Gold and silver powder transfer printing process and equipment

A technology for transfer printing and transfer printing paper, applied in the field of textile printing and dyeing, can solve the problems of low production efficiency, poor product quality, time-consuming and labor-intensive, etc., and achieve the effects of saving manpower and resources, reducing printing processes, and shortening processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

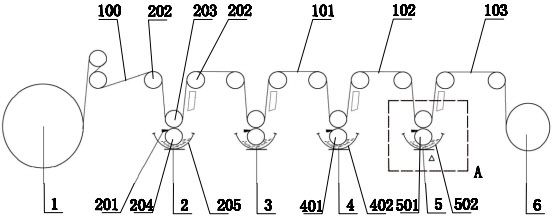

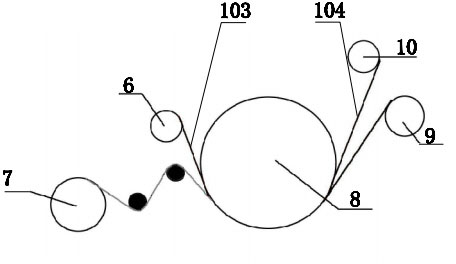

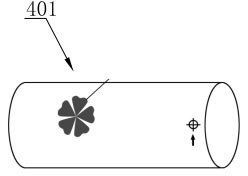

[0030] The present invention utilizes the principle of transfer printing, first prints the general transfer printing pattern and the pattern of the gold and silver powder area together on the printing base paper, and then transfers and prints the general printing and the gold and silver powder on the carrier through high temperature. With a complete process flow, the two processes of ordinary transfer printing and gold and silver powder transfer printing can be completed at the same time, which greatly improves the production efficiency and product quality. Wherein, the technical process and equipment of printing common transfer printing patterns on printing base paper are the same as the prior art, such as figure 1 As shown, the blank printing base paper 100 passes through the conductive roller 202 from the raw material roll 1 and passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com