Cloth winding mechanism of cloth printing machine

A printing machine and cloth technology, which is applied in the direction of thin material processing, winding strips, sending objects, etc., can solve the problems of up and down shaking, wear between the cloth take-up roller and the support structures at both ends, and uneven cloth take-up, etc. Lifting, which is conducive to the effect of tidy collection and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

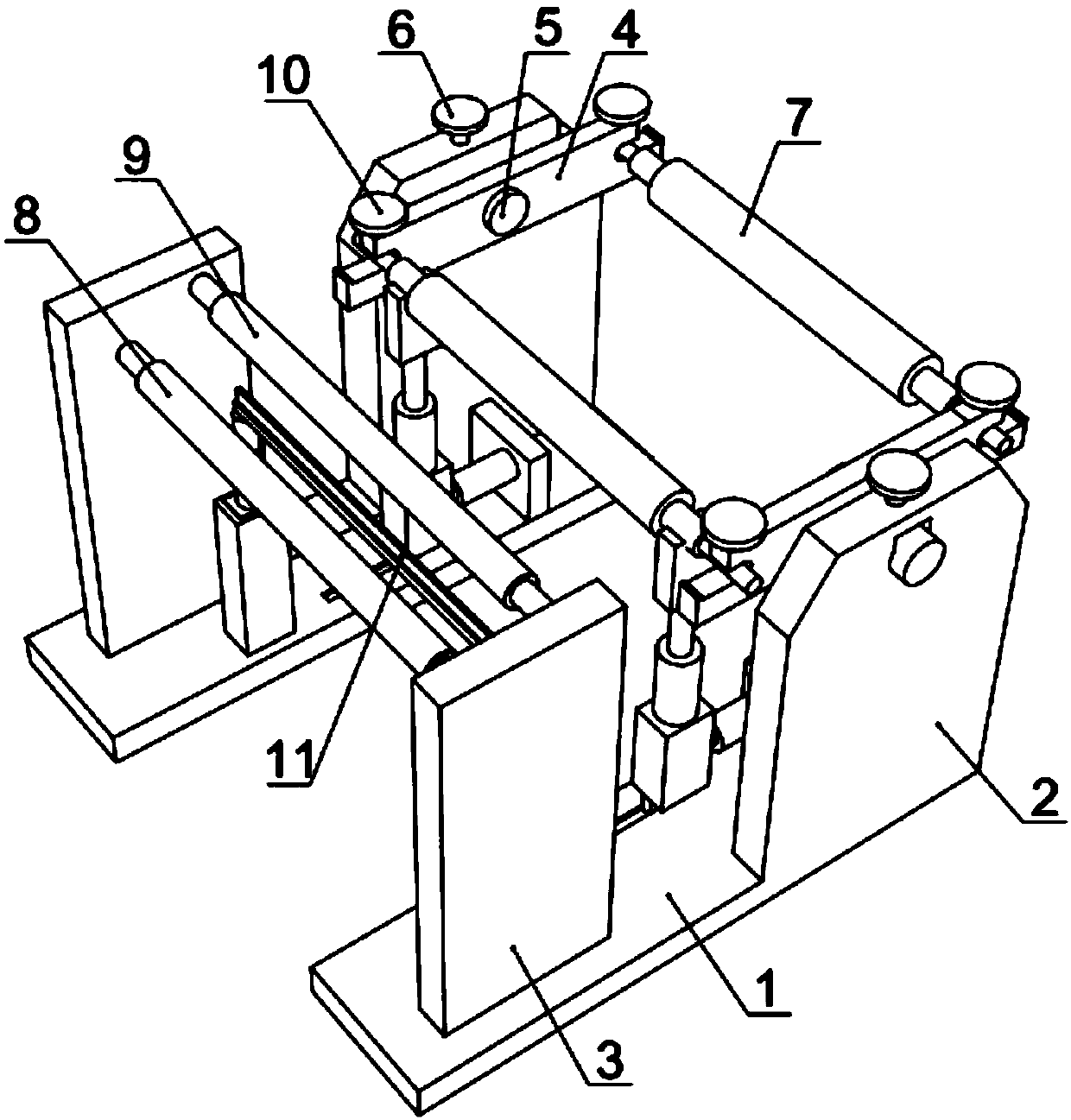

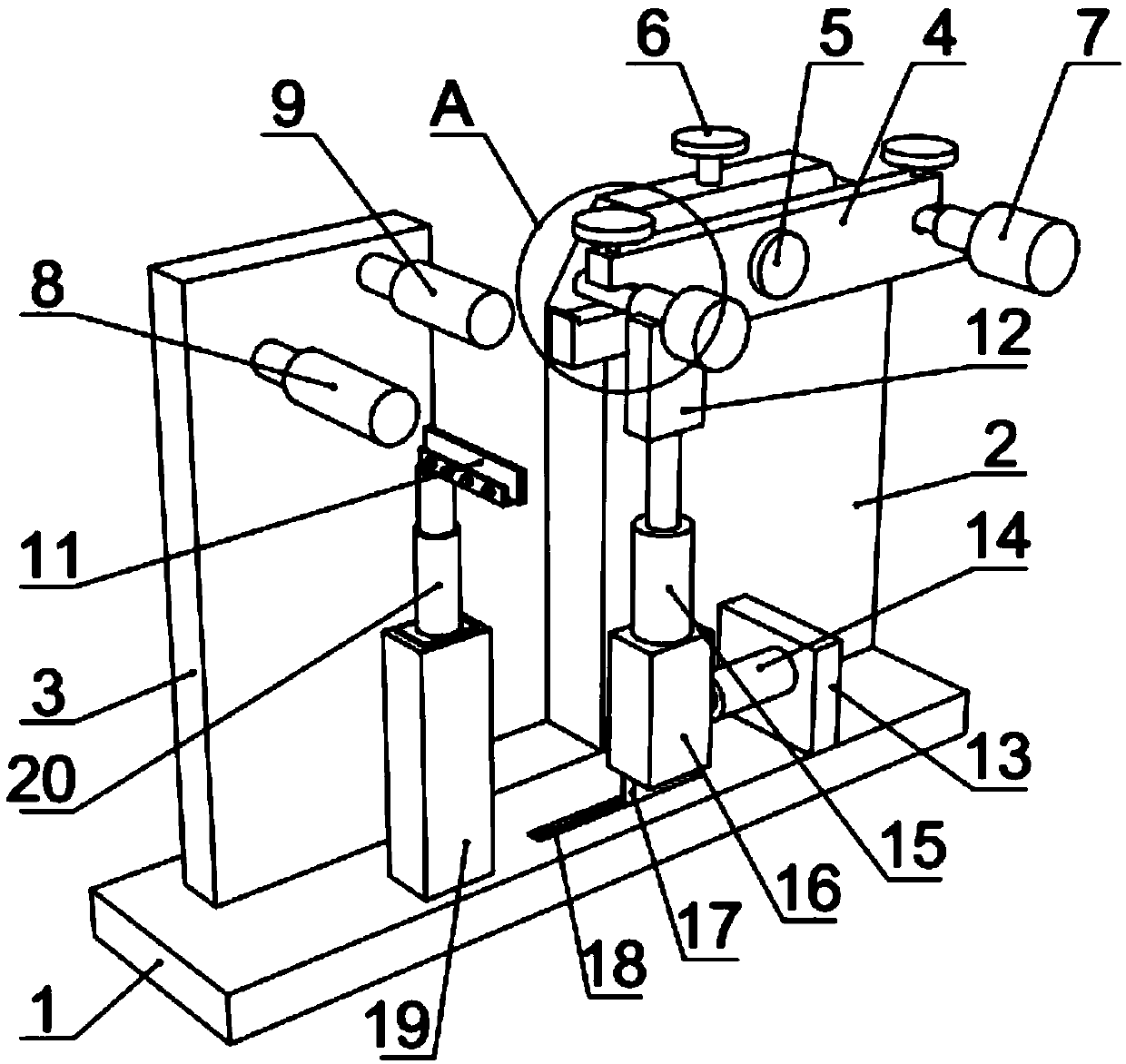

