Oscillating opening fiber carding method

An oscillating, fiber-based technology, which is applied in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of high-quality fiber opening and carding, and is easy to promote and use in large areas, with small damage and reduced damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below according to the drawings and embodiments.

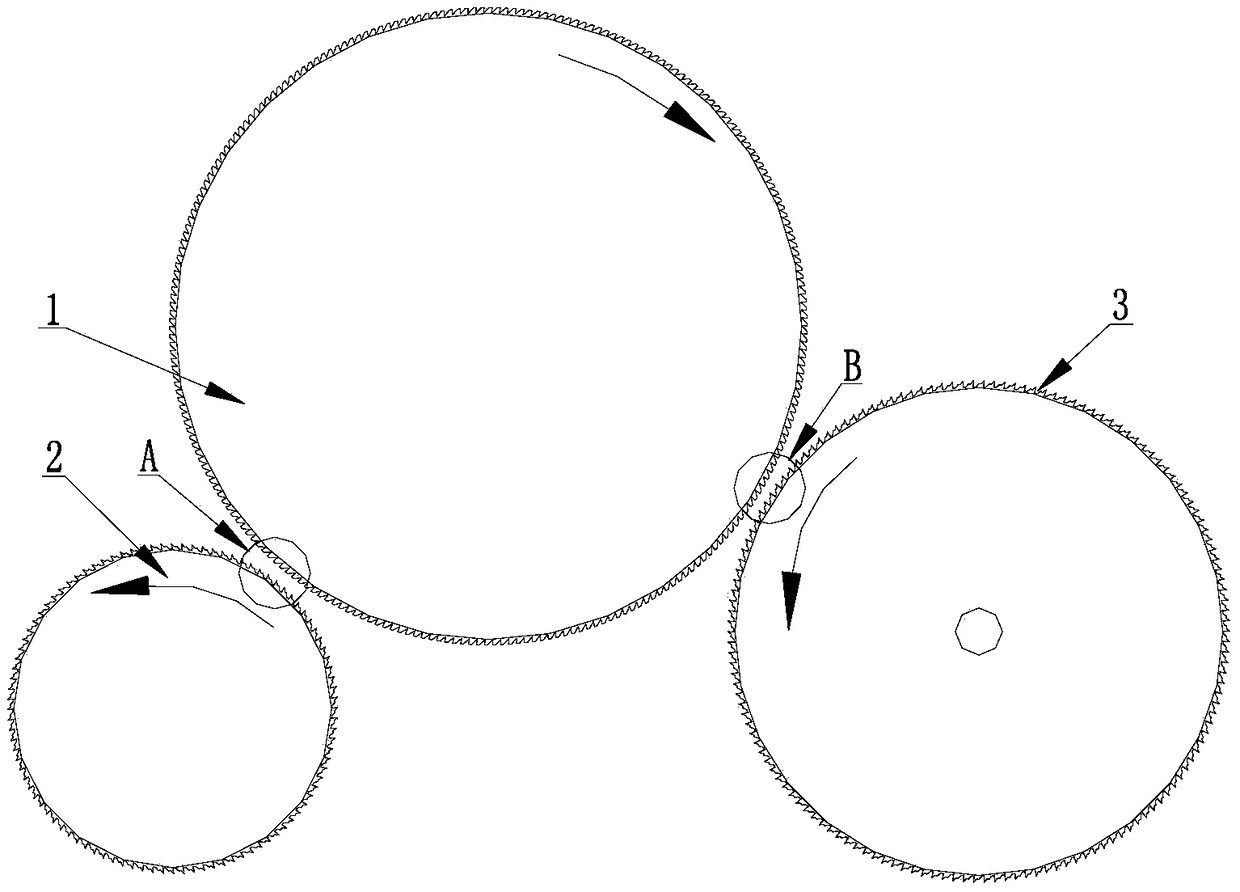

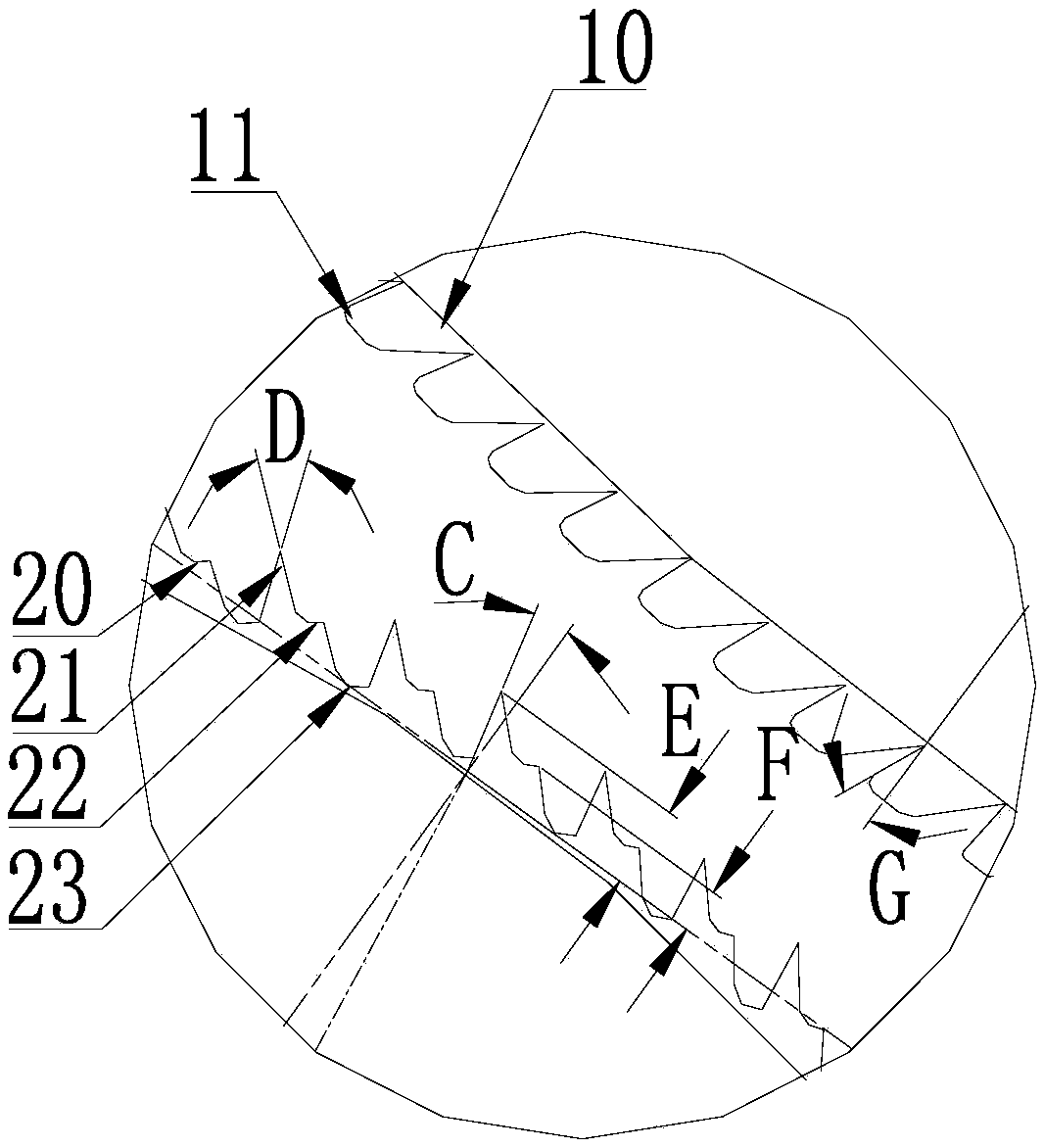

