780 mpa low yield ratio round steel pipe for building structure with excellent shock resistance and production process

A steel pipe and round technology, applied in the field of round steel pipes and their manufacturing, can solve the problems of unconsidered hardness of round steel pipes and difficult manufacturing management, and achieve the effects of improving shock resistance, crack resistance and ensuring ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

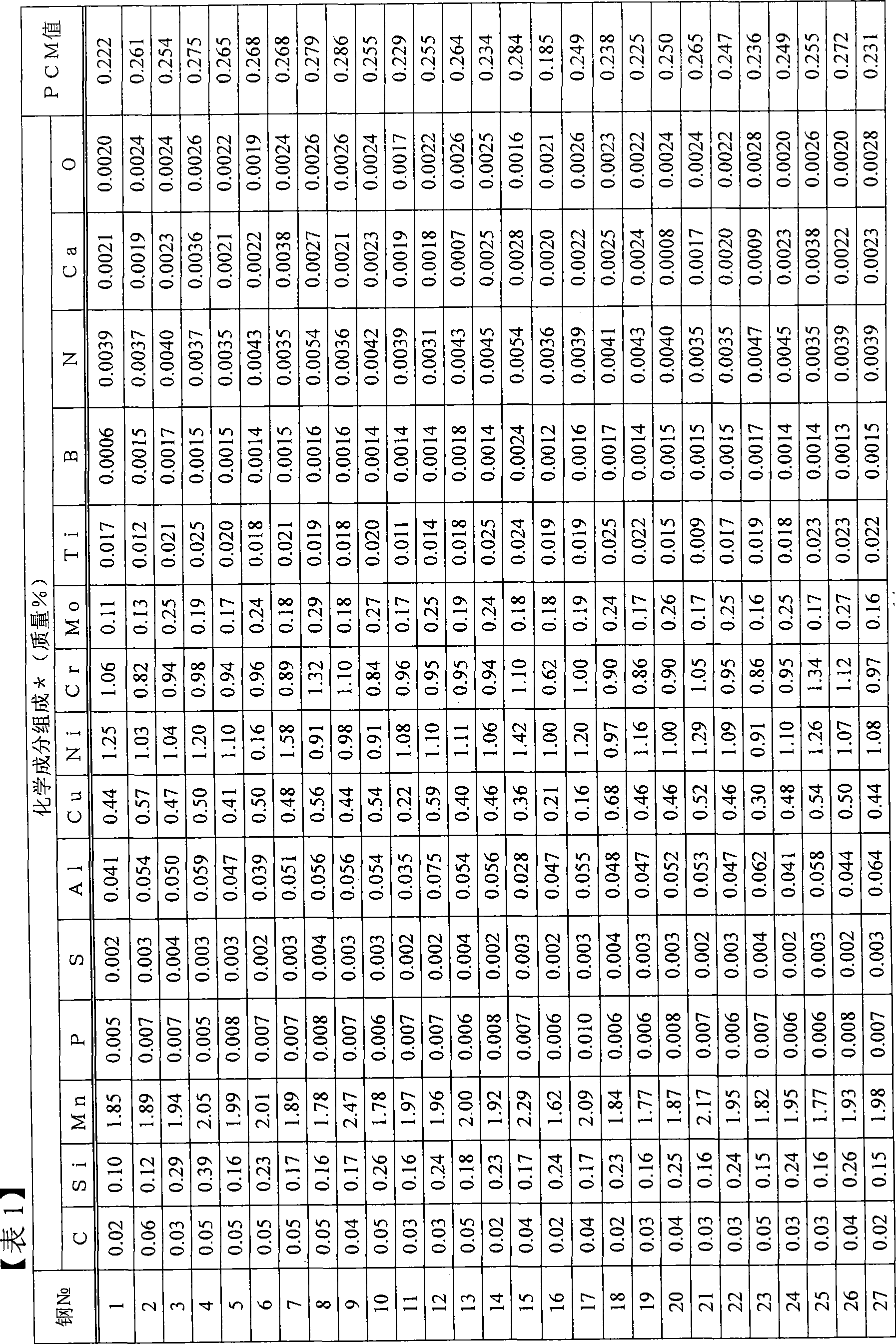

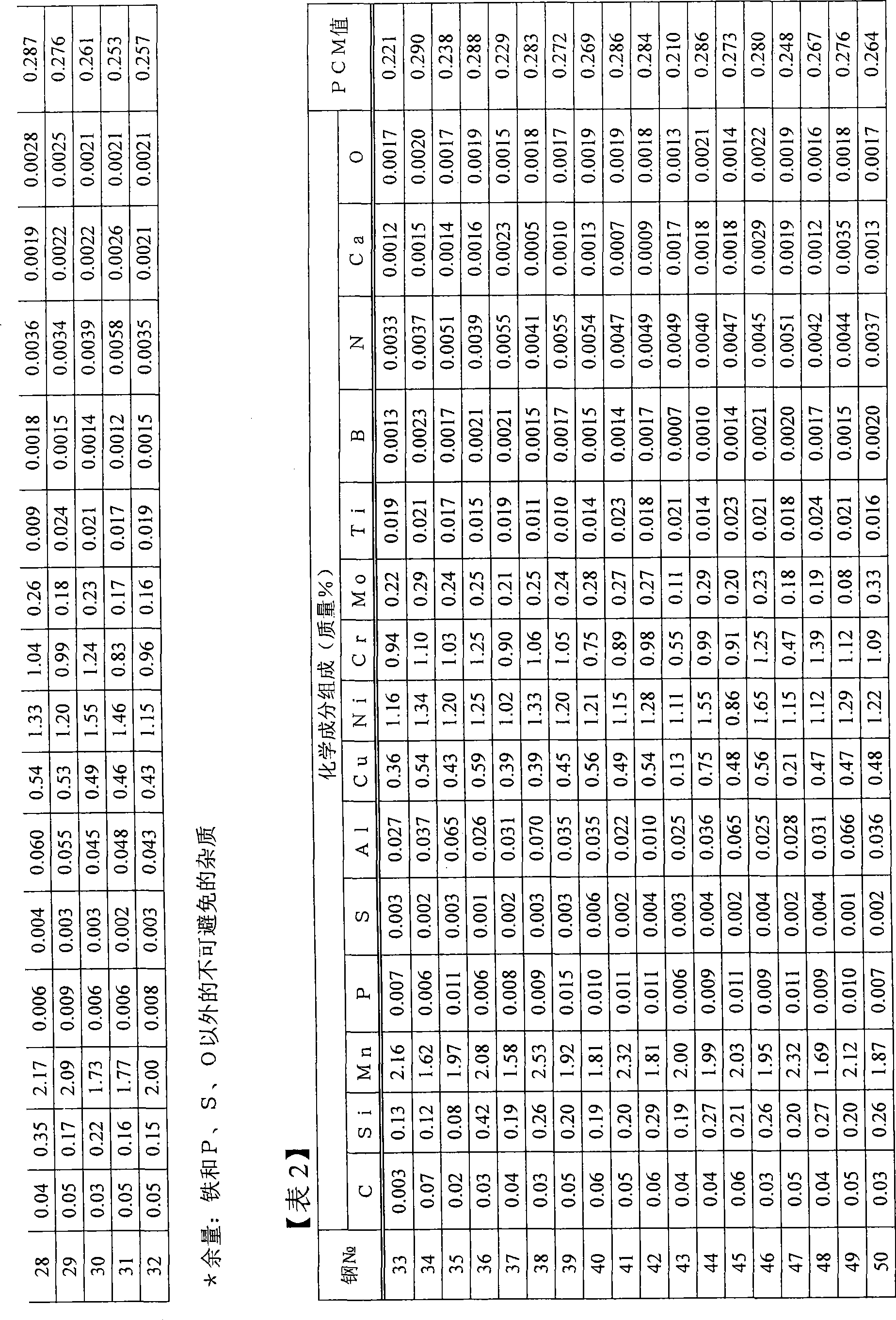

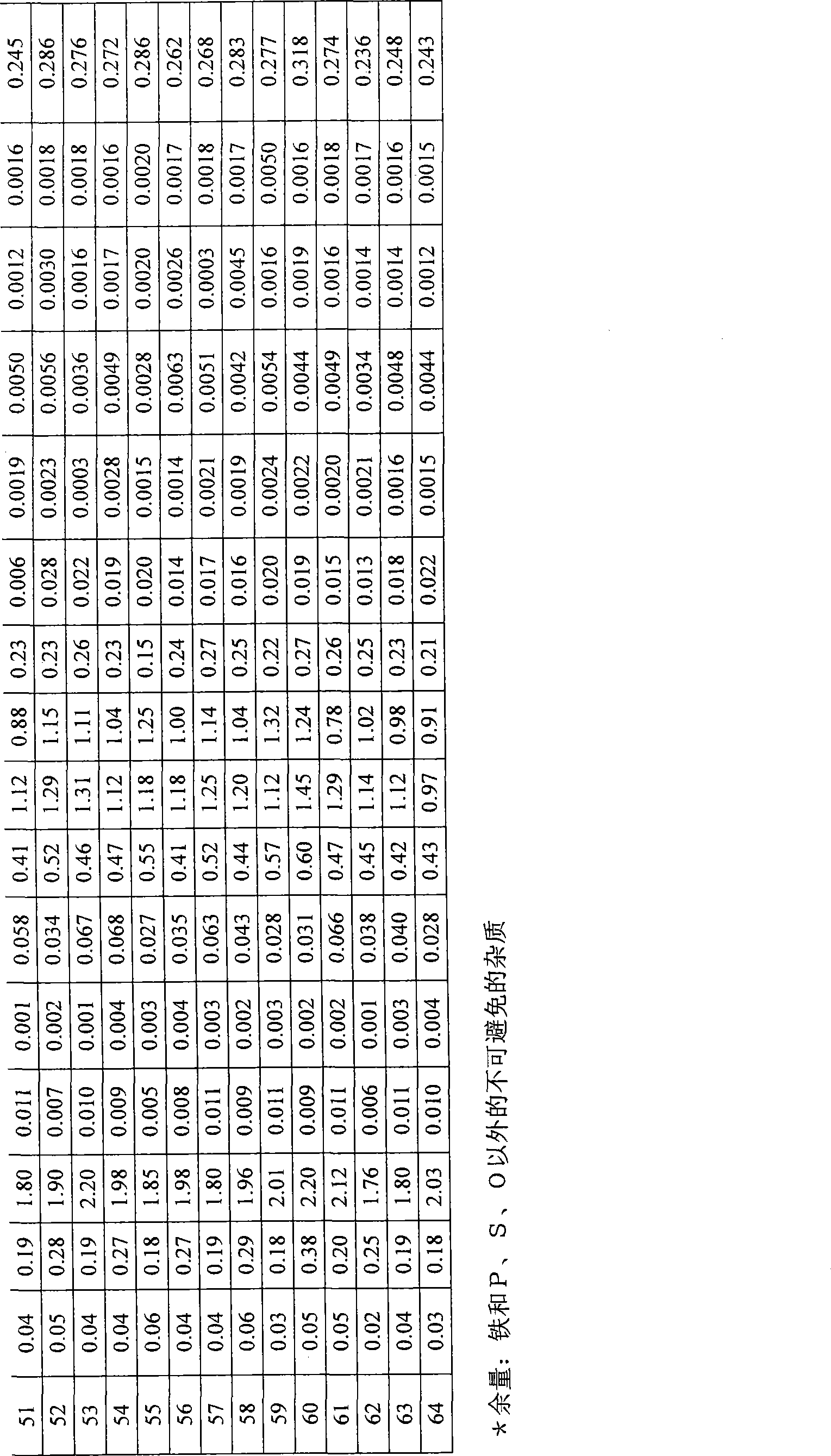

[0089] Steels with the chemical compositions shown in the following Tables 1 and 2 were smelted by a common melting method to form