Annular reduction furnace capable of not leaking material at furnace bottom

A technology for reducing furnaces and furnace bottoms, applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve problems such as cleaning troubles, and achieve the effect of reducing cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

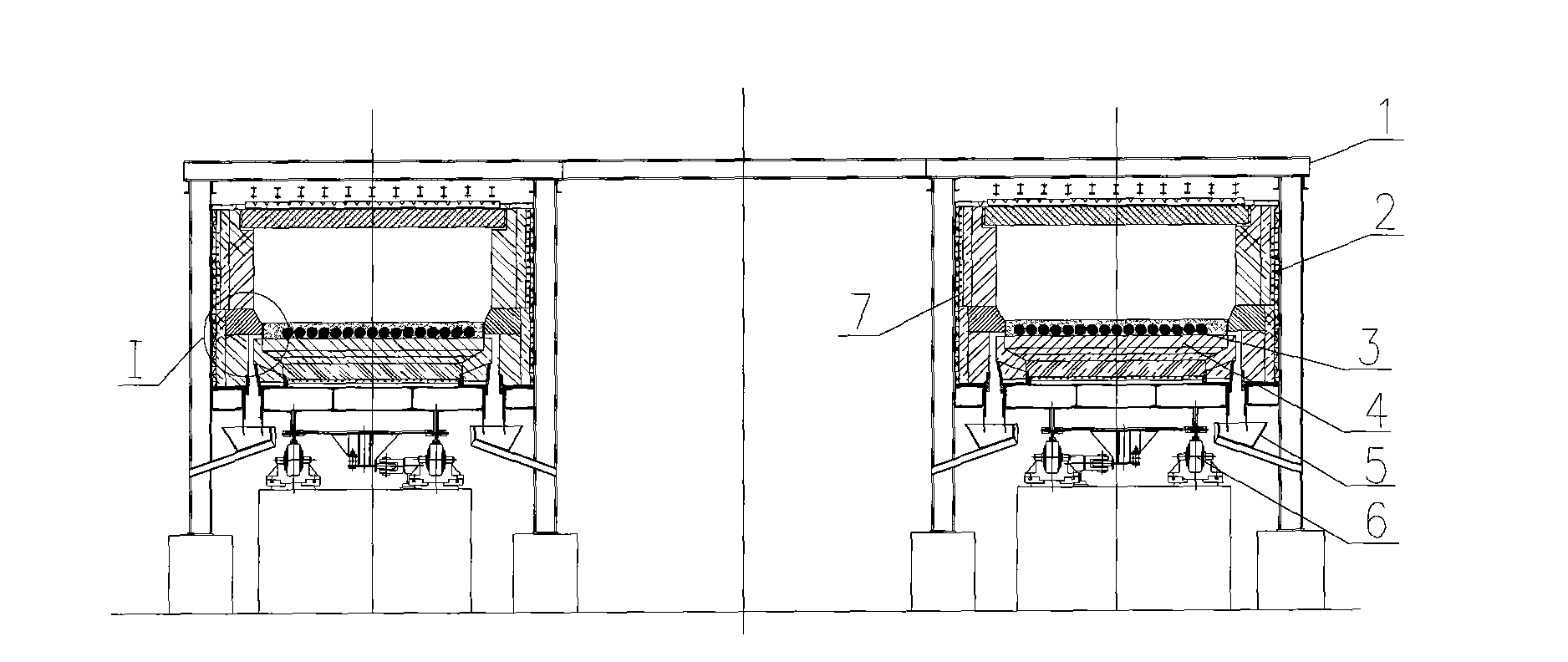

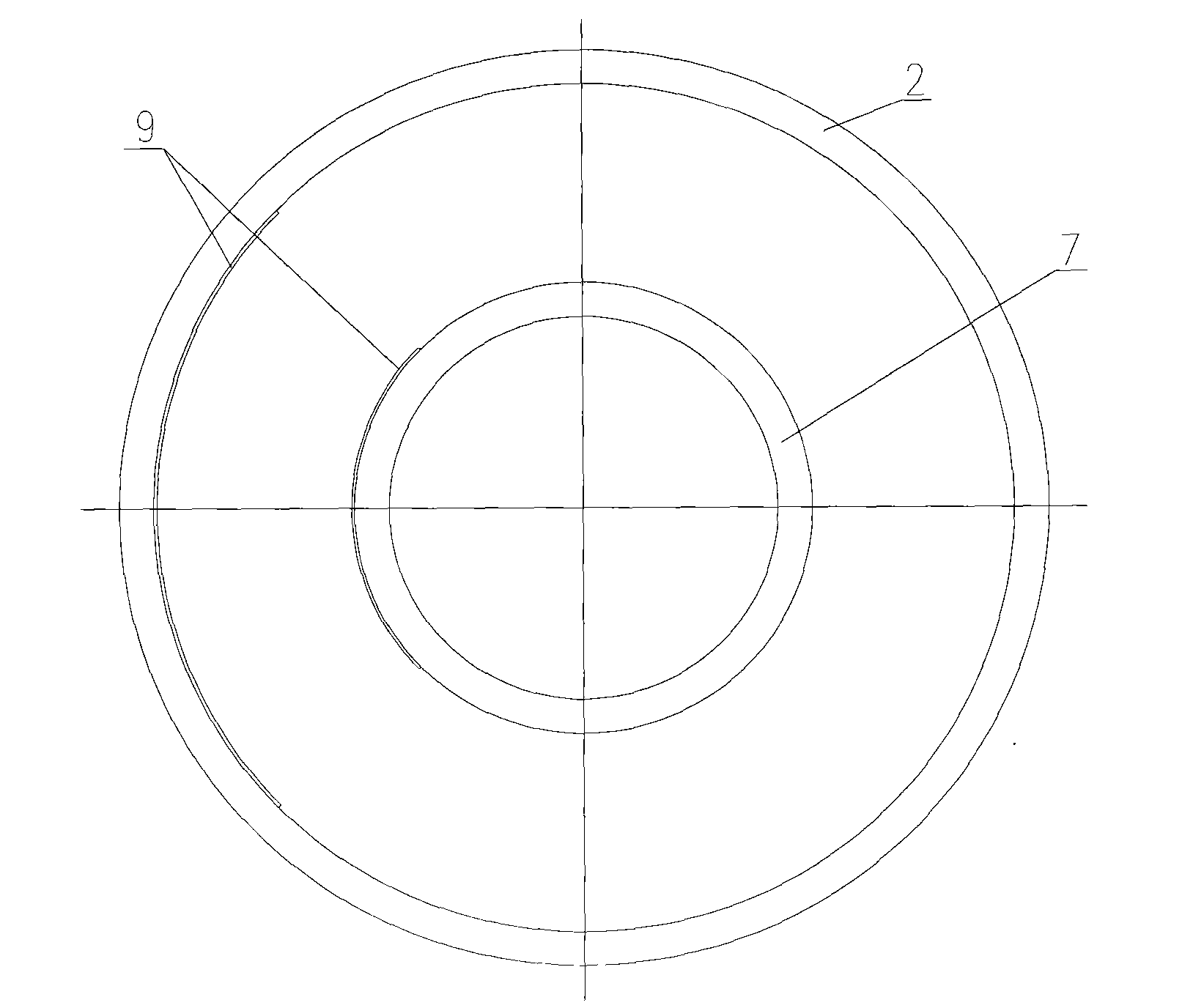

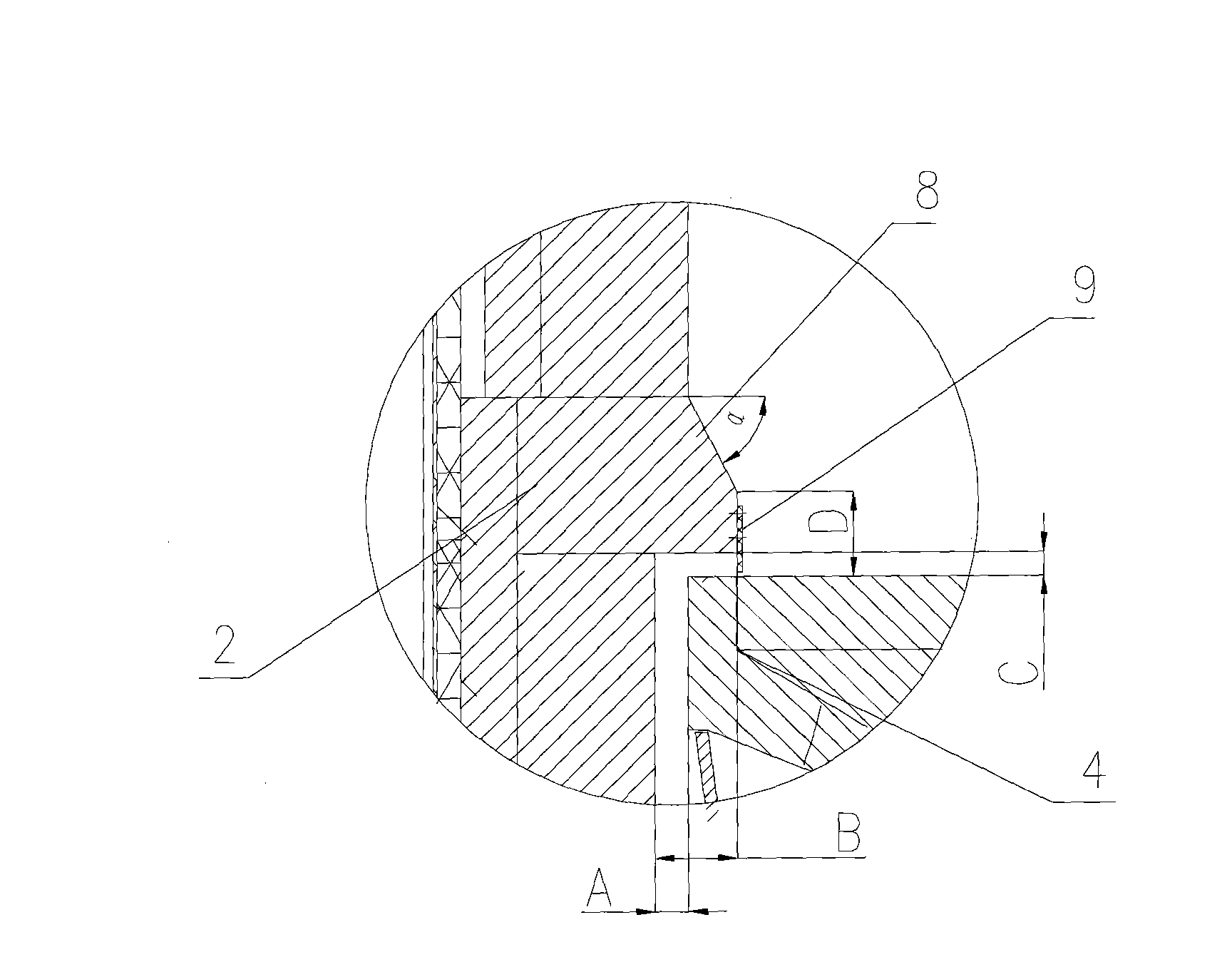

[0023] Such as figure 1 , figure 2 with image 3 Shown is a ring-shaped reduction furnace with no material leakage at the bottom of the furnace, including a furnace frame 1, an outer furnace wall 2, a furnace bottom 4, a water seal tank 5, a furnace bottom machine 6, an inner furnace wall 7, and heat-resistant rubber 9. Such as figure 1 As shown, the outer furnace wall 2 and the inner furnace wall 7 are arranged in the furnace frame 1, an annular furnace is formed between the outer furnace wall 2 and the inner furnace wall 7, the furnace bottom 4 is arranged at the bottom of the annular furnace, and the furnace bottom machinery 6 is arranged Below the furnace bottom 4, the furnace bottom machine 6 can drive the furnace bottom 4 to make a circular motion in the annular furnace. The bottom of the outer furnace wall 2 and the furnace bottom 4 is provided with a water seal groove 5 , and the bottom of the inner furnace wall 7 and the furnace bottom 4 is provided with a water s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com