Double slashed droope hem western-style clothes and its making process

A technology for suits and slits, applied in the field of pendant suits and their production, can solve the problems of weak rhythmic swing ability of the back piece, misalignment of the side piece and the back piece, unsightly clothing, etc., and achieve low cost and high swing ability Enhanced, Visible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

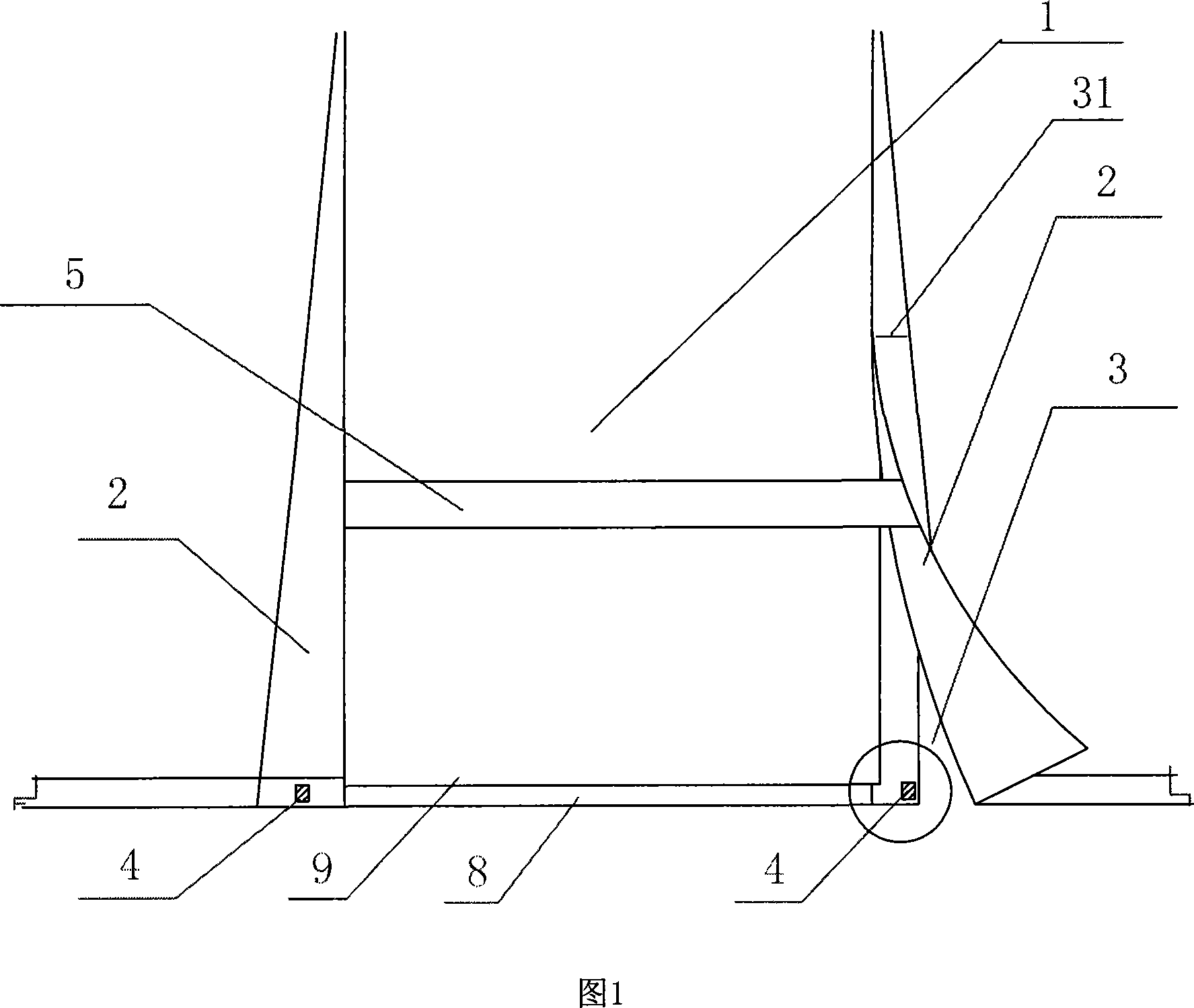

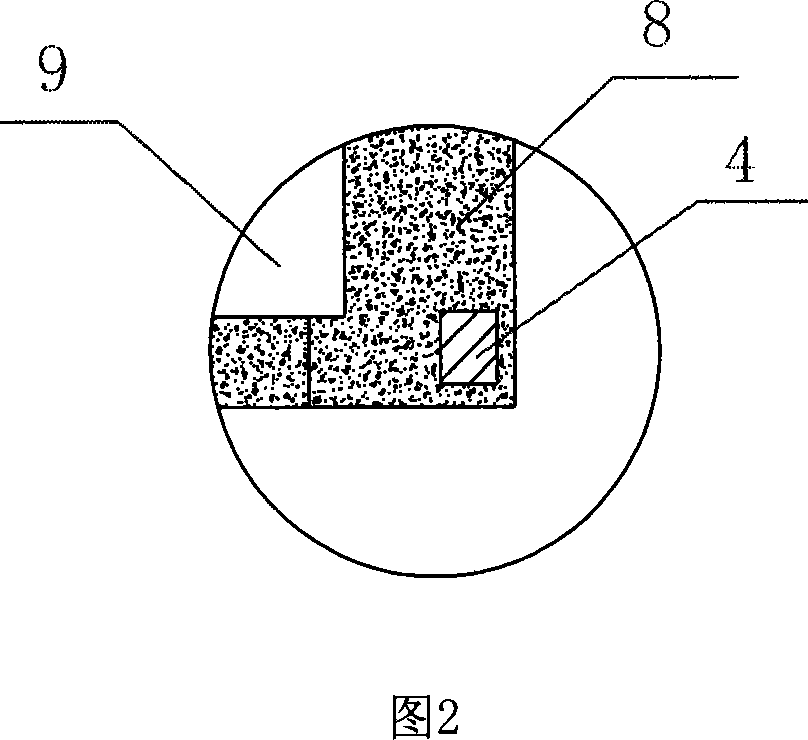

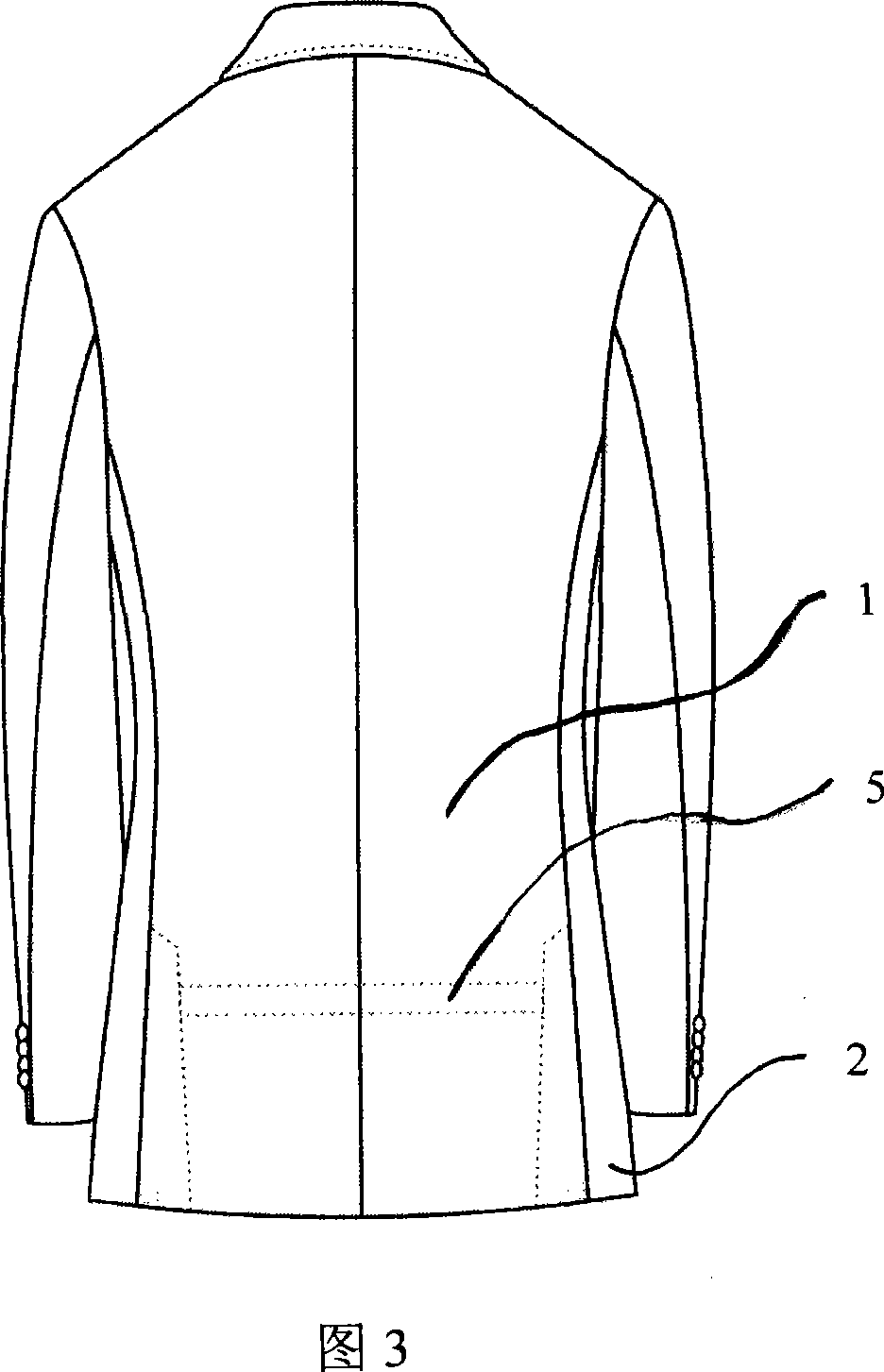

[0014] Embodiment 1: As shown in the figure, a double-slit drapey suit includes side panels 2 and a back panel 1, the unsewn part between the back panel 1 and the side panels is a slit 3, and