Patents

Literature

61results about How to "Improve neatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

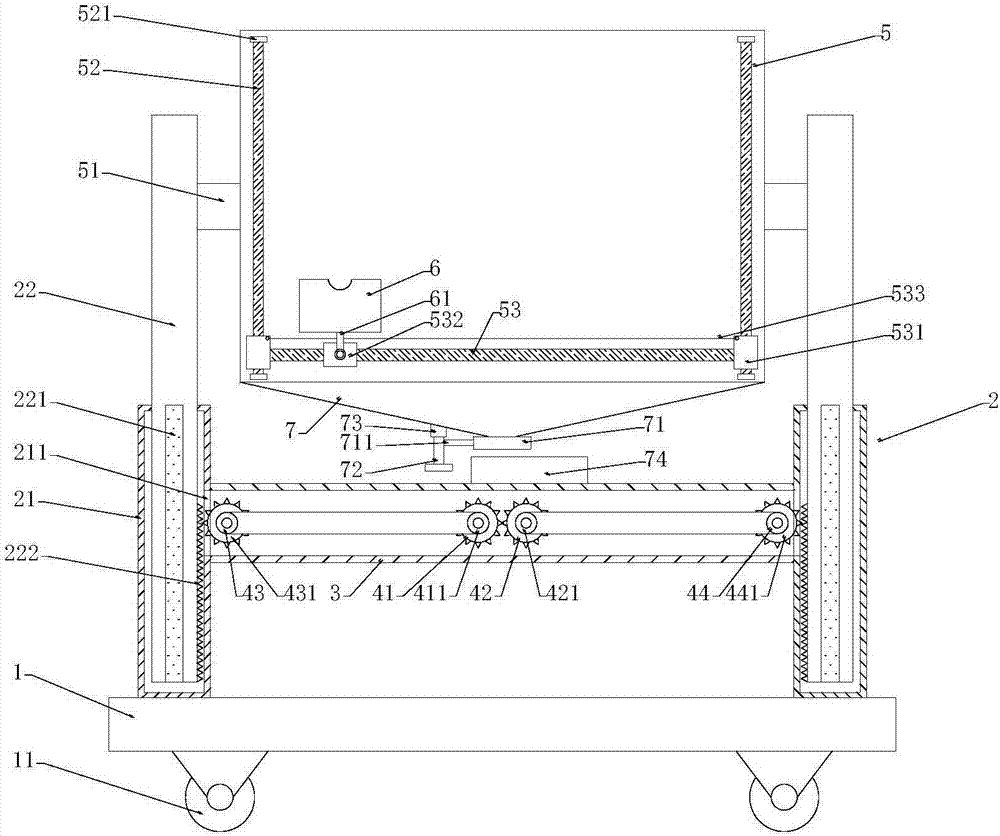

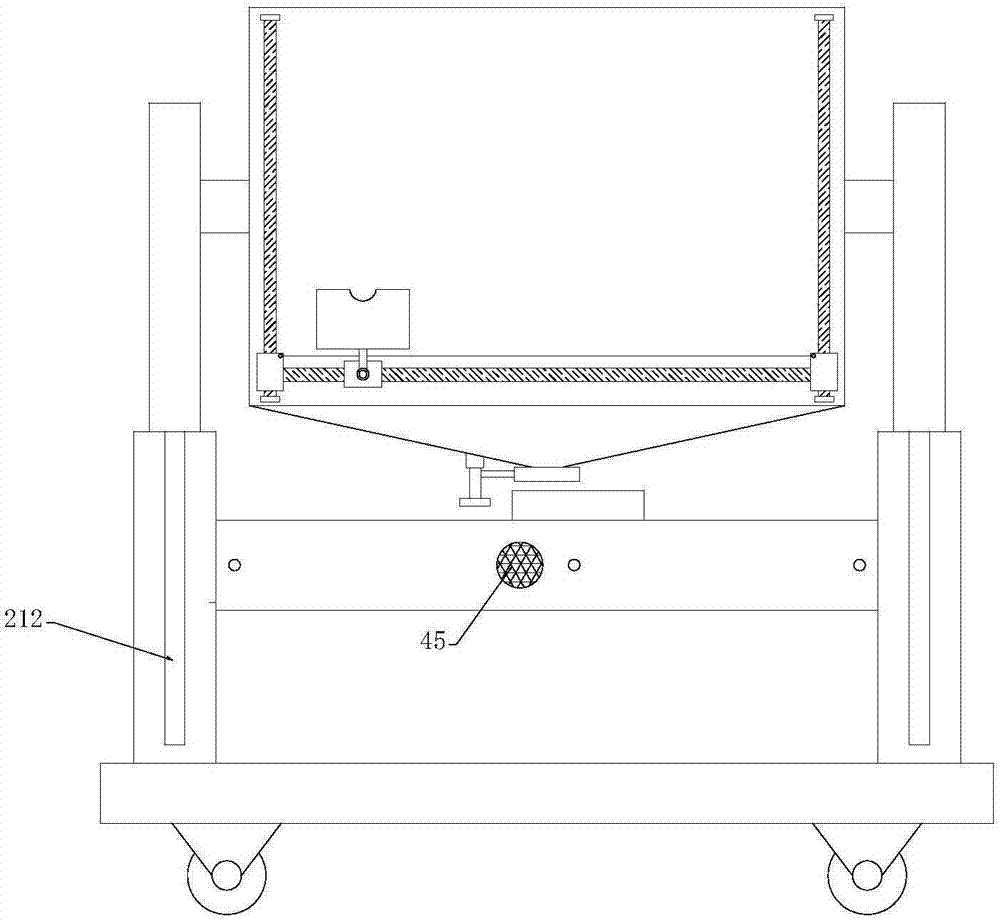

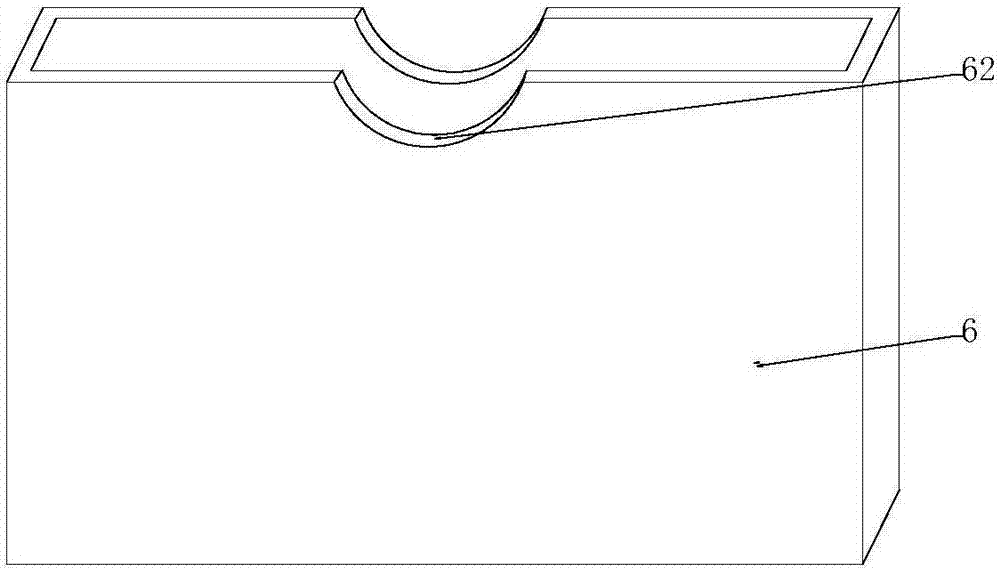

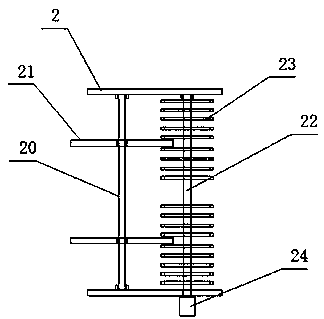

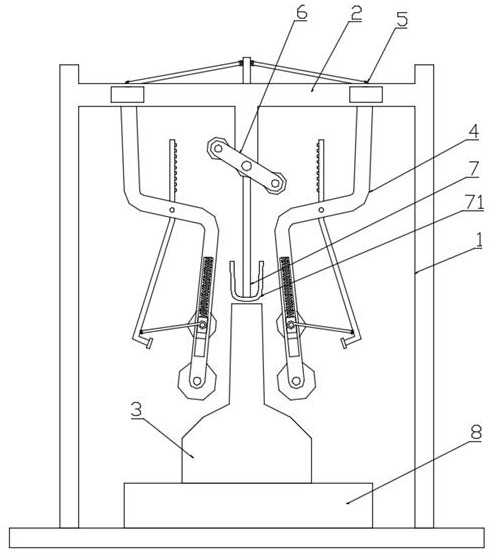

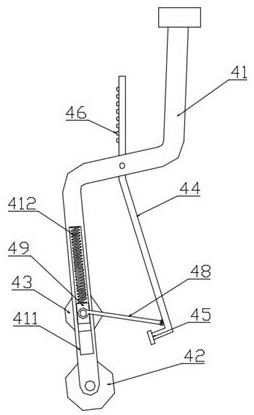

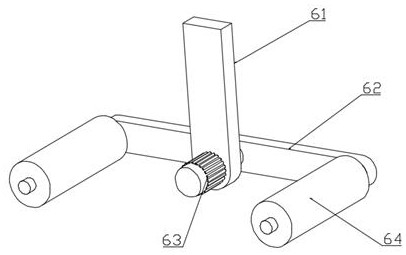

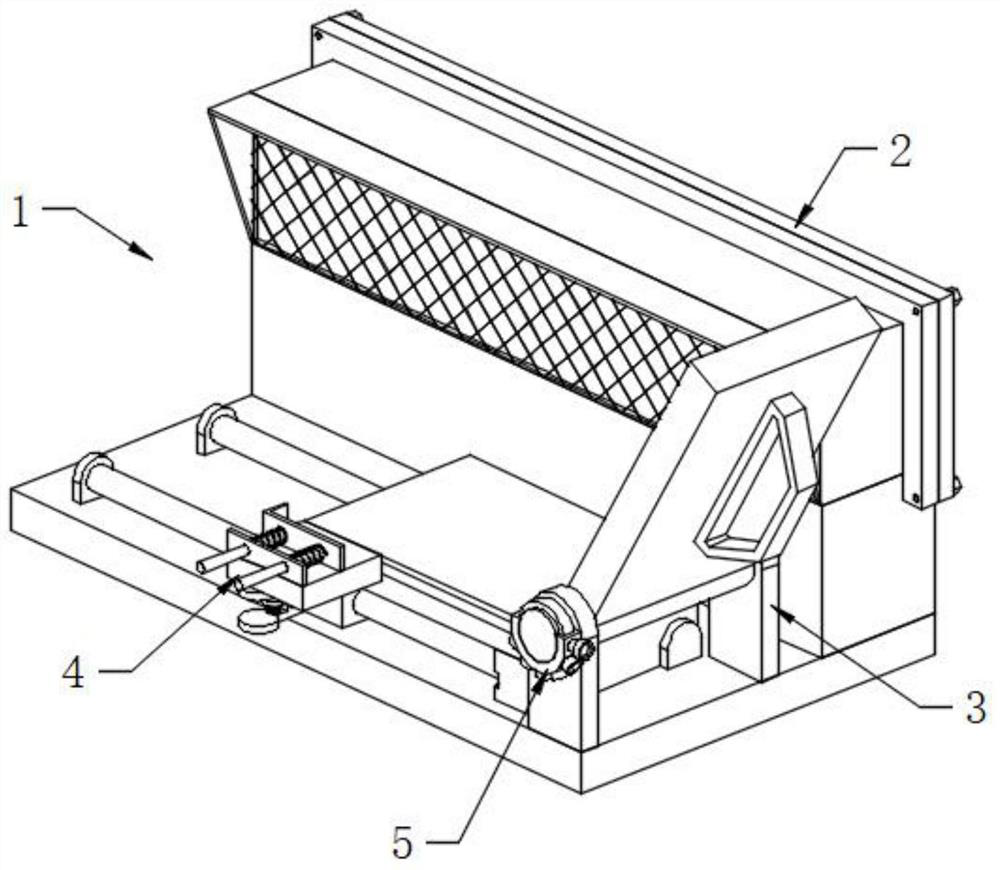

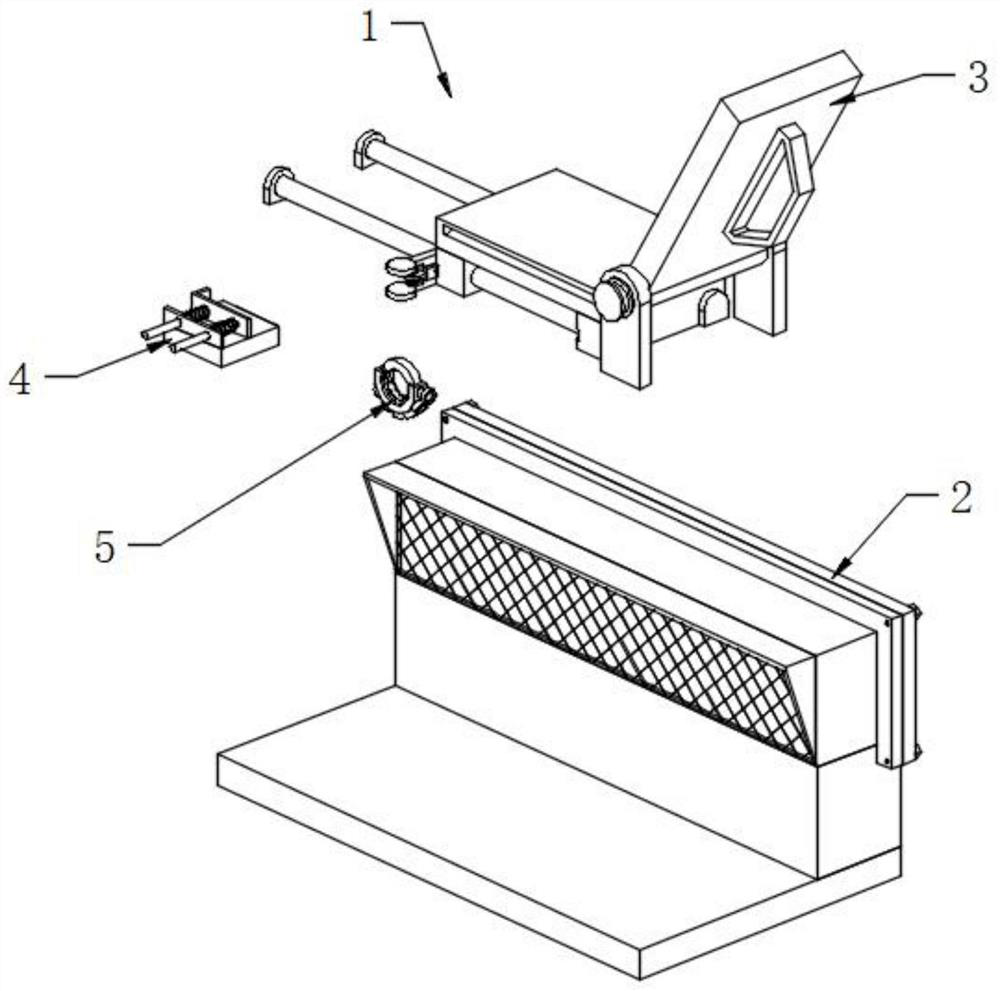

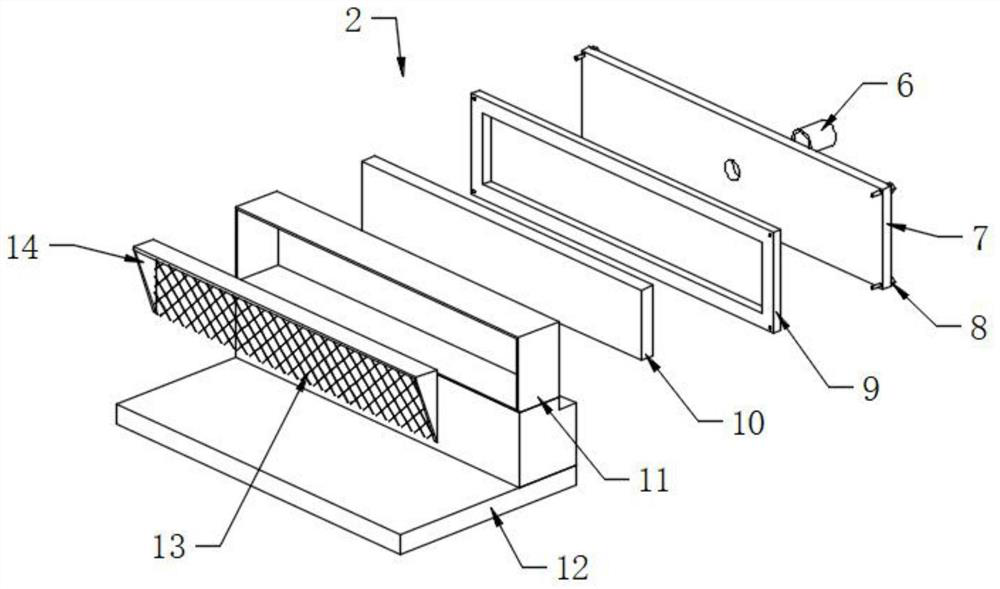

Multifunctional lifting type teaching blackboard

InactiveCN107415531ARealize synchronous scalingAvoid leaningWriting boardsFurniture partsEngineeringOmni directional

