Hot-rolled wire rod for 70-kilogram-level welding wire and production method thereof

A technology of hot-rolled wire rod and production method is applied in the field of metallurgy to achieve the effects of saving production cost, improving toughness and plasticity, and high and low temperature impact toughness performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

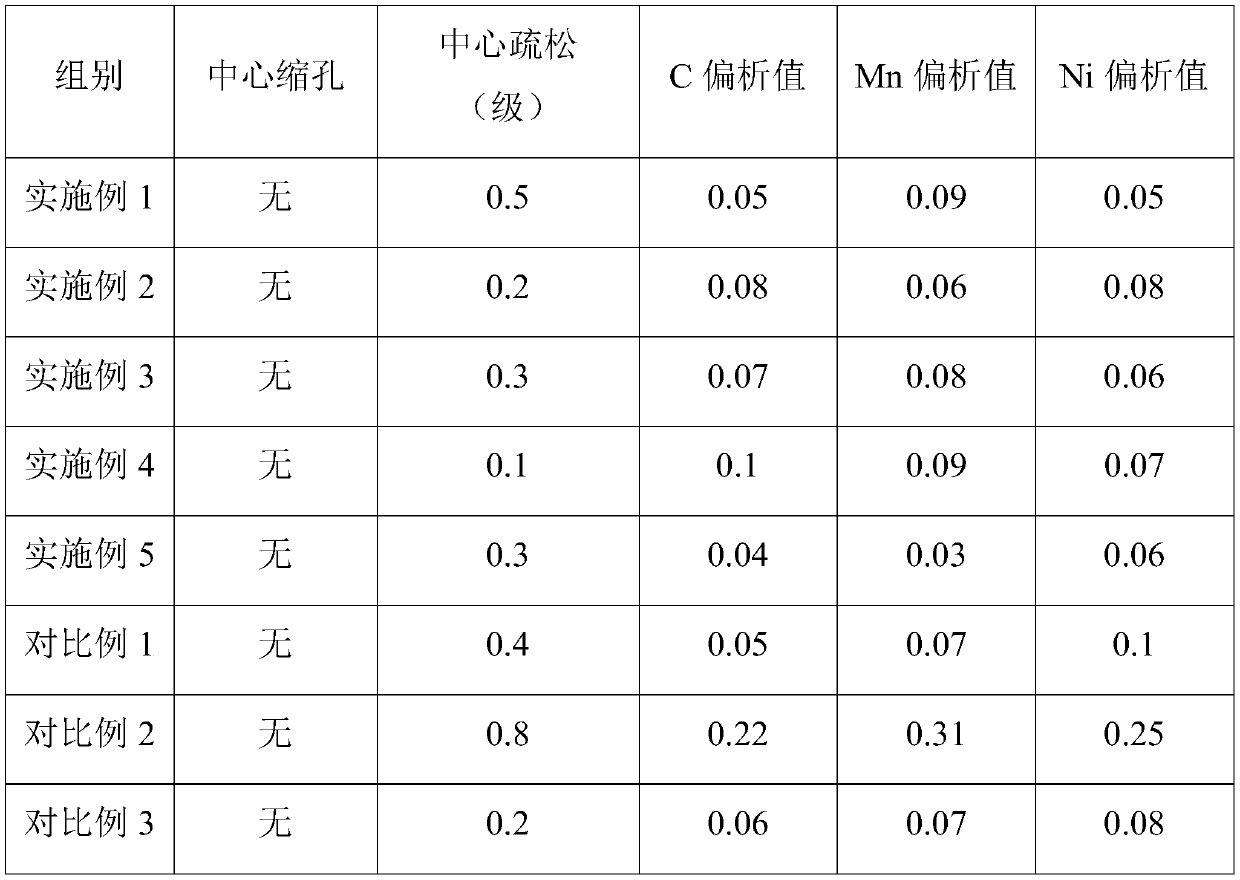

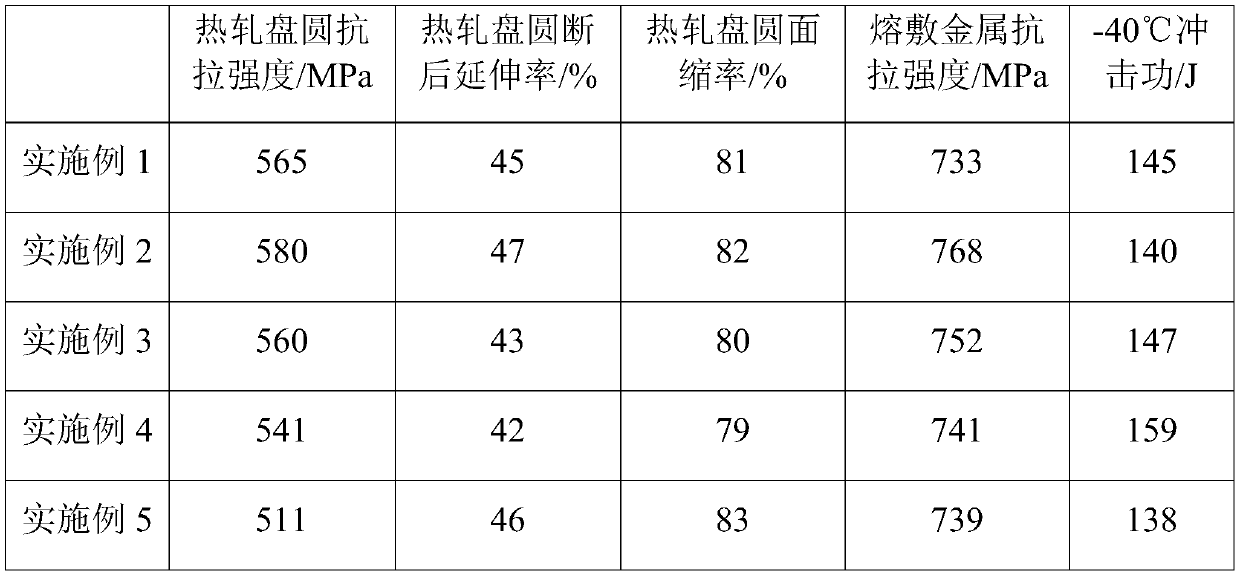

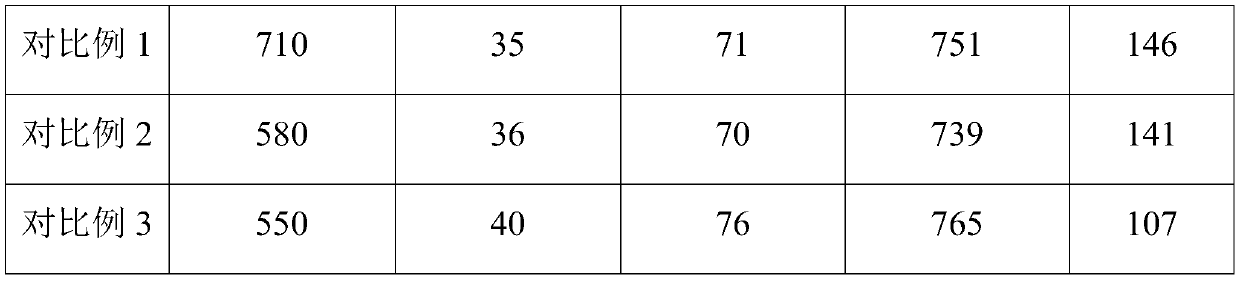

Examples

Embodiment 1

[0038] The embodiment of the present invention provides a kind of hot-rolled wire rod for 70 kilograms welding wire, and its chemical composition is:

[0039] C: 0.06%, Si: 0.60%, Mn: 1.40%, Ni: 0.50%, Mo: 0.30%, Cr: 0.05%, V: 0.05%, Ti: 0.1%, Al: 0.015%, Zr: 0.05%, P: 0.01%, S: 0.002%, As: 0.0011%, Sb: 0.003%, B: 0.005%, Se: 0.002%, Ca: 0.01%, Pb: 0.002%, Bi: 0.003%, Te: 0.005%, O: 0.005%, H: 0.0001%, and the balance is Fe.

[0040] The production method of the hot-rolled wire rod for above-mentioned 70 kg grade welding wire is as follows:

[0041] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting billet with a specification of 165×165mm is obtained; wherein, in the continuous casting process, electromagnetic stirring of the crystallizer and electromagnetic stirring of the solidification end are used , where the electromagnetic stirring at the solidification end is equipped with two elec...

Embodiment 2

[0046] The embodiment of the present invention provides a kind of hot-rolled wire rod for 70 kilograms welding wire, and its chemical composition is:

