Making method for sawteeth of dual metal saw

A manufacturing method and bimetallic technology, which is applied in the manufacture of cutting tools of sawing machine devices, metal sawing equipment, and manufacturing tools, can solve the problems of high manufacturing cost and unsharp tooth tips, and achieve low machining cost and high production efficiency , Improve cutting efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

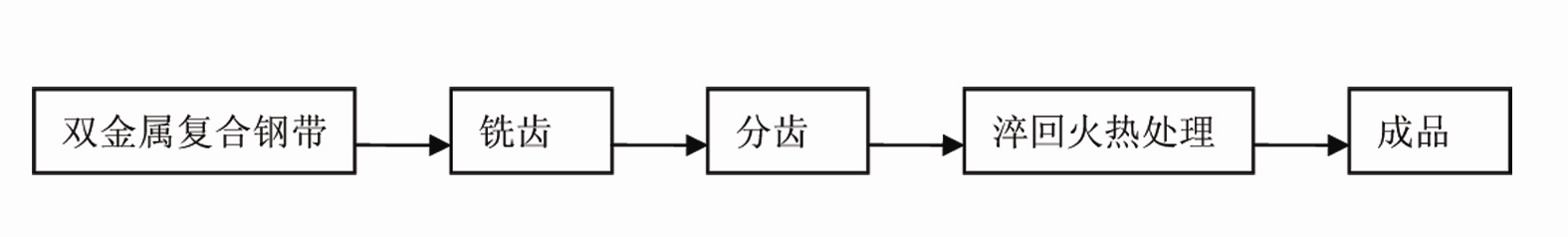

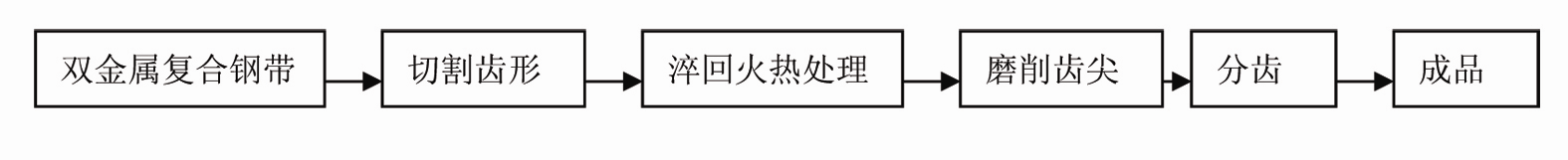

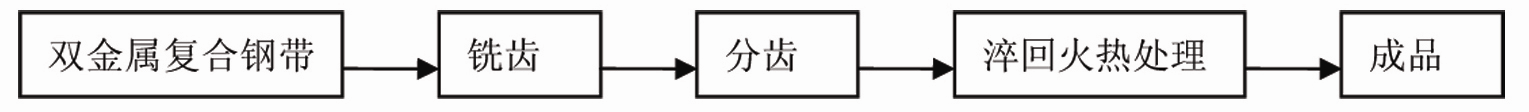

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The 54mm wide saw blade is produced by the manufacturing method of the bimetallic saw blade saw tooth, the raw material is a bimetallic composite steel strip whose back is special spring steel and the teeth are high-speed steel, and the width is 54mm; the teeth can be M42 high-speed steel; production process steps for:

[0021] (1) Carry out laser cutting and forming of the saw blade raw material bimetal composite steel strip according to the tooth shape:

[0022] Use a laser cutting machine to cut the tooth shape, and cut the required tooth shape through CNC programming; the laser cutting and shaping of the tooth shape is carried out continuously according to the beat, cutting 5 or more tooth pitches per beat, cutting 5-8 meters per minute, and the tooth tip Form an arc of 0.05mm-0.1mm;

[0023] Laser cutting equipment can choose German Trumpf Trulaser3030 laser cutting machine, or Swiss Bystronic laser cutting machine, or other suitable laser cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com