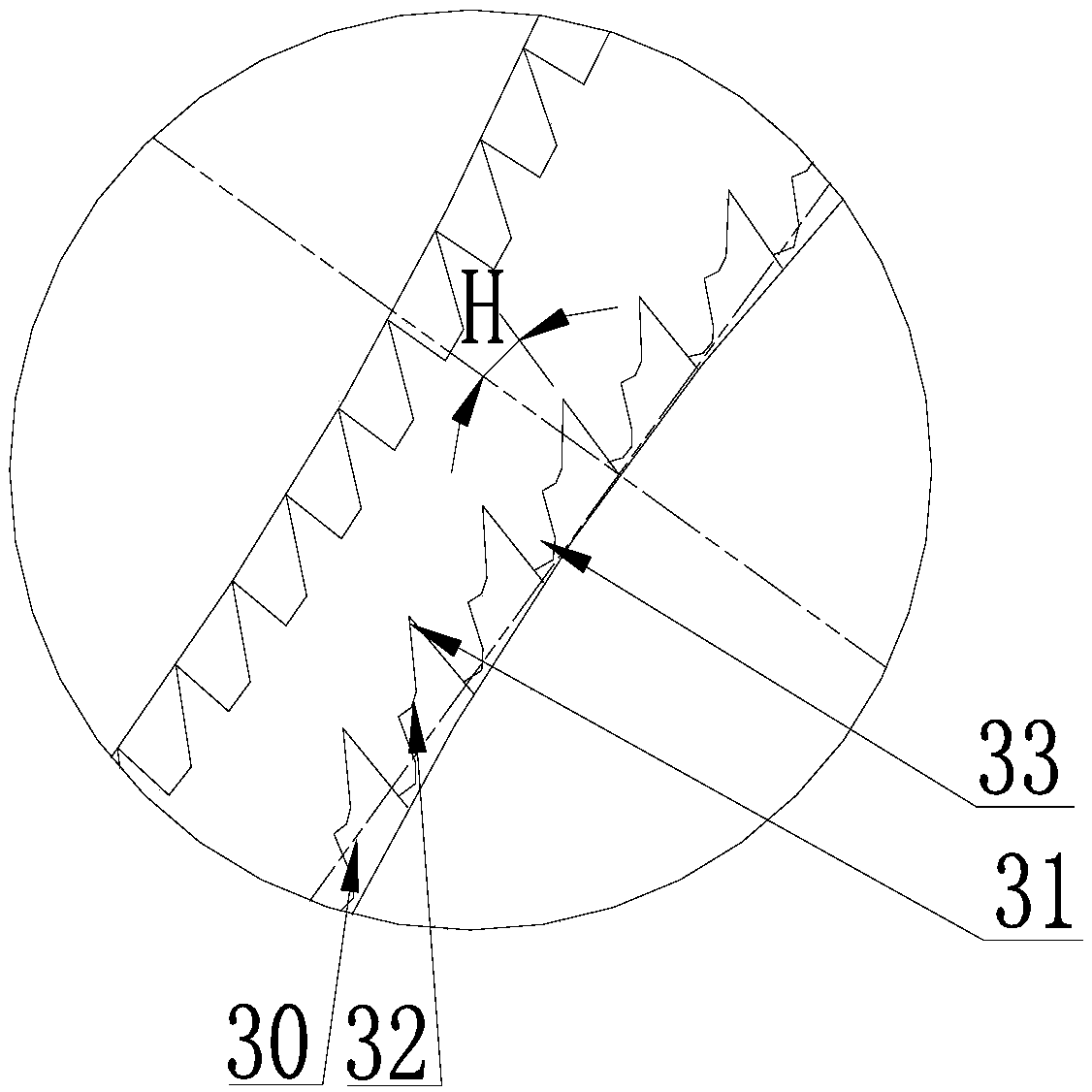

[0027] An oscillating opening fiber carding method adopts a carding mechanism for oscillating opening fibers, such as Figure 1-3 As shown, the carding mechanism includes licker-in roller 2, cylinder 1 and doffer 3. The licker-in roller 2 is wound with multiple licker-in needle belts 20 in the front-rear direction or in the axial direction along the licker-in roller surface, and the surface of the licker-in roller needle belt 20 is provided with opening needle teeth, and the opening needle teeth are in the shape of stepped high and low peaks, The peak 21 of the opening needle teeth is at an acute angle, which is beneficial for the licker-in roller to effectively penetrate the fiber whiskers and improve the opening effect. The low peak 22 of the opening needle teeth is located at the middle step of the opening needle teeth, and the low peak 22 of the opening needle teeth ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com