Owner:六安市智奇工业设计有限公司

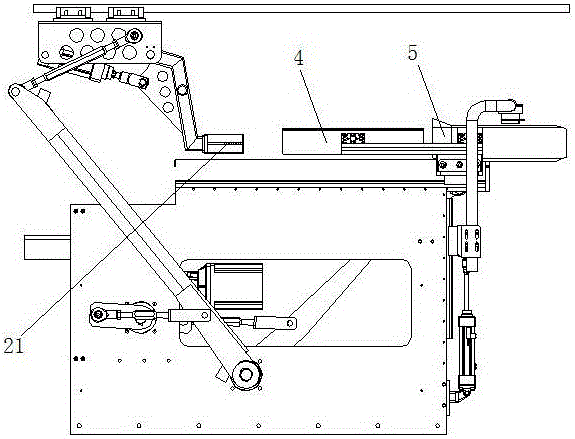

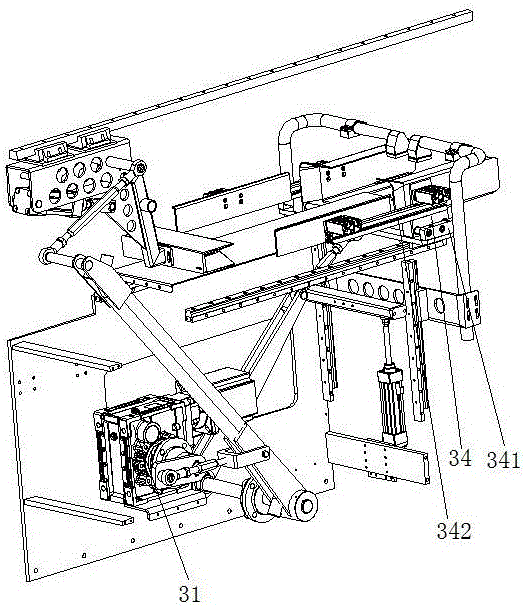

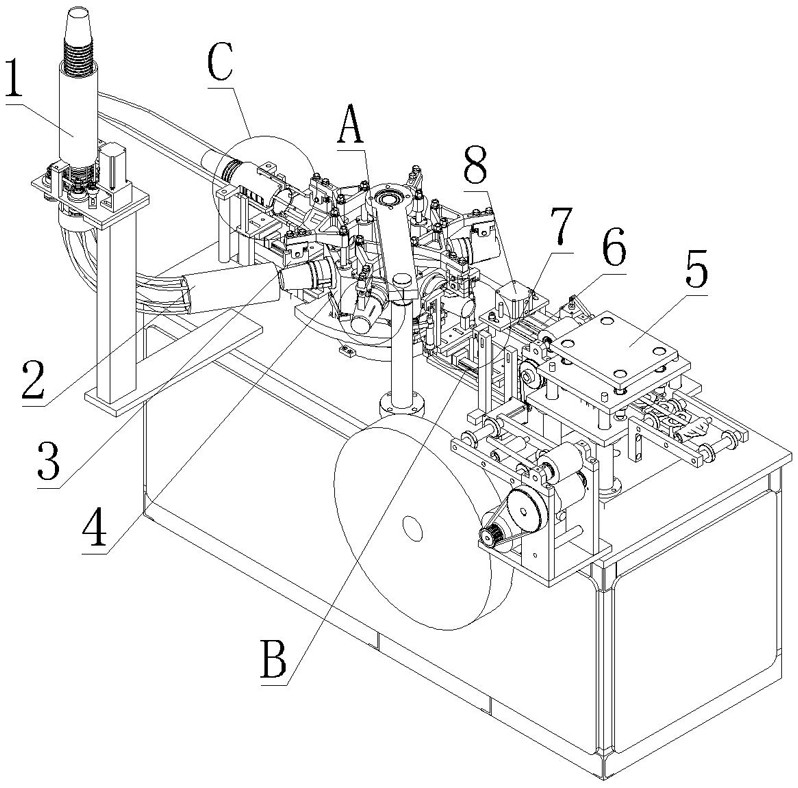

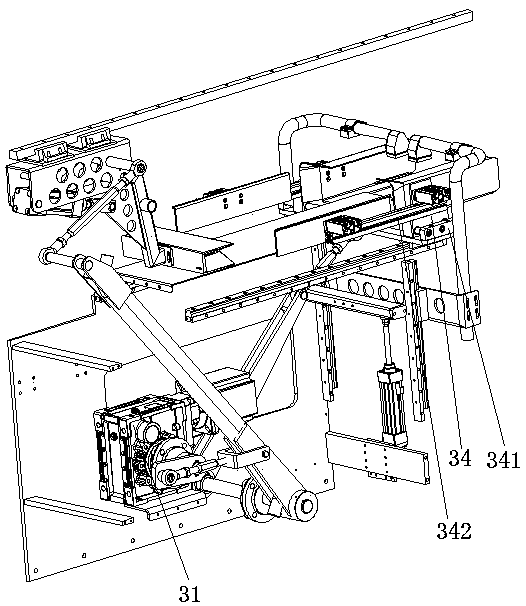

Control system of prefabricated bag packing machine

ActiveCN105857649AShort tripPrevent the situation of dumpingSolid materialRolling paperControl system

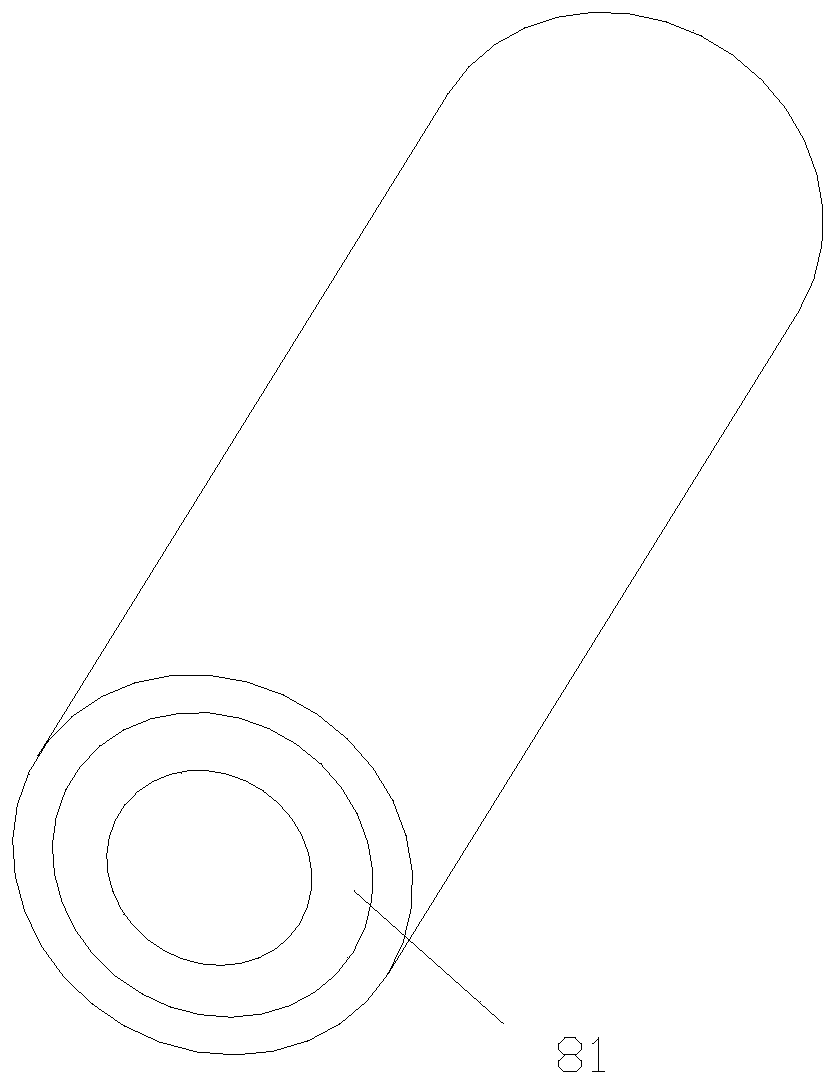

The invention discloses a control system of a prefabricated bag packing machine and relates to the technical field of mechanical control of packing machines. The control system of the prefabricated bag packing machine comprises a feeding mechanism, a pushing mechanism, a bag stretching mechanism, a bag opening mechanism and a bag conveying mechanism and is characterized by further comprising a clamping mechanism and a translation mechanism. The control system of the prefabricated bag packing machine is applicable to packing machines for packing via prefabricated bags such as small packing machines, medium packing machines and large packing machines and the like; meanwhile, the control system of the prefabricated bag packing machine is also suitable for packing materials such as facial tissues, flat paper, paper towels, blocky foods, drugs, roll paper, unpackaged foods and the like. Through the control system of the prefabricated bag packing machine, the problems that processes in single station of the prefabricated bag packing machine are complex, various packing actions are needed, the travel distance among the stations is long, the equipment occupied area is large, the material is irregular and is easy to pour, the prefabricated bags are easy to break, the material-pushing travel distance is long, the packing effect is poor, and the packaging efficiency is low in the prior art can be solved.

Owner:上海松川峰冠包装自动化有限公司

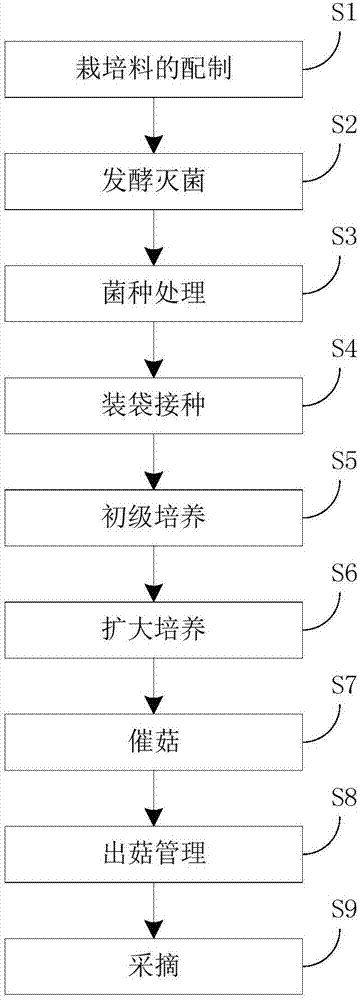

Shiitake mushroom culture method

InactiveCN107980479AImprove sterilization effectKill bacteriaCalcareous fertilisersBioloigcal waste fertilisersShiitake mushroomsGermination

The invention discloses a shiitake mushroom culture method which includes the steps of preparation of culture media, fermenting while sterilizing, strain treatment, packaging and inoculating, primaryculturing, expanded culturing, fruiting promoting, fruiting management and picking. The culture media prepared according to formulas are comprehensive in nutrition. The culture media are turned over frequently so that the culture media are fermented and sterilized fully. By twice of seed dressing, activated treatment of strains of shiitake mushroom is realized, growth of shiitake mushroom is improved, fruiting time is shortened, and yield is increased. By the steps of primary culture and further culture, the germination rate of shiitake mushroom strain can be increased, fruiting evenness is improved, and germination cycle of the strains is shortened. Strain bags are pierced so that an appropriate amount of oxygen gas is injected to the strain bags to promote growth of mycelia, fruiting ofshiitake mushroom is promoted and uniform relatively. High yield is achieved since temperature and humidity are controlled during fruiting management. The shiitake mushroom culture method realizes culture of high-quality shiitake mushroom, shortens growth cycle of shiitake mushroom and increases the yield of shiitake mushroom by 25%.

Owner:罗成喜

Ceramic underglaze five-color silk screen transfer printing method

The invention relates to a ceramic underglaze five-color silk screen transfer printing method which comprises the following steps: carrying out ball milling on a ceramic raw material and screening to prepare a slurry, and carrying out mold injection molding into the required shape to obtain a billet; glazing, and firing to obtain a glaze billet; brushing a water-containing adhesive on the surface of the glaze billet; attaching a silk screen prepared according to the required pattern to the surface of the glaze billet by silk screen transfer printing, spreading the prepared pigments in the pattern formed by the silk screen on the glaze billet, peeling off the silk screen to form the required pattern outline, dipping the underglaze five-color pigments with a painting device, carrying out painting decoration on the pattern outline to obtain a color billet, and carrying out color treatment to spread a glaze layer on the surface of the color billet; and firing the color billet coated with the transparent glaze in a kiln at high temperature to obtain the underglaze five-color ceramic article.

