Preparation method of ACR elastic resin with core-shell structure

A technology of elastic resin and core-shell structure, which is applied in the field of preparation of ACR elastic resin with core-shell structure, can solve the problem of ACR elastic resin losing elasticity, achieve the effects of improving elastic properties, excellent low-temperature performance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

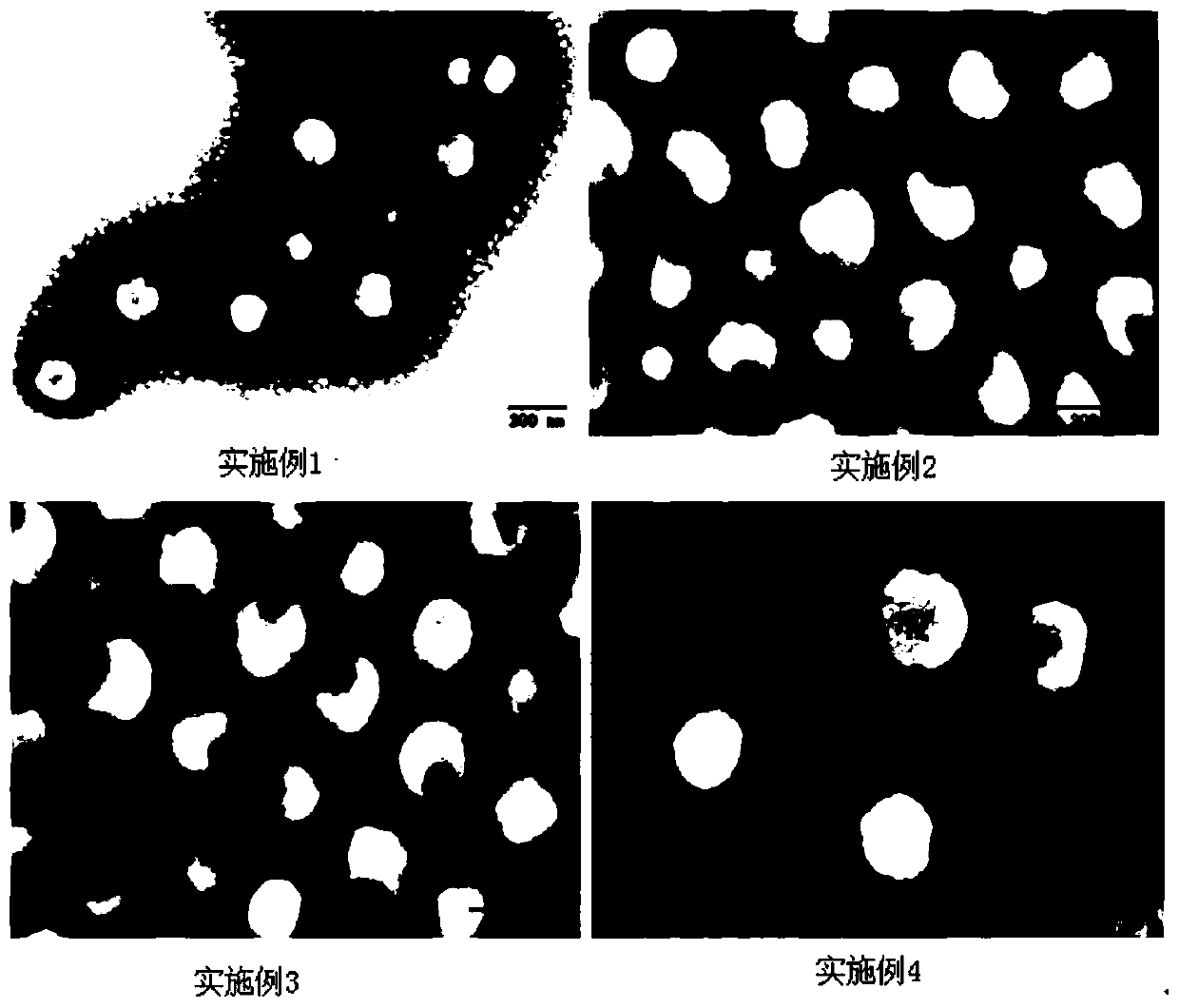

Image

Examples

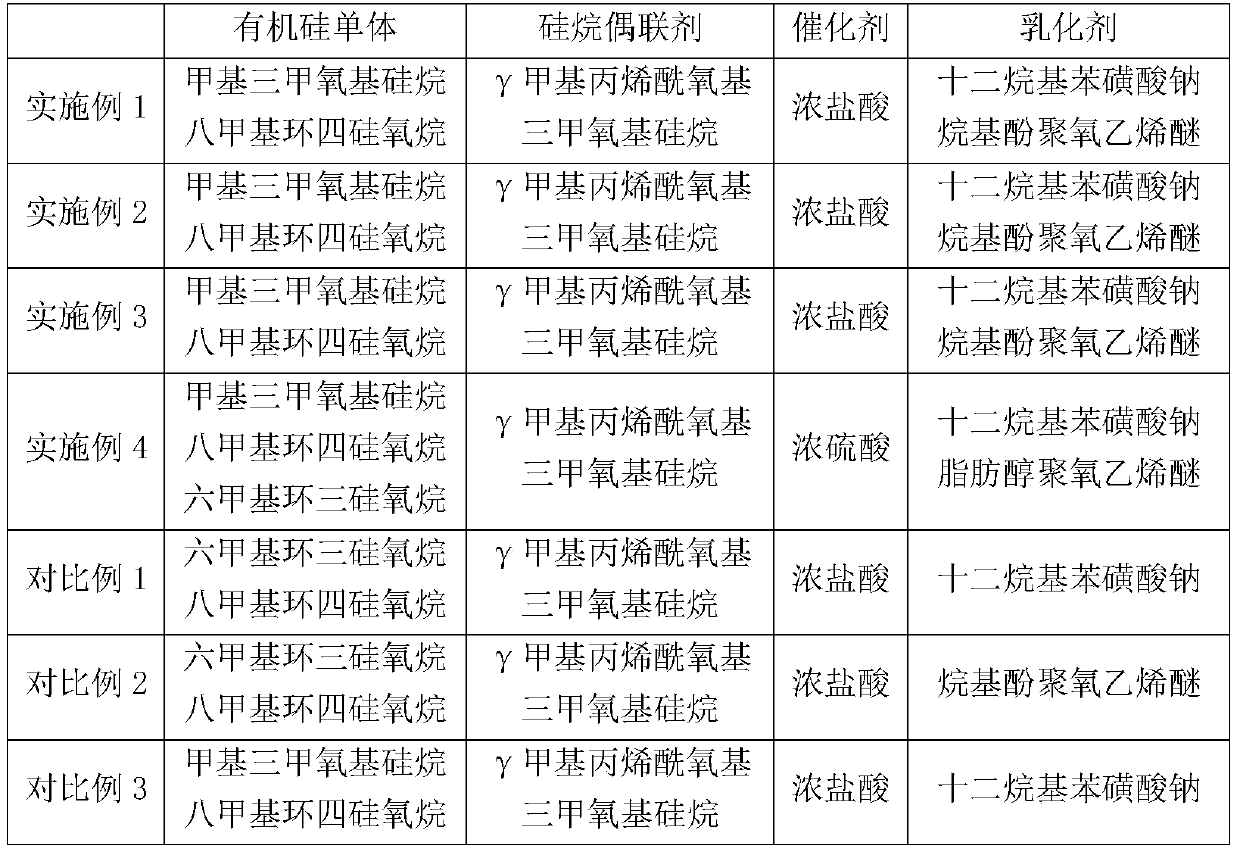

Embodiment 1

[0043] (a) Synthesis of polysiloxane core emulsion

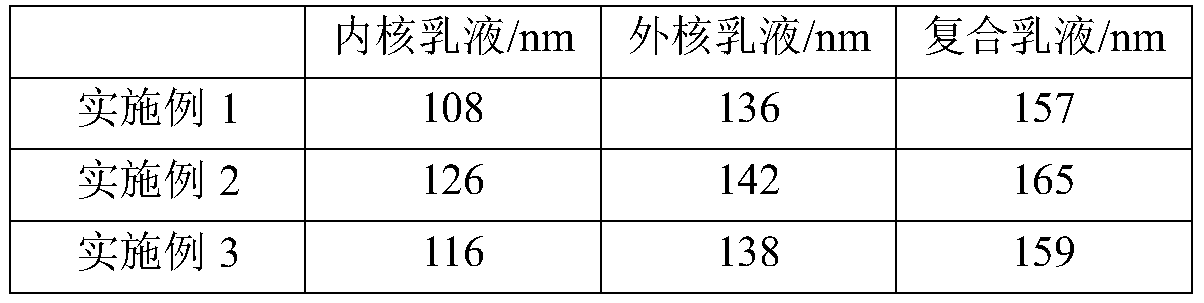

[0044] At room temperature, mix 40 parts of octamethylcyclotetraoxosilane, 1.0 parts of methyltrimethoxysilane, 1.2 parts of γ-methacryloxytrimethoxysilane, 100 parts of deionized water, and 1.2 parts of 31% concentrated hydrochloric acid , 0.8 parts of sodium dodecylbenzene sulfonate, and 0.2 parts of alkylphenol polyoxyethylene ether were mixed, pre-emulsified by a high-shear emulsifier for 10 minutes, and after deoxygenation by nitrogen, at a temperature of 80°C and a stirring rate of 250r React for 25.0 hours under the condition of / min, add 10% sodium hydroxide solution to adjust the pH value to 7, and obtain polysiloxane core emulsion, and the particle size of polysiloxane seed emulsion is 108nm;

