A microwave power transistor internal matching network and its manufacturing method

A microwave power and internal matching technology, which is applied in the manufacturing of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of rising overall device cost, scrapping of internal matching devices, scrapping of tubes and shells, etc., to reduce and simplify the requirements. Manufacturing process, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

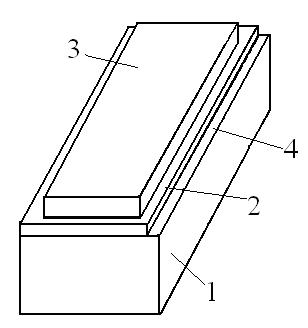

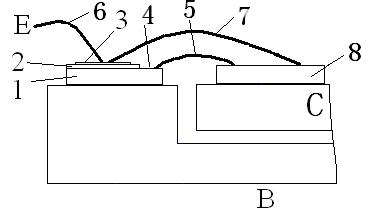

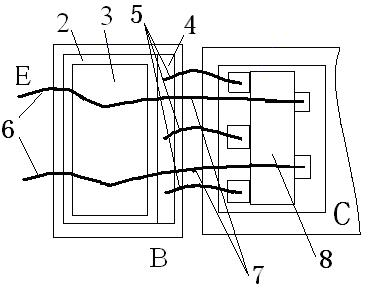

[0035] Embodiment 1 (the embodiment of the matching network in the microwave power transistor that improves the shell utilization rate of the present invention, see Figure 1-Figure 4 )

[0036] An internal matching network for microwave power transistors that improves the utilization of the shell, is characterized in that it includes an internal matching MOM capacitor composed of a lower electrode 1, an oxide medium layer 2 and an upper electrode 3, and a lower electrode lead wire 5, which is used as a first The first upper electrode lead-out line 6 of the matching inductance L1, the second upper electrode lead-out line 7 used as the second matching inductance L2; the lower electrode 1 of the internal matching MOM capacitor is wider than its oxide medium layer 2; the MOM capacitor The lower electrode lead-out line 5 is drawn from the upper surface 4 of the lower electrode exposed by photolithography, and its other end is connected to the ground pin of the transistor core 8; t...

Embodiment 2

[0045] Embodiment 2 (the embodiment of the matching network manufacturing method in the microwave power transistor that improves the shell utilization rate of the present invention, see Figure 1-Figure 3 )

[0046] A method for manufacturing an internal matching network of a microwave power transistor, characterized in that the process steps of the method are:

[0047] a. The silicon wafer is oxidized to form an oxide medium layer 2 between the upper and lower electrodes of the inner matching MOM capacitor;

[0048] b. Fabricate a metal lower electrode 1 that internally matches the MOM capacitor on the oxide medium layer;

[0049] c. Corrosion of silicon wafers;

[0050] d, on the other side of the oxidized medium layer, make the metal upper electrode 3 that matches the MOM capacitor;

[0051] e, photoetching the oxide medium layer, leading the lead wire of the lower electrode of the capacitor from the upper surface 4 of the lower electrode of the capacitor exposed by photol...

Embodiment 3

[0055] Embodiment 3 (the embodiment of the method for replacing the matching network in the microwave power transistor of the present invention to improve the utilization rate of the shell, see Figure 2-Figure 3 )

[0056] When the capacitance value of the internal matching MOM capacitor is not suitable, the replacement steps of the internal matching network of the microwave power transistor are as follows:

[0057] a. Remove the lower electrode lead-out line 5, the first upper electrode lead-out line 6 and the second upper electrode lead-out line 7 on the original inner matching MOM capacitor;

[0058] b. Remove the original internal matching MOM capacitor;

[0059] c. Install the solder and the new internal matching MOM capacitor on the base of the shell in turn, and sinter the new internal matching MOM capacitor;

[0060] d. Bond the lower electrode lead wire 5, the first upper electrode lead wire 6 and the second upper electrode lead wire 7 of the new inner matching MOM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com