Owner:HUNAN NEW CENTURY CERAMICS

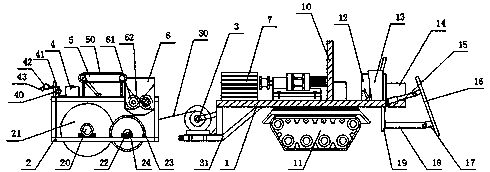

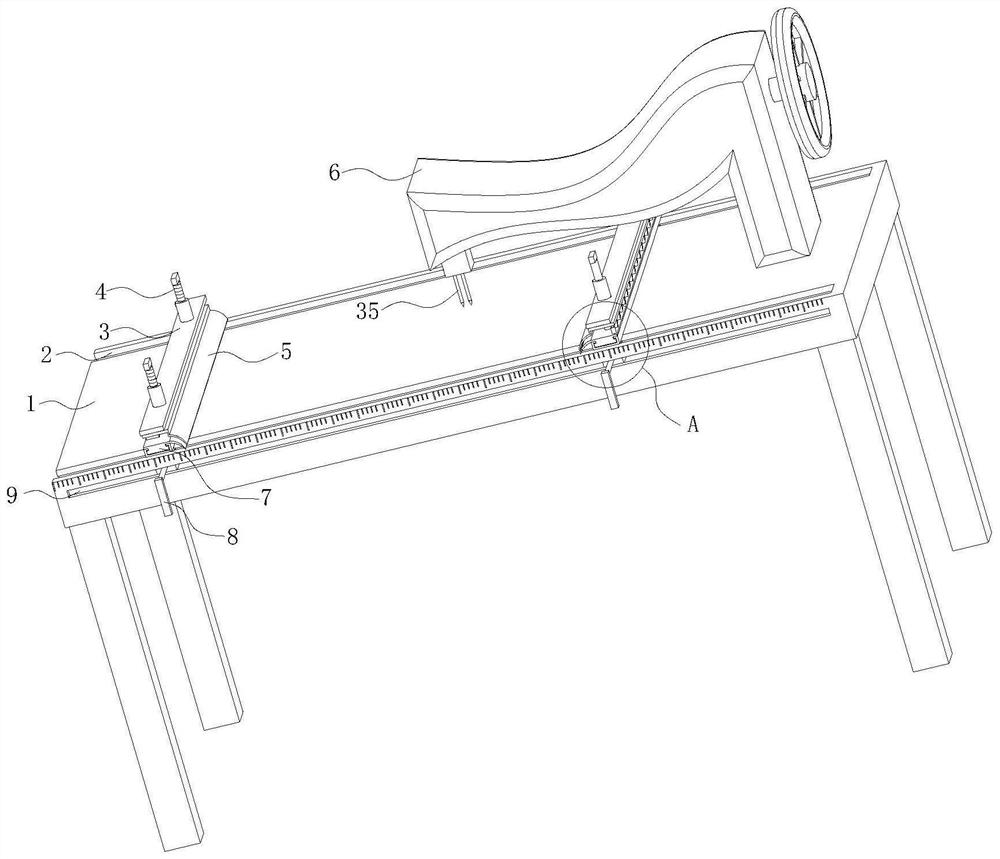

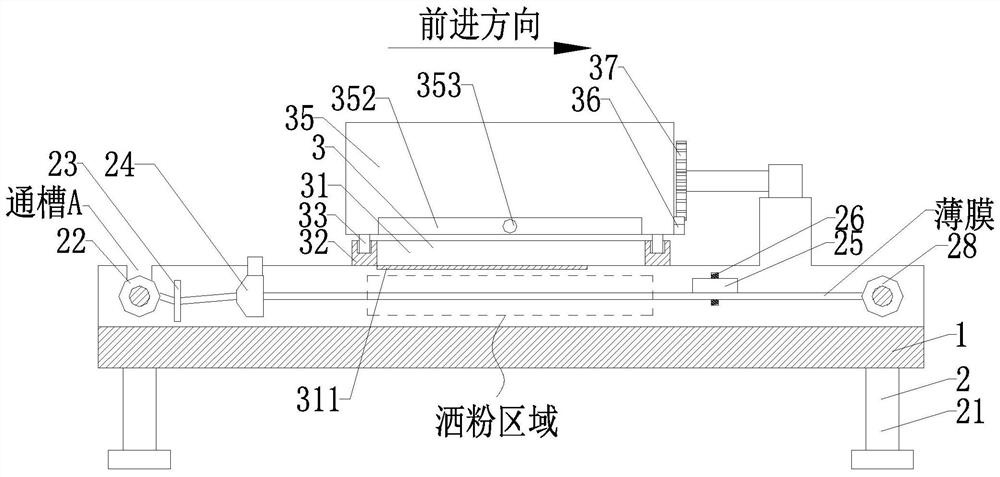

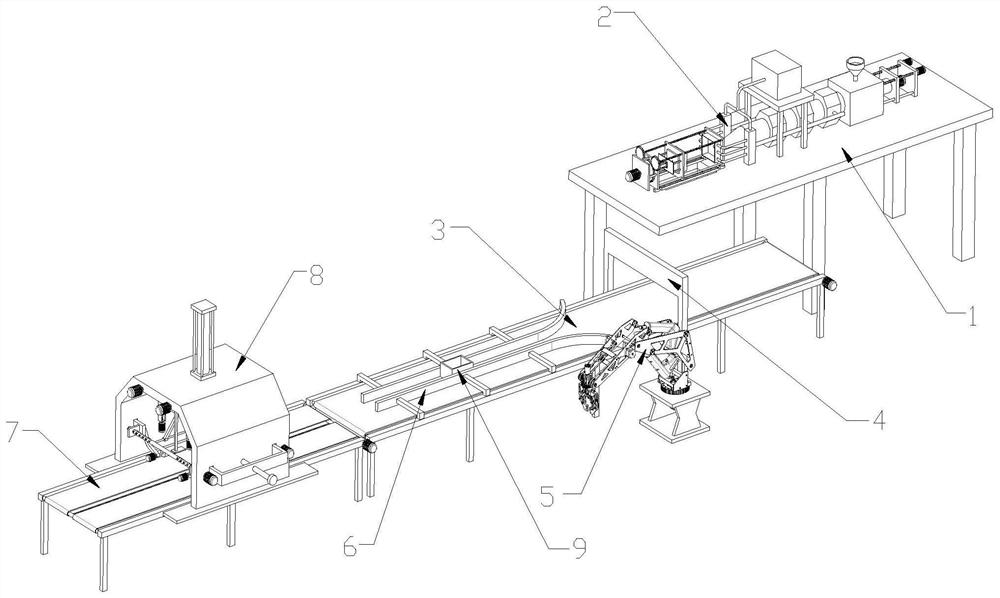

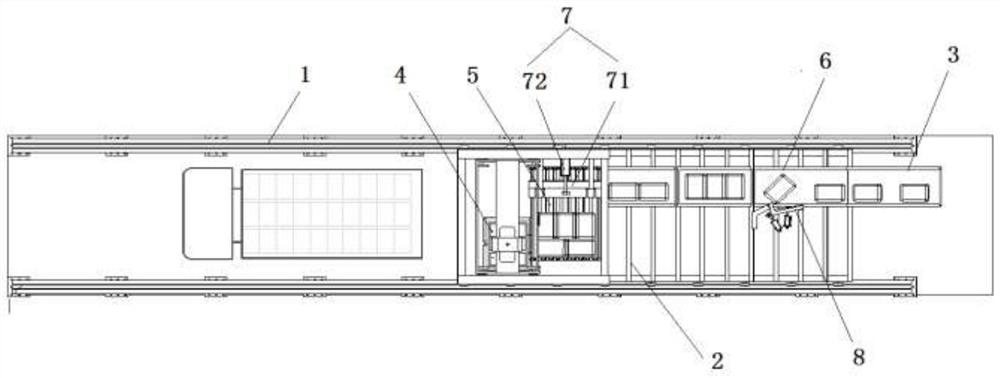

Traction grass planter for desert control

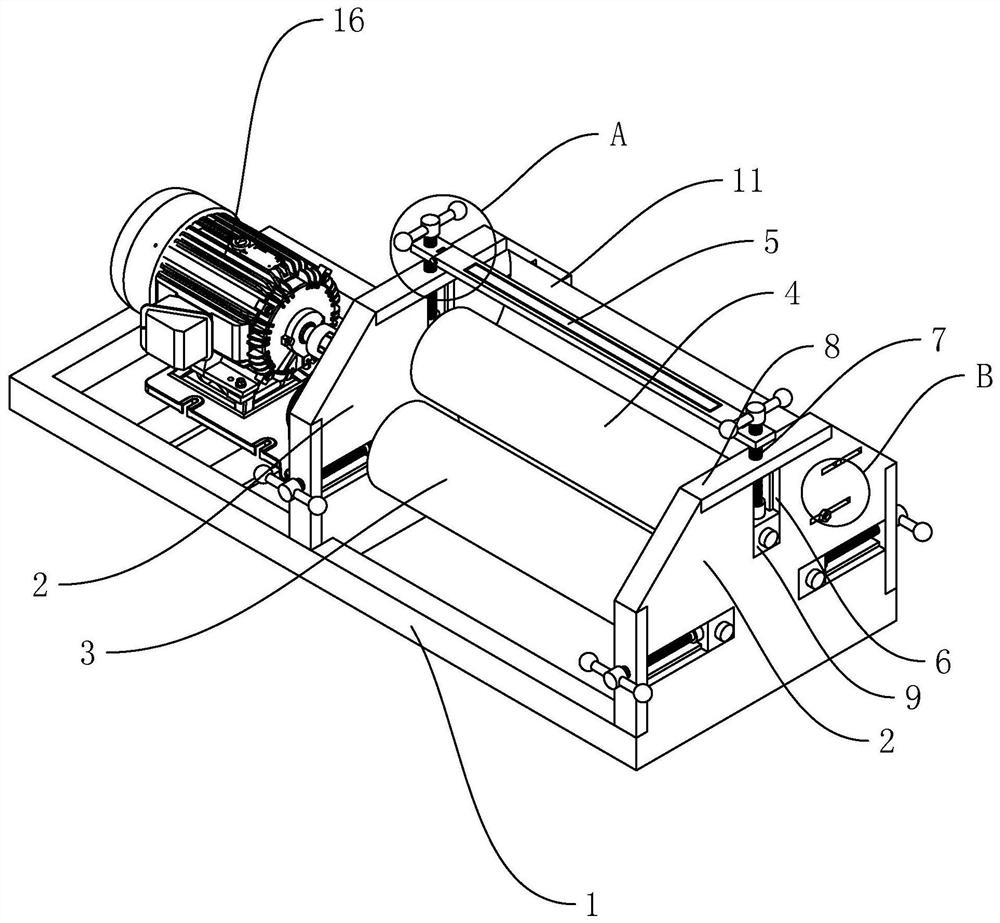

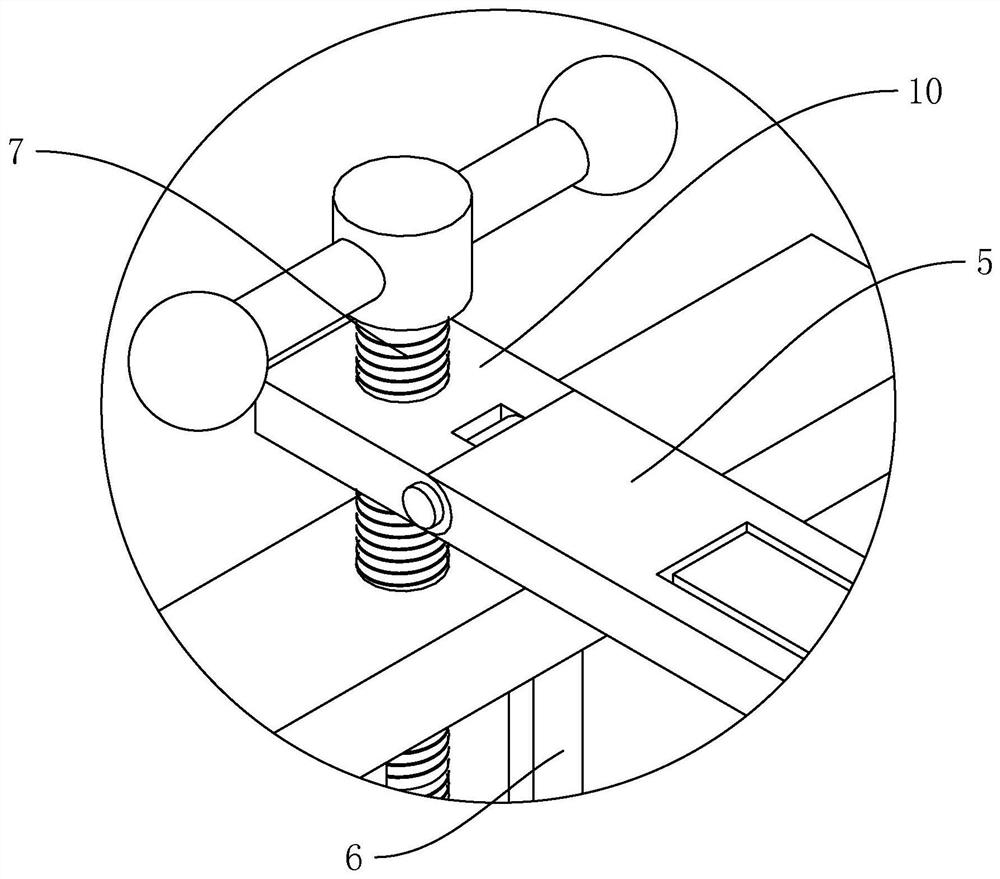

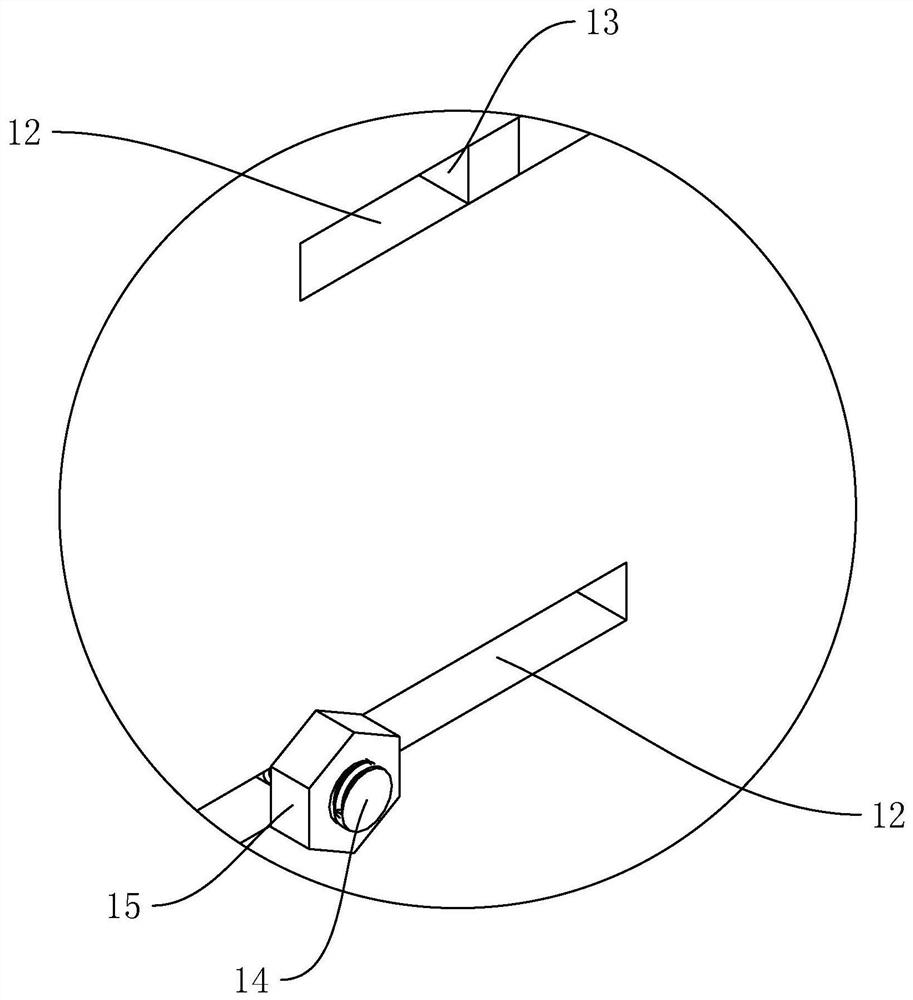

PendingCN109819705AGrass planting process is stableImprove neatnessSpadesWatering devicesEngineeringConveyor belt

The invention discloses a traction grass planter for desert control. The traction grass planter comprises a traction power rack, a grass planting rack, a longitudinal hoisting machine, a water spraying device, a conveyor belt and a grass box; a longitudinal hoisting machine rack is fixedly arranged at the left end of the traction power rack, the longitudinal hoisting machine is fixedly disposed onthe longitudinal hoisting machine rack, an output end of the longitudinal hoisting machine is connected with a steel wire rope, and the other end of the steel wire rope is fixedly disposed on the grass planting rack; a machine frame of the grass planting rack is sequentially provided with the water spraying device, a conveying device and the grass box from left to right. Through a walking caterpillar band, the traction power rack walks more stably in a desert, so that the overall efficiency of the grass planter is improved. Through arrangement of the water spraying device, water is sprayed onto grass seeds or tree seeds in grass squares synchronously, so that the survival rate of the grass seeds or tree seeds is increased. Through mechanized equipment, the overall grass planting efficiency is improved, and the work intensity of operators is reduced.

Owner:佘书强

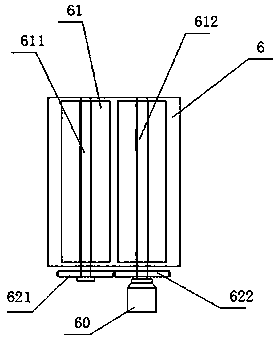

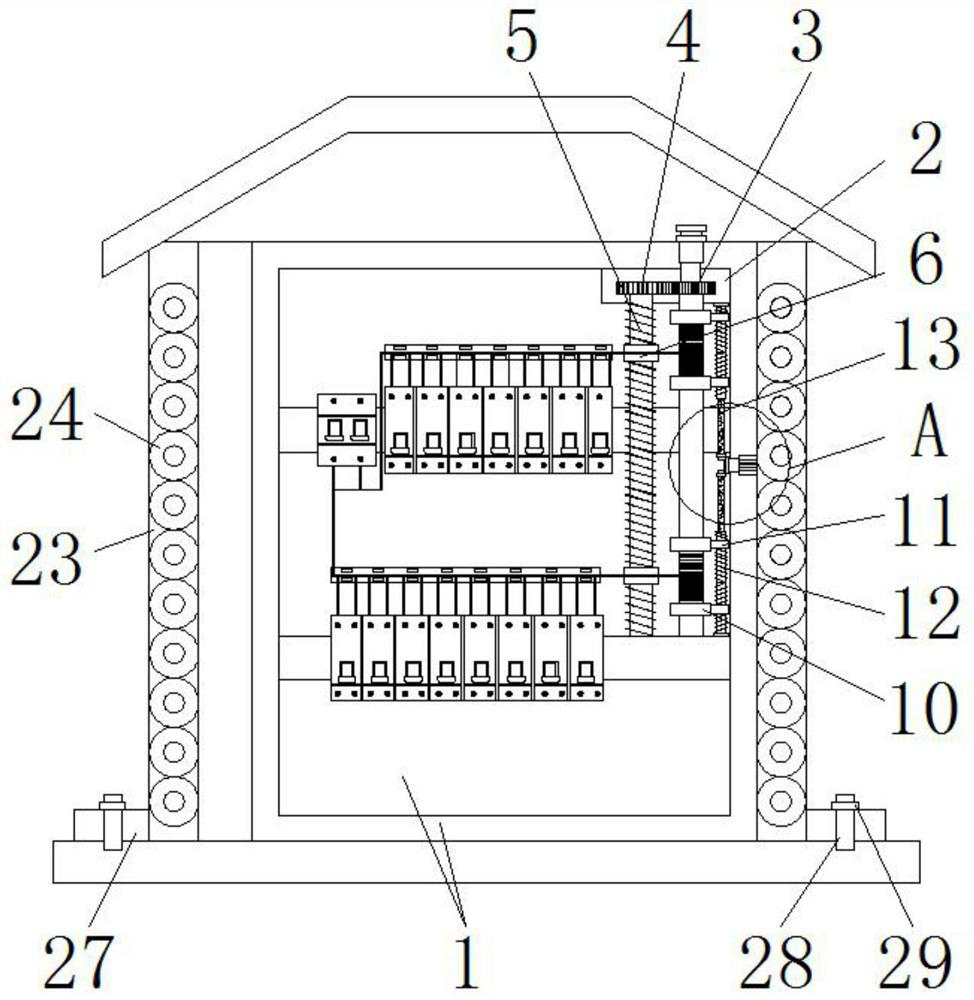

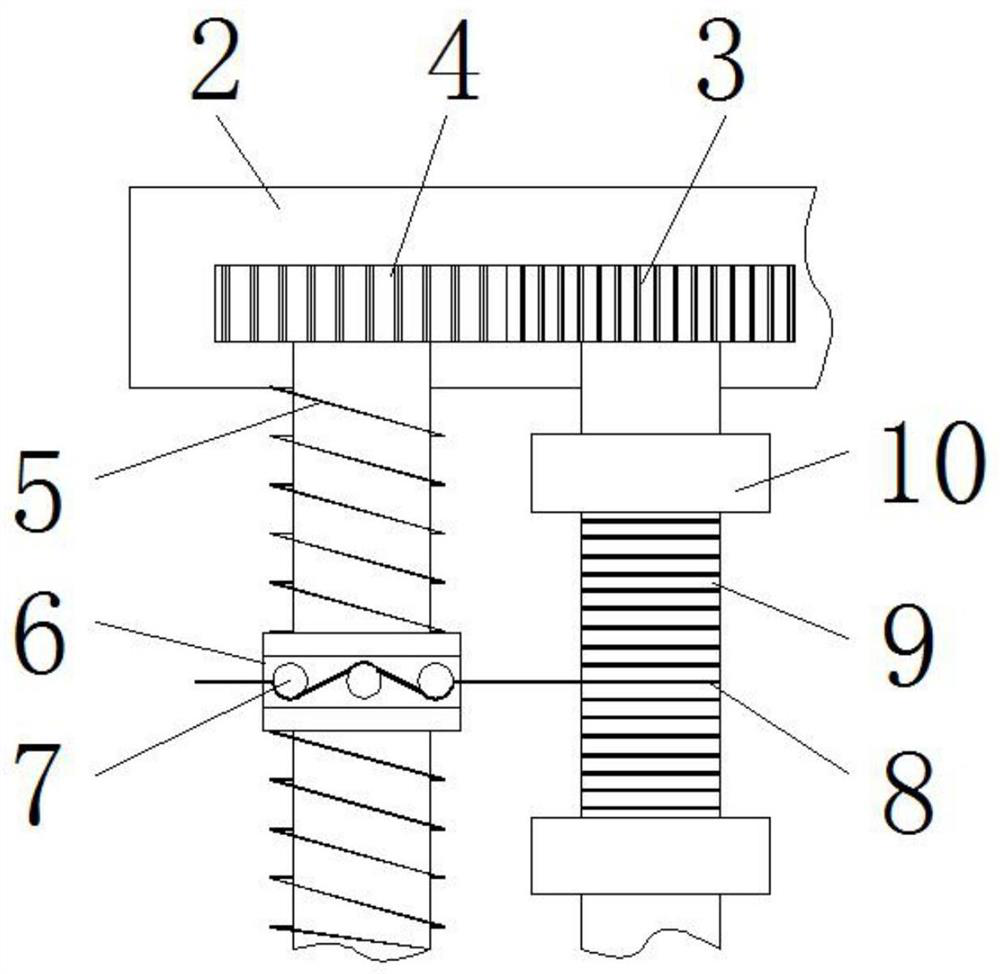

Distribution box with neat take-up and high safety performance

ActiveCN112652976ANeat line take-up and high safety performanceImprove securityBus-bar/wiring layoutsFilament handlingDrive wheelGear wheel

The invention discloses a distribution box with neat take-up and high safety performance. The distribution box comprises a distribution box body and a threading plate, a connecting plate is arranged in the distribution box body, a driving wheel is arranged in the connecting plate, a driven wheel is connected to the exterior of the driving wheel, a lead screw is arranged below the driven wheel, a sliding block is connected to the exterior of the lead screw in a sleeving mode, and the threading plate is connected with the sliding block in a sleeving mode. And a limiting column is installed outside the sliding block, and the surface of the sliding block is connected with an electric wire. According to the power distribution box with neat take-up and high safety performance, a main shaft is rotated to drive a gear to rotate, the gear rotates to enable toothed bars on the two sides to move through meshing connection, the toothed bars move to play a supporting role through assistance of sliding connection with supporting rods, and then the toothed bars move to drive two clamping buckles which are integrally installed to move relatively, so the wires re conveniently fixed, stored and arranged, potential safety hazards caused by mutual knotting and winding of the wires are prevented, and the safety performance of the power distribution box body is improved.

