Wire cutter

A cutter and wire technology, which is applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of light peeling force that cannot be peeled off, high occurrence rate of defective products, low tool safety, etc. Simple operation and enhanced versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings:

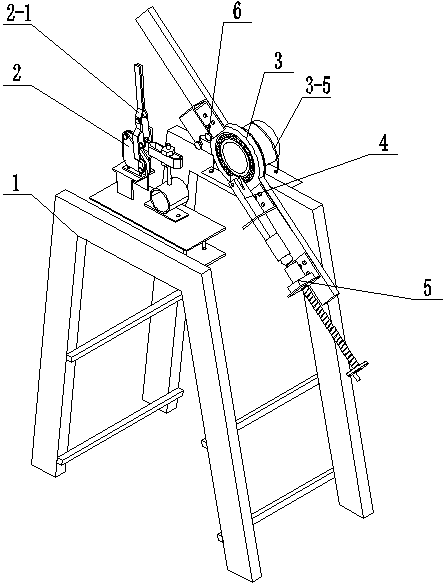

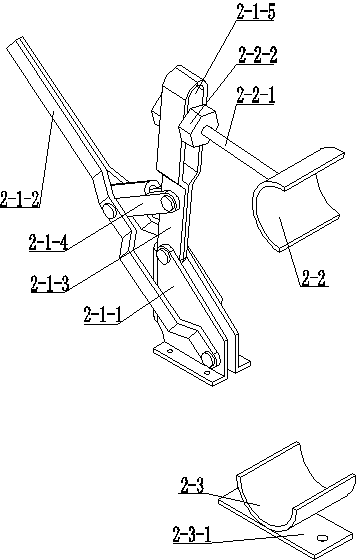

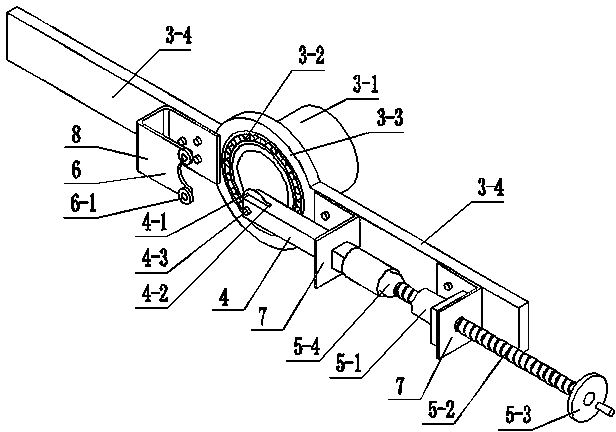

[0023] The main structure of the present invention is as figure 1 As shown, it includes the operating table 1, the retaining and pressing device 2 is fixed on the operating table 1 by bolts, the rotating device 3 is fixed on the operating table 1 by the steel band 3-5, and the base 3-1 of the rotating device 3 The central axis coincides with the central axis of the cylinder formed by the upper and lower mold shells of the retaining and pressing device 2, the tool holder 4 is fixed on a connecting plate 3-4 of the rotating device 3, and the rear end of the tool holder 4 is connected to the The front end of the lead screw 5-2 of the feeding device 5 is connected, and the pressing wheel device 6 is installed on another connecting plate 3-4 corresponding to the blade 4-1. The invention can quickly cut the aluminum stranded wire on the outer layer of the iron core aluminum strand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com