the back panel 1 and the side panels The upper edge 31 of the slit 3 between the 2 is horizontally stitched with the back panel 1 and the side panel 2 by sutures, and the back panel 1 is partially covered on the outside of the side panel 2, and the back panel 1 includes an outer layer of fabric 8 and an inner layer. Lining 9 of the first layer, a tin-lead alloy sheet 4 is embedded near the right angle of the back sheet 1, and the tin-lead alloy sheet 4 is embedded between the fabric 8 and the lining 9, and the edge of the two side sheets 2 is provided with A width is 3 centimetres, and the distance between the inner leash 5 and the upper edge 31 of the slit 3 is 5 centimeters.

[0015] The manufacturing method of the pendulum suit of the present embodiment comprises the following steps: ①...

Embodiment 2

[0016] Embodiment two: other structures and methods are all the same as embodiment one, the difference is that the inner strap width is 2.5 centimeters, and the distance between the inner strap and the upper edge 31 of the slit 3 is 6 centimeters.

Embodiment 3

[0017] Embodiment three: other structures and methods are all the same as in embodiment one, except that the inner strap width is 3.5 centimeters, and the distance between the inner strap and the upper edge 31 of the slit 3 is 4 centimeters.

[0018] In the above embodiments, the tin-lead alloy sheet 4 can be replaced by a tin alloy sheet or a lead alloy sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com