Furrowing and deep-fertilizing machine for orchards

A technology of fertilizer applicator and trench depth, which is applied to fertilizer applicators, excavation/covering trenches, fertilizer distributors, etc., can solve the problems of low operation efficiency, residual soil belt at the bottom of trenches, etc., and achieves good effect, accelerated and reduced fertilizer Effects of Polarization Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

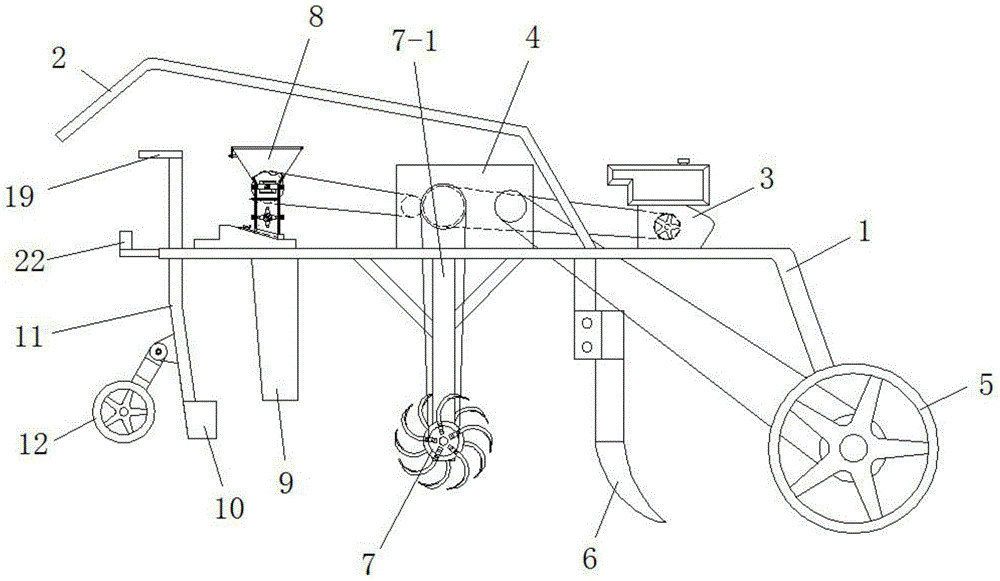

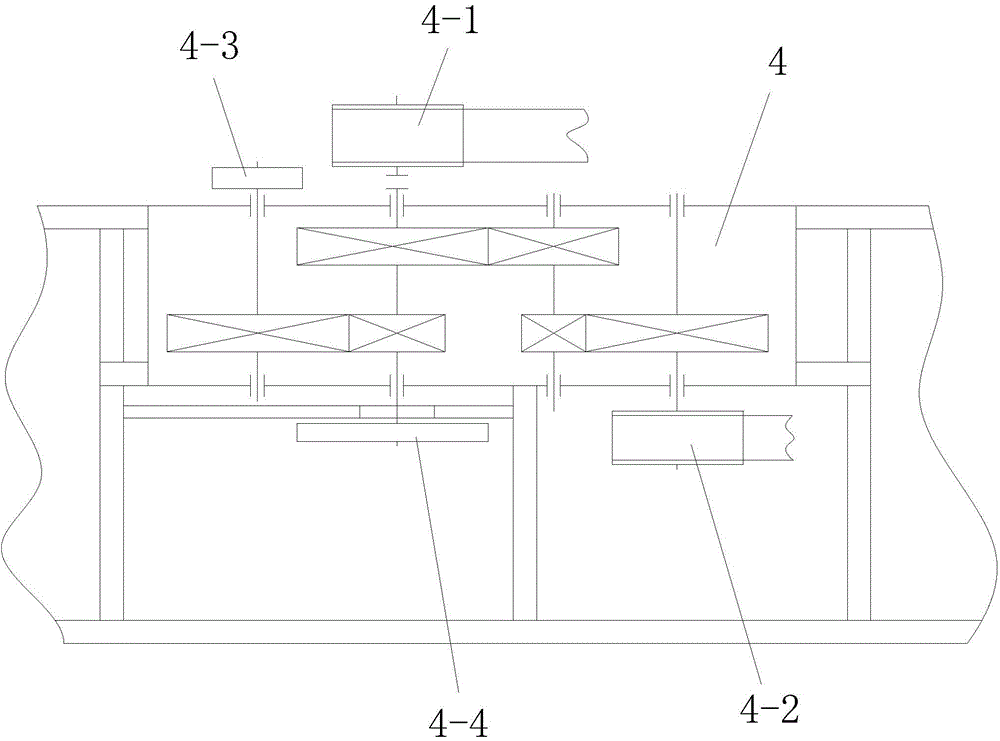

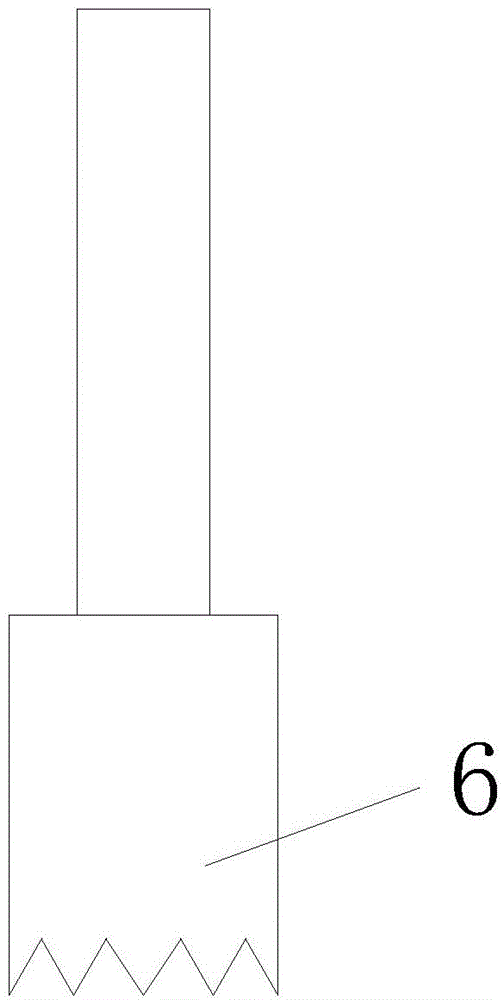

[0034] With reference to accompanying drawing: in the present embodiment, orchard ditches deep fertilizing machine, comprises frame 1, handrail 2, is installed with diesel engine 3, the gearbox 4 that is connected with diesel engine 3 transmissions on frame 1, and the front end of frame 1 is installed There are traveling wheels 5, and the rear of the traveling wheels 5 is equipped with a soil-breaking shovel 6, and the bottom of the soil-breaking shovel 6 is provided with a row of pointed structures, and the top of the soil-breaking shovel 6 is fixed on the bottom of the frame 1; Device 7, the ditching device 7 comprises a fixed frame 7-1 fixed on the bottom of the frame 1, a rotating seat 7-2 connected to the bottom of the fixed frame 7-1 in rotation, and a knife handle 7-3 is fixed at intervals on the rotating seat 7-2 ; The knife handle 7-3 is a curved structure in an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com