part 2 includes the main teeth 8 and the auxiliary tooth part connected to each other. The auxiliary tooth part is formed by the third smooth concave arc between the three auxiliary teeth. The arcs 14 are connected to form a first auxiliary tooth 10 , a second auxiliary tooth 15 and a third auxiliary tooth 16 respectively, and the shapes of the first auxiliary tooth 10 , the second auxiliary tooth 15 and the third auxiliary tooth 16 are the same.

[0051] The main tooth 8 includes a main tooth front and a main tooth back connected to each other, the main tooth front includes a first main tooth front line 3, and one end of the first main tooth front line 3 i...

Embodiment 2

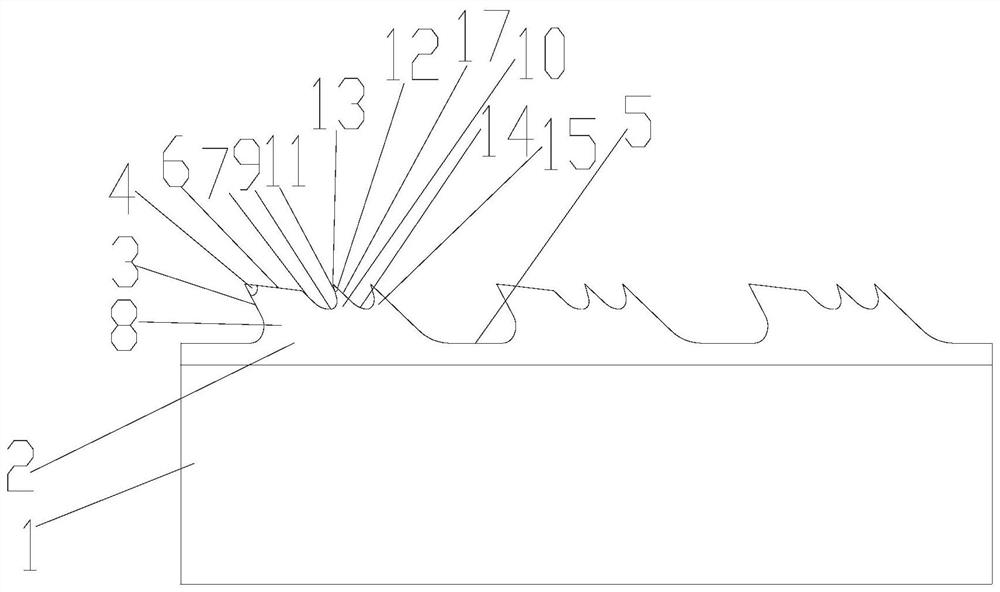

[0054] The example is image 3 and Figure 4 As shown, this embodiment provides a single-tooth multi-toothed cylinder card clothing, including a base 1, a plurality of needle teeth 2 all arranged on the base 1, and the two adjacent needle teeth 2 They are connected together by the first smooth concave arc line 5. The needle tooth part 2 includes the main teeth 8 and the auxiliary tooth part connected to each other. The auxiliary tooth part is formed by the third smooth concave arc between the three auxiliary teeth. The arcs 14 are connected to form a first auxiliary tooth 10 and a second auxiliary tooth 15 respectively, and the shapes of the first auxiliary tooth 10 and the second auxiliary tooth 15 are the same.

[0055] The main tooth 8 includes a main tooth front and a main tooth back connected to each other, the main tooth front includes a first main tooth front line 3, and one end of the first main tooth front line 3 is connected to the first smooth concave arc 5 , and ...

Embodiment 3

[0058] Such as Figure 5 and Figure 6As shown, the difference between the cylinder wire in this embodiment and that in Embodiment 1 is that this embodiment provides a single-tooth multi-point cylinder wire, including a base 1, a plurality of 1, the two adjacent needle teeth 2 are connected together by the first smooth concave arc 5, and the needle teeth 2 include the main teeth 8 and auxiliary teeth connected to each other , the auxiliary teeth portion is formed by connecting two auxiliary teeth through third smooth concave arcs 14 , which are the first auxiliary teeth 10 and the second auxiliary teeth 15 .

[0059] The main tooth 8 includes a main tooth front and a main tooth back connected to each other, the main tooth front includes a first main tooth front line 3, and one end of the first main tooth front line 3 is connected to the first smooth concave arc 5 , and the other end is connected to the back of the main tooth. The main tooth back includes a first main tooth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com