Owner:ANHUI HONGQIAO METAL MFG

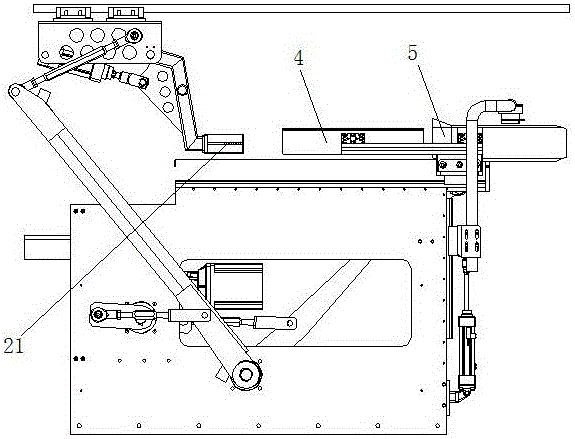

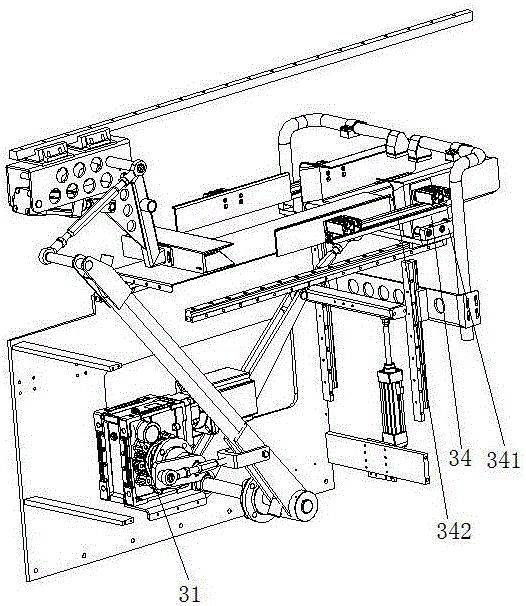

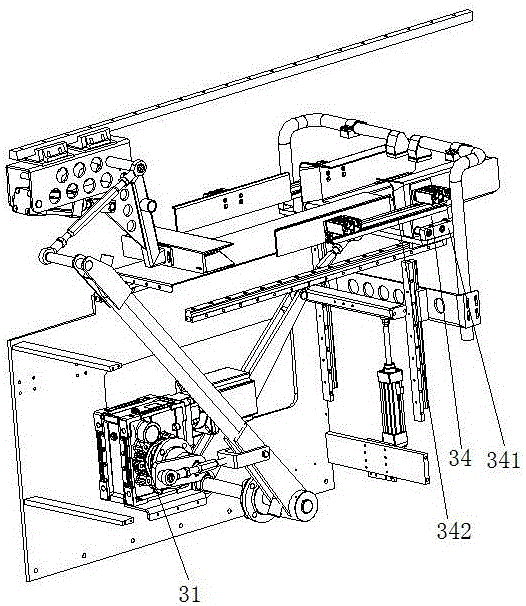

Material conveying and pushing method for prefabricated bag packaging machine

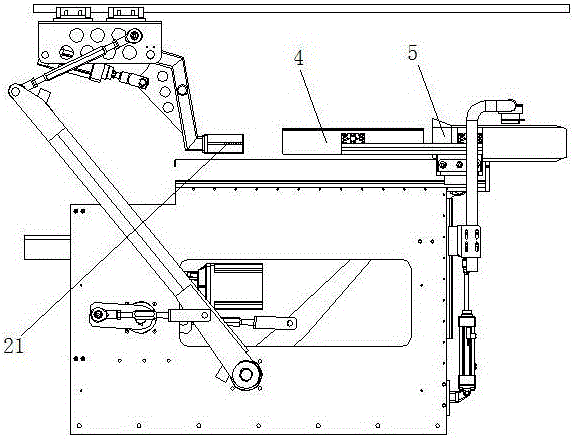

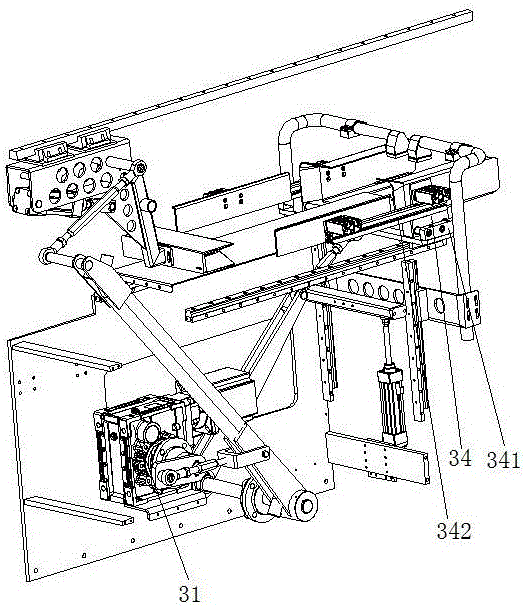

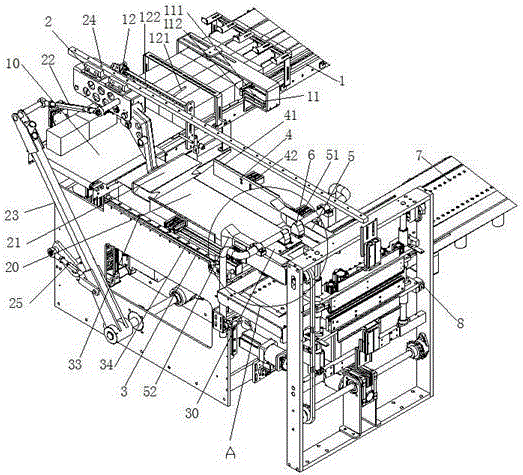

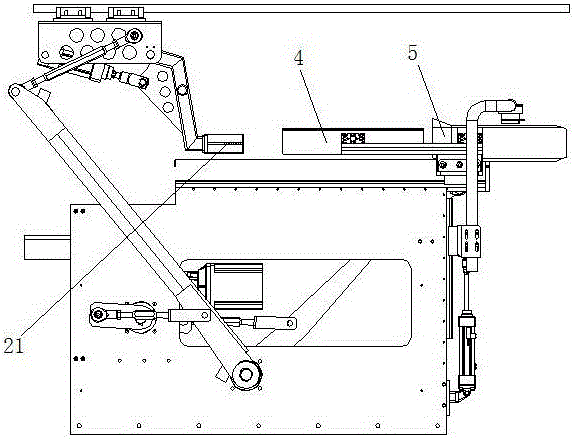

ActiveCN105691676ARealize the action of opening and opening bagsReduce processIndividual articlesRisk strokeSingle station

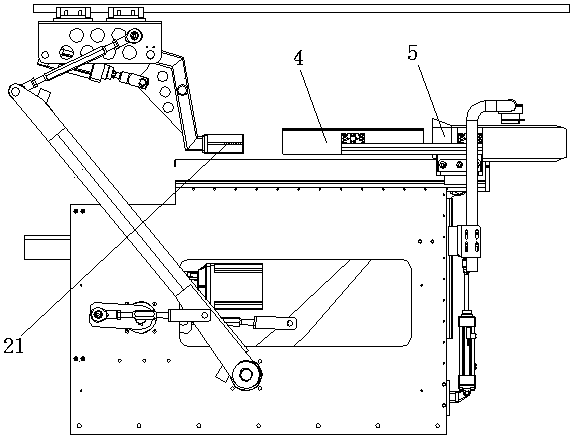

The invention discloses a material conveying and pushing method for a prefabricated bag packaging machine and relates to the technical field of packaging machine packaging processes. The material conveying and pushing method includes the steps that materials are conveyed to a to-be-clamped station; the materials conveyed to the to-be-clamped station are conveyed to a to-be-pushed station in a clamped manner; in the process of conveying the materials to the to-be-clamped station or the to-be-pushed station, prefabricated bags are conveyed to a bag opening station and opened on the bag opening station; the prefabricated bags are opened while the materials on the to-be-clamped station are conveyed to the to-be-pushed station in the clamped manner; in the material pushing process, the prefabricated bags and the materials move in the opposite directions; and the materials are pushed into the prefabricated bags moving in the direction opposite to the material pushing direction, and the prefabricated bags containing the materials in a wrapping manner are pushed to the assigned positions in the original material pushing direction. The material conveying and pushing method for the prefabricated bag packaging machine can solve the problems that by means of a prefabricated bag packaging machine in the prior art, the working procedures of a single station are complex, the number of the packaging actions is large, the stroke among different stations is long, the area occupied by equipment is large, material dumping occurs easily and the prefabricated bags are broken easily due to the fact that materials are irregular, the material pushing stroke is long, the packaging effect is poor, and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

Material clamping and conveying method for prefabricated bag packaging machine

The invention discloses a material clamping and conveying method for a prefabricated bag packaging machine, and belongs to the field of material packaging. The material clamping and conveying method is characterized by comprising the following steps: a, a material is fed by a material feeding mechanism to a to-be-clamped station, and clamped by the two sides in the horizontal material conveying direction of a clamping mechanism; b, the clamped material is conveyed to a to-be-pushed station, and a prefabricated bag is expanded by a bag expanding mechanism; and c, the material conveyed to the to-be-pushed station is pushed by a material pushing mechanism, and meanwhile the prefabricated bag is driven by the bag expanding mechanism to move opposite to the pushed material. By adoption of the material clamping and conveying method, the material can be pushed by the material pushing mechanism into the prefabricated bag continuously, and the continuous degree of material conveying and pushing is high. Besides, the material clamping and conveying method has the characteristics that the conveying and packaging stroke is short, and the packaging efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

Material packaging method for prefabricated bag packaging machine

ActiveCN105691677AHigh degree of continuityImprove packaging efficiencyIndividual articlesEngineeringPacking method

The invention discloses a material packaging method for a prefabricated bag packaging machine, and belongs to the technical field of material packaging. The material packaging method comprises the following steps: material clamping or holding, prefabricated bag expanding, material pushing and prefabricated bag removing, wherein in the material clamping or holding process, a material is clamped or held under the action of a clamping mechanism or a holding mechanism, and conveyed to a to-be-pushed station; in the prefabricated bag expanding process; the left and right sides of the bag mouth of the prefabricated bag are expanded under the action of a bag expanding mechanism; in the material pushing process, the material moves under the action of a material pushing mechanism in the direction of the bag mouth of the prefabricated bag to the bottom of the prefabricated bag, and continues being pushed along with the prefabricated bag; and in the prefabricated bag removing process, after moving to the bottom of the prefabricated bag, the material continues being pushed by the material pushing mechanism, and then is removed from the bag expanding mechanism. By adoption of the material packaging method, the material can be pushed by a material pushing head into the prefabricated bag continuously, and the continuous degree of material conveying and pushing is high. Compared with a conventional packaging method, the material packaging method provided by the invention has the advantages that the conveying and packaging stroke is shorter, and the packaging efficiency is higher.

Owner:上海松川峰冠包装自动化有限公司

Material conveying method for prefabricated bag packing machine

The invention discloses a material conveying method for a prefabricated bag packing machine, and belongs to the technical field of material packing. The material conveying method is characterized by comprising the following steps that (a), material after being held or clamped is conveyed to a station to be pushed in the opening direction of a prefabricated bag; (b), the left side and the right side of the prefabricated bag are opened; (c), the material is pushed on the station to be pushed, the precast bag is moved, the material and the prefabricated bag perform opposite motion, and the material is pushed into the prefabricated bag; (d), the material is pushed to the bottom of the prefabricated bag, and the material continues moves along with the prefabricated bag in the pushed direction; (e), next material is cyclically conveyed according to the steps. The material conveying method disclosed by the invention has the characteristics that the material pushing serialization degree is high, the conveying and packing distance is short, the materials cannot fall, and the conveying and packing efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

