Probe

The technology of a probe and a probe seat is applied to a probe. It can solve problems such as waste of human resources, fire, unstable and safe use, and achieve the effect of solving heating problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the specific embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

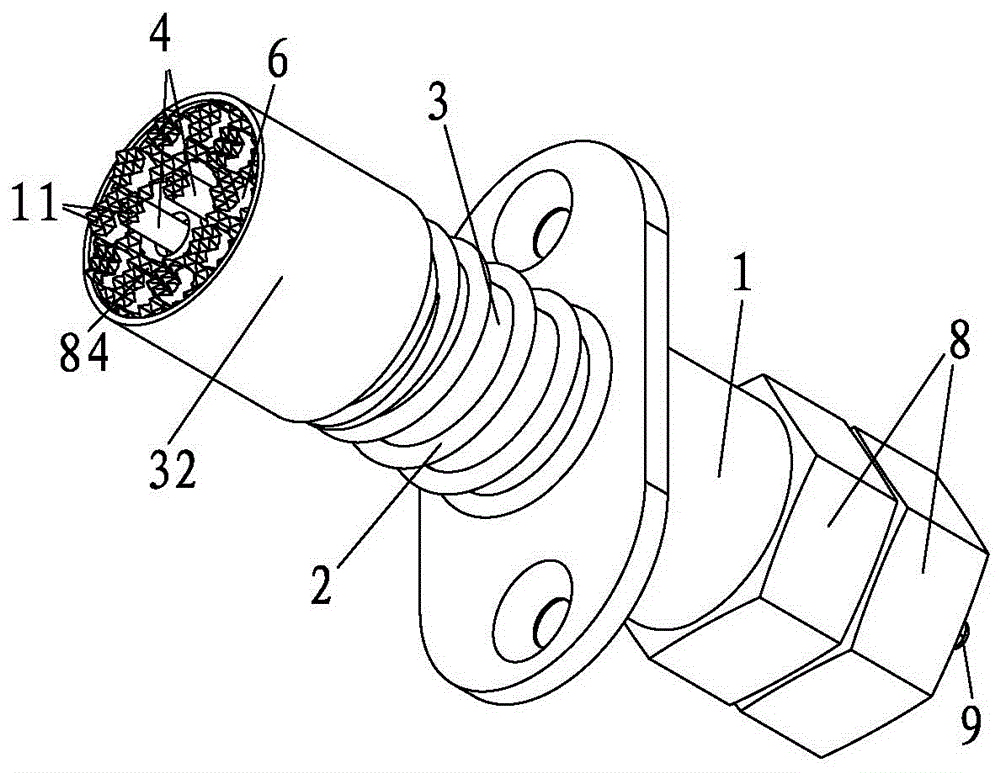

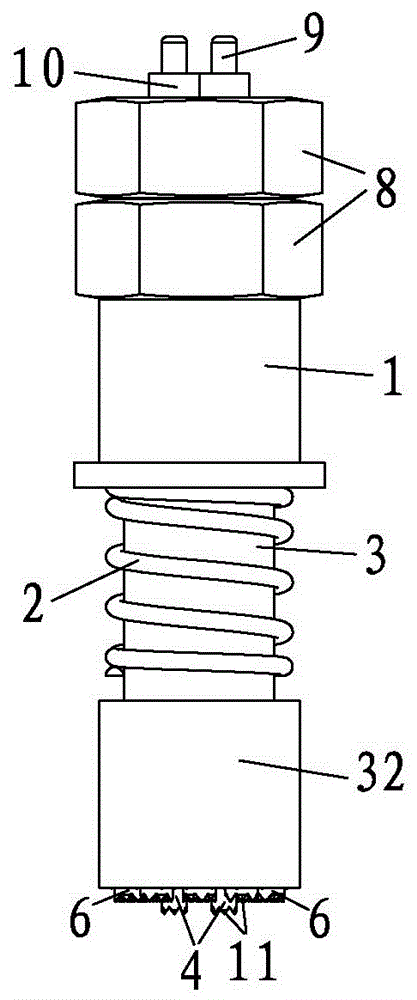

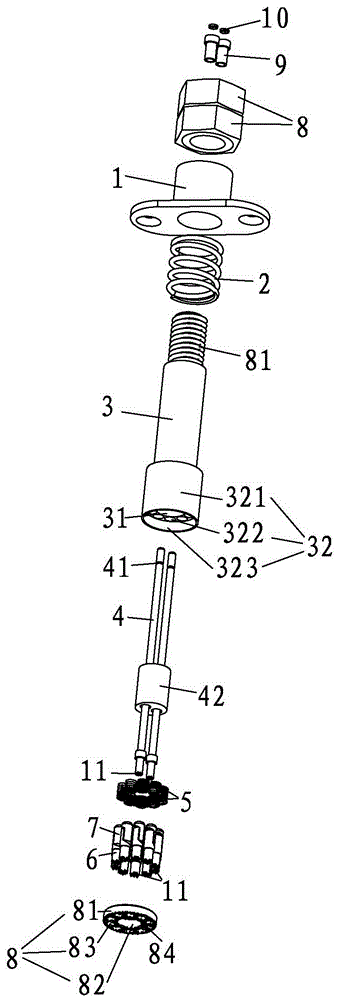

[0024] like Figure 1~4 As shown, a probe includes a probe base 1, a first spring 2, a current needle bar 3, a voltage needle 4, a second spring 5, a current needle head 6, an expansion head 7 and a probe end cover 8, the first The spring 2 and the probe base 1 are sequentially set on the current needle bar 3. The material of the probe base 1 is made of PBT plus fiber, so that it can work normally at a temperature within 120 degrees. The current needle bar 3 is set as a hollow cavity 31, and the current The needle bar 3 is made of brass, and the relative force between it and the probe base 1 is generated by the first external spring 2. One end of the voltage needle 4 passes through the hollow cavity 31 and protrudes from the current needle bar 3, and the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com