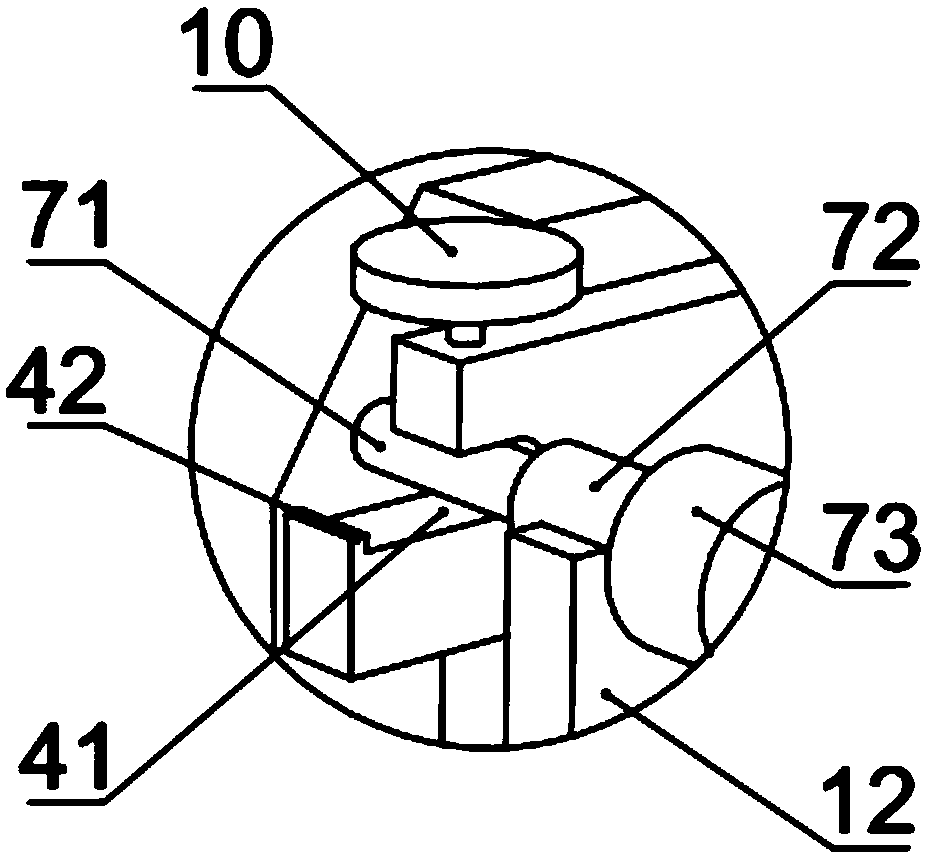

[0024] like Figure 1 to Figure 5 As shown, a cloth receiving mechanism of a cloth printing machine includes a base 1, a pair of first supporting boards 2 arranged above the base 1, and two cloth receiving rollers 7 arranged between the first supporting boards 2, and the cloth receiving rollers 7 includes a cloth receiving shaft 73, a support shaft 72 connected to both ends of the cloth receiving shaft 73, and a fixed shaft 71 connected to the support shaft 72; The first fastening bolt 6 of the rotating shaft 5, the rotating shaft 5 is fixedly connected with the support plate 4, and both ends of the support plate 4 are provided with a transverse U-shaped fixing groove 41, and a fixing shaft 71 is installed in the fixing groove 41, and the fixing groove 41 above The second fastening bolt 10 for fixing the fixed shaft 71 is provided, and the end of the fixed groove 41 is provided with a stopper 42, which can prevent the cloth receiving roller from rolling off during the replacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com