Adjustable crank handle

An adjustable and adjustable handle technology, applied in pull-out switch cabinets, switchgears, electrical components, etc., can solve the problems of delayed work progress, wrong crank handle, and large volume of the crank handle, so as to reduce weight and volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the drawings:

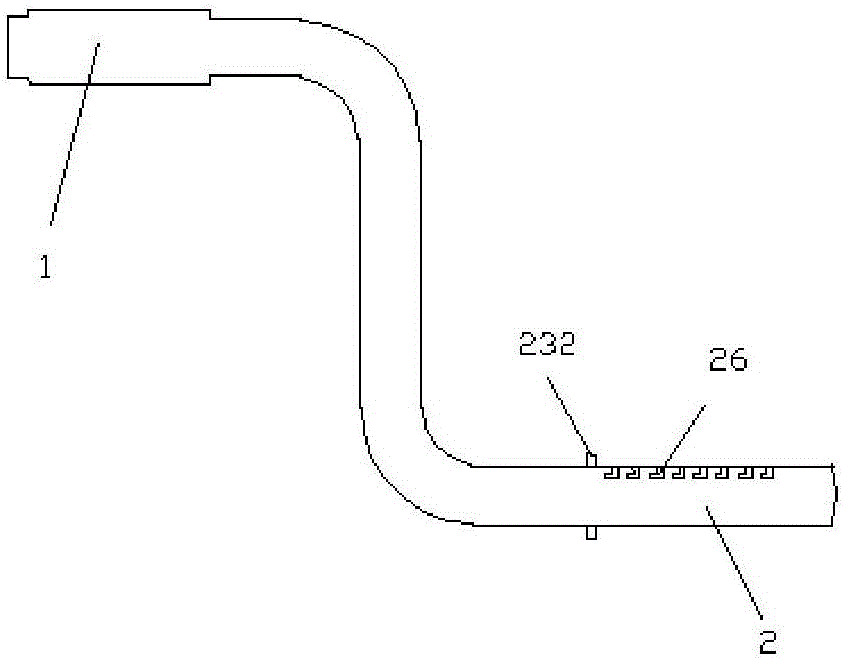

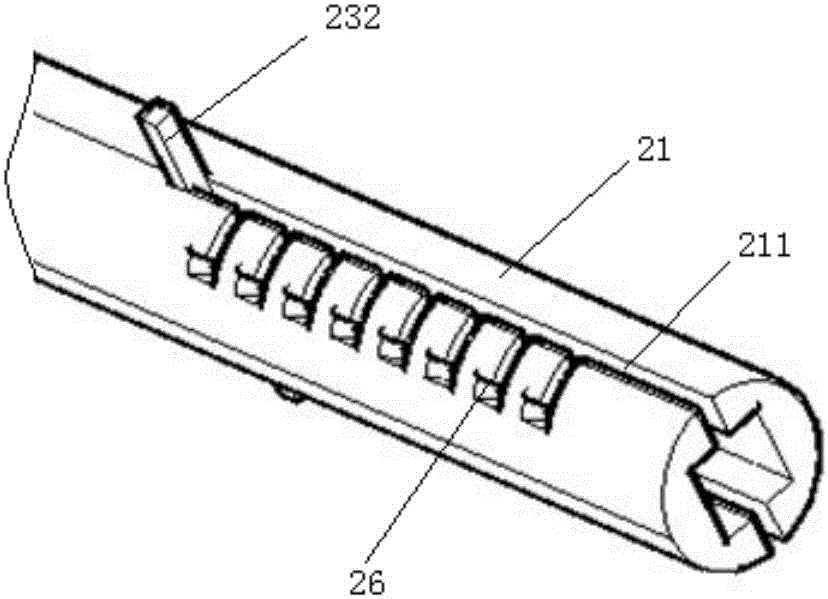

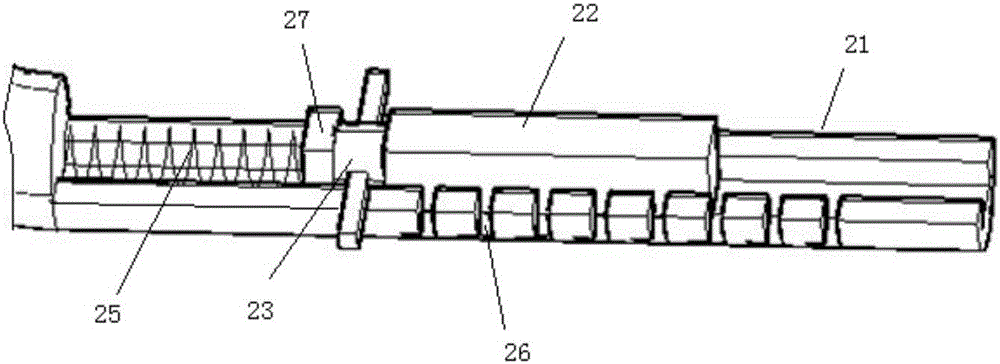

[0023] Such as Figure 1-9 As shown, the adjustable crank of this embodiment includes a handle part 1 and a handle head 2. The head 2 includes a sleeve 21 and a handle core 22 installed in the sleeve 21 and slidingly fitted with the sleeve 21, Match the shape of the core 22 with the shape of the opening inside the sleeve 21. In this embodiment, the core 22 is rectangular, such as Figure 5 As shown, an adjustment handle 23 is provided on the handle core 22, and an adjustment hole 211 that cooperates with the adjustment handle 23 to adjust the length of the core 22 is provided on the sleeve 21 and a fixing member for fixing the displacement position of the adjustment handle 23. The fixing member can be a buckle or a baffle that can fix the adjusting handle 23 on the sleeve. In this embodiment, the fixing member is composed of a plurality of grooves sequentially arranged along the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com