Spiral pipe cutting machine

A tube cutting machine and spiral technology, which is applied to the grinding frame, grinding machine, grinding bed and other directions, can solve the problem of inability to complete the cutting work, and achieve the effect of good cutting effect, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the solution of the present invention, and to make the above-mentioned purpose, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings of the embodiments.

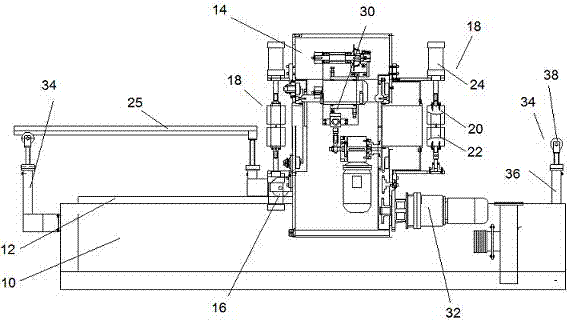

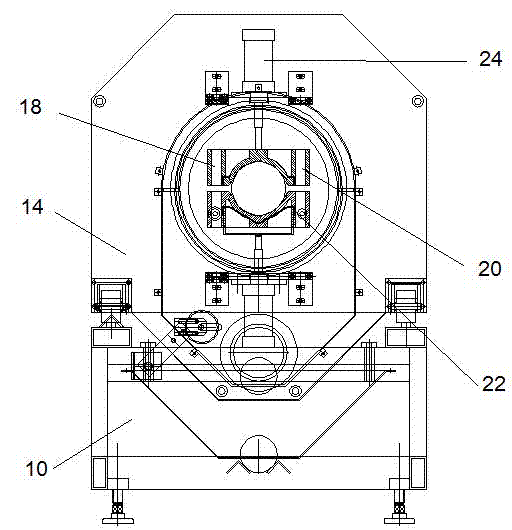

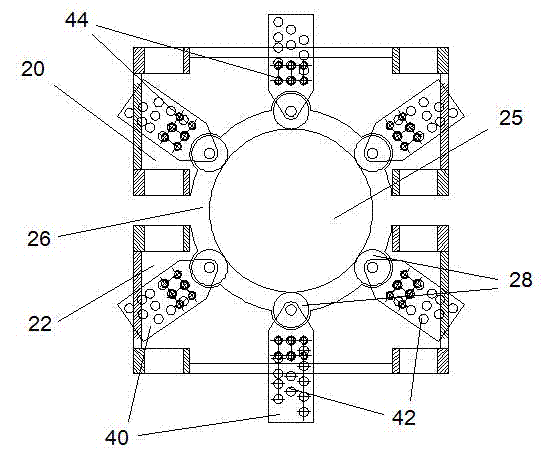

[0016] Such as figure 1 , figure 2 and image 3 As shown, a kind of spiral pipe cutting machine of the present invention comprises frame 10, and frame 10 is provided with horizontal guide rail 12, and guide rail 12 is provided with cutting table 14, and cutting table 14 is provided with roller 16, makes cutting table 14 The whole can move horizontally along the guide rail 12. Both sides of the cutting table 14 are provided with a pressing mechanism 18, the pressing mechanism 18 includes an upper pressing part 20, a lower pressing part 22 and a cylinder 24, and the upper pressing part 20 is verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com