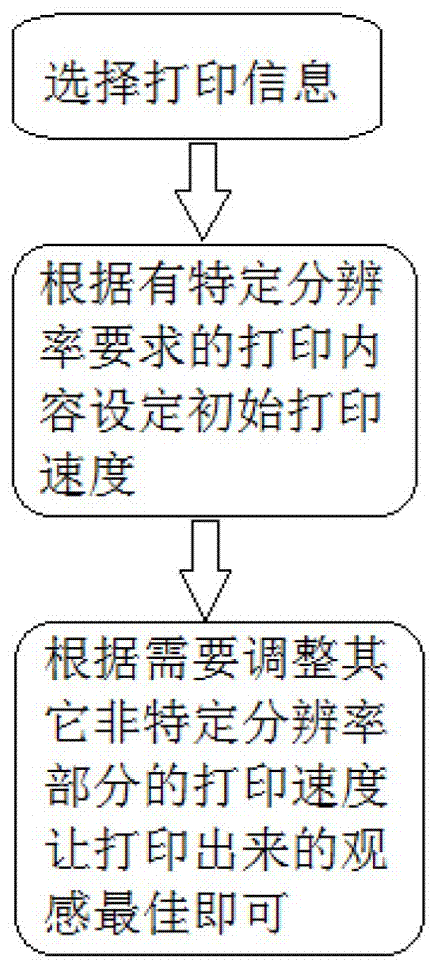

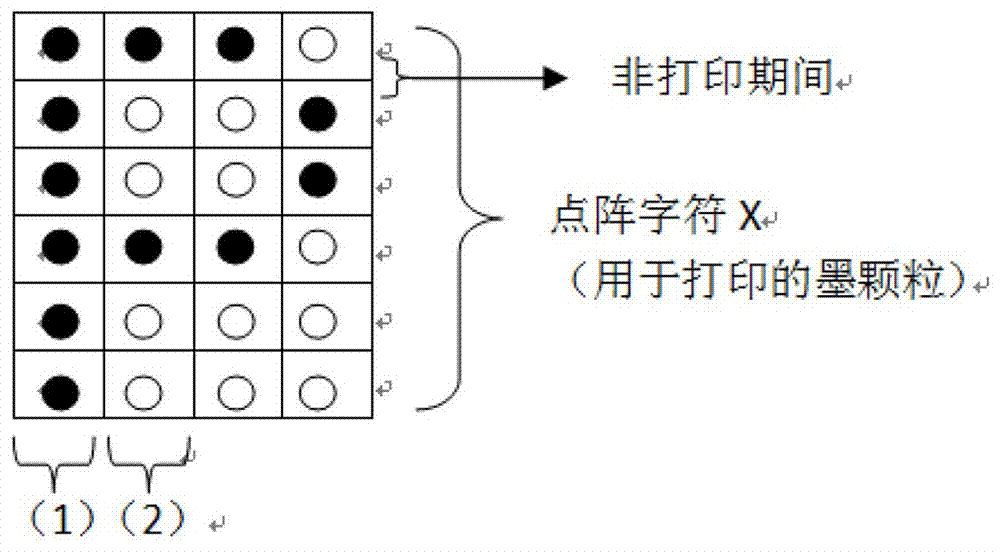

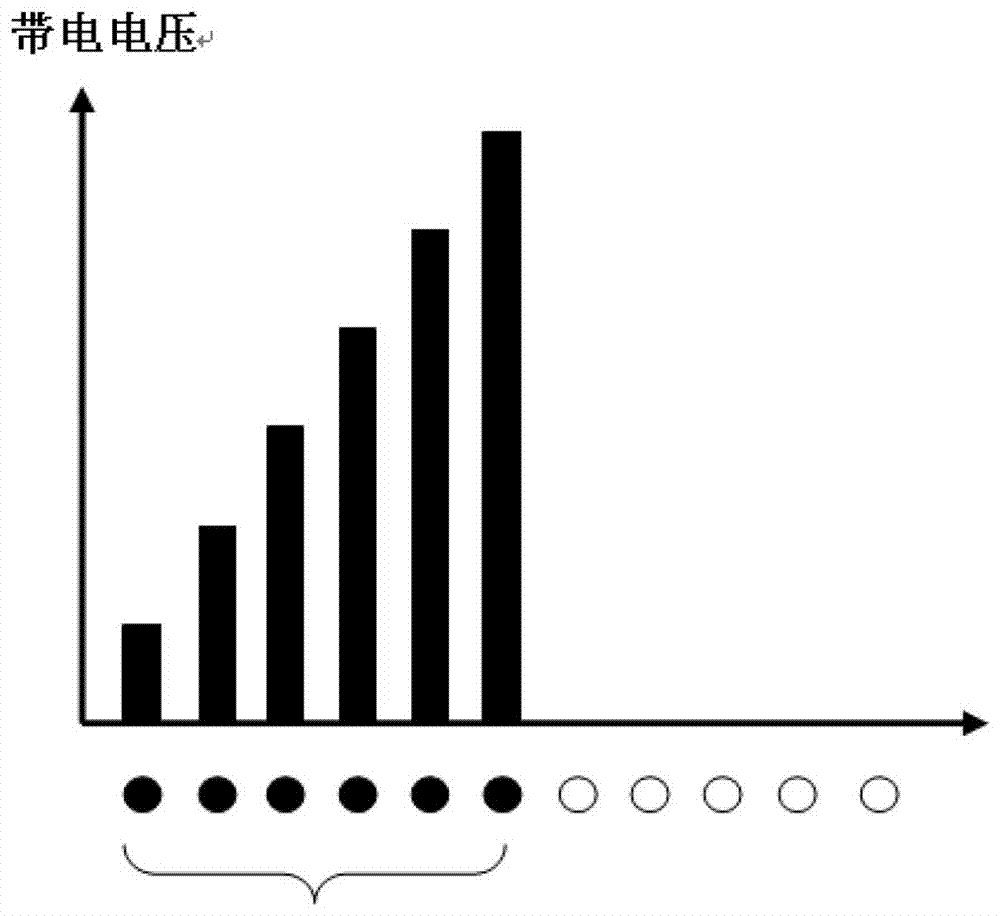

Variable-speed printing control algorithm of CIJ ink-jet printing machine

The variable-speed printing control algorithm of CIJ inkjet printer disclosed by the present invention includes: first setting the initial printing speed for a piece of printing data, and the initial printing speed can make the printing data clearly printed; If the data with different horizontal resolutions is required, the printing data is divided into the modified speed area and the constant speed area. For the printing data in the modified speed area, by inserting the corresponding printing ink drop between the printing ink drop and the printing ink drop Increase the spacing between printed ink dots by increasing the spacing between printed ink dots by more non-printing ink drops than in the speed constant area to reduce the printing speed in the modified speed area. The invention can effectively reduce the interference between ink dots in the high-resolution printing information and reduce the scattered ink around the information, improve the neatness and aesthetics of the printing content, and realize the best printing effect.

Owner:XIAMEN YINGJIEHUA ELECTROMECHANICAL TECH

Heat sealing device for food packaging bag

InactiveCN114655518AEasy to heat sealAvoid affecting the heat sealing effectWrapper twisting/gatheringHeat sealerEngineering

The invention discloses a heat sealing device of a food packaging bag, and relates to the technical field of packaging auxiliary equipment.The heat sealing device comprises a heat sealing rack and two heat sealing mechanisms, the top of the heat sealing rack is provided with a top frame, and each heat sealing mechanism comprises a side pressing support, a side pressing roller, a flattening piece and a heat sealing rotating supporting rod; the side pressing roller is arranged at the end, away from the top frame, of the side pressing support, the leveling piece is slidably arranged on the rod wall of the side pressing roller, the side pressing roller is provided with an elastic returning piece, the heat-sealing rotating supporting rod penetrates through the middle of the side pressing support and is rotationally connected with the side portion of the side pressing support, and a heat-sealing melting pressing plate is arranged at the bottom of the heat-sealing rotating supporting rod; a push-pull rod is arranged between the end part of the flattening piece and the heat-sealing rotating support rod; the device further comprises a driving piece and a flattening shifting piece. The flat shifting piece is arranged on the top frame and located between the two heat sealing mechanisms. The food packaging bag heat sealing device is simple in structure, the heat sealing flatness of food packaging bags can be improved through flatness and side pressure, then the heat sealing effect is improved, operation is convenient and fast, and practicability is high.

