Automatic orientated balance mechanism for circular-disc-shaped structure

A balancing mechanism and disc-shaped technology, applied in the field of machinery, can solve the problems such as the support function of a large disc that cannot be placed horizontally, and achieve the effects of simple structure, convenient use and increased load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

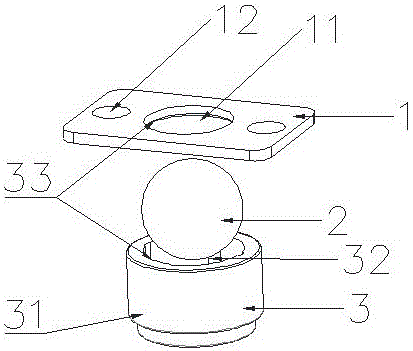

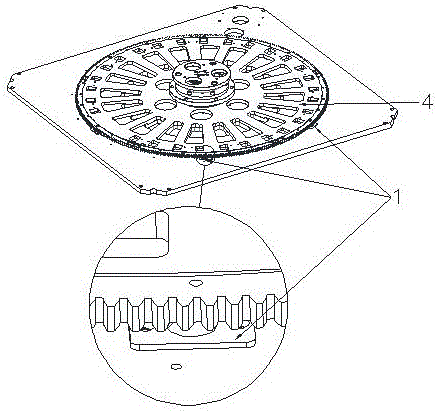

[0025] An automatic orientation balance mechanism for a disc-shaped structure, including a steel ball anti-off piece 1, a steel ball 2 and a steel ball base 3; the steel ball base 3 is a metal cylinder 31 as a whole; the cylinder 31 is internally provided with four Groove 32; the groove 32 is arranged parallel to the generatrix of the cylinder 31, and the inner wall of the bottom of the cylinder 31 is provided with an arc-shaped chamfer 33, and the radian of the arc-shaped chamfer 33 is equal to the arc of the surface of the steel ball 2 ;

[0026] The steel ball 2 is arranged on the top of the steel ball base 3, and the steel ball anti-off piece 1 is fixed on the top of the steel ball 2 by screws;

[0027] The steel ball anti-off sheet 1 is sheet-shaped, and is provided with a steel ball hole 11 and a fixing hole 12 , and the diameter of the steel ball hole 11 is smaller than the diameter of the steel ball 2 .

[0028] The distances between the grooves 32 are the same.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com