steel slabs, followed by hot rolling, accelerated cooling (cooling after rolling), dual-phase domain quenching, and tempering to manufacture steel sheets. Using the obtained steel sheet, it was formed into a circular steel pipe by a press bending method. In addition, Tables 1 and 2 also show the PCM values defined by the aforementioned formula (1). The production conditions at this time are as follows.

[0090] (manufacturing conditions)

[0091] In steel No.1-60, after heating the ingot to 1150±50°C, hot rolling is carried out at the finish rolling temperature (surface temperature) in the range of 900±30°C to a plate thickness of 60 mm, followed by t / 4(t : The cooling rate at the position of plate thickness) is controlled at 5 to 25°C / sec, so that the surface temperature when the cooling stops is below 250°C. In addition, the two-phase region...

Embodiment 2

[0119] Using steel Nos. 1 to 11 shown in Table 1 (the chemical composition satisfies the range specified in the present invention), steel sheets were produced according to various manufacturing conditions (DQ-Q'-T) shown in Table 7 below (experimental No.1~20). Using the obtained steel sheet, it was formed into a circular steel pipe by a press bending method. Same as embodiment for the circular steel pipe obtained, to material (yield stress YS, tensile strength TS, yield ratio YR and toughness vE -20 ) and weldability were evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com