High-performance iron-based amorphous nanocrystalline alloy thermal treatment method

A technology of nanocrystalline alloys and heat treatment methods, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of unfavorable access to high-performance alloys, achieve the effects of improving toughness and plasticity, uniform stress state, and reducing coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

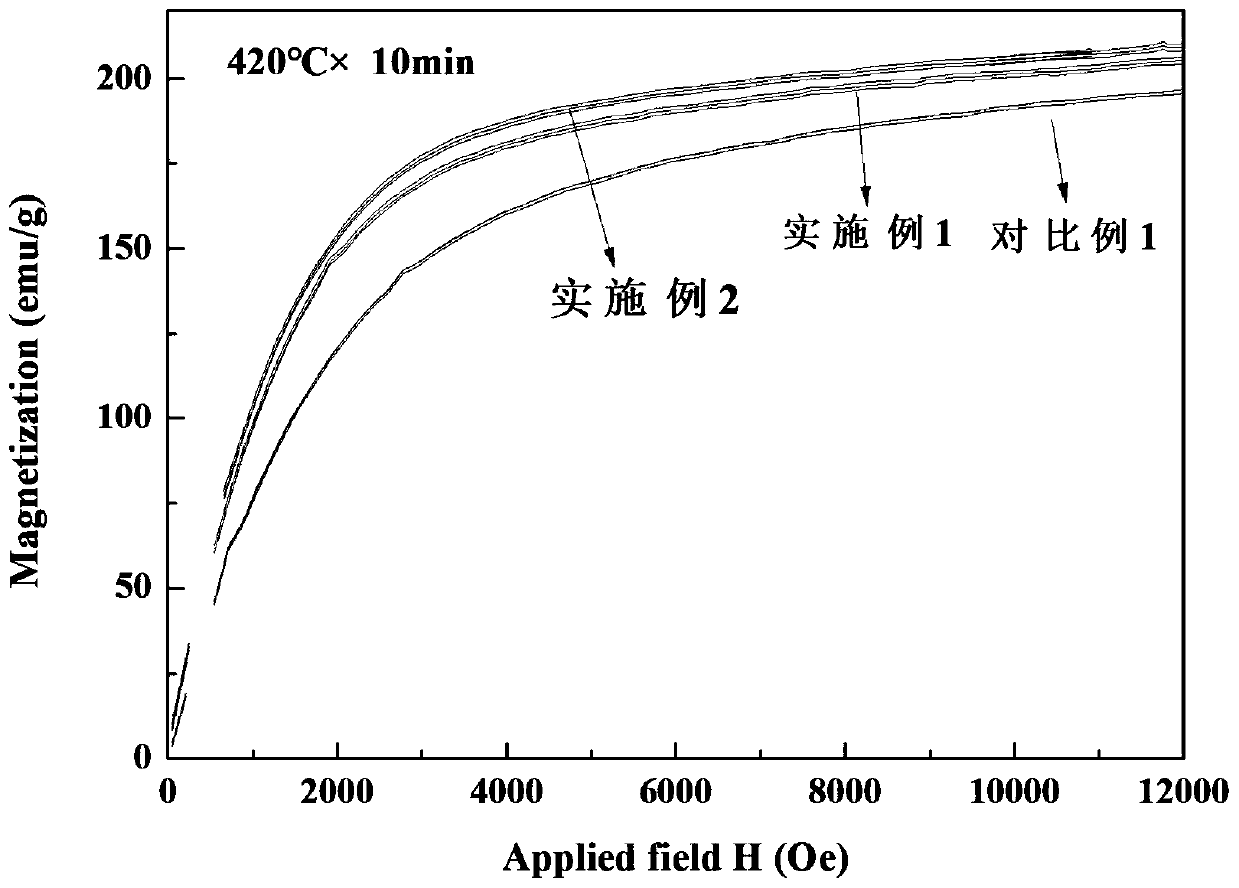

Embodiment 1

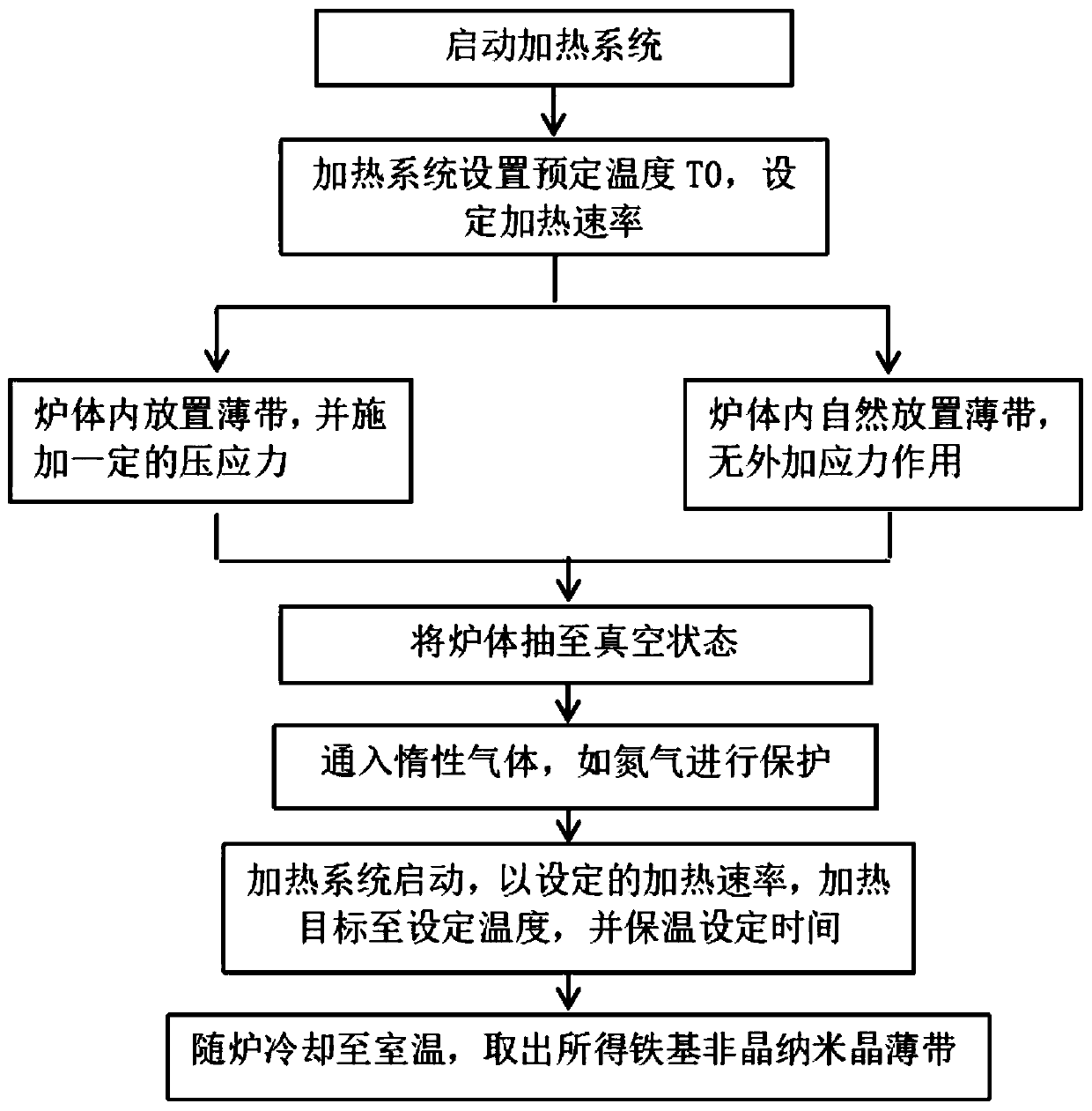

[0032] Carry out heat treatment to iron-based amorphous nanocrystalline alloy according to the following method;

[0033] 1. Start the heating system; 2. Put iron-based amorphous nanocrystalline alloy in the furnace, and apply a compressive stress of 1MPa on the strip, and close the furnace door; 3. Vacuumize the furnace body to -0.1MPa; 4. Turn off the vacuum pump, feed high-purity nitrogen gas (99.99%) into the furnace body, and the gas flow rate is 2-5mL / s; 5. Heat from room temperature to 420 °C at a heating rate of 20 °C / min, and keep it warm for 10 minutes; cool to room temperature with the furnace Finally, the thin strip is taken out to obtain a heat-treated iron-based amorphous nanocrystalline alloy.

Embodiment 2

[0035] Carry out heat treatment to iron-based amorphous nanocrystalline alloy according to the following method;

[0036] 1. Start the heating system; 2. Put iron-based amorphous nanocrystalline alloy in the furnace, and apply a compressive stress of 5MPa on the strip, and close the furnace door; 3. Vacuumize the furnace body to -0.1MPa; 4. Turn off the vacuum pump, feed high-purity nitrogen gas (99.99%) into the furnace body, and the gas flow rate is 2-5mL / s; 5. Heating from room temperature to 420°C at a heating rate of 20°C / min, and keeping it warm for 10 minutes; 6. Cooling with the furnace After reaching room temperature, the thin strip is taken out to obtain a heat-treated iron-based amorphous nanocrystalline alloy.

