Method for producing 4Cr5Mo2V hot work die steel

A technology of hot work die steel and production method, applied in the field of metallurgy, can solve problems affecting the ductility and toughness of steel ingots, cracks, cracking of 4Cr5Mo2V hot work die, etc., and achieve the effect of ensuring ductility and toughness and avoiding cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

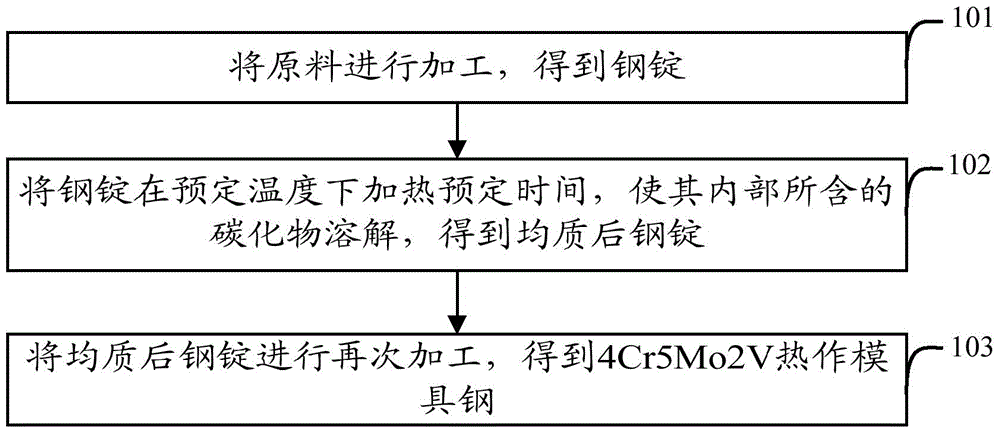

[0014] A kind of production method of 4Cr5Mo2V hot work die steel is provided in the embodiment of the present invention, comprises the following steps, please refer to figure 1 :

[0015] Step 101: Processing raw materials to obtain steel ingots;

[0016] In step 101, the raw material is processed through a series of processes to obtain a steel ingot. Specifically, the raw materials used may be steel scrap concentrates. In addition, in this step, care should be taken to control the content range of various elements in the raw materials in the smelting process, especially the range of copper content. Through practical experience, the chemical composition contained in the 4Cr5Mo2V hot work die steel of this embodiment The range can refer to Table 1;

[0017] Table 1 The range of chemical components contained in the 4Cr5Mo2V hot work die steel of this embodiment (weight percentage)

[0018]

[0019] Wherein, in the specific processing process, preferably, in order to ensu...

Embodiment 2

[0032] Preferably, in this embodiment, specifically, in step 102 of Embodiment 1, it may be specifically to keep the steel ingot at a temperature of 1280°C-1350°C for 20 hours-40 hours, so that the carbide contained inside Dissolved; homogeneous steel ingots were obtained.

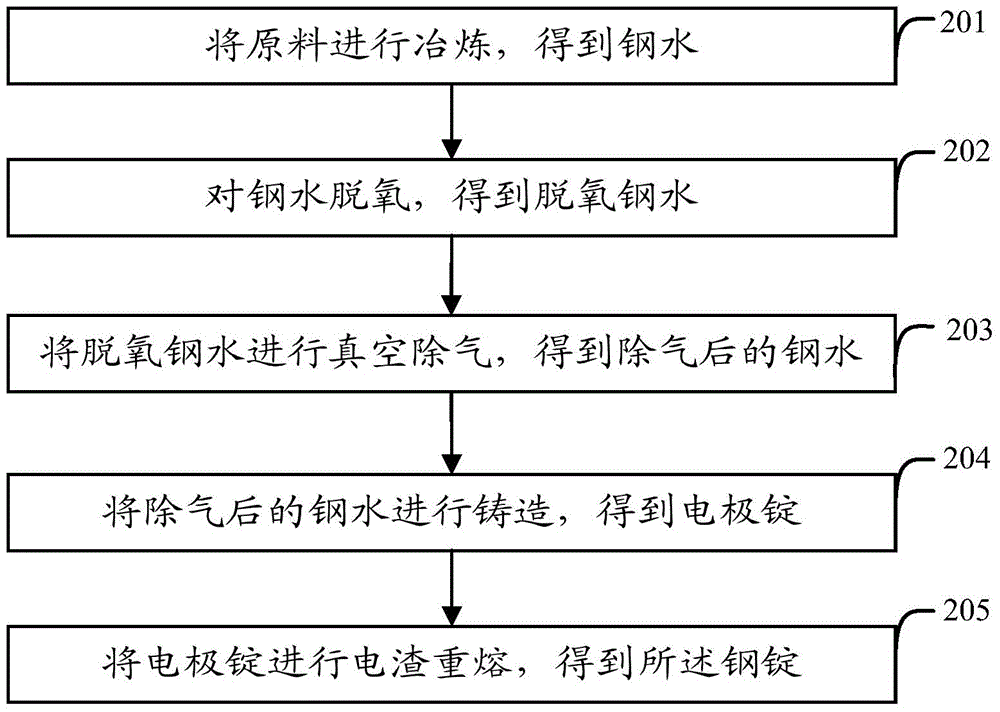

[0033] Preferably, in step 101 of Embodiment 1, the following steps may be included, please refer to figure 2 :

[0034] Step 201: Smelting raw materials to obtain molten steel;

[0035] Step 202: deoxidizing molten steel to obtain deoxidized molten steel;

[0036] The molten steel obtained by smelting contains a large amount of oxygen, so it needs to be deoxidized. Specifically, the deoxidizer can be Al. After Al is added to the molten steel, it can be used as a reducing agent and then removed from the molten steel. Contains a lot of oxygen.

[0037] Step 203: vacuum degassing the deoxidized molten steel to obtain degassed molten steel;

[0038] During the vacuum degassing process, it is necessary t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com