[0045] (b) Synthesis of polysiloxane modified outer core emulsion

[0046] Mix 60 parts of butyl acrylate, 0.9 parts of sodium dodecyl sulfonate, 0.3 parts of alkylphenol polyoxyethylene ether, 0.5 parts of divinylbenzene, ...

Embodiment 2

[0050] (a) Synthesis of polysiloxane core emulsion

[0051] At room temperature, mix 30 parts of octamethylcyclotetraoxosilane, 0.6 parts of methyltrimethoxysilane, 1.8 parts of γ-methacryloxytrimethoxysilane, 90 parts of deionized water, and 0.7 parts of 31% concentrated hydrochloric acid , 0.6 parts of sodium dodecylbenzene sulfonate, and 0.2 parts of alkylphenol polyoxyethylene ether were mixed, pre-emulsified by a high-shear emulsifier for 10 minutes, and after deoxygenation by nitrogen, at a temperature of 65°C and a stirring rate of 250r React for 35.0 hours under the condition of / min, add 10% sodium hydroxide solution to adjust the pH value to 8, and obtain polysiloxane core emulsion, and the particle size of polysiloxane seed emulsion is 126nm;

[0052] (b) Synthesis of polysiloxane modified outer core emulsion

[0053] After mixing 70 parts of butyl acrylate, 1.2 parts of sodium dodecyl sulfonate, 0.4 parts of alkylphenol polyoxyethylene ether, 0.75 parts of allyl m...

Embodiment 3

[0057] (a) Synthesis of polysiloxane core emulsion

[0058] At room temperature, mix 60 parts of octamethylcyclotetraoxosilane, 0.3 parts of methyltrimethoxysilane, 6 parts of γ-methacryloxytrimethoxysilane, 150 parts of deionized water, and 1.5 parts of 31% concentrated hydrochloric acid , 1.5 parts of sodium dodecylbenzenesulfonate, and 0.5 parts of alkylphenol polyoxyethylene ether were mixed, pre-emulsified by a high-shear emulsifier for 10 minutes, and after deoxygenation by nitrogen, at a temperature of 70°C and a stirring rate of 210r React for 24.0 hours under the condition of / min, add 10% sodium hydroxide solution to adjust the pH value to 6, and obtain polysiloxane core emulsion, and the particle size of polysiloxane seed emulsion is 116nm;

[0059] (b) Synthesis of polysiloxane modified outer core emulsion

[0060] After mixing 40 parts of butyl acrylate, 0.6 parts of sodium dodecyl sulfonate, 0.2 parts of alkylphenol polyoxyethylene ether, 0.32 parts of 1,4 butan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com