Textile dispersed direct-injected ink and preparation method thereof

A textile and direct injection technology, applied in textiles and papermaking, ink, dyeing, etc., can solve the problems of long production process, poor clarity, and poor stability, and achieve low equipment requirements, simple steps, and avoid sewage discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

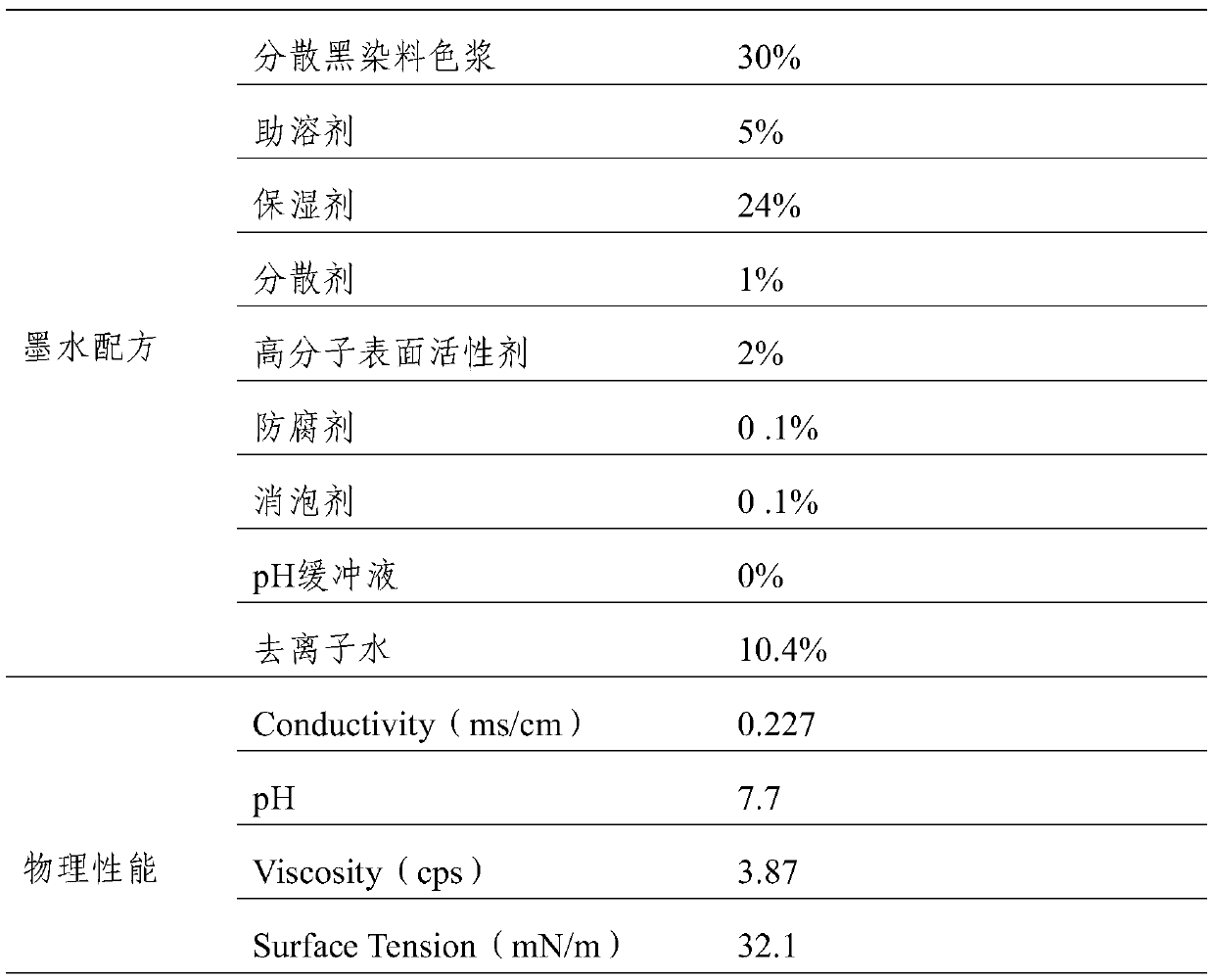

[0026] Embodiment 1 Preparation of the black dye dispersion direct jet ink of the embodiment of the present invention

[0027] 1. Calculated according to mass percentage, at room temperature, add 30% of high temperature disperse black dye, 5% of cosolvent, 24% of humectant, 1% of dispersant, 2% of polymer surfactant, and add 10.4% of The water is fully mixed evenly, and after stirring for 60 minutes, a mixture is formed, and the mixture is sanded for 6-10 hours in a sand mill using zirconium beads with a diameter of 0.4-0.5 mm, and the sanding speed is 500 rpm. The volume of the sanding beads and the mixture The ratio is 1:3. Among them, the disperse black dye paste is mixed with 15% by mass of C.I.Disperse Yellow 54, 50% of Disperse Blue 360, and 35% of Dispersered 60. The cosolvent is urea, and the humectant is glycerin and ethylene glycol. Alcohol, sulfonated lignin Reax LS and sodium naphthalene sulfonate formaldehyde condensate Demol MS as dispersant, Surfynol 465 as pol...