Owner:安徽德隆环保包装科技有限公司

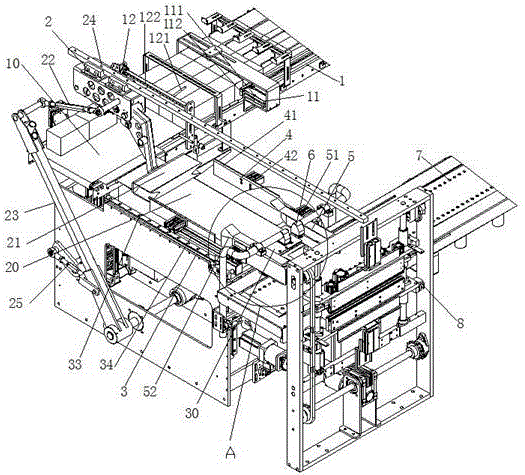

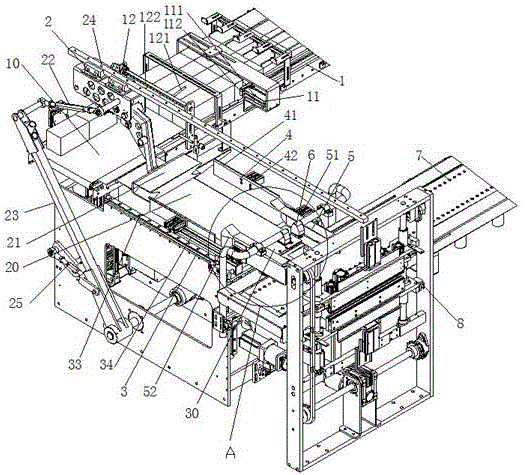

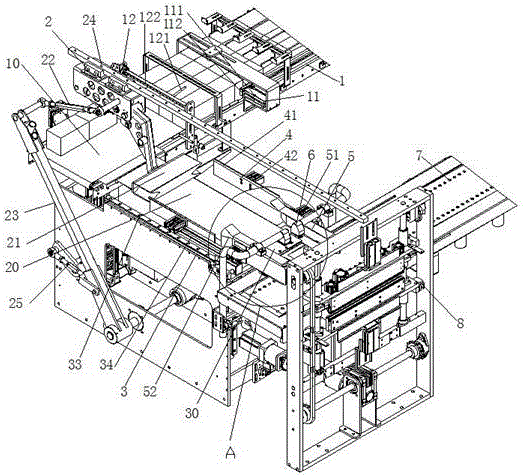

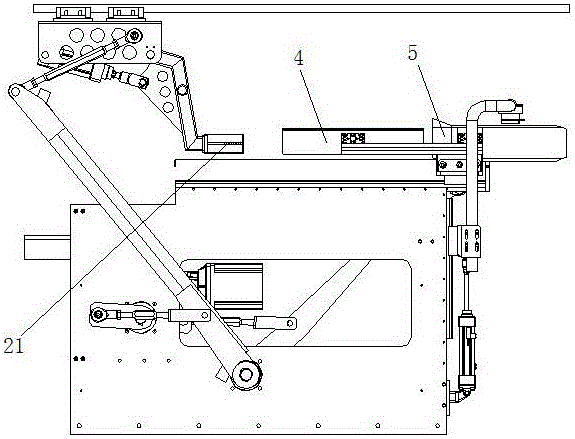

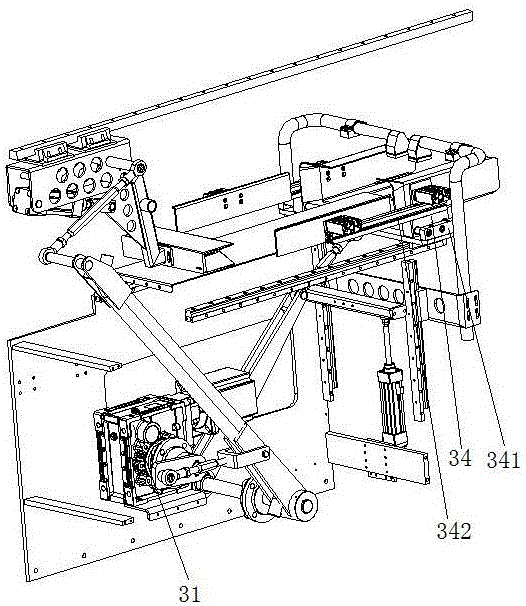

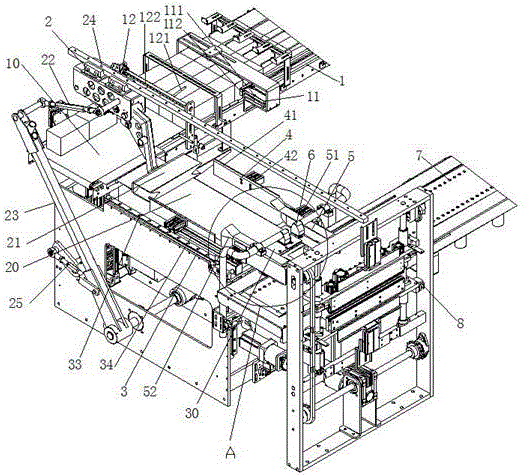

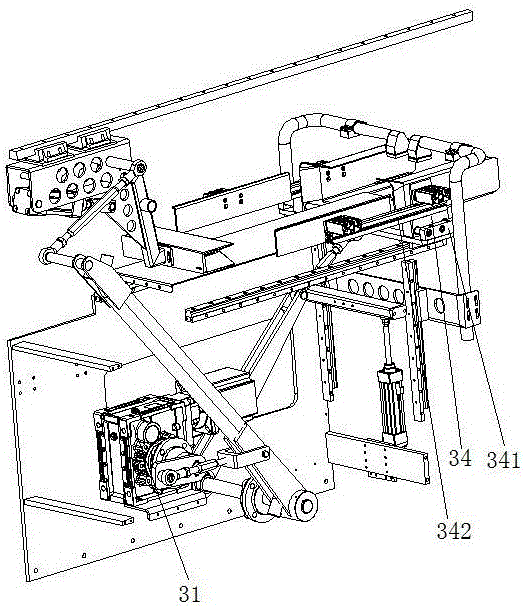

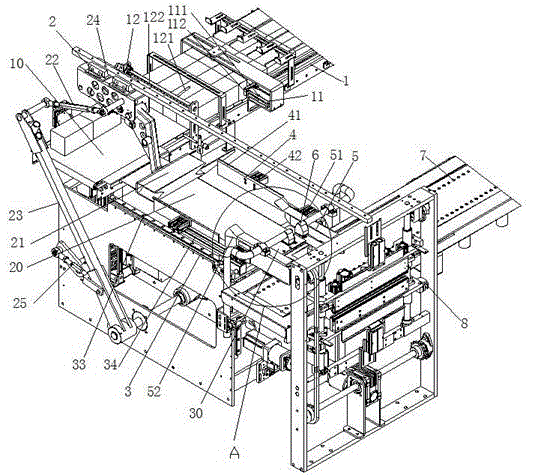

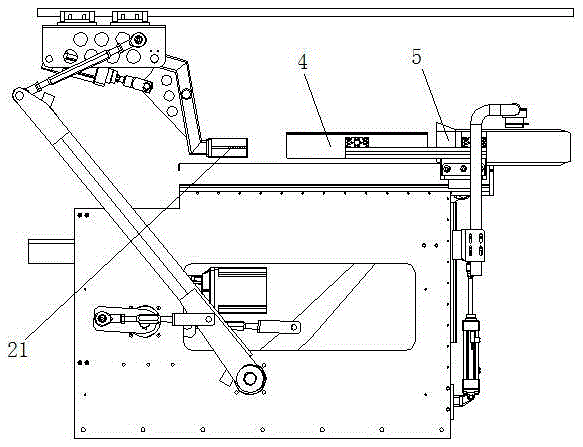

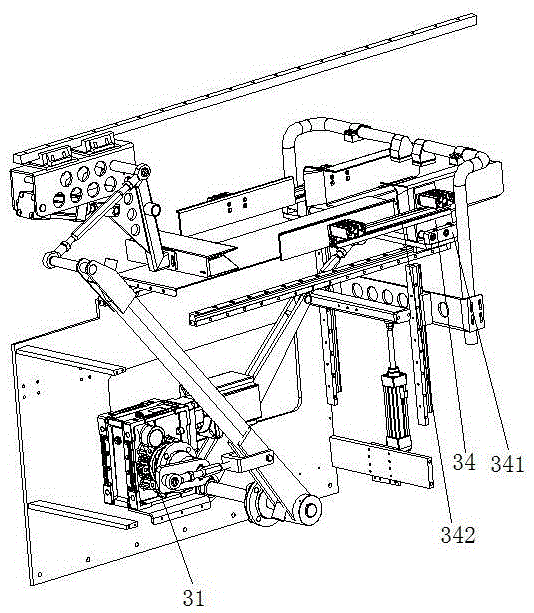

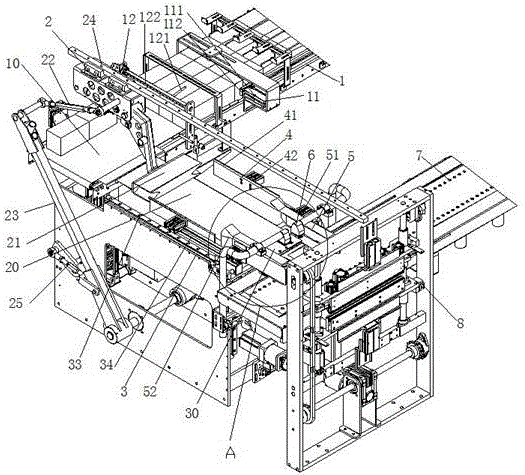

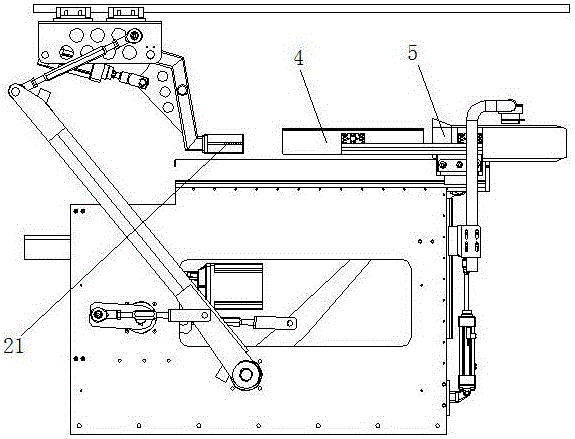

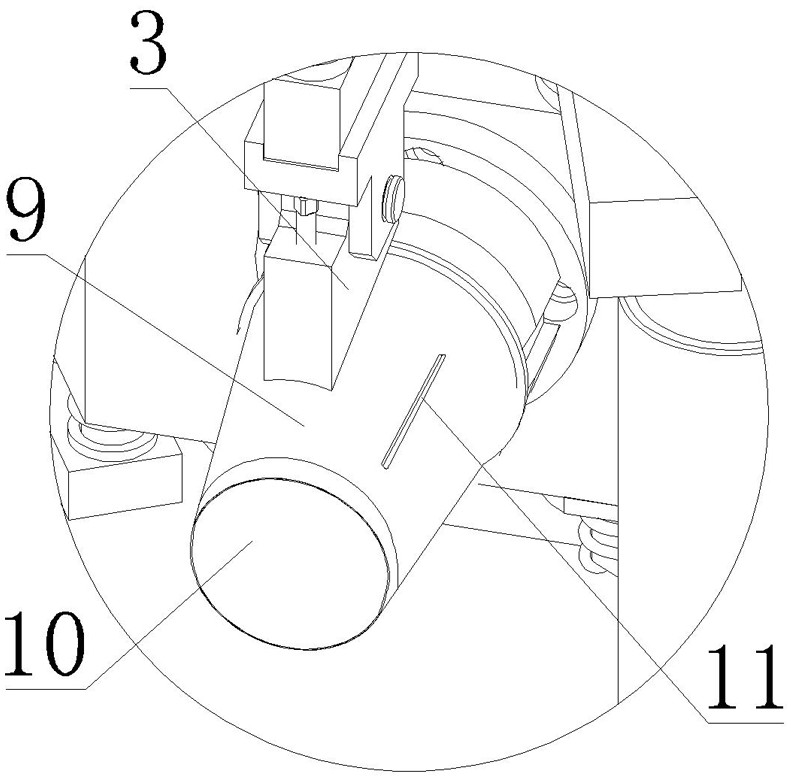

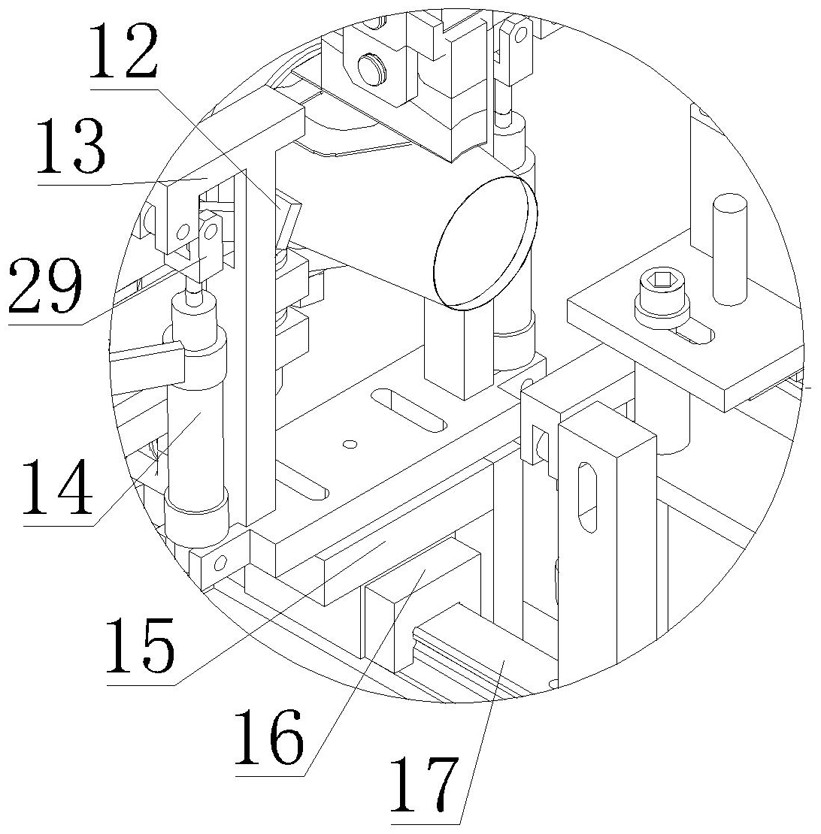

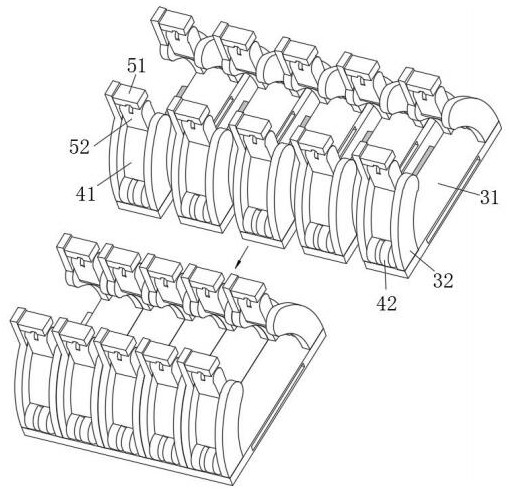

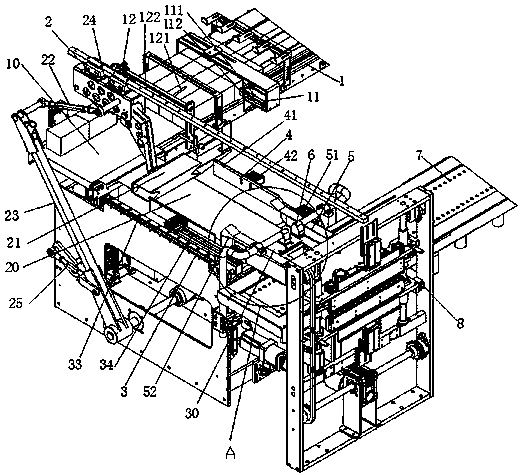

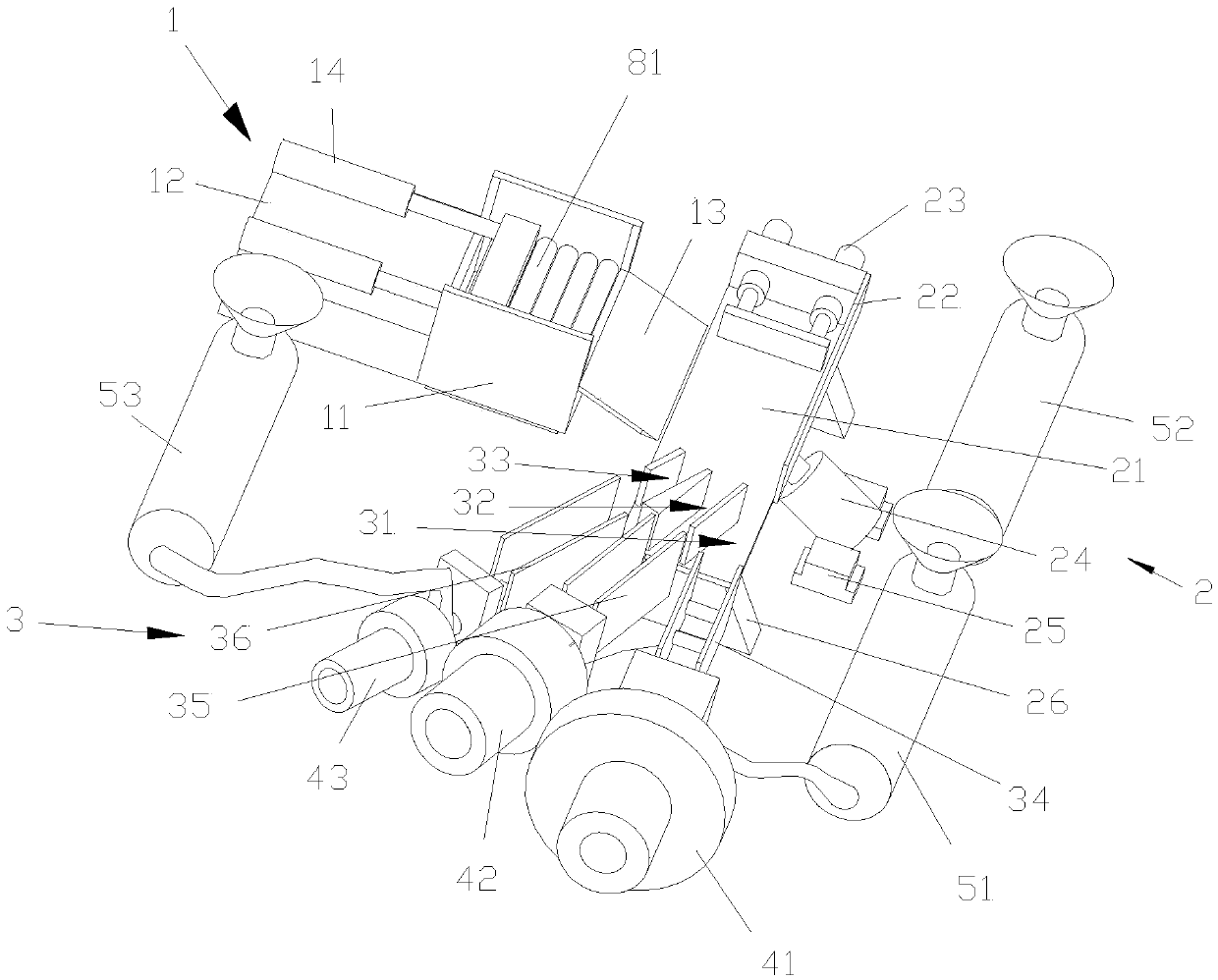

Packaging machine for packaging by adopting prefabricated bags

ActiveCN105620826ARealize the clamping effectRealize hugging and conveyingPackagingEngineeringSingle station

The invention discloses a packaging machine for packaging by adopting prefabricated bags, and relates to the technical field of packaging machinery. The packaging machine comprises a bag opening mechanism and further comprises a translation mechanism and a conveying device for moving in a material clamping or holding-conveying direction, wherein the conveying device is arranged behind the bag opening mechanism; the conveying device is connected to the translation mechanism, and is driven by the translation mechanism to move back and forth in the material clamping or holding-conveying direction. The packaging machine can solve the problems such as complex processes, many packaging actions, relatively long stroke between stations, great equipment floor space, easy material pouring due to irregular materials, easy prefabricated bag breaking, a long material pushing stroke, poor packaging effect, low packaging efficiency and the like on single station of prefabricated bag packaging machinery in the prior art.

Owner:上海松川峰冠包装自动化有限公司

Prefabricated bag packaging machine

ActiveCN105691713ASolve complexitySolve problems with more motionPackagingReciprocating motionEngineering

The invention discloses a prefabricated bag packaging machine, and relates to the technical field of packaging machinery. The prefabricated bag packaging machine adopts the structure that a clamping and conveying device is arranged between a to-be-clamped station and a bag opening station; the clamping and conveying device comprises a clamping mechanism and a translation mechanism; and the translation mechanism drives the clamping mechanism to perform reciprocating motion in the material clamping and conveying direction. The prefabricated bag packaging machine provided by the invention solves a plurality of problems in the prior art, for example, the working procedure at a single station of a conventional prefabricated bag packaging machine is complex; the quantity of packaging actions is large; the strokes among various stations are relatively long; the equipment occupied area is large; materials are irregular, and the possibility of material overturning is high; a prefabricated bag is liable to broken; the material pushing stroke is long; the packaging effect is poor; and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

Horizontal paper cup handle sticking machine

PendingCN111844882APrecise positioning weldingImprove aestheticsPaper-makingBox making operationsEngineeringPaper cup

The invention discloses a horizontal paper cup handle sticking machine. The horizontal paper cup handle sticking machine is characterized by comprising a paper cup conveying mechanism and a rotating frame, cup molds are arranged on the outer side wall of the rotating frame in a surrounding mode, a paper cup positioning rotating mechanism and a cup handle forming conveying mechanism are sequentially arranged along the rotating path of the rotating frame, a hot ironing head is arranged above each cup mold, and the hot ironing heads are connected with a lifting driving assembly. The horizontal paper cup handle sticking machine is simple in structure and reasonable in design, automatic forming and positioning welding operation of cup handles can be achieved, and the handle sticking quality andefficiency are effectively improved.

Owner:ZHEJIANG RUIDA MACHINERY

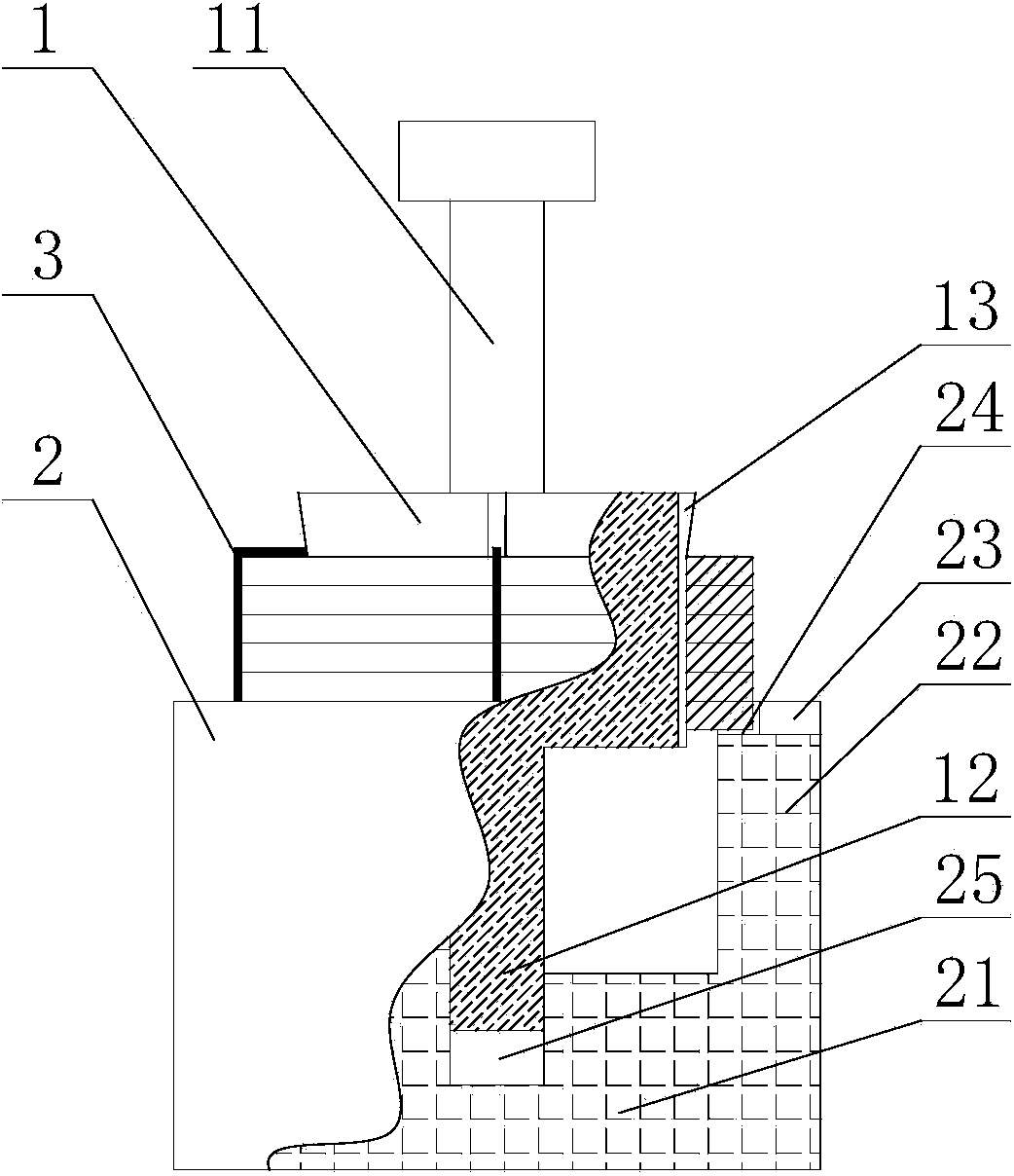

Efficient mobile phone laminator

ActiveCN111703065AEnsure gas cleanlinessImprove film application efficiencyDispersed particle filtrationDomestic articlesElectrical and Electronics engineeringMechanical engineering

The invention discloses an efficient mobile phone laminator. The efficient mobile phone laminator comprises a mobile phone laminator structure, wherein the mobile phone laminator structure comprises alaminating machine, the laminating machine comprises a machine cover and a machine body, the mobile phone laminator structure further comprises a purification body, a correction body and a machine cover locating body, the lower end of the laminating machine is fixedly mounted on the upper wall of the front portion of the purification body, the rear end of the purification body is connected with an external air pump pipeline, the laminating machine is connected with the external air pump pipeline, the machine cover locating body is fixedly mounted at the front end of one side of the laminatingmachine, the correction body is mounted at the front end of the other side of the laminating machine in a sliding mode, the purification body comprises a connector, a sealing cover, a first screw, aflange, a filter sheet, a sealing frame, a fixed frame and a supporting net, the front end of the connector is fixedly connected to the rear end of the sealing cover, and front-side space of the sealing cover is connected with internal space of the connector in a communicating mode. The efficient mobile phone laminator can improve laminating working efficiency and better meet application demands.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

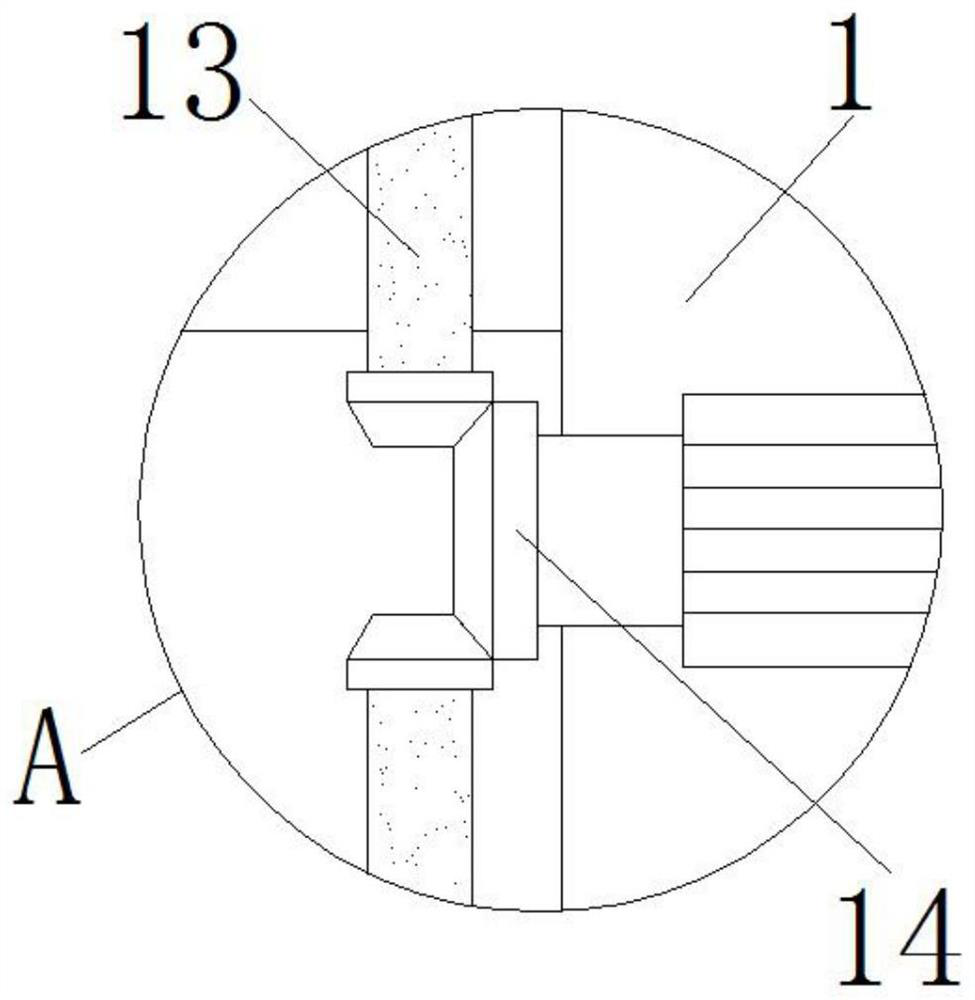

Steel wire retainer ring shaping mechanism

The invention discloses a steel wire retainer ring shaping mechanism. The mechanism comprises a cylinder core body, a sleeve and a fastening steel wire, wherein a stress block upwards projected is arranged in the middle of the upper surface of the cylinder core body, and a guide support column downwards extending is arranged on the lower surface of the cylinder core body; a groove downwards axially extending from the upper surface is formed in the side wall of the cylinder core body; the outer wall of the cylinder core body and the inner wall of a steel wire retainer ring to be shaped fit in shape; the sleeve comprises a baseplate and a cylindrical side wall, and coats the external of the cylinder core body; an annular limiting piece upwards extending from the top surface is arranged at the top of the cylindrical side wall, and is coaxial with the cylindrical side wall; a notch is formed in the inner wall of the annular limiting piece, and is opposite to the groove of the cylinder core body; a guide through hole axially downwards extending from the upper surface is formed in the baseplate, and fits the guide support column for use; and the fastening steel wire fastens the steel wire retainer ring to be shaped on the outer wall of the cylinder core body, and is positioned in the groove and the notch. The mechanism is simple in structure and easy in operation, and realizes the batch shaping of the steel wire retainer ring.

