Torque adjustable overload prevention shaft transmission mechanism

A shaft transmission, anti-overload technology, applied in the field of mechanical transmission, can solve the problem that the anti-overload function cannot be reused many times, and achieve the effect of easy automatic disengagement and recovery, increased surface hardness, and simple setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

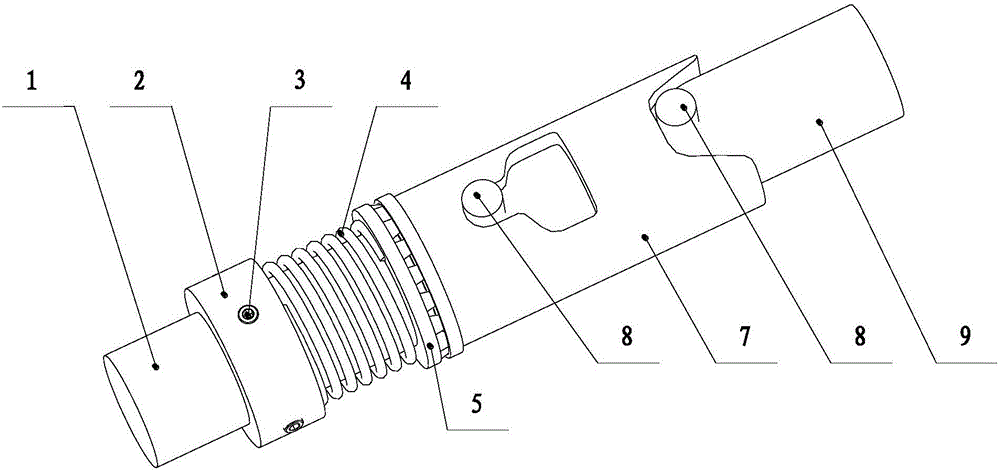

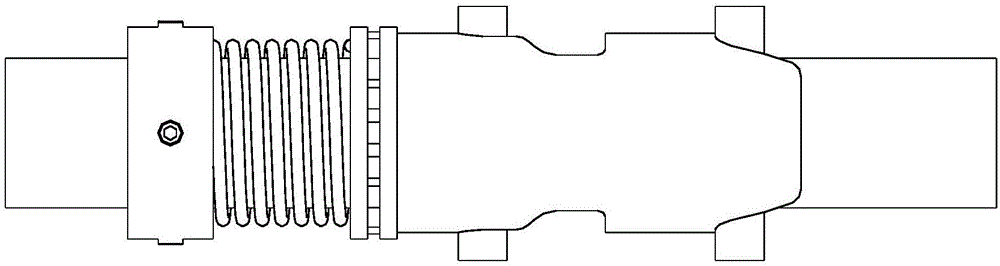

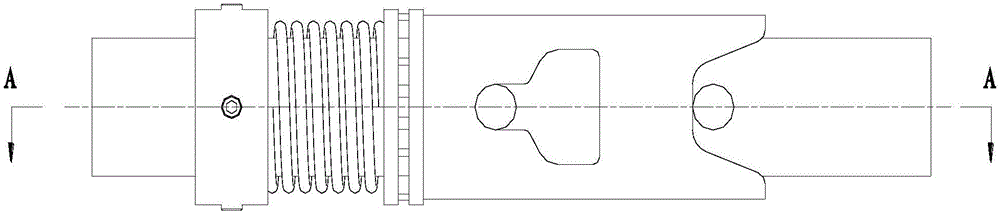

[0031] The invention provides an anti-overload shaft transmission mechanism with adjustable torque, such as figure 1 As shown, the shaft transmission mechanism includes a driving shaft 1, a shaft sleeve 2, a tightening screw 3, a spring 4, a bearing 5, a driving shaft pin 6, a sliding sleeve 7, a driven shaft pin 8 and a driven shaft 9, and the driving shaft 1. The surface of shaft sleeve 2, sliding sleeve 7 and driven shaft 9 is quenched to increase surface hardness.

[0032] Such as Figure 6 As shown, the sliding sleeve 7 is a cylindrical structure with both ends open, and one end is provided with two grooves running through the end. The central axis of the two grooves is located at the end face of this end of the sliding sleeve 7; the sliding sleeve 7 is provided with a convex-shaped through hole that runs through the outer peripheral surface, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com