Waterproof coating preparing and processing system

A processing system and waterproof coating technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of small cross-sectional area of raw materials and filter screen, incomplete filtration, incomplete crushing, etc., to increase the effective filtration area and prevent Clogging the mesh of the filter, which is beneficial to the effect of preparation and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

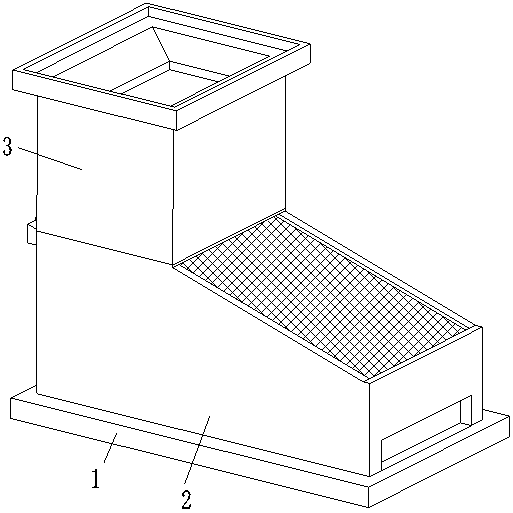

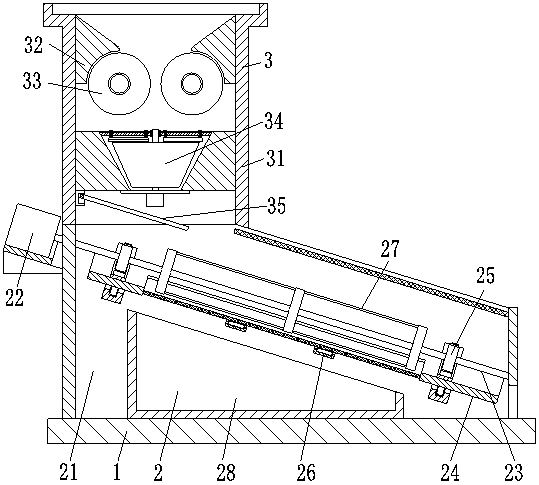

[0030] like Figure 1 to Figure 6 As shown, a waterproof paint preparation and processing system includes a bottom plate 1, a screening device 2 and a grinding device 3. The upper end of the bottom plate 1 is equipped with a screening device 2, and the left side of the upper end of the screening device 2 is provided with an open slot, and the opening is Grinding device 3 is installed on the groove.

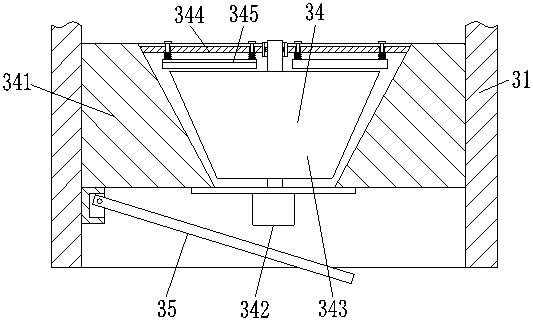

[0031]Described screening device 2 comprises housing frame 21, driving motor 22, drive shaft 23, screening plate 24, swing mechanism 25, vibrating screen mechanism 26, cleaning mechanism 27 and collection box 28, described housing frame 21 Installed on the upper end of the bottom plate 1, the left end of the housing frame 21 is equipped with a drive mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com