[0047] C: 0.010%, Si: 0.35%, Mn: 1.47%, Ni: 0.70%, Mo: 0.15%, Cr: 0.20%, V: 0.01%, Ti: 0.05%, Al: 0.025%, Zr: 0.03%, P: 0.007%, S: 0.01%, As: 0.01%, Sb: 0.0032%, B: 0.002%, Se: 0.001%, Ca: 0.001%, Pb: 0.002%, Bi: 0.001%, Te: 0.003%, O: 0.0041%, H: 0.000045%, balance Fe.

[0048] The production method of the hot-rolled wire rod for above-mentioned 70 kg grade welding wire is as follows:

[0049] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting billet with a specification of 165×165mm is obtained; wherein, in the continuous casting process, electromagnetic stirring of the crystallizer and electromagnetic stirring of the solidification end are used , where the electromagnetic stirring at the solidification end is equipped with two electromag...

Embodiment 3

[0054] The embodiment of the present invention provides a kind of hot-rolled wire rod for 70 kilograms welding wire, and its chemical composition is:

[0055] C: 0.072%, Si: 0.46%, Mn: 1.60%, Ni: 0.67%, Mo: 0.17%, Cr: 0.07%, V: 0.012%, Ti: 0.05%, Al: 0.015%, Zr: 0.032%, P: 0.009%, S: 0.0031%, As: 0.0021%, Sb: 0.01%, B: 0.003%, Se: 0.01%, Ca: 0.0013%, Pb: 0.01%, Bi: 0.001%, Te: 0.002%, O: 0.0025%, H: 0.00006%; the balance is Fe.

[0056] The production method of the hot-rolled wire rod for above-mentioned 70 kg grade welding wire is as follows:

[0057] Step 1. Using steel scrap as raw material, after electric arc furnace smelting, LF refining, and continuous casting, a continuous casting billet with a specification of 155×155 mm is obtained; wherein, in the continuous casting process, electromagnetic stirring of the crystallizer and electromagnetic stirring of the solidification end are used , where the electromagnetic stirring at the solidification end is equipped with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com