A transfer film prepared by digital printing, its preparation method and its application

A transfer film and digital printing technology, which is applied in the field of transfer film prepared by digital printing, can solve the problems of short nozzle life, inability to set a white background, high comprehensive cost, etc., achieve high-efficiency industrial productivity, and improve printing environmental protection , the effect of omitting print issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

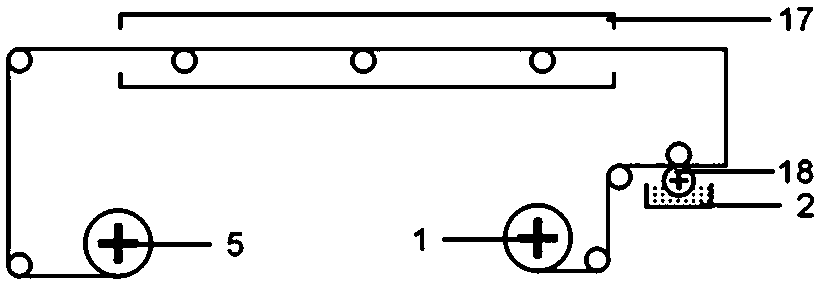

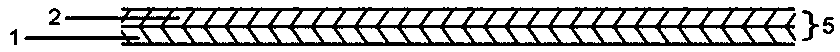

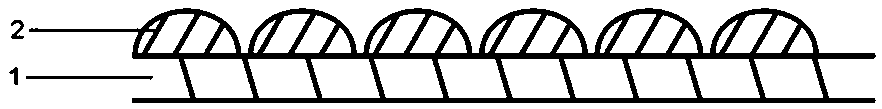

[0050] The embodiment of the present invention discloses a method for preparing a transfer film prepared by digital printing, see figure 1 As shown, the thickness is 10 to 40 microns, preferably, a 38um transparent biaxially stretched non-corona PET film is used as the carrier film 1, and then an anilox coating roller 18 is used to support the coating machine, which will have a separation function The water-based wax 2 is coated and superimposed and solidified on 1, and dried in a drying box 17, and then rolled into a roll to prepare a transfer base film 5 with a separation function.

[0051] Among them, the water-based wax 2 with separation function, preferably, its components and proportions are 10% to 15% of carnauba wax emulsion, 30% to 35% of ethanol, 50% to 60% of water, and the setting amount is 0.12% dry coating amount. ~0.15g / ㎡.

[0052] Preferably, its composition and ratio are 12% of carnauba wax emulsion, 33% of ethanol, and 55% of water, and the setting amount is...

Embodiment 2

[0079] In the preparation method of a transfer film prepared by digital printing in this embodiment, preferably, the present embodiment adopts a roll material transparent biaxially stretched non-corona PET film with a thickness of 20 microns as the carrier film, referring to Example 1 The preparation method obtains a transfer film prepared by digital printing of the present invention.

[0080] The transfer function layer of the transfer film, including the color toner layer and the water-based wax layer not covered by the color toner layer, is subjected to in-line or off-line corona treatment, see Figure 11 As shown, after the transfer film 7 is corona treated off-line by the corona treatment machine 25, its surface tension is greater than or equal to 38 mN / m.

[0081] see Figure 12 As shown, the corona-treated transfer film prepared by digital printing is coated with solvent-based glue off-line, and an anilox coating roller is used to coat the transfer film 7 on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com