Process of fabricating implants having three distinct surfaces

a technology of three distinct surfaces and implants, applied in the field of spinal implants having at least three distinct surfaces, can solve the problems of impaired discs, affecting the anatomical functions of vertebrae, and affecting the health of discs, so as to avoid unintentional laceration or abrasion of delicate soft tissues, improve the effect of bone remodeling and fusion response, and improve the effect of fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

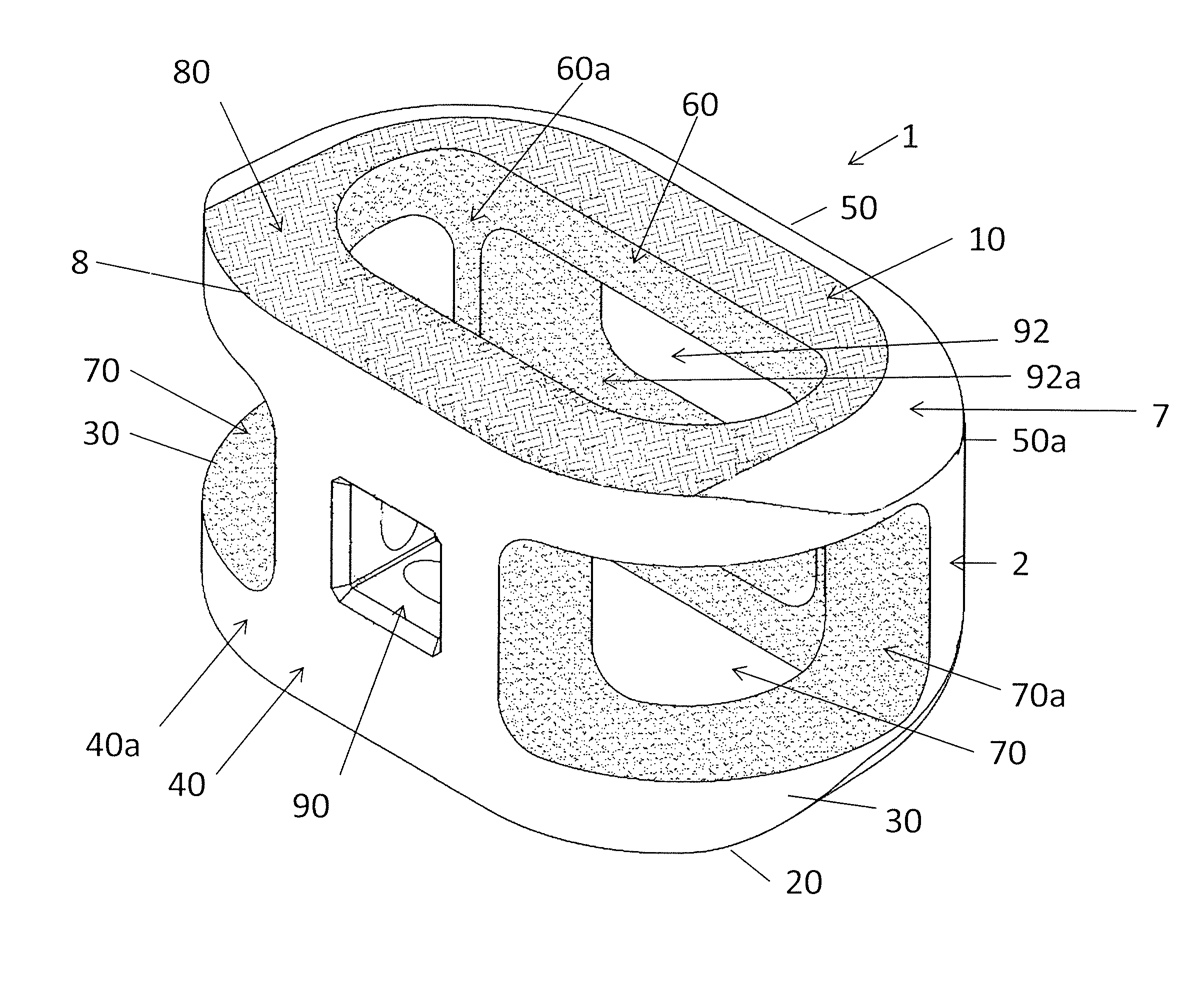

