Digital ink-jet printing ink based on extract of stems and leaves of celosia cristata L.

A digital inkjet and printing ink technology, applied in the development of natural plant dyes, can solve the problems of harmful chemical components of printing inks, unfavorable skin, complicated processes, etc., achieve good water vapor permeability, reduce environmental pollution problems and health problem, effect of giving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Washing, drying and pulverizing the stems and leaves respectively to 50 meshes, and then mixing the pulverized powders together;

[0030] (2) The mixture of the pulverized stems and leaves obtained in step (1) is dissolved in the mixed solution of ethanol and water (wherein the volume ratio of ethanol and water is 10:1 ), then ultrasonic treatment with a power of 750w for 50min, filtration, and separation of the filtrate;

[0031] (3) The filtrate obtained in the step (3) is spray-dried under the conditions of an inlet air temperature of 140° C. and an outlet air temperature of 80° C. to obtain the stem and leaf extract of Celosia celosia.

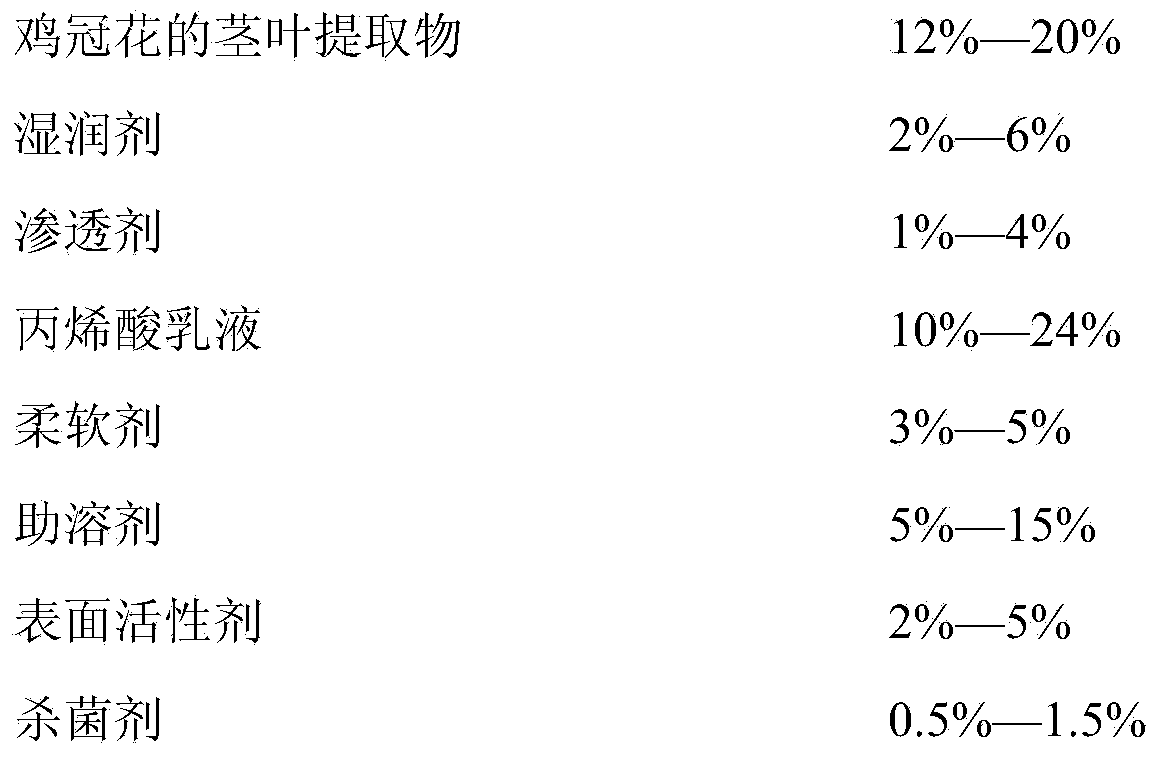

[0032] The stem and leaf extract of cockscomb prepared by the above method is used as a plant dye to prepare digital printing ink, and the weight percentage and process of each component are as follows:

[0033]

[0034] The rest is deionized water.

[0035] According to the weight percentage of each component in the above ...

