Method for machining stainless steel singe dual-lug support plate nut

A technology of pallet nuts and processing methods, which is applied in the field of cold processing of stainless steel pallet fasteners, can solve problems such as difficult to ensure thickness requirements, difficult cold heading forming, large cold heading deformation, etc., to ensure ductility and fluidity , Improve cutting performance and meet assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

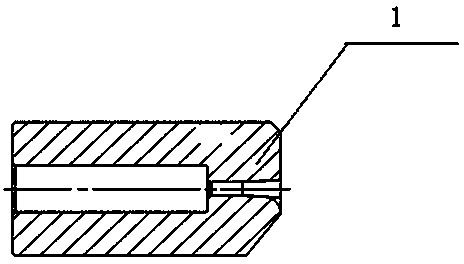

[0037] A kind of stainless steel single and double lug bracket nut processing method provided by the present invention will be further explained below in conjunction with accompanying drawing.

[0038] The processing method of the stainless steel single and double lug nuts comprises the following steps:

[0039] A. Processing cold heading die

[0040] The stainless steel wire is processed on the cold heading machine and the blank 5 of the single and double ear plate nut is obtained, and the specific steps are:

[0041] A1, initial heading

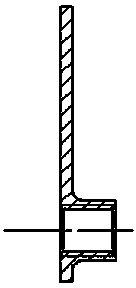

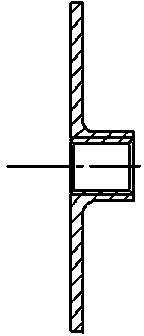

[0042] Such as image 3 As shown, after cold heading and straightening, the stainless steel wire is sent to the initial heading die 1 by the feeding roller, and the initial heading and extrusion processing are carried out, so that the stainless steel wire reaches the required volume for the final heading deformation, and the initial blank is obtained ;

[0043] Due to the relatively large deformation ratio of the parts, the ductility an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com