Owner:ANHUI NINGGUO DONGBO FASTENER

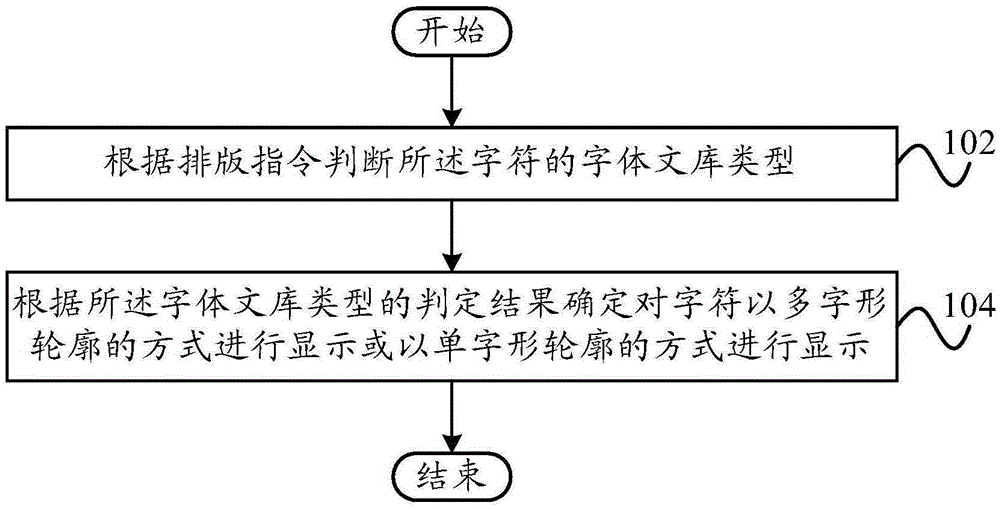

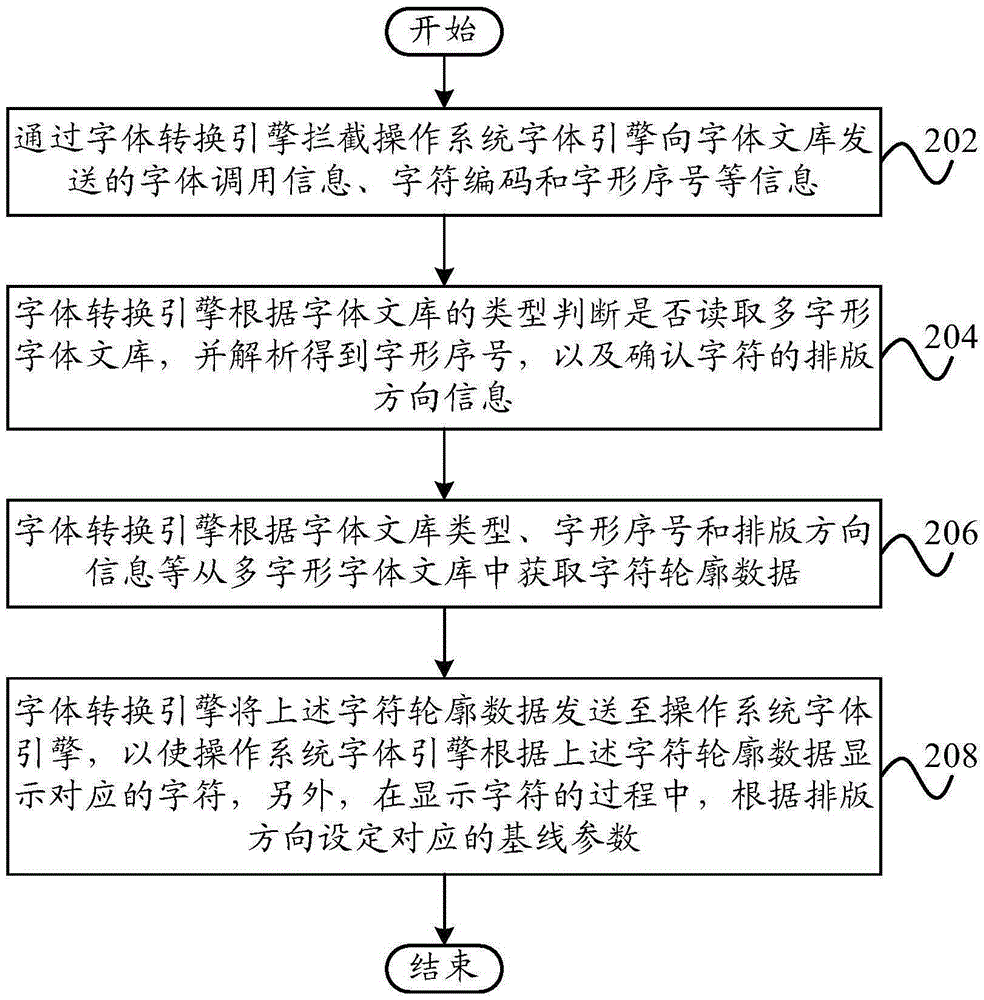

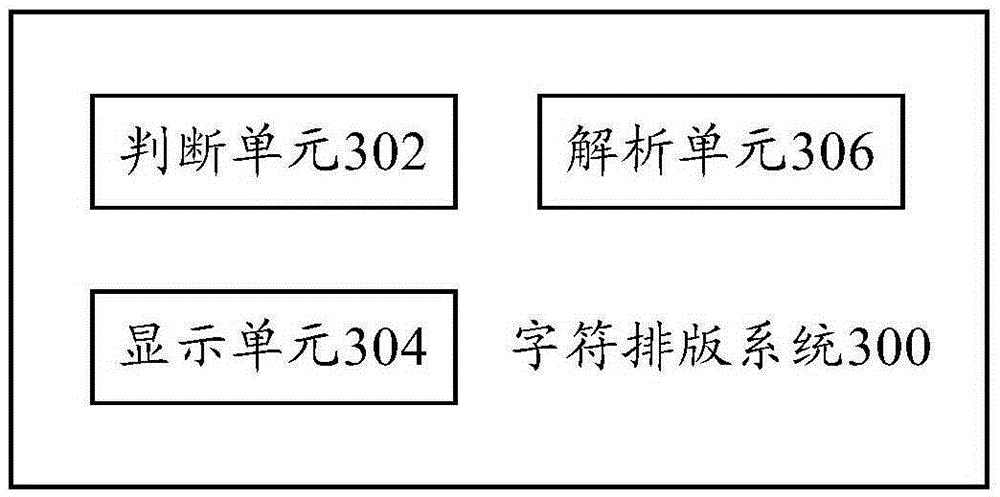

Character typesetting method, system and apparatus

InactiveCN106708788ARich display methodsSimplify typesetting stepsSpecial data processing applicationsGlyphAlgorithm

The invention provides a character typesetting method, system and apparatus. The character typesetting method comprises the steps of judging a font library type of a character according to a typesetting instruction; and determining that the character is displayed in a multi-font or single-font outline manner according to a judgment result of the font library type. Through the technical scheme, the character display mode is enriched, baseline adjustment of characters in different typesetting directions is realized, the typesetting efficiency is improved, the operation step of a user is simplified, and the usage experience of the user is improved.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

Double-chain stitch sewing machine

The invention belongs to the technical field of double-chain stitch sewing machines, and particularly relates to a double-chain stitch sewing machine which comprises a working platform, a machine base and machine needles, wherein the machine base is fixedly mounted on the upper surface of the working platform; the two groups of machine needles are arranged at the end part of the machine base; horizontal sliding rails are arranged on the front side and the rear side of the upper surface of the working platform; a first sliding block is arranged in the horizontal sliding rail located at the front end in a sliding mode; and a second sliding block is arranged in the horizontal sliding rail located at the rear end in a sliding mode. An elastic pressing plate can press two sides of fabric needing to be sewn to the top of a guide sliding plate, then the position of the fabric is fixed, and then the guide sliding plate is pushed to slide in a limiting sliding groove body, so that threading of the machine needles can be more straight, the stitch neatness of sewn clothes is improved, and thus the quality of the clothes is improved. The device is particularly suitable for being used by a sewing novice, and the situation that a hand is punctured by the needles when the novice puts the fabric needing to be sewn to be close to the machine needles and tightly presses the fabric on the working platform with the hand is avoided.

Owner:徐州力达缝纫设备制造有限公司

Metal surface treatment electroplating processing method

PendingCN113832515AImprove the quality of electroplatingEfficient removalGrinding machinesCleansing AgentsMachine tool

The invention discloses a metal surface treatment electroplating processing method. The metal surface treatment electroplating processing method comprises the following steps: A, oil removal, cleaning and drying treatment is carried out on the surface of a metal part; and B, cutting and grinding treatment is conducted on the metal part. In the step A, the metal part is put into an oil removal agent for oil removal treatment, then the metal part is put into a cleaning agent for cleaning treatment, finally the metal part is put into a drying box for drying treatment, the drying temperature is 80-100 DEG C, and the drying time is 3-8 minutes; and in the step B, the metal part is cut and ground through a machine tool, and the surface of the metal part is more neat. According to the metal surface treatment electroplating processing method, the surface of the metal part is subjected to oil removal, cleaning and drying treatment firstly, oil stains and other impurities on the surface of the metal part can be effectively removed, the metal part is cut and ground after being dried, and the surface neatness of the metal part can be effectively improved; and meanwhile, the metal part is rinsed after electroplating is completed, and redundant electroplating liquid on the surface of the metal part can be effectively rinsed, so that the electroplating quality of the metal part is effectively improved.

Owner:邦仪精密科技(苏州)有限公司

A kind of underglaze multicolored screen printing method for ceramics

The invention relates to a ceramic underglaze five-color silk screen transfer printing method which comprises the following steps: carrying out ball milling on a ceramic raw material and screening to prepare a slurry, and carrying out mold injection molding into the required shape to obtain a billet; glazing, and firing to obtain a glaze billet; brushing a water-containing adhesive on the surface of the glaze billet; attaching a silk screen prepared according to the required pattern to the surface of the glaze billet by silk screen transfer printing, spreading the prepared pigments in the pattern formed by the silk screen on the glaze billet, peeling off the silk screen to form the required pattern outline, dipping the underglaze five-color pigments with a painting device, carrying out painting decoration on the pattern outline to obtain a color billet, and carrying out color treatment to spread a glaze layer on the surface of the color billet; and firing the color billet coated with the transparent glaze in a kiln at high temperature to obtain the underglaze five-color ceramic article.

