Modular design and quick assembly super high-rise building jacking form and jacking method

A modular design, super-high-rise technology, applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of high cost, long preparation time for climbing, and inability to adjust, so as to achieve high work efficiency and economy The effect of excellent benefit index and short installation and jacking preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as figure 1 As shown, the super high-rise building top form with modular design and quick assembly includes several shafts arranged side by side. The wells are all equipped with jacking platforms and combined into a top form. One or more jacking platforms can be carried out. Jack up. This solution divides the top mold into several wells that can be replaced arbitrarily to form a modular design, which facilitates its rapid assembly, and realizes single, multiple or all jacking of the platform through the jacking mechanism, so that when in use The flexibility is higher, and the adjustment will not be impossible due to the obstruction of the flow nodes during construction, and the reuse effect is good, which reduces the construction cost.

Embodiment approach

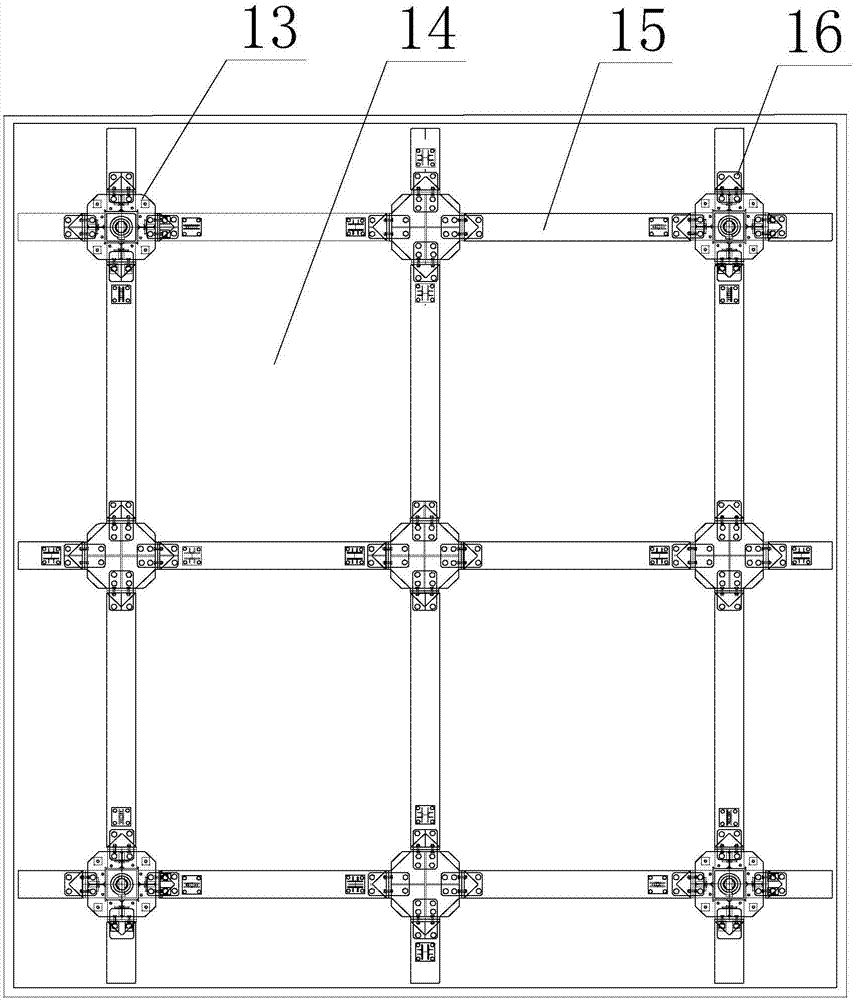

[0043] Such as figure 1 As shown, on the basis of Embodiment 1, the jacking platform includes several structural units 14 arranged side by side and connected, and several jacking mechanisms are arranged below the jacking platform, and the jacking mechanisms are respectively connected to the corresponding structural units 14 connected, the jacking mechanisms in each jacking platform act synchronously. The number of structural units 14 in the jacking platform is four, and the four structural units 14 are juxtaposed to form a rectangle. Each structural unit 14 in the structural unit 14 is a rectangle formed by connecting four stressed rods 15 and four mounting plates 13 at intervals, and adjacent structural units 14 share one stressed rod 15 and two mounting plates. plate 13. There are four jacking mechanisms, and each jacking mechanism is respectively fixed to the bottom of the mounting plate 13 at the four corners of the rectangle formed by the mounting plate 13 . A high-str...

