Glass bottle label and manufacturing method thereof

A production method and glass bottle technology, applied in the field of labels, can solve the problems of high cost of glass bottle labels, invisible in the bottle, and many printing processes, and achieve the effects of reducing printing processes, high resolution, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

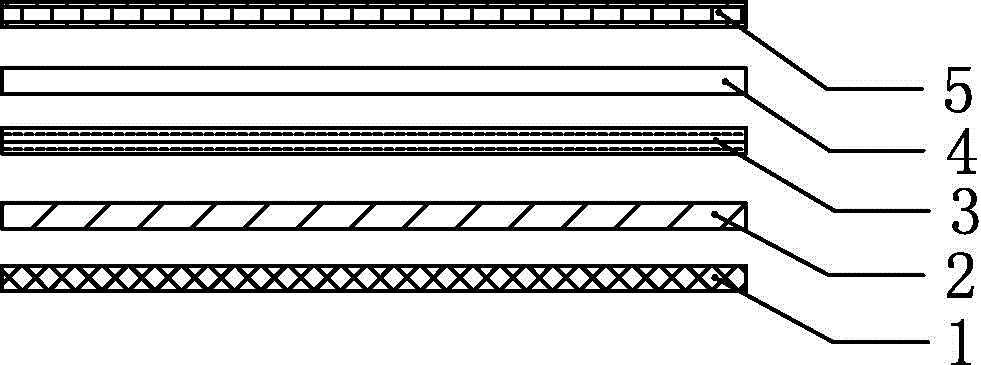

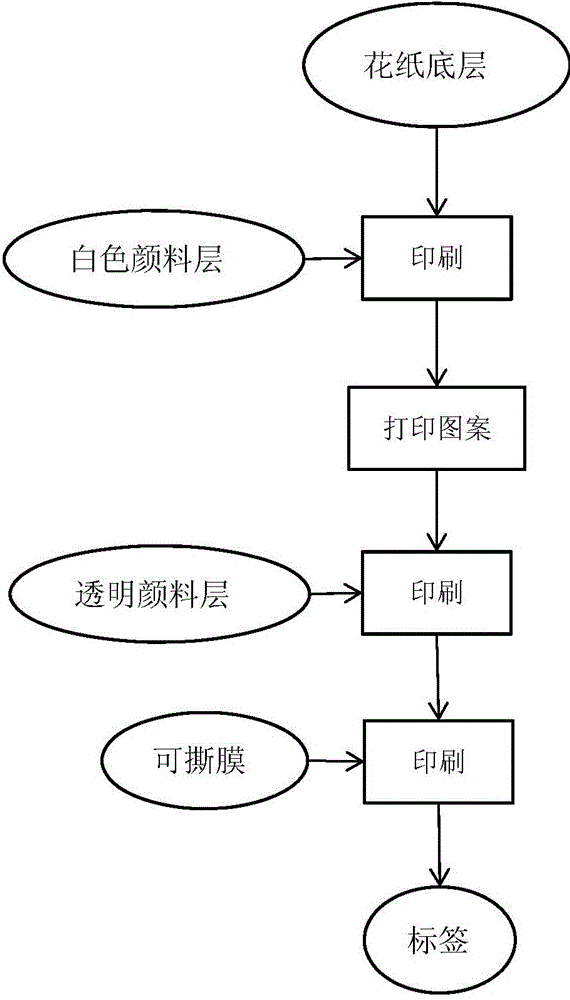

[0029] Embodiment one: if figure 1 , figure 2 Shown, in concrete implementation process, glass bottle label of the present invention, manufacture method is:

[0030] a. Print the white pigment layer 2 on the decal paper bottom layer 1 by screen printing;

[0031] b printing pattern 3 on white pigment layer 2;

[0032] c print the transparent pigment layer 4 on the pattern 3 by screen printing;

[0033] d Finally print a tearable film 5 on the transparent pigment layer 4 by screen printing.

[0034] A glass bottle label including a pattern layer is made, and the order from the bottom layer 1 of the decal paper to the tearable film 5 is as follows: the bottom layer 1 of the decal paper, the white pigment layer 2, the pattern 3, the transparent pigment layer 4, the tearable film 5, When sticking a label on a glass bottle, soak a glass bottle label in water, then tear off the bottom layer 1 of the flower paper, stick the label on the glass bottle, tear off the tearable film 5...

Embodiment 2

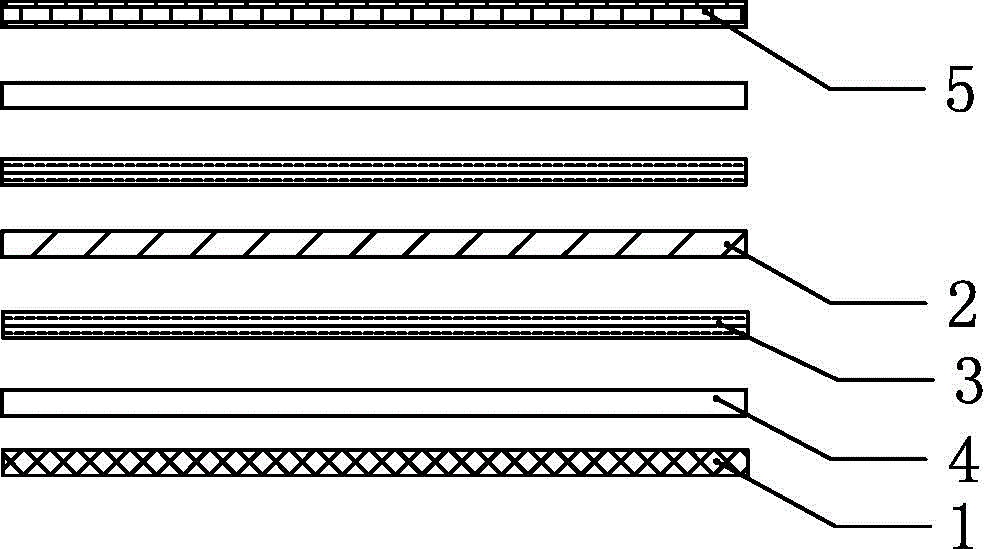

[0036] Embodiment two, such as image 3 , Figure 4 Shown, in concrete implementation process, a kind of glass bottle label of the present invention, manufacture method is:

[0037] a, the first layer of transparent pigment layer 4 is printed on the decal paper bottom layer 1 by screen printing;

[0038] b print the first layer pattern 3- on the transparent pigment layer 4;

[0039] c print the first layer of white pigment layer 2 on the first layer of pattern 3 by screen printing;

[0040] d print the second layer pattern 3 on the first layer of white pigment layer 2;

[0041] e prints the second layer of transparent pigment layer 4 in the mode of screen printing on the second layer pattern 3;

[0042] f Finally print the tearable film 5 on the second transparent pigment layer 4 by screen printing.

[0043] A glass bottle label including a pattern layer is produced, from the bottom layer of decal paper 1 to the tearable film 5 in order: bottom layer of decal paper 1, tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com