Embodiment 2

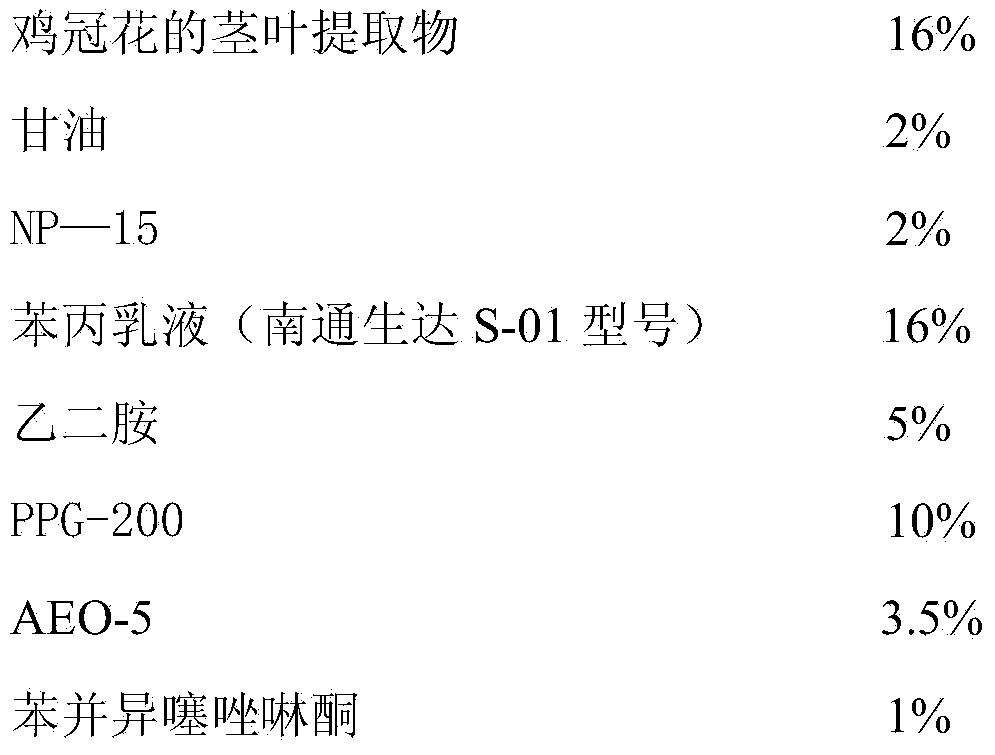

[0037] The stem and leaf extract of the cockscomb prepared by the method in Example 1 is used as a vegetable dye to prepare digital printing ink, and the weight percentage and process of each component are as follows:

[0038]

[0039] The rest is deionized water.

[0040] Preparation of digital printing ink:

[0041] According to the weight percentage of each component in the above formula, each component is mixed, and the following preparation procedure is the same as that of Example 1.

Embodiment 3

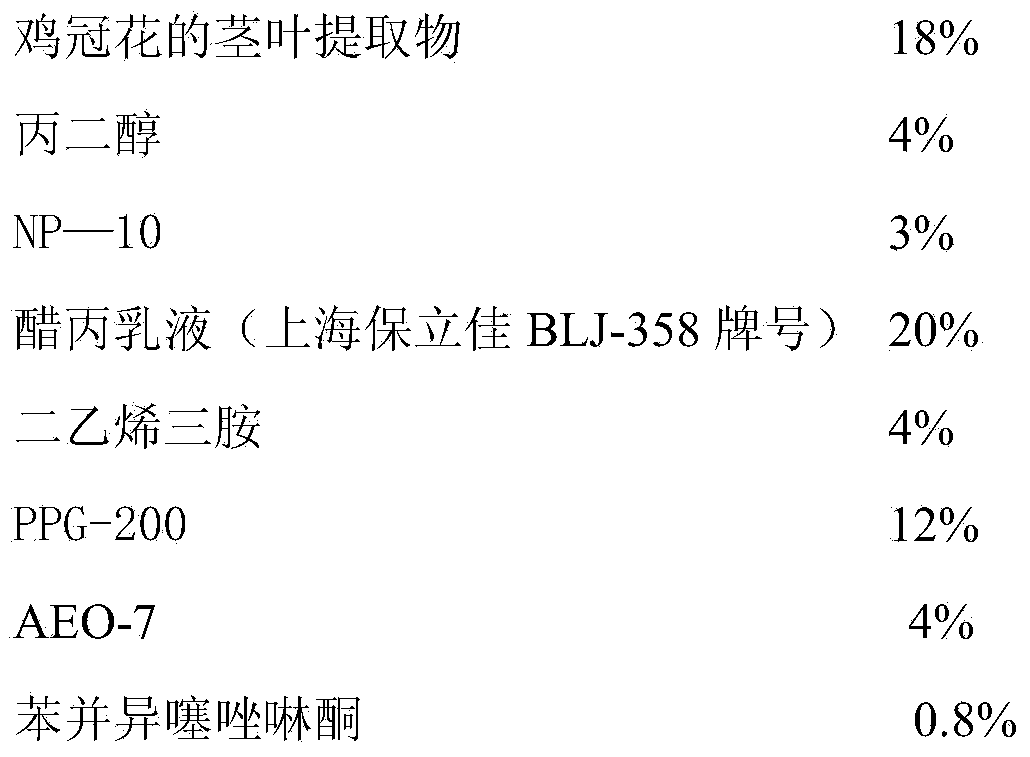

[0043] The stem and leaf extract of the cockscomb prepared by the method in Example 1 is used as a vegetable dye to prepare digital printing ink, and the weight percentage and process of each component are as follows:

[0044]

[0045] The rest is deionized water.

[0046] Preparation of digital printing ink:

[0047] According to the weight percentage of each component in the above formula, each component is mixed, and the following preparation procedure is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com