Working method of long-strip-shaped material equidistant cutting device with ratchet wheel auxiliary feeding function

A technology for assisting feeding and cutting devices, applied in feeding devices, shearing devices, accessories of shearing machines, etc., can solve the problems of inaccurate cutting length of materials, injury to staff, damage to cutting blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

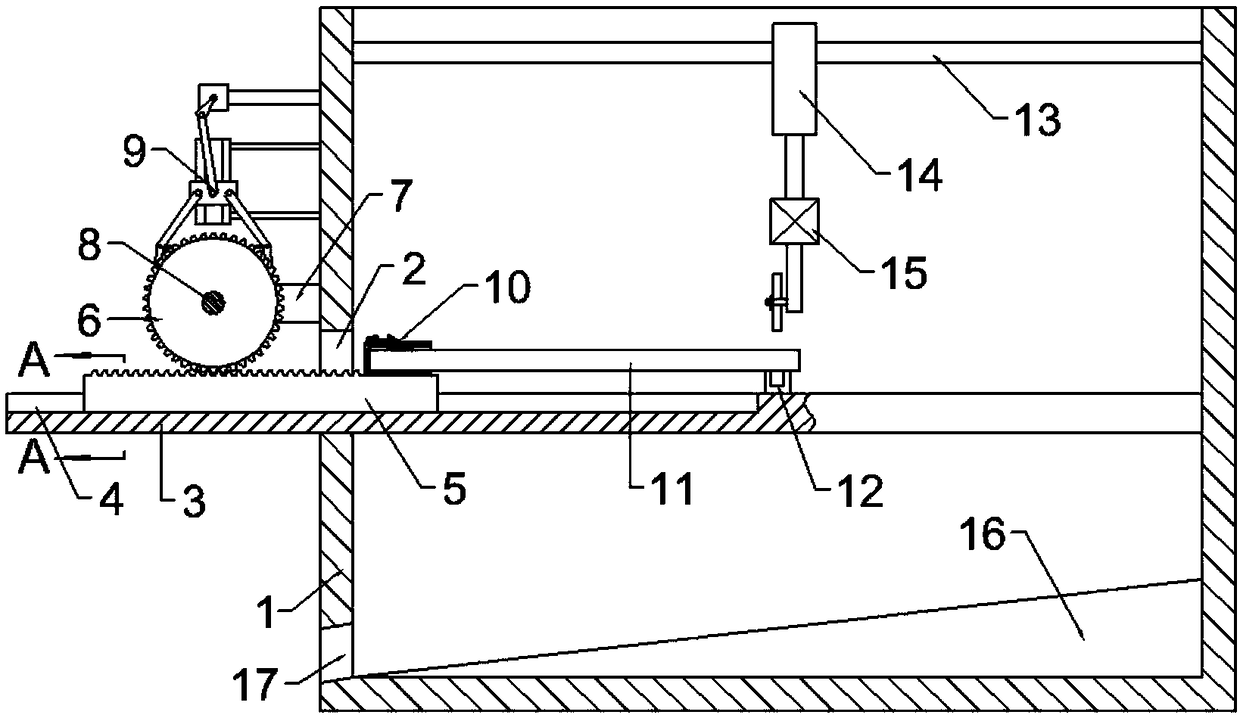

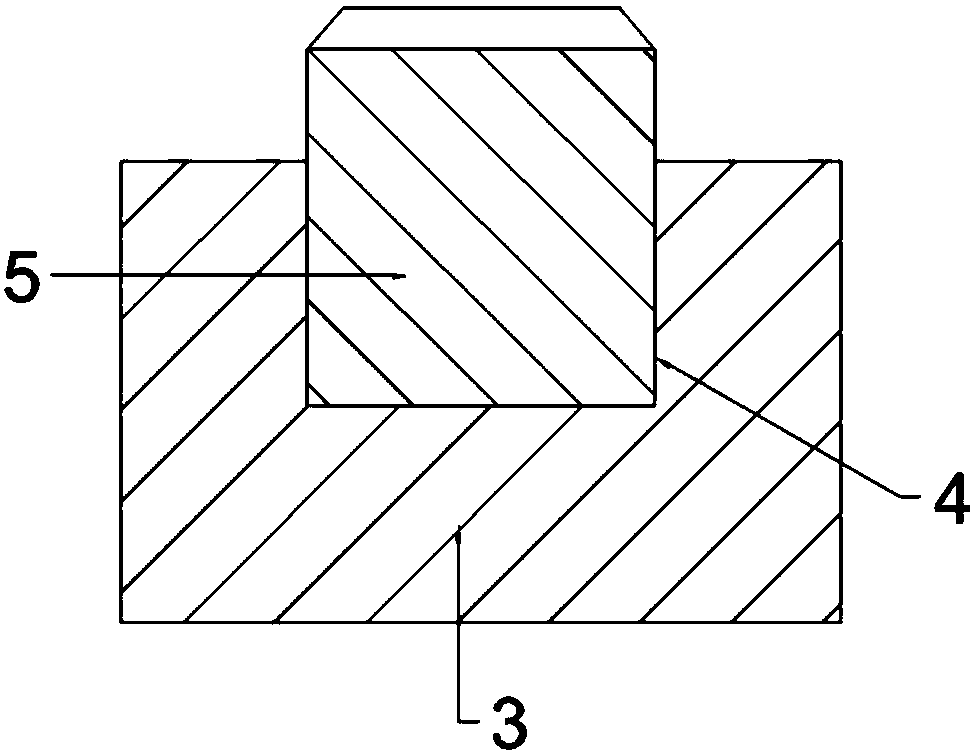

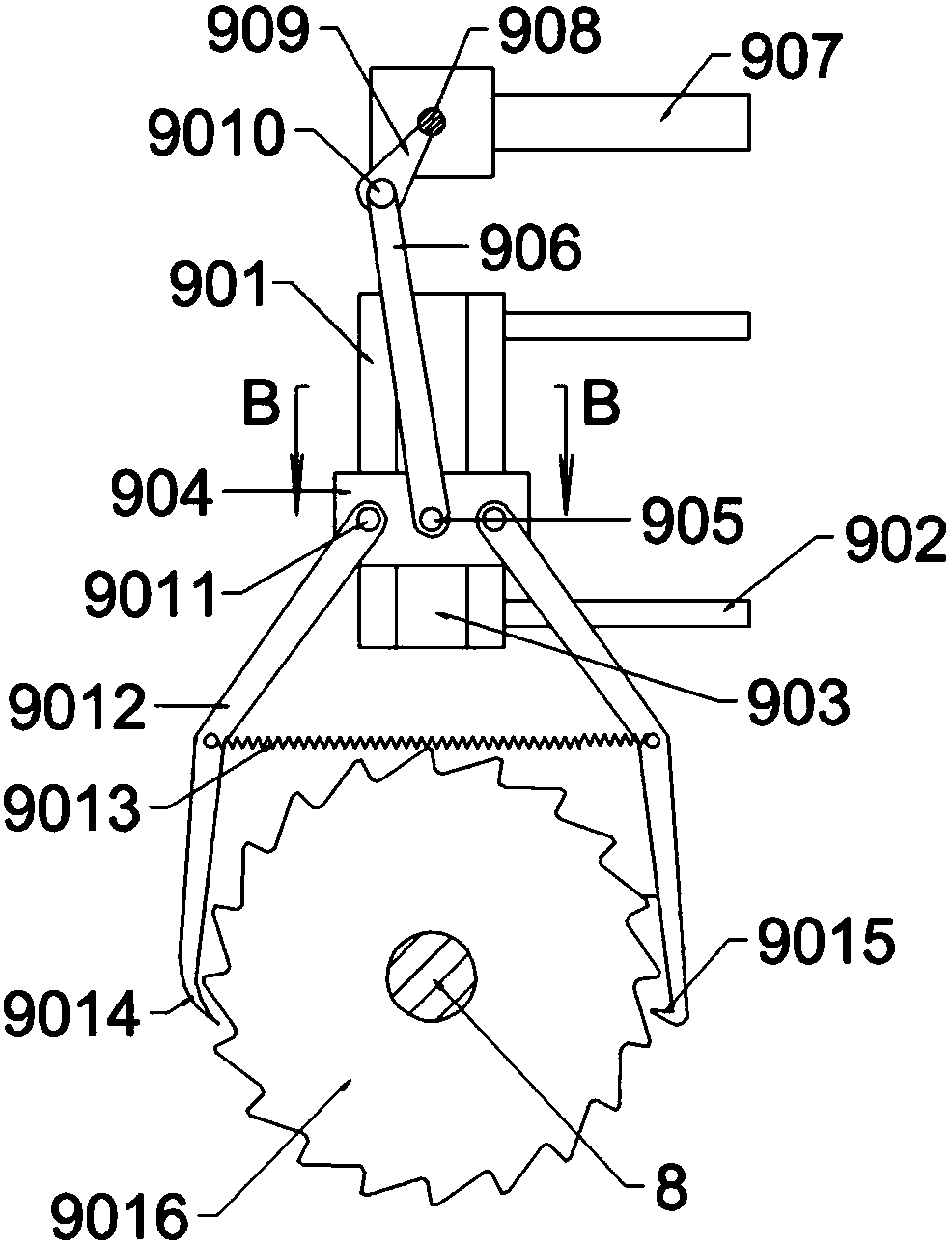

[0029] see figure 1 and figure 2 , in this embodiment, a strip-shaped material equidistant cutting device with a ratchet auxiliary feeding function, including a processing cabinet 1, the top of the processing cabinet 1 is open, and the left side wall of the processing cabinet 1 There is an inlet and outlet through hole 2 on the top, and a feed support plate 3 is fixedly connected to the inlet and outlet through hole 2. The left end of the feed support plate 3 extends to the outside of the processing cabinet 1, and the right end of the feed support plate 3 is connected to the right side of the processing cabinet 1. The walls are fixedly connected, and the feeding support plate 3 is provided with a first moving slot 4 with the opening facing upwards, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com