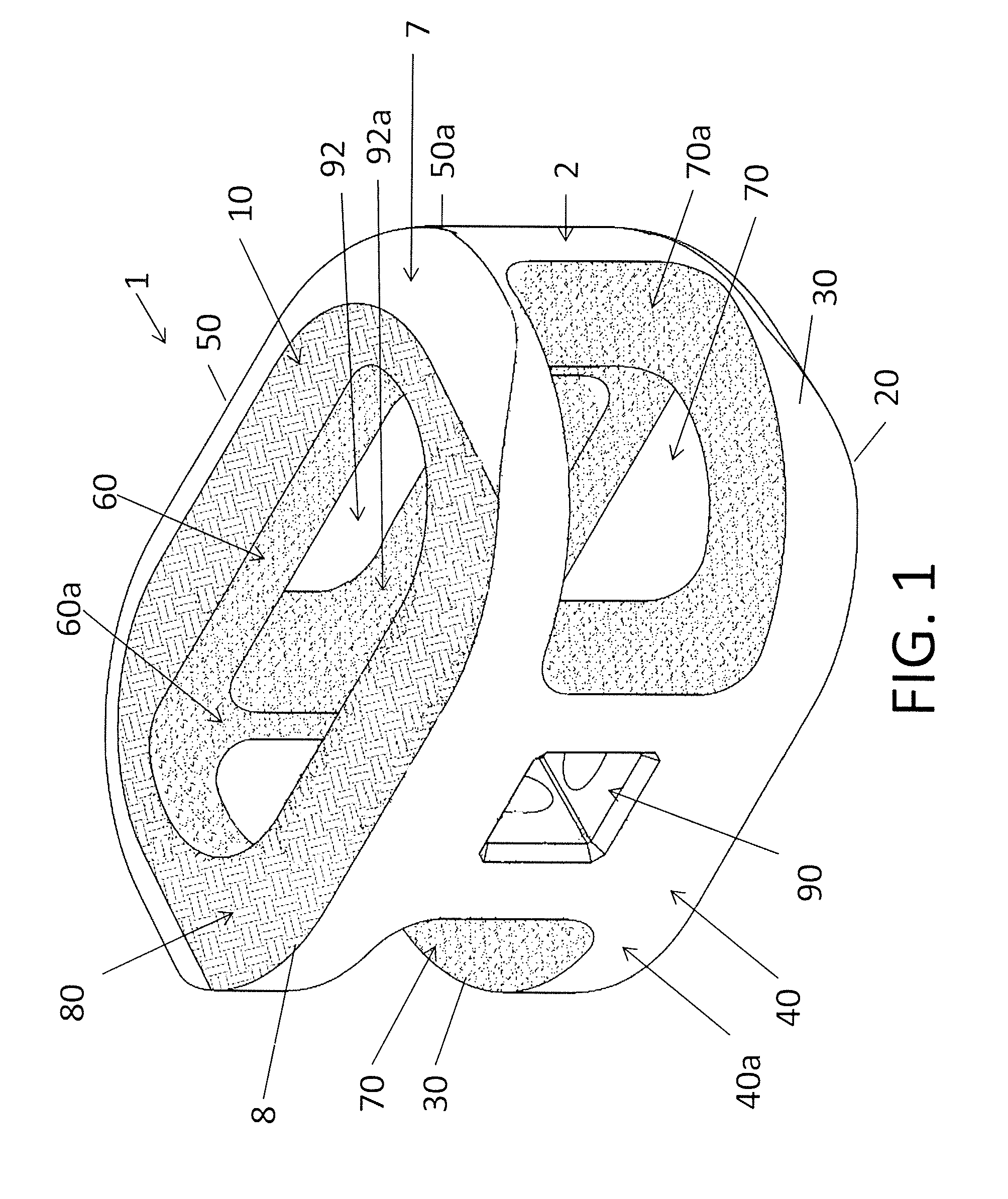

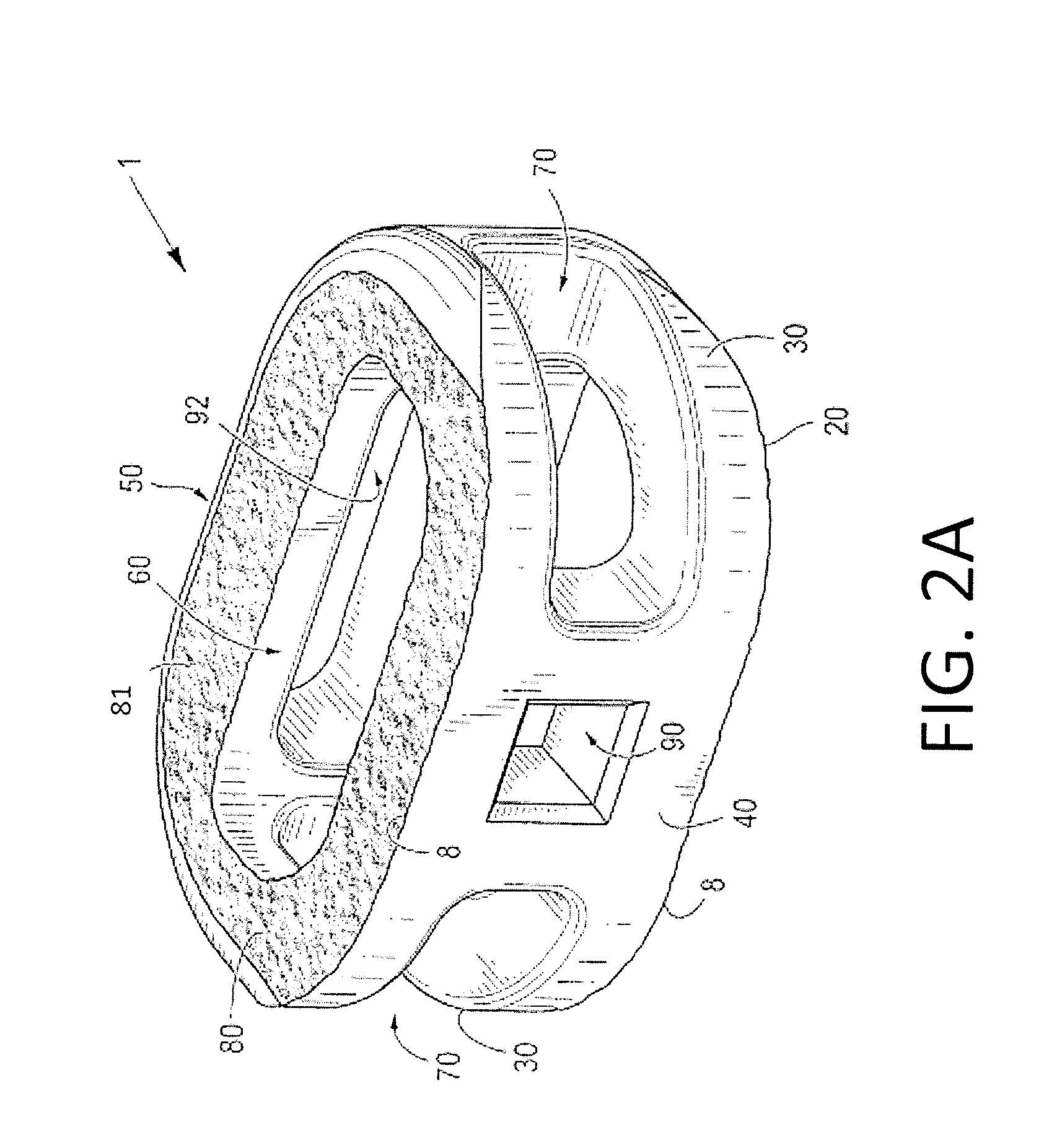

[0035]Certain embodiments of the present invention may be especially suited for placement between adjacent human vertebral bodies. The implants of the present invention may be used in procedures such as Anterior Lumbar Interbody Fusion (ALIF), Posterior Lumbar Interbody Fusion (PLIF), Transforaminal Lumbar Interbody Fusion (TLIF), and cervical fusion. Certain embodiments do not extend beyond the outer dimensions of the vertebral bodies.

[0036]The ability to achieve spinal fusion is directly related to the available vascular contact area over which fusion is desired, the quality and quantity of the fusion mass, and the stability of the interbody spinal implant. Interbody spinal implants, as now taught, allow for improved seating over the apophyseal rim of the vertebral body. Still further, interbody spinal implants, as now taught, better utilize this vital surface area over which fusion may occur and may better bear the considerable biomechanical loads presented through the spinal col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| etch depth | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com