Probe structure and manufacturing method thereof

A manufacturing method and probe technology, applied in the direction of instruments, measuring devices, measuring electricity, etc., can solve the problem of easy overheating of probes, and achieve the effect of overheating easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

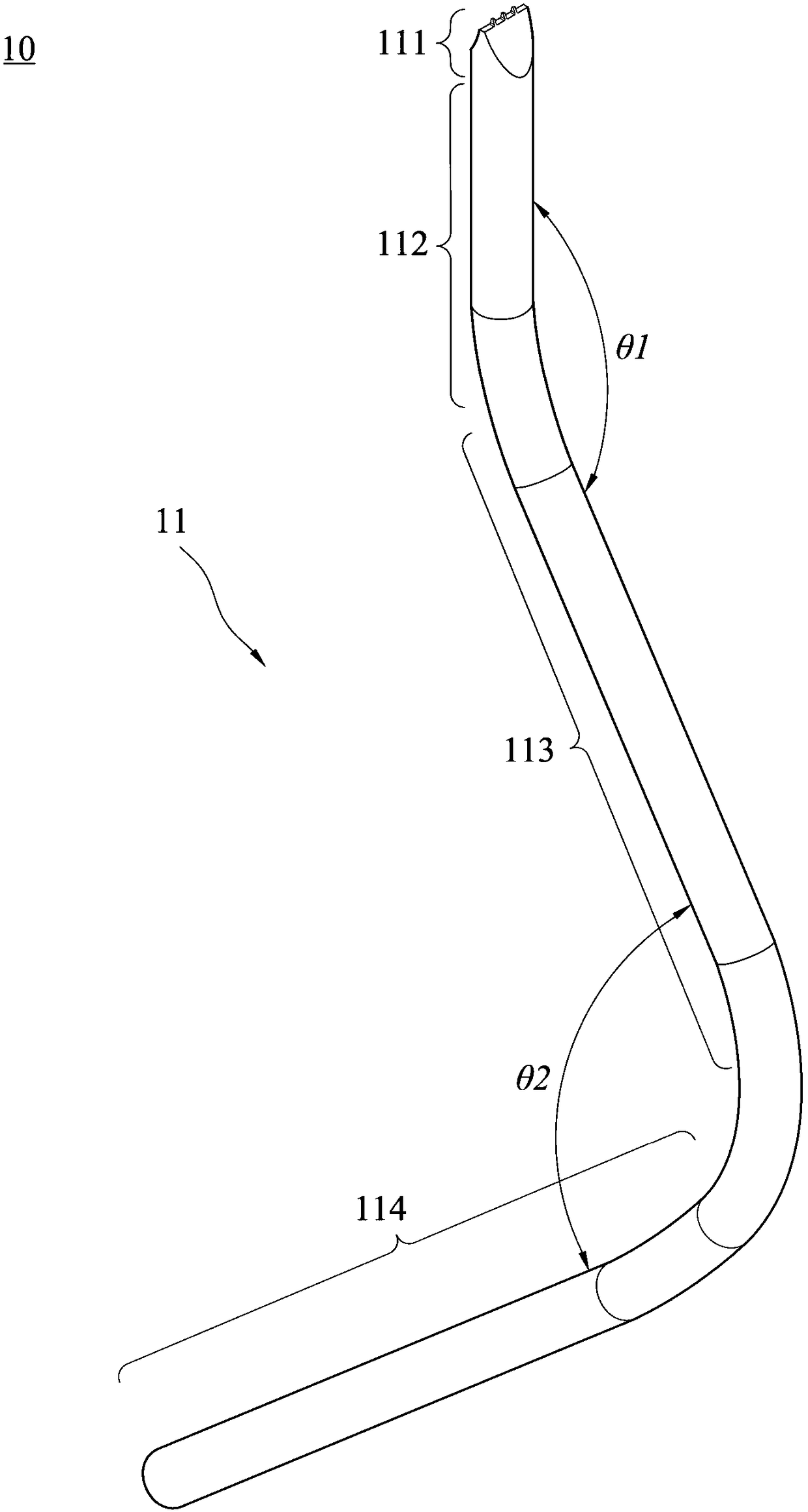

[0049] Please refer to Figure 1A , is a schematic diagram of the probe structure of the present invention. The disclosed probe structure 10 includes a probe body 11 , and the probe body 11 includes a needle tip 111 , a needle tail 112 , a first segment 113 and a second segment 114 . The needle tail 112 is directly connected to the needle tip 111 , and the two ends of the first section 113 are respectively connected to the needle tail 112 and the second section 114 . The needle tail 112 and the first section 113 define a first included angle θ1, which is in the range of 150 degrees to 175 degrees. The first segment 113 and the second segment 114 define a second included angle θ2, which is in the range of 75 degrees to 105 degrees. In this embodiment, the needle tip 111 , the needle tail 112 , the first segment 113 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com