Heat treatment method for synchronously improving strength and ductility of 7-series aluminum alloy plate

A technology of aluminum alloy plate and heat treatment method, applied in the field of aluminum alloy, to achieve the effect of uniform element distribution, elimination of harmful texture, and reduction of work hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

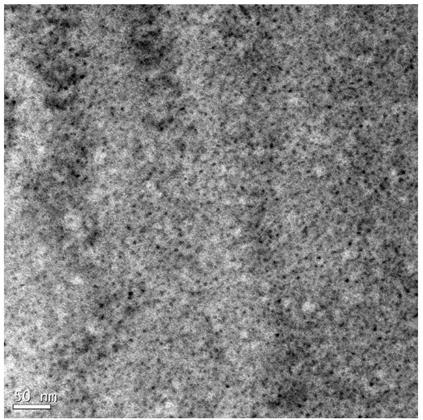

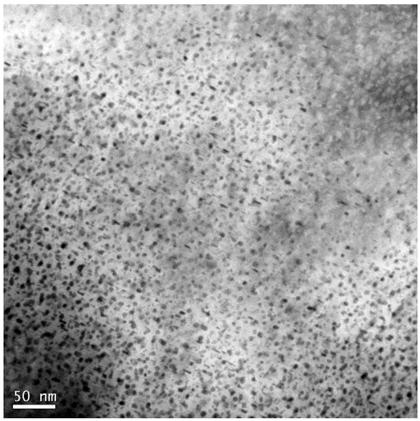

Image

Examples

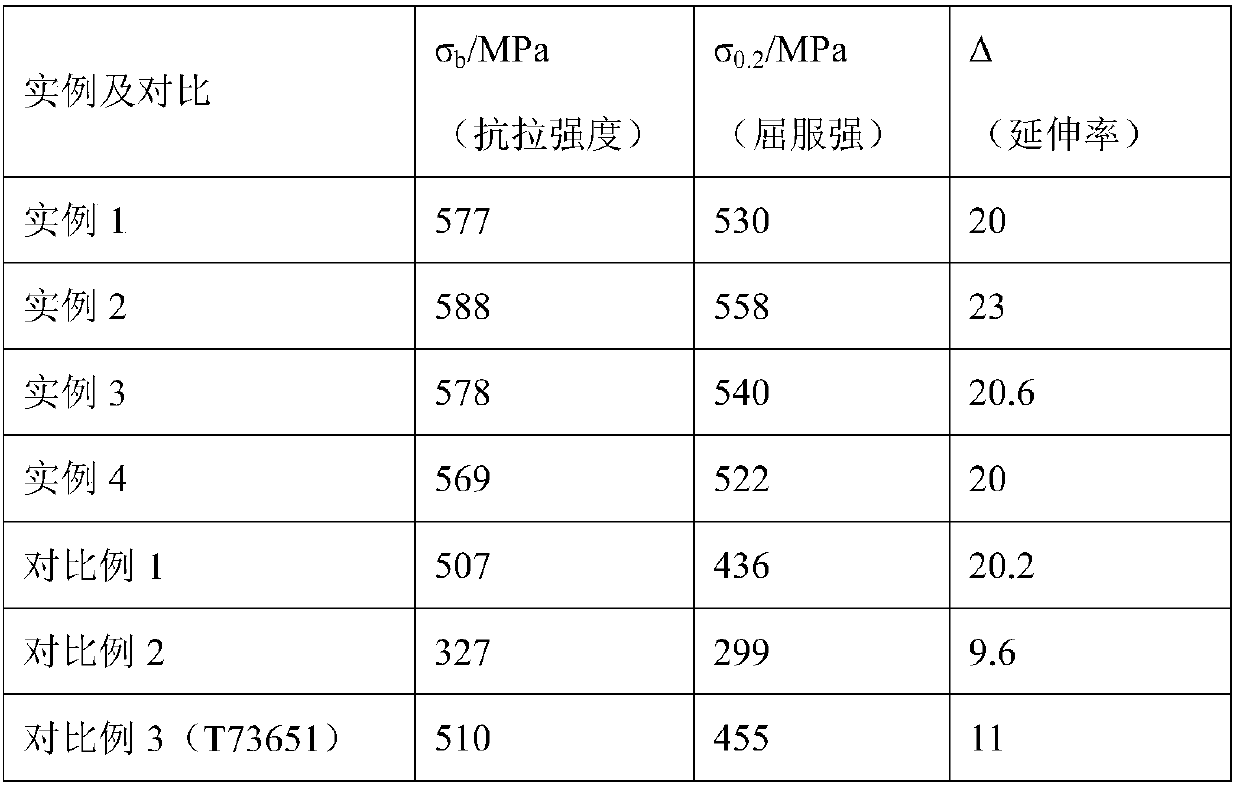

Embodiment 1

[0029] The alloy is hot-rolled and deformed at 460-480°C, the reduction is 95%, the alloy is heated at 470°C, and kept for 2 hours for solution treatment, and then quenched with water at room temperature at 24°C. The sample is required The transfer time is less than 5 seconds; the quenched alloy is immediately kept at 115°C for 25 hours for pre-aging treatment, and cooling in water at room temperature of 24°C requires the transfer time of the sample to be less than 5 seconds. Heat the pre-aged alloy to 160°C at a heating rate of 5°C per minute, perform reheating, and cool in water at room temperature 24°C, requiring the sample transfer time to be less than 5 seconds; put the regressed alloy at 115°C Insulate for 20 hours, carry out re-aging treatment, and finally carry out air cooling. Under the process conditions, the tensile strength of the 7050 alloy is 577MPa, the yield strength is 530MPa, and the elongation is 20%.

Embodiment 2

[0031] The alloy is hot-rolled and deformed at 460-480°C, and the reduction is 95%; the alloy is heated at 475°C and kept for 1 hour for solution treatment, and then quenched with water at room temperature at 25°C. The sample is required The transfer time is less than 5 seconds; the quenched alloy is immediately kept at 120°C for 24 hours for pre-aging treatment, and the sample transfer time is required to be less than 5 seconds for cooling in water at room temperature 25°C. Heat the pre-aged alloy to 190°C at a heating rate of 5°C per minute, perform reheating, and cool in water at room temperature 25°C. The transfer time of the sample is required to be less than 5 seconds; the regressed alloy is placed at 120°C Insulated for 28 hours, re-aged, and finally air-cooled. Under the process conditions, the tensile strength of the 7050 alloy is 588MPa, the yield strength is 558MPa, and the elongation is 23%.

Embodiment 3

[0033] The alloy is hot-rolled and deformed at 460-480°C, and the reduction is 95%; the alloy is heated at 480°C and kept for 1.5 hours for solution treatment, and then quenched in water at room temperature at 26°C. The sample is required The transfer time is less than 5 seconds; the quenched alloy is immediately kept at 120°C for 28 hours for pre-aging treatment, and the sample transfer time is required to be less than 5 seconds for cooling in water at room temperature 25°C. Heat the pre-aged alloy to 220°C at a heating rate of 5°C per minute, perform reheating, and cool in water at a room temperature of 26°C. The transfer time of the sample is required to be less than 5 seconds; the regressed alloy is placed at 120°C Insulated for 24 hours, re-aged, and finally air-cooled. Under the process conditions, the tensile strength of the 7050 alloy is 578MPa, the yield strength is 540MPa, and the elongation is 20.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com