Equipment for manufacturing multilayer gradual change and light change effect and use method thereof

A kind of equipment and fluorescent ink technology, applied in the general parts of printing machinery, rotary printing machines, printing, etc., can solve the problems of single optical change effect and weak anti-counterfeiting performance, and achieve improved technical efficiency, strong anti-counterfeiting, enhanced application and The effect of anti-counterfeiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

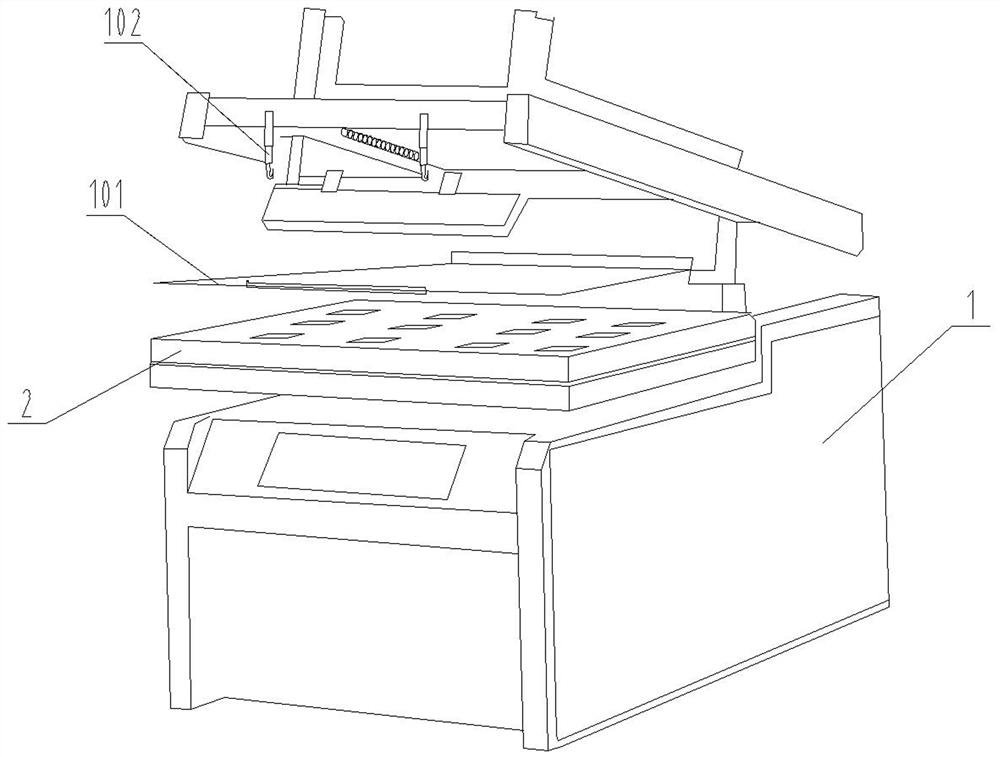

[0036] Such as Figure 1 to Figure 3 As shown, a device for producing multi-layer gradient and optical change effects, including a screen machine 1, the screen machine 1 is an existing printing device, and the screen plate 101 passes through the hook 102, the hook buckle 103 and the screen locking mechanism 104 etc. are installed on the screen machine 1.

[0037] There are generally substrate platforms with different sizes according to the equipment specifications. After dismantling them, the modified substrate plane magnetic table 2 for placing printed products is installed. The substrate plane magnetic table 2 includes the substrate plane table 201, and the substrate A plurality of magnetic grooves 203 are opened on the flat platform 201, and a planar magnet 202 is installed in the magnetic groove 203. The top surface of the planar magnet 202 needs to be flush with the substrate flat platform 201. 1. The support seat 204 is fixedly connected, and the substrate plane table 2...

Embodiment 2

[0046] A method of using the equipment for making multi-layer gradients and light-varying effects as shown in Embodiment 1:

[0047] 1) Alignment of printed matter: Alignment typesetting of printed matter 4 and planar magnet 202 of substrate planar magnetic table 2, that is, making gradient and light-changing effect patterns and planar magnet 202 at one position.

[0048] 2) Ink adjustment and inking: the magnetic fluorescent ink prepared on the screen plate 101 of the screen machine 1;

[0049] Magnetic fluorescent ink is based on magnetic ink, and optically variable fluorescent pigments are added to the magnetic ink.

[0050] The preferred blending ratio is 2000g magnetic ink: 435g optically variable fluorescent pigment. When the proportion of optically variable fluorescent pigment gradually increases, it will cover the effect of gradient levels. It is obviously enhanced, but the gradient effect affects the light change effect. If it is less, the gradient effect will be red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com