Plastic tray seedling raising dibble seedling full-automatic transplanter

A plastic tray and fully automatic technology, applied in the field of rice transplanting agricultural machinery and tools, can solve the problems of expensive, difficult to turn green, slow seedlings and other problems, and achieve the effect of high transplanting efficiency, adjustable depth and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

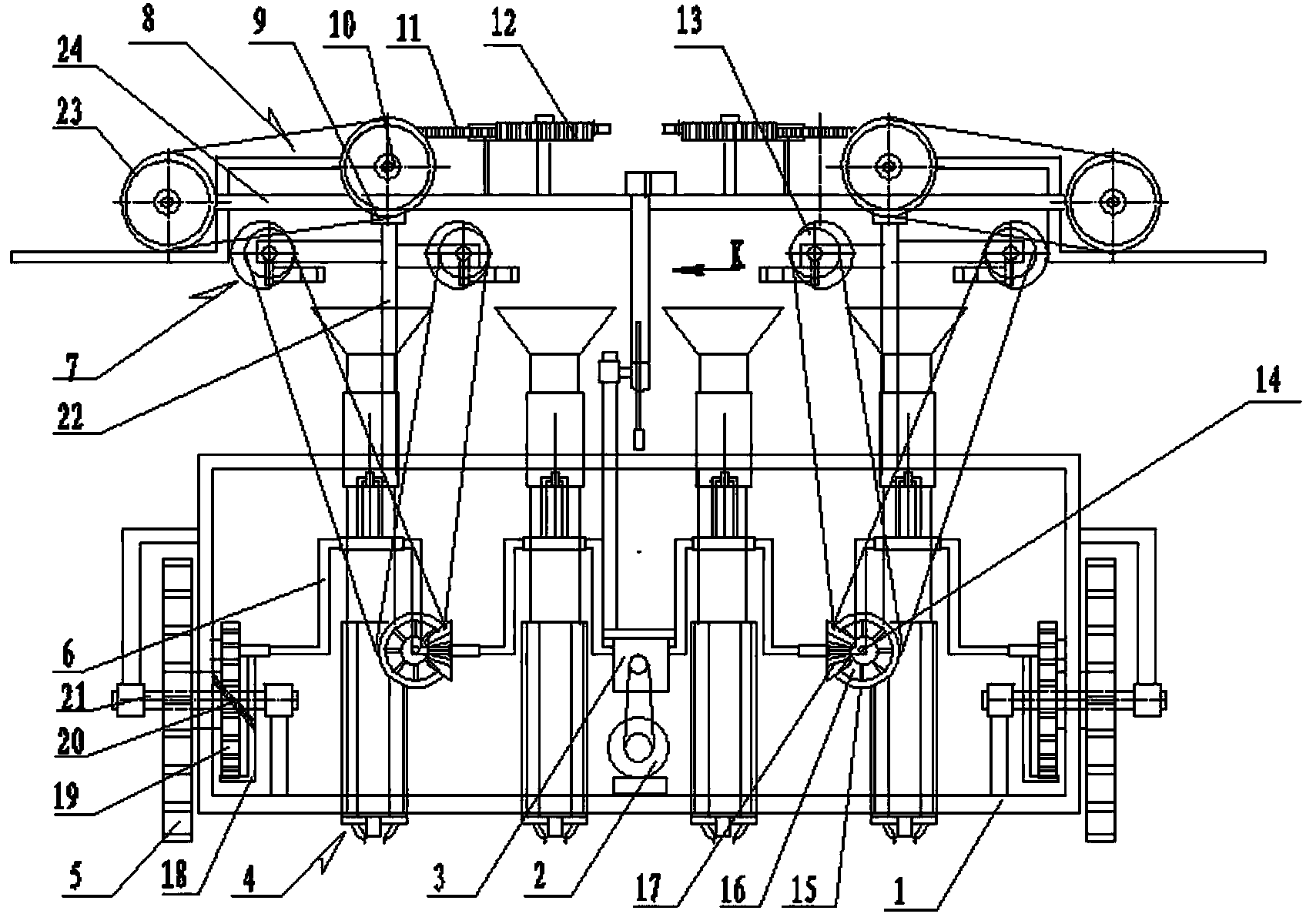

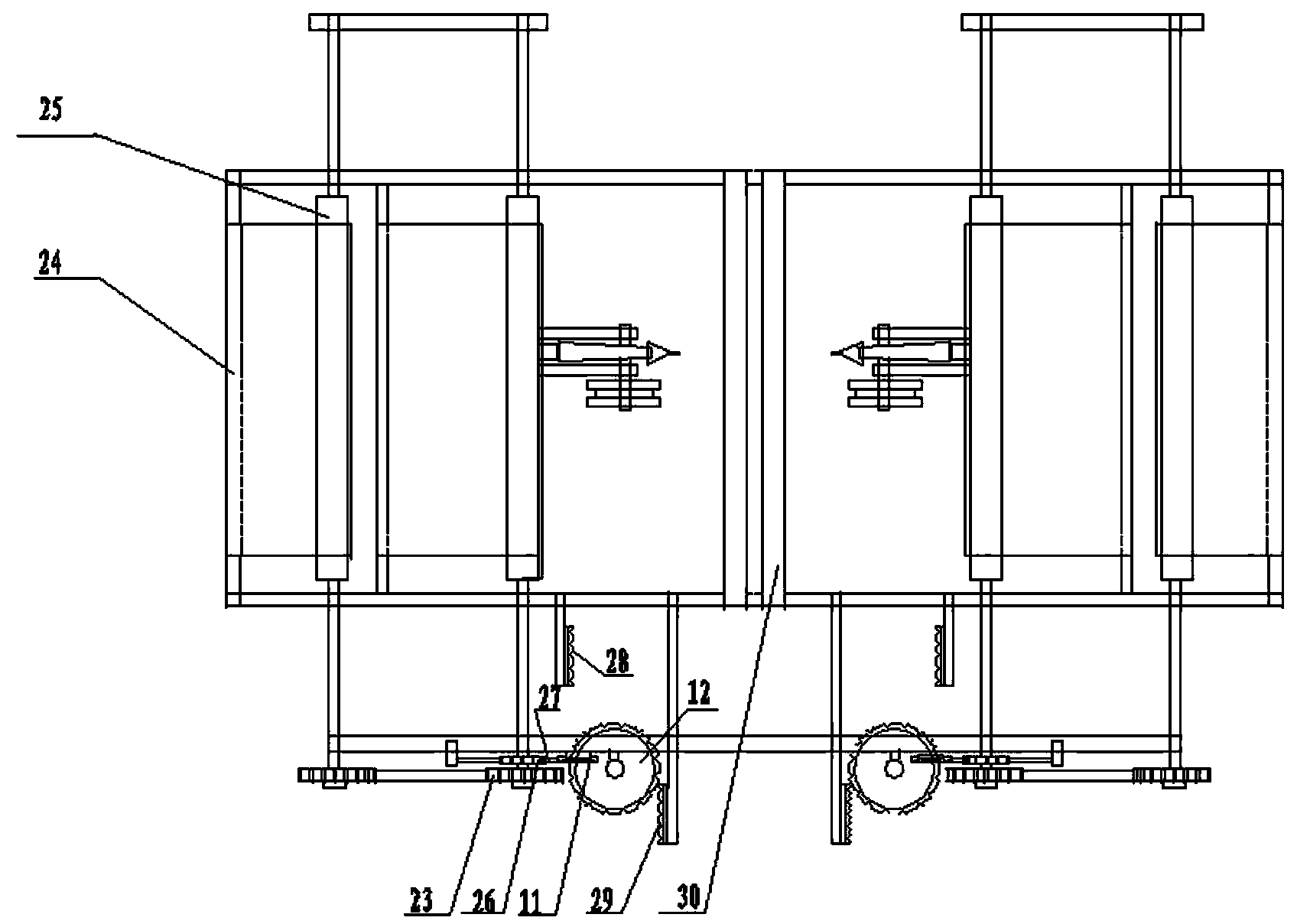

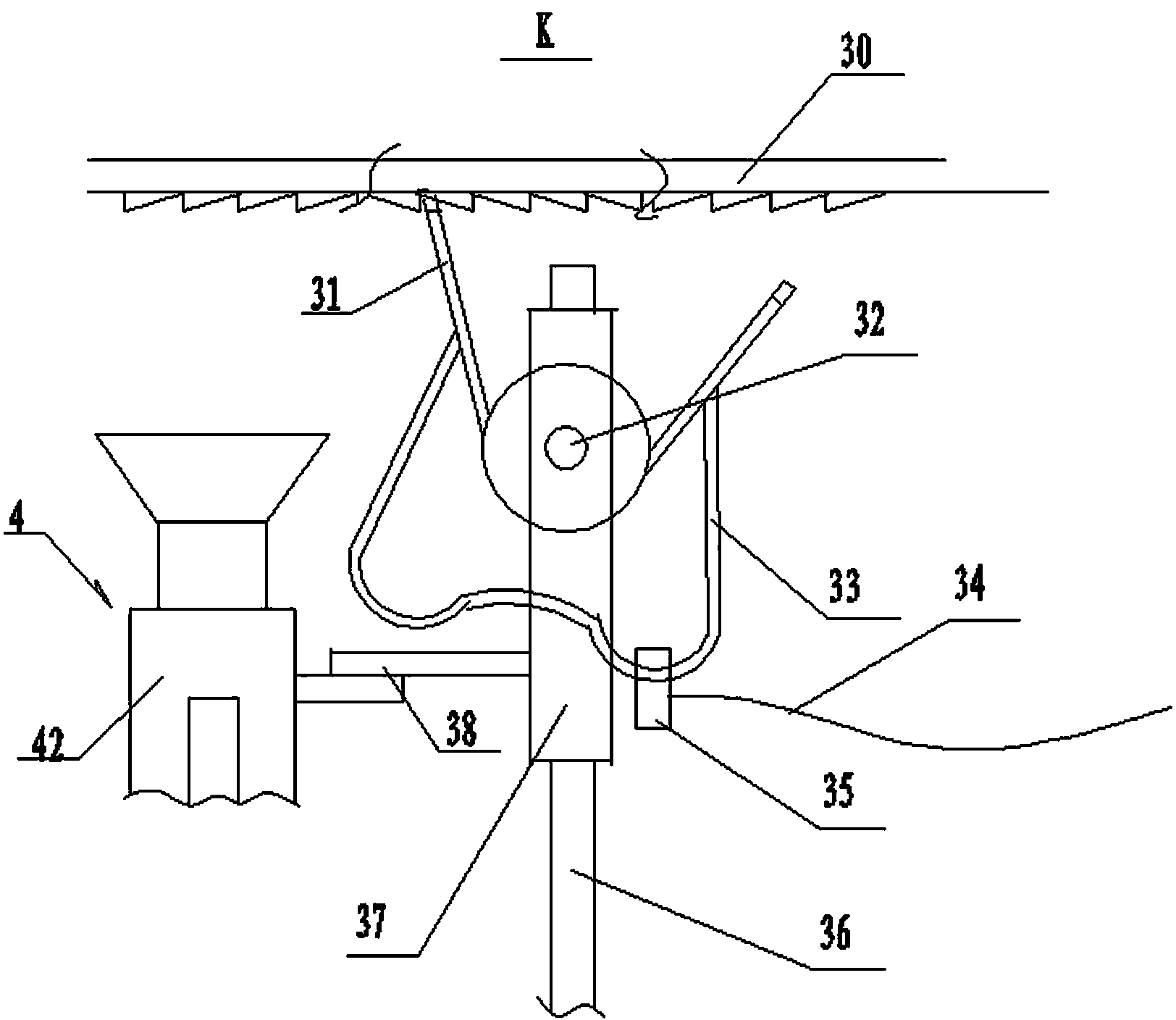

[0015] A full-automatic rice transplanter for seedlings raised in plastic trays, comprising a frame 1, an engine 2, a gearbox 3, a traveling wheel 5, a crankshaft 6, a seedling sending mechanism 8, a seedling taking mechanism 7, and a rice transplanting mechanism 4. The engine 2 is installed on the frame 1 at the front end of the gearbox 3, the output shaft of the generator 2 is connected to the input shaft of the gearbox 3 through a belt drive, the output shaft at both ends of the gearbox 3 is connected to the crankshaft 6, and the two ends of the crankshaft 6 are connected with The bearing is supported on the frame, and the crankshaft drives the traveling wheel 5, the rice seedling sending mechanism 8, the rice seedling taking mechanism 7 and the rice transplanting mechanism 4 simultaneously. Traveling wheel axle 21 is housed on frame 1 both sides, and traveling wheel 5 and traveling wheel driving gear 19 are respectively installed on the traveling wheel axle 21 of frame outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com