Embodiment 2

[0037] Embodiment 2 Preparation of the red dye dispersion direct-jet ink of the embodiment of the present invention

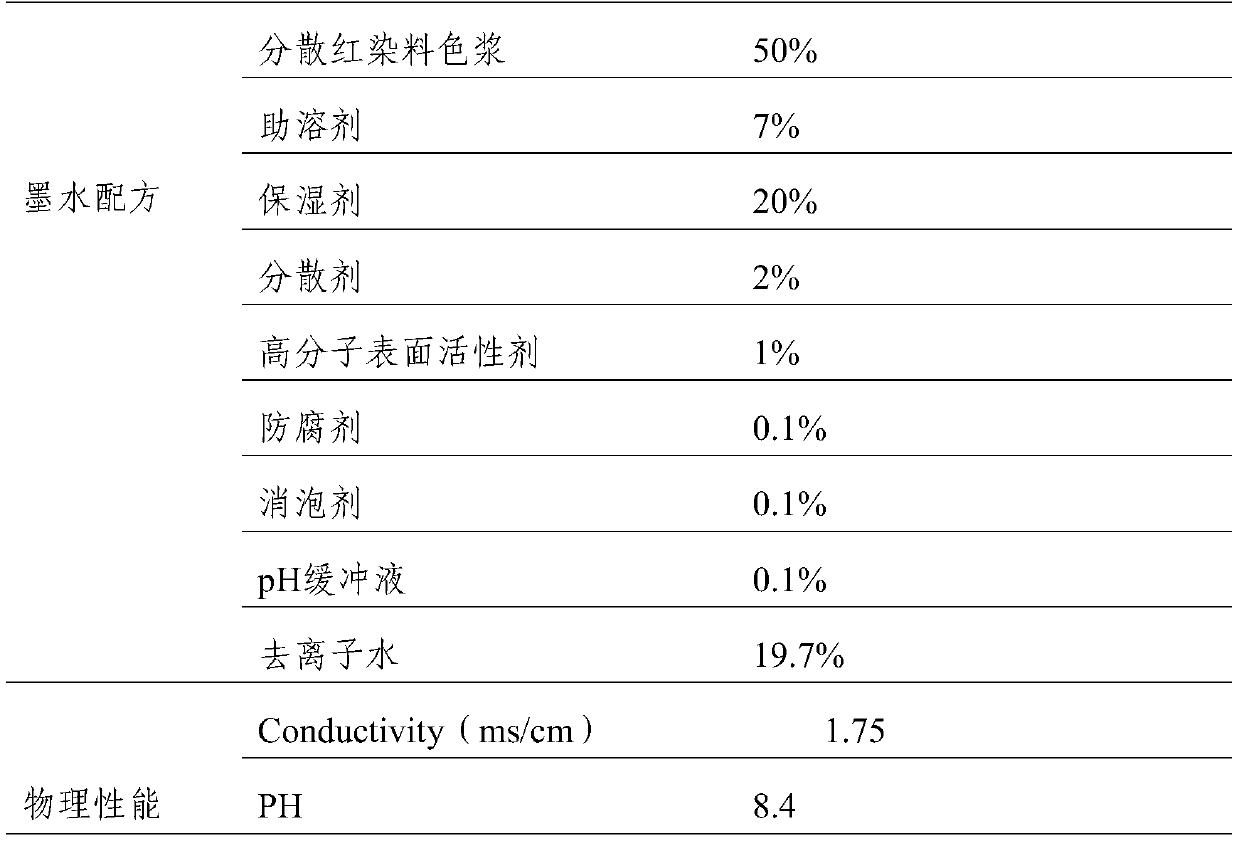

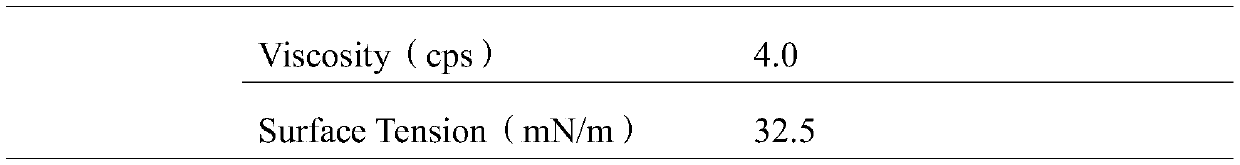

[0038]1. Calculated according to the mass percentage, at room temperature, mix 50% high temperature disperse red dye paste 68, that is, C.I. Disperse Red 68, 7% cosolvent, 20% humectant, 2% dispersant, Molecular surfactant, add 47.3% water and mix well, after stirring for 60 minutes, a mixture is formed, and the mixture is sanded in a sand mill using zirconium beads with a diameter of 0.4-0.5mm for 6-10h, and the sanding speed is 500rpm. The volume ratio of the sanding beads to the mixture is 1:3. The co-solvent is urea, the moisturizing agent is glycerin and ethylene glycol, the dispersant is sulfonated lignin Reax LS and sodium naphthalenesulfonate formaldehyde condensate Demol MS, and the polymer surfactant is Surfynol 465.

[0039] 2. After beating the above mixture evenly, pour it into a grinder for grinding, and control the grinding temperature at 60°C±2...

Embodiment 3

[0048] Embodiment 3 Preparation of the blue dye dispersion direct jet ink of the embodiment of the present invention

[0049] 1. Calculated according to mass percentage, at room temperature, mix 45% high temperature disperse blue dye 60 color paste, C.I. Surfactant, add 18.3% water and mix well, after stirring for 60min, form a mixture, use zirconium beads with a diameter of 0.4-0.5mm in the sand mill for 3-10h, sand milling speed is 500rpm, sand mill The volume ratio of beads to mixture was 1:3. The cosolvent is urea, the moisturizing agent is glycerin and ethylene glycol, the dispersant is sulfonated lignin Reax LS and naphthalenesulfonate sodium formaldehyde condensate Demol MS, and the polymer surfactant is Surfynol 465.

[0050] 2. After beating the above mixture evenly, pour it into a grinder for grinding, and control the grinding temperature at 60°C±2°C until the median diameter reaches 185nm;

[0051] 3. After discharging the material at a standardized concentration,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com