Embodiment 3

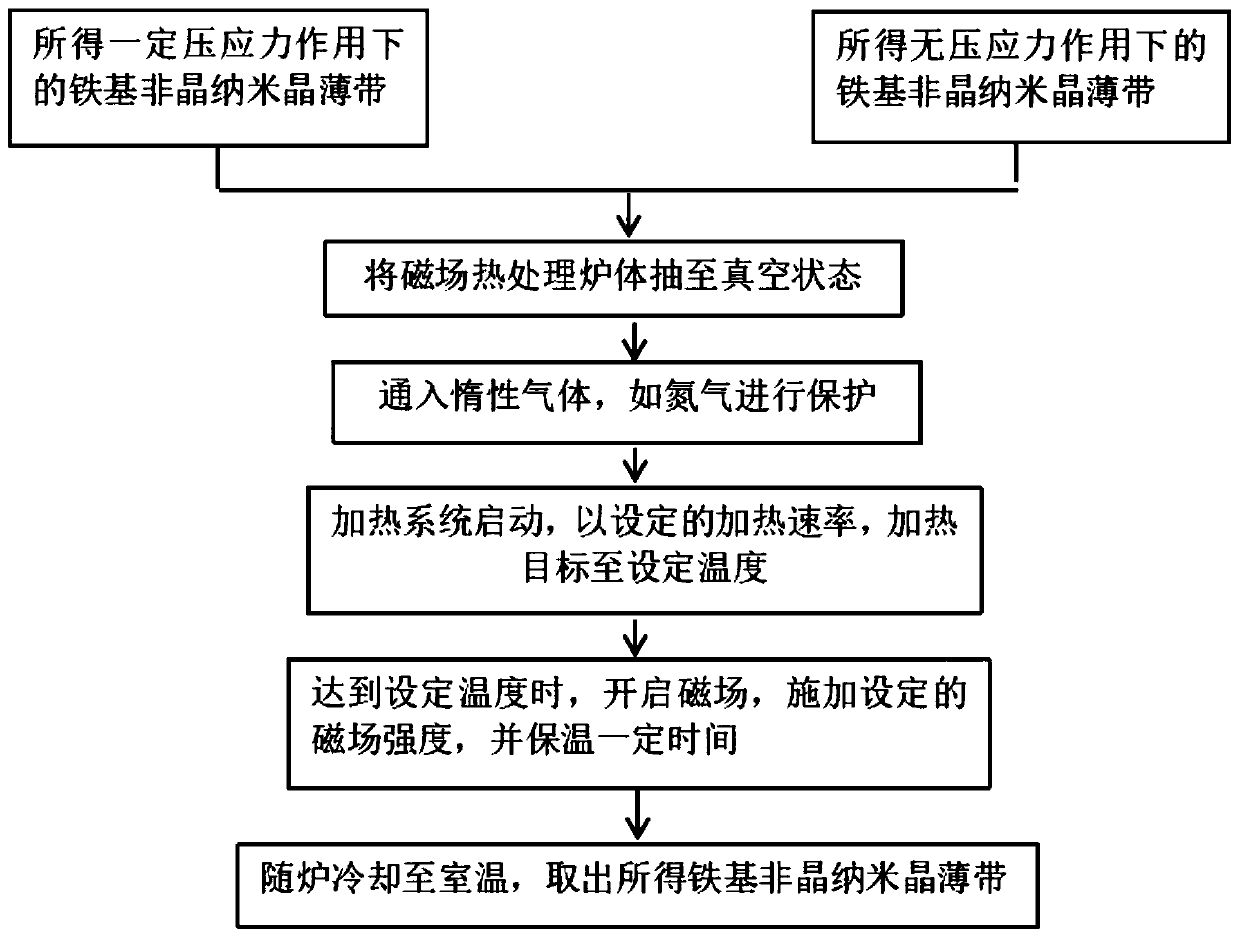

[0038] Carry out heat treatment to iron-based amorphous nanocrystalline alloy according to the following method;

[0039] 1. Start the heating system; 2. Put iron-based amorphous nanocrystalline alloy in the furnace, and apply a compressive stress of 1 MPa on the strip, and close the furnace door; 3. Turn on the mechanical pump and vacuum the furnace body to -0.1 MPa; turn off the mechanical pump, feed high-purity nitrogen gas (99.99%) into the furnace body, and the gas flow rate is 2-5mL / s; 4. Heating from room temperature to 420°C at a heating rate of 20°C / min, and keeping it warm for 10min; 5. Put the obtained iron-based amorphous nanocrystalline ribbon into the magnetic field heat treatment furnace again; 6, open the mechanical pump, and vacuumize the furnace body to -0.1MPa; 7, close the mechanical pump, and feed high-purity nitrogen into the furnace body ( 99.99%) to the furnace pressure -0.05MPa; 8. Heating from room temperature to 340 °C at a heating rate of 5 °C / min; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com