Hot-rolled wire rod for 90-kilogram-grade welding wire and production method thereof

A technology of hot-rolled wire rod and production method, which is applied in the field of metallurgy to achieve the effects of increasing strength, increasing hardenability, and improving toughness and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

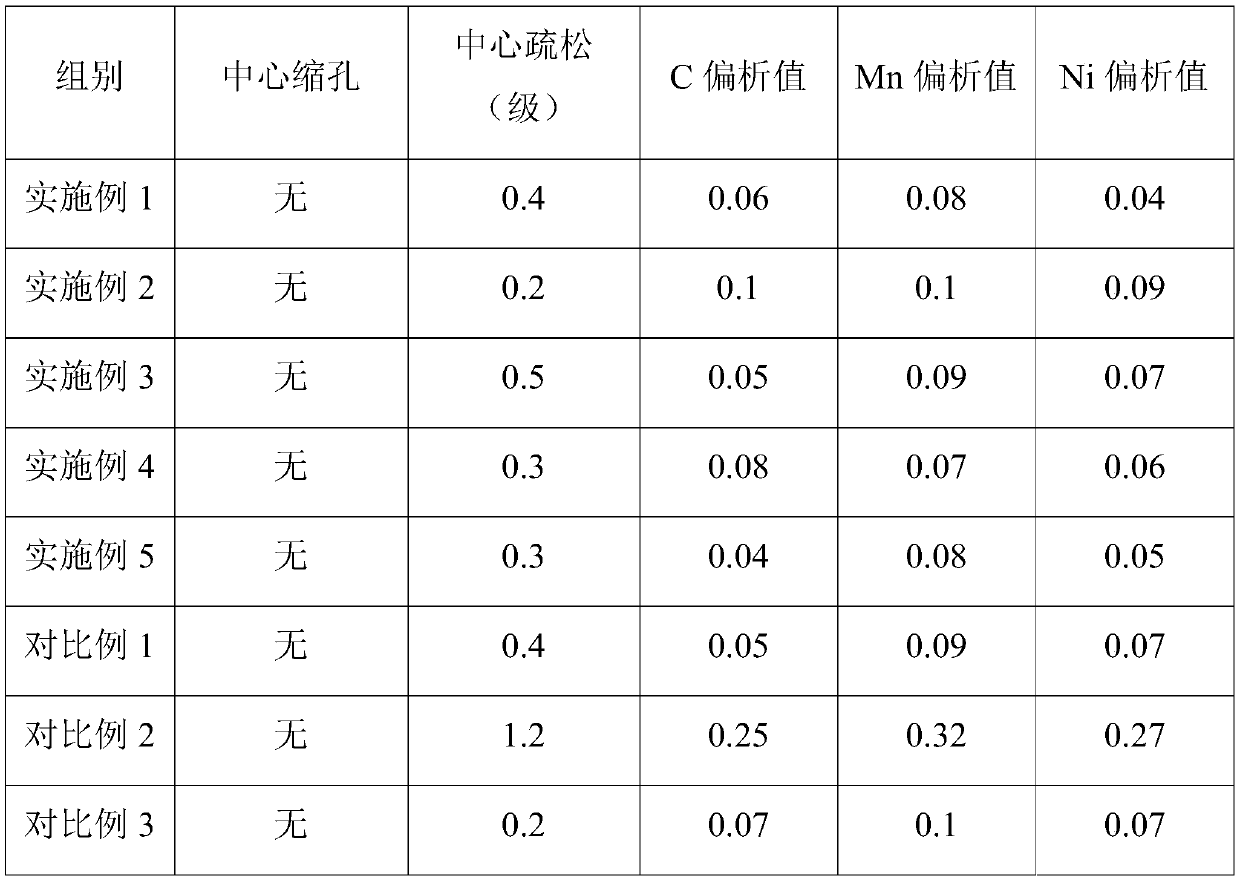

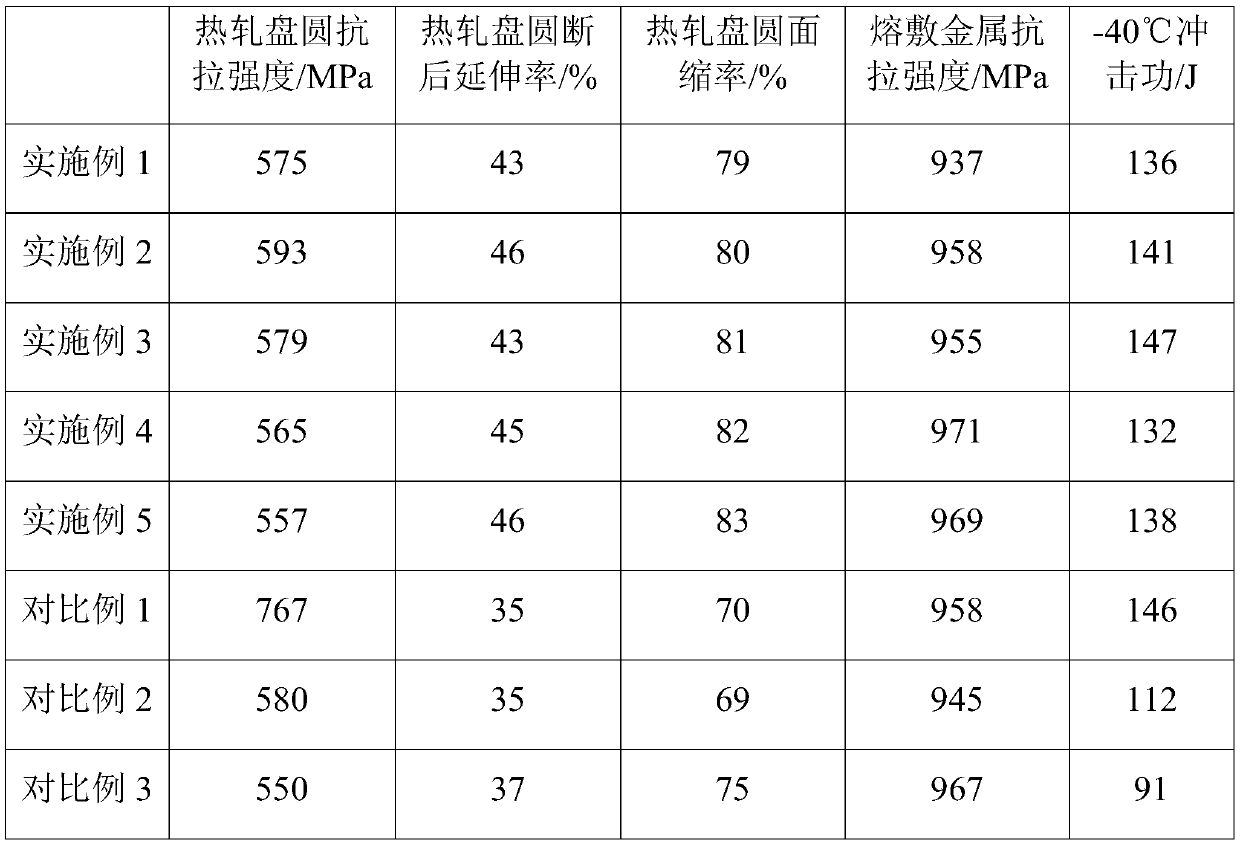

Examples

Embodiment 1

[0040] The embodiment of the present invention provides a kind of hot-rolled wire rod for 90 kilograms welding wire, and its chemical composition is:

[0041] C: 0.06%, Si: 0.70%, Mn: 1.50%, Ni: 2.1%, Mo: 0.35%, Cr: 0.05%, V: 0.06%, Ti: 0.08%, Al: 0.035%, N: 0.09%, Zr: 0.05%, P: 0.01%, S: 0.01%, As: 0.0021%, Sb: 0.001%, B: 0.0035%, Se: 0.01%, Ca: 0.001%, Pb: 0.0015%, Bi: 0.01%, Te: 0.0022%, O: 0.006%, H: 0.000045%, and the balance is Fe.

[0042] The production method of the hot-rolled wire rod for the above-mentioned 90 kg grade welding wire is as follows:

[0043] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting billet with a specification of 165×165mm is obtained; wherein, in the continuous casting process, electromagnetic stirring of the crystallizer and electromagnetic stirring of the solidification end are used , where the electromagnetic stirring at the solidification end is equip...

Embodiment 2

[0048] The embodiment of the present invention provides a kind of hot-rolled wire rod for 90 kilograms welding wire, and its chemical composition is:

[0049] C: 0.10%, Si: 0.45%, Mn: 1.60%, Ni: 1.95%, Mo: 0.53%, Cr: 0.11%, V: 0.03%, Ti: 0.05%, Al: 0.06%, N: 0.06%, Zr: 0.07%, P: 0.0075%, S: 0.0033%, As: 0.01%, Sb: 0.01%, B: 0.0025%, Se: 0.0021%, Ca: 0.01%, Pb: 0.002%, Bi: 0.003%, Te: 0.01%, O: 0.0041%, H: 0.0001%, balance Fe.

[0050] The production method of the hot-rolled wire rod for the above-mentioned 90 kg grade welding wire is as follows:

[0051] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting billet with a specification of 165×165mm is obtained; wherein, in the continuous casting process, electromagnetic stirring of the crystallizer and electromagnetic stirring of the solidification end are used , where the electromagnetic stirring at the solidification end is equipped with two...

Embodiment 3

[0056] The embodiment of the present invention provides a kind of hot-rolled wire rod for 90 kilograms welding wire, and its chemical composition is:

[0057] C: 0.072%, Si: 0.60%, Mn: 1.70%, Ni: 1.50%, Mo: 0.37%, Cr: 0.07%, V: 0.052%, Ti: 0.05%, Al: 0.046%, N: 0.071%, Zr: 0.033%, P: 0.009%, S: 0.0037%, As: 0.0021%, Sb: 0.0013%, B: 0.0038%, Se: 0.0061%, Ca: 0.0013%, Pb: 0.0014%, Bi: 0.001%, Te: 0.002%, O: 0.0025%, H: 0.00005%; the balance is Fe.

[0058] The production method of the hot-rolled wire rod for the above-mentioned 90 kg grade welding wire is as follows:

[0059] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting billet with a specification of 155×155 mm is obtained; wherein, in the continuous casting process, electromagnetic stirring of the crystallizer and electromagnetic stirring of the solidification end are used , where the electromagnetic stirring at the solidification end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com