Full automatic subassembly of lock bolt

A fully automatic technology for anti-loosening bolts, applied in the direction of bolts, threaded fasteners, screws, etc., can solve the problems of reducing the strength of bolts and nuts, inconvenient disassembly and maintenance, complicated processes, etc., and achieves convenient processing and use, simple structure, Good effect of anti-loosening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

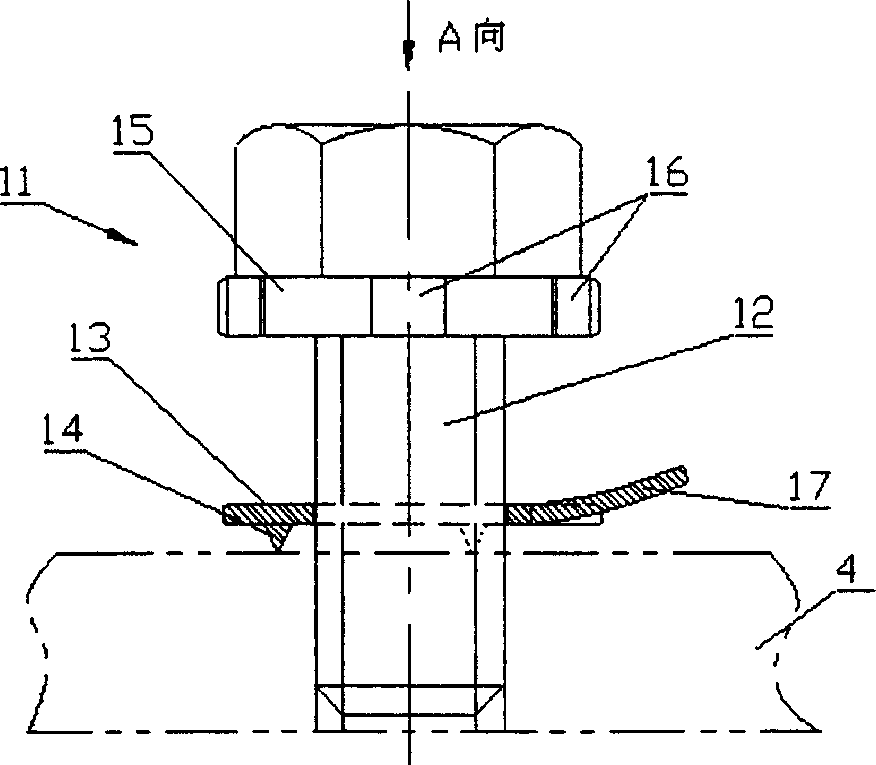

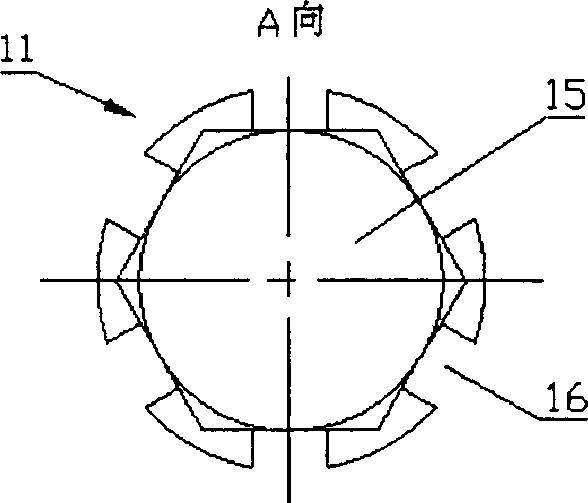

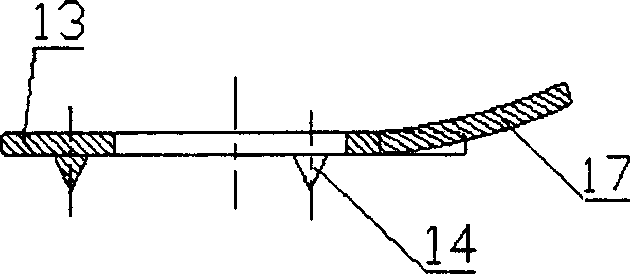

[0022] Embodiments of the present invention are as Figure 1-Figure 4 As shown, it includes a bolt 11 and a washer 13 sleeved on the periphery of the screw rod 12 of the bolt. It is characterized in that: the front side of the washer has tines 14 for fastening the supporting surface of the connected part, and the rear peripheral part of the washer A positioning piece 17 is provided on the top for fastening the channel 16 provided on the outer peripheral wall of the nut 15 of the bolt. The above-mentioned locating elements are elastic locating elements distributed on the radial periphery of the rear side of the washer and can be bent backwards.

[0023] When in use, when the bolt is tightened, first press the tines on the front side of the washer into the supporting surface of the connected part, so that the washer is fastened on the connected part; when the bolt continues to rotate until one of the elastic positioning parts corresponds to the outer circumference of the nut Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com