Embodiment 3

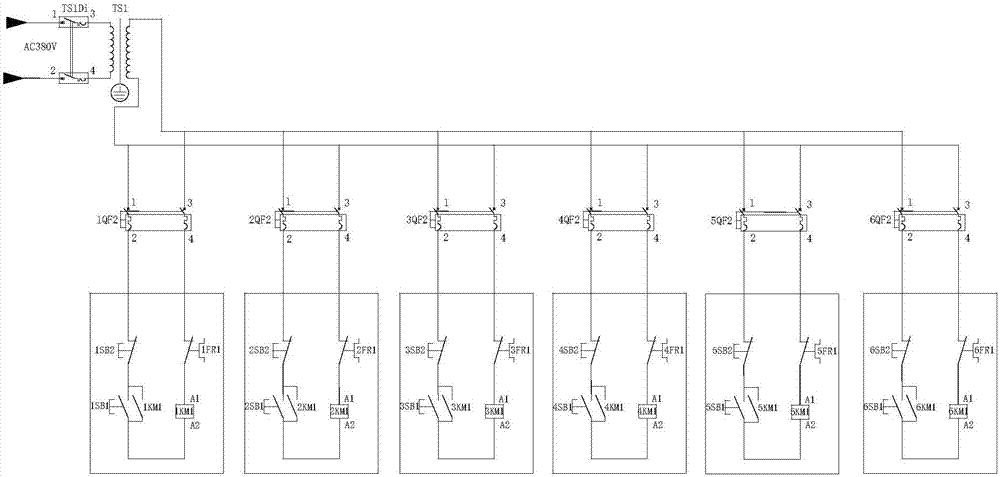

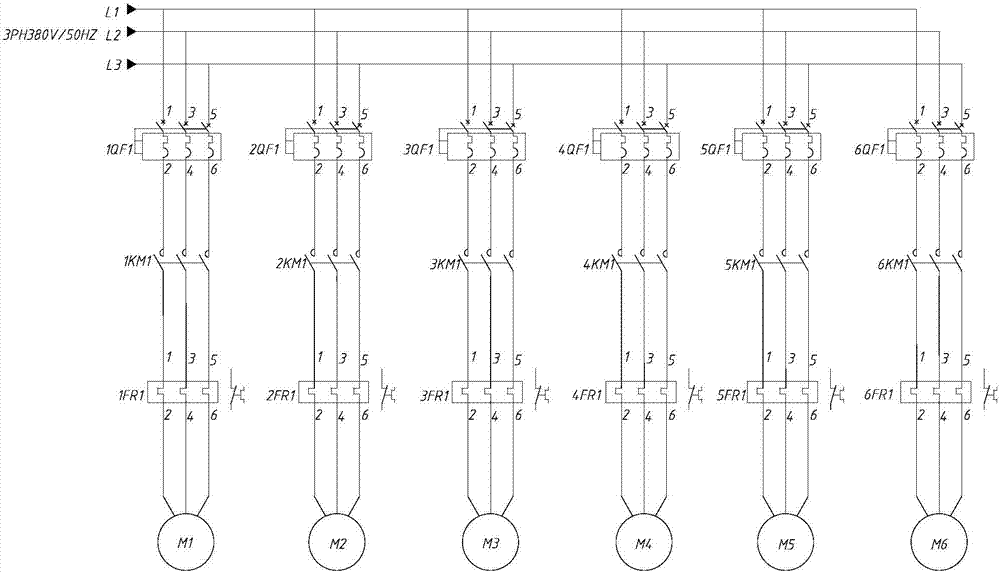

[0052] Such as Figure 2 to Figure 4 As shown, the control method of the overall climbing steel platform that can realize the overall jacking and partial jacking, each platform unit in the platform unit is equipped with a group of hydraulic control units.

[0053] This plan takes the super high-rise of six jacking platforms as an example, when any platform needs to be jacked up (take the first platform as an example):

[0054] (1) First close the main power switch 1QF1, the control transformer power switch TS1Di and the control circuit switch 1QF2;

[0055] (2) When starting, press the start switch 1SB on the electromagnetic starter related to the above control circuit 1 , so that the 1KM1 main contactor coil is energized and drives the normally open auxiliary head of the 1KM1 main contactor to close and self-lock, and the main contact of the 1KM1 main contactor is also closed at the same time, and the motor M1 is energized to start and run continuously;

[0056] (3) When st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com