Owner:HUNAN NEW CENTURY CERAMICS

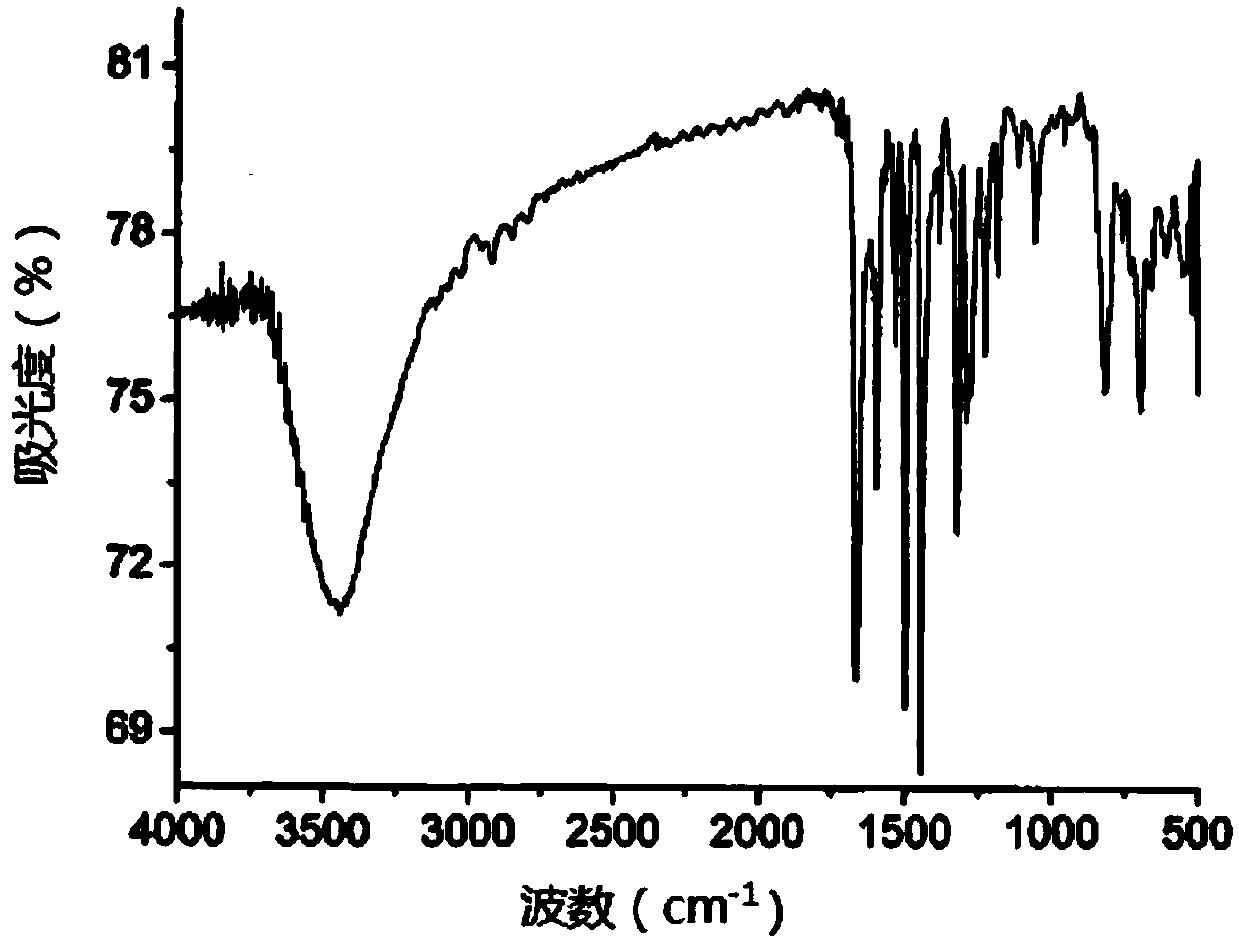

Preparation method of graphene film

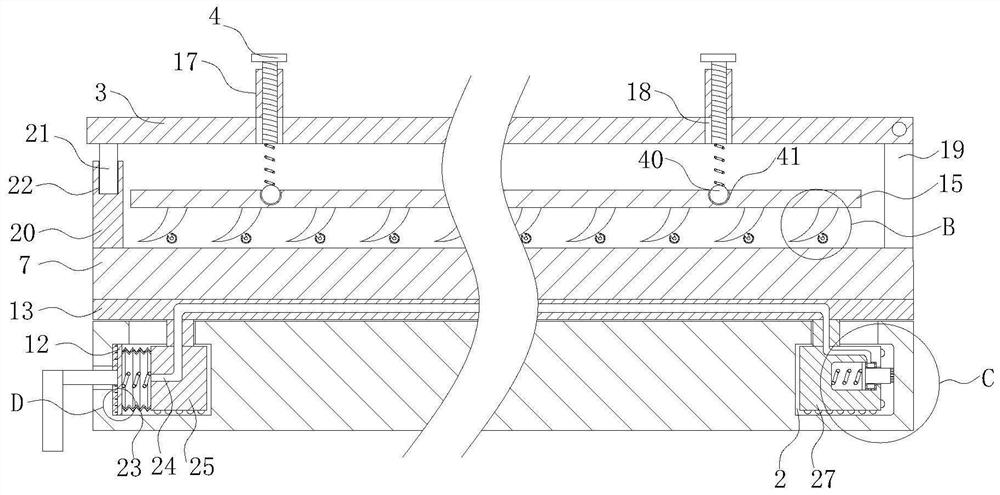

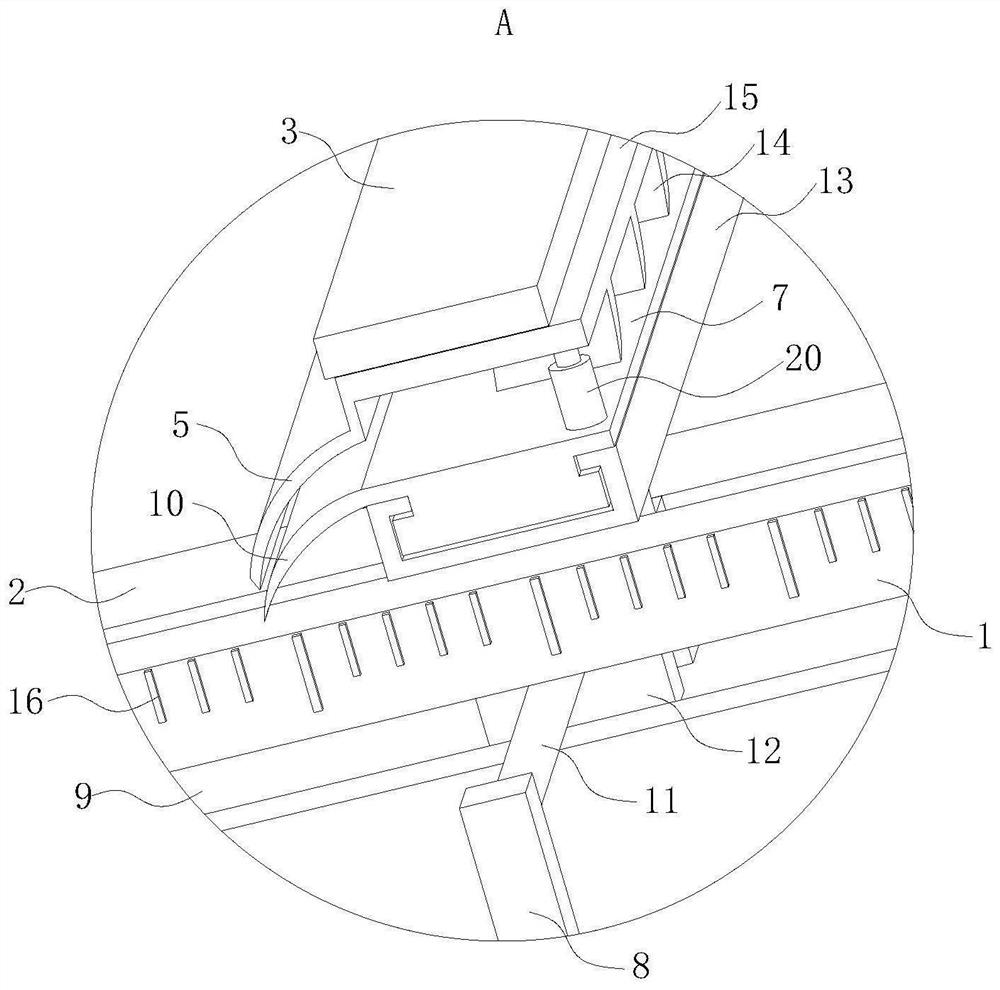

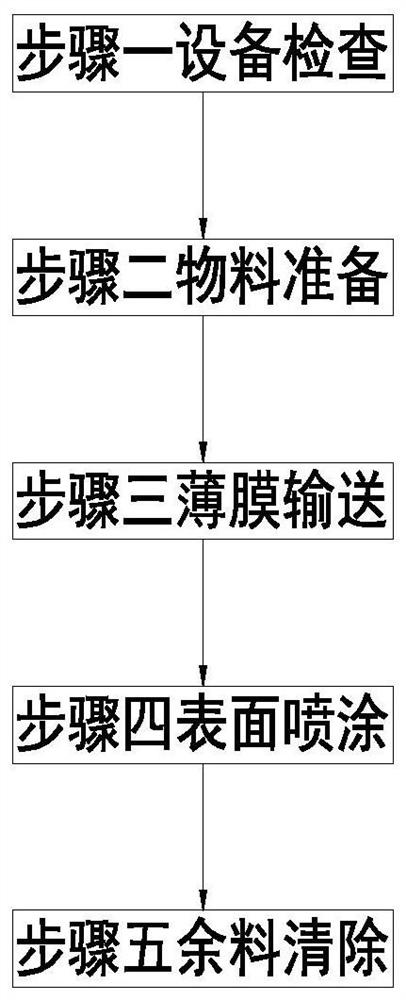

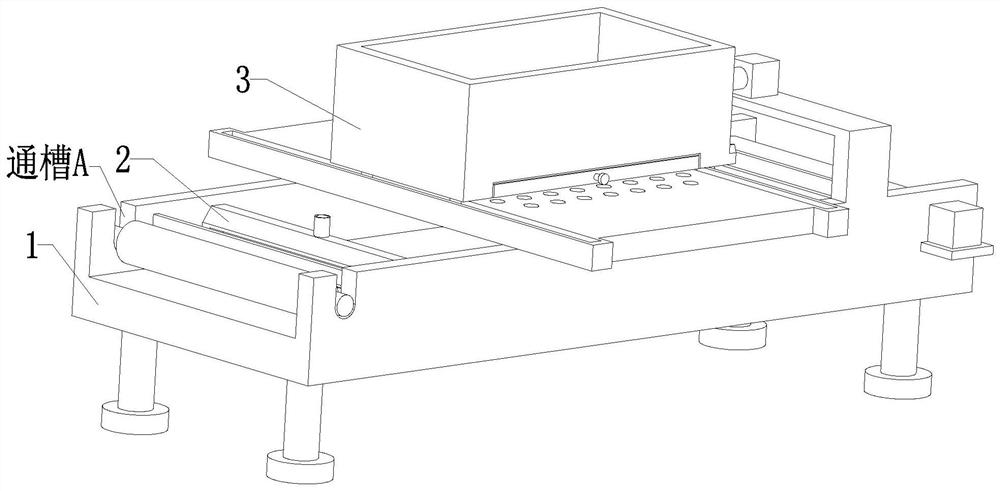

ActiveCN113117993AImprove uniformityImprove laying effectLiquid surface applicatorsCleaning using toolsThin membraneGraphene

The invention relates to a preparation method of a graphene film. The preparation method mainly comprises the following steps of equipment inspection, material preparation, film conveying, surface spraying and excess material removal. Graphene film forming equipment comprises a mounting frame, a traction set and a spraying set, and the traction set and the spraying set are sequentially arranged on the mounting frame from outside to inside. According to the invention, the following problems in the production process of an existing graphene film can be solved: a, graphene on the surface of the film is often not uniformly covered when the existing graphene film is produced, so that the quality of the graphene film is greatly influenced; and b, when the existing graphene film is laminated, the surface of the graphene film is often dirty, so that a blind area appears when the graphene powder is covered, the laminating effect of the graphene powder is further influenced, and the quality of the graphene film is reduced.

Owner:东莞轻享生活科技有限公司

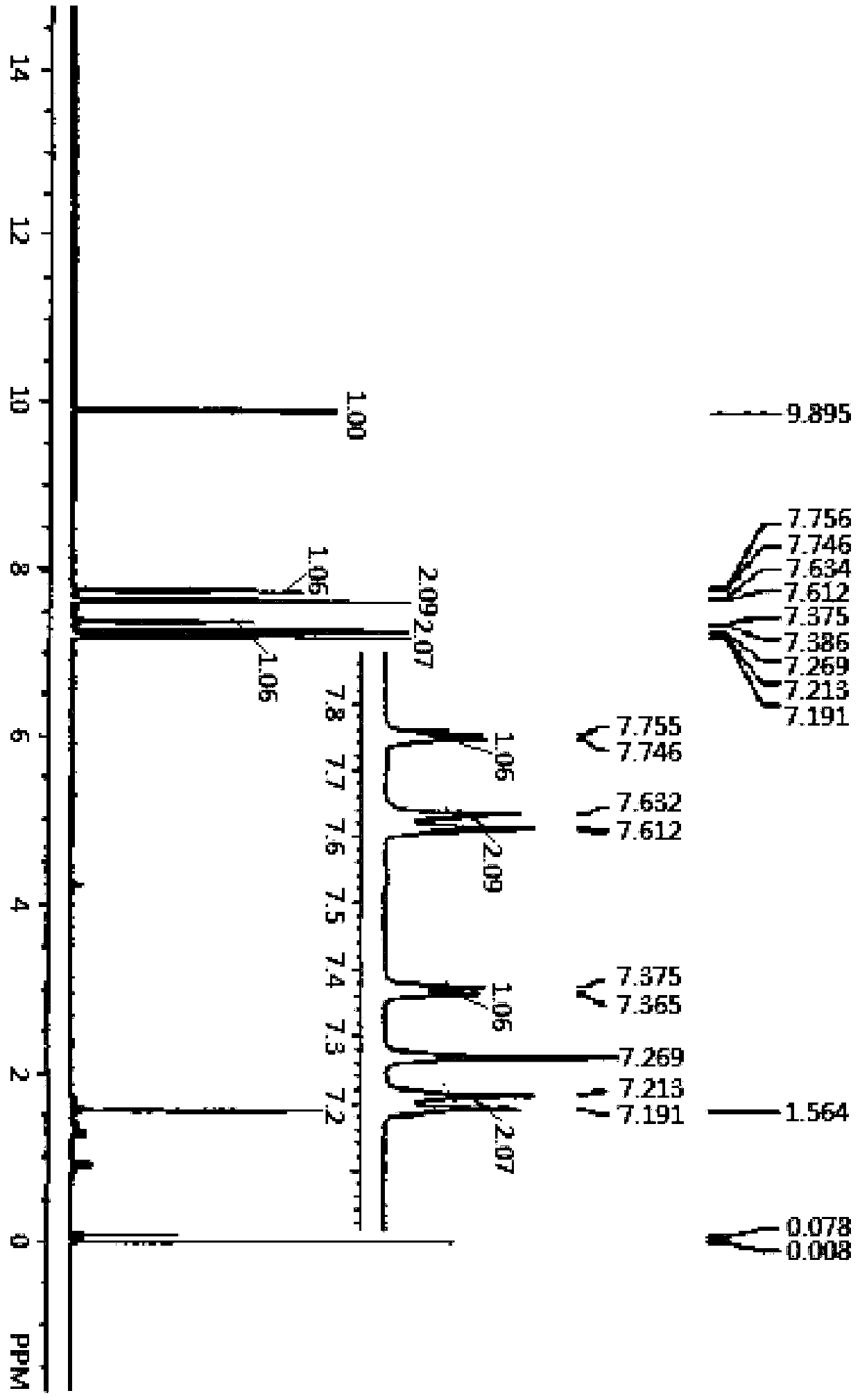

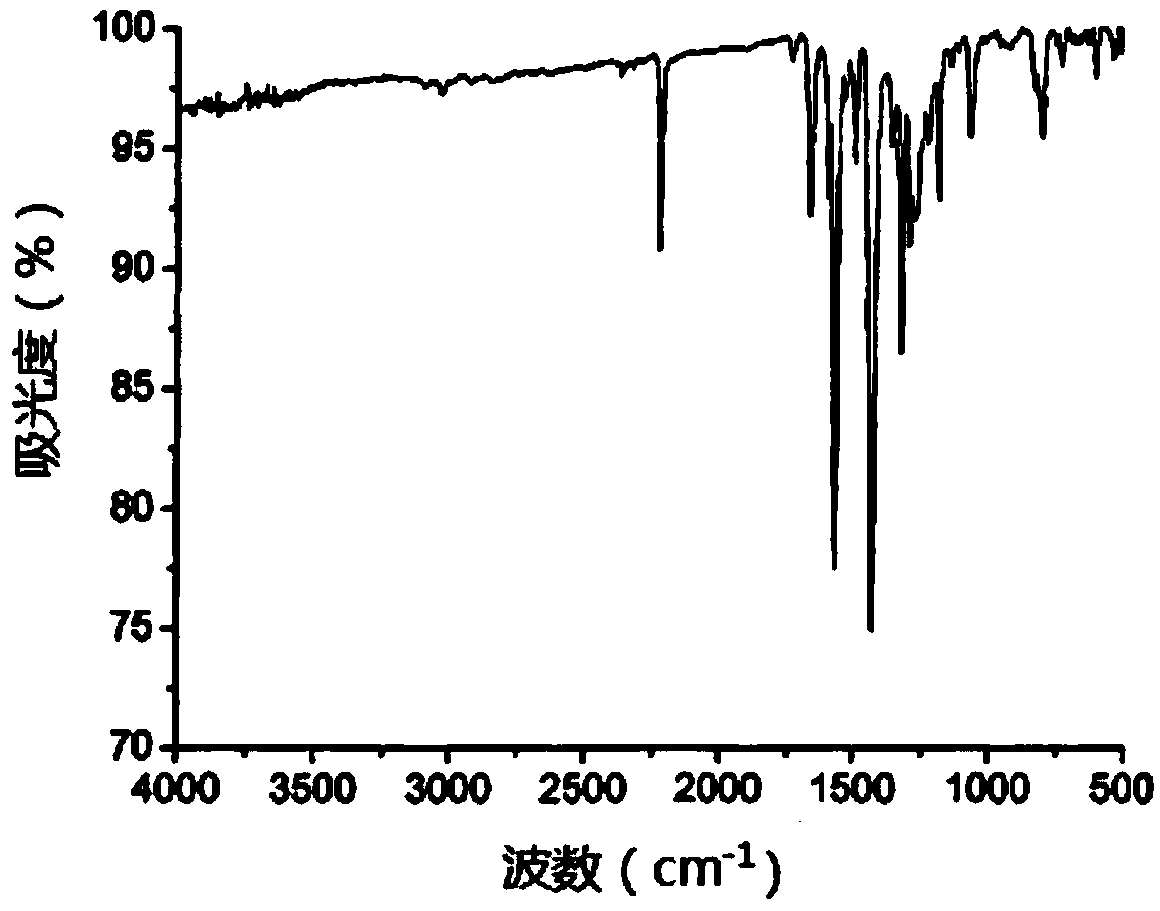

Organic hole transport material, preparation method and applications thereof

InactiveCN111116544AHigh melting pointHigh glass transition temperatureOrganic chemistrySolid-state devicesArylPolymer science

The invention provides an organic hole transport material, a preparation method and applications thereof. The organic hole transport material is one or a plurality of materials selected from triarylamine-thiophene system compounds, wherein the structure is represented by a formula I, R<1>, R<2>, R<3>, R<4>, R<5>, R<6>, R<7>, R<8> and R<9> are respectively and independently selected from a hydrogenatom, a halogen atom, a formyl group, a carboxyl group, a C1-C6 substituted or unsubstituted alkyl group, a C2-C5 substituted or unsubstituted alkenyl group, a C3-C10 substituted or unsubstituted cycloalkyl group and a C6-C10 aryl group. By adopting the organic hole transport material, the problems of poor hole transport capacity, low glass-transition temperature and poor film-forming property ofthe hole transport material in the prior art are solved.

Owner:紫石能源有限公司

Steel rolling process and rolling machine

PendingCN113579017AImprove wear resistanceImprove extreme pressure performanceShaping toolsOther manufacturing equipments/toolsEngineeringMachine

The invention discloses a steel rolling process and a rolling machine, relates to steel processing, and aims to solve the problems that when adjustment is carried out on compression rollers, the acting force of the two ends of the compression rollers to steel is easily inconsistent, the pressure borne by the two edges of the steel is different, and the regularity and the wall thickness of rolling are affected. According to the key points of the technical scheme, the rolling machine comprises a machine frame, supporting frames are fixedly connected to the machine frame, a plurality of transmission rollers are rotationally connected to a position between the supporting frames, the compression rollers rotationally connected with the supporting frames are slidably connected to the supporting frames, adjusting assemblies connected with the compression rollers to drive the compression rollers to move vertically are arranged at the top ends of the supporting frames, and a balancing rod is arranged between the adjacent adjusting assemblies in a hinged mode. According to the steel rolling process and the rolling machine, the balance rod is arranged between the two adjusting assemblies in a hinged mode, the two adjusting assemblies independently adjust the ends of the compression rollers, people can judge the levelness of the compression rollers by detecting the levelness of the balance rod, then people can conveniently know the extrusion condition of the compression rollers on the steel and the transmission rollers, and the consistency of rolling of the steel is improved.

Owner:嵊州市升达钢材有限公司

An electrical control cabinet

ActiveCN113241615BAvoid wastingImprove neatnessBus-bar/wiring layoutsElectrical controlControl theory

The invention provides an electrical control cabinet, which belongs to the technical field of electrical control, and includes a cabinet body. The cabinet body is provided with an assembly layout surface, and an auxiliary connection part is correspondingly provided on the assembly layout surface. The path extension part of the reserved amount of the connection line, the force point transfer part is connected between the path extension part and the auxiliary connection part, and the positioning component and the restriction component are connected between the auxiliary connection part and the path expansion part. The invention forms a rigid expansion route through the combination of the auxiliary connection part, the path expansion part, the force point transfer part, the positioning component and the limiting component, and precisely controls the reserved amount of the connecting line, effectively avoiding the problem of the connection line. Waste greatly improves the neatness and aesthetics of the wiring arrangement in the control cabinet, and correspondingly improves the neatness inside the control cabinet. At the same time, it has the advantages of good stability, energy saving, environmental protection and space saving.

Owner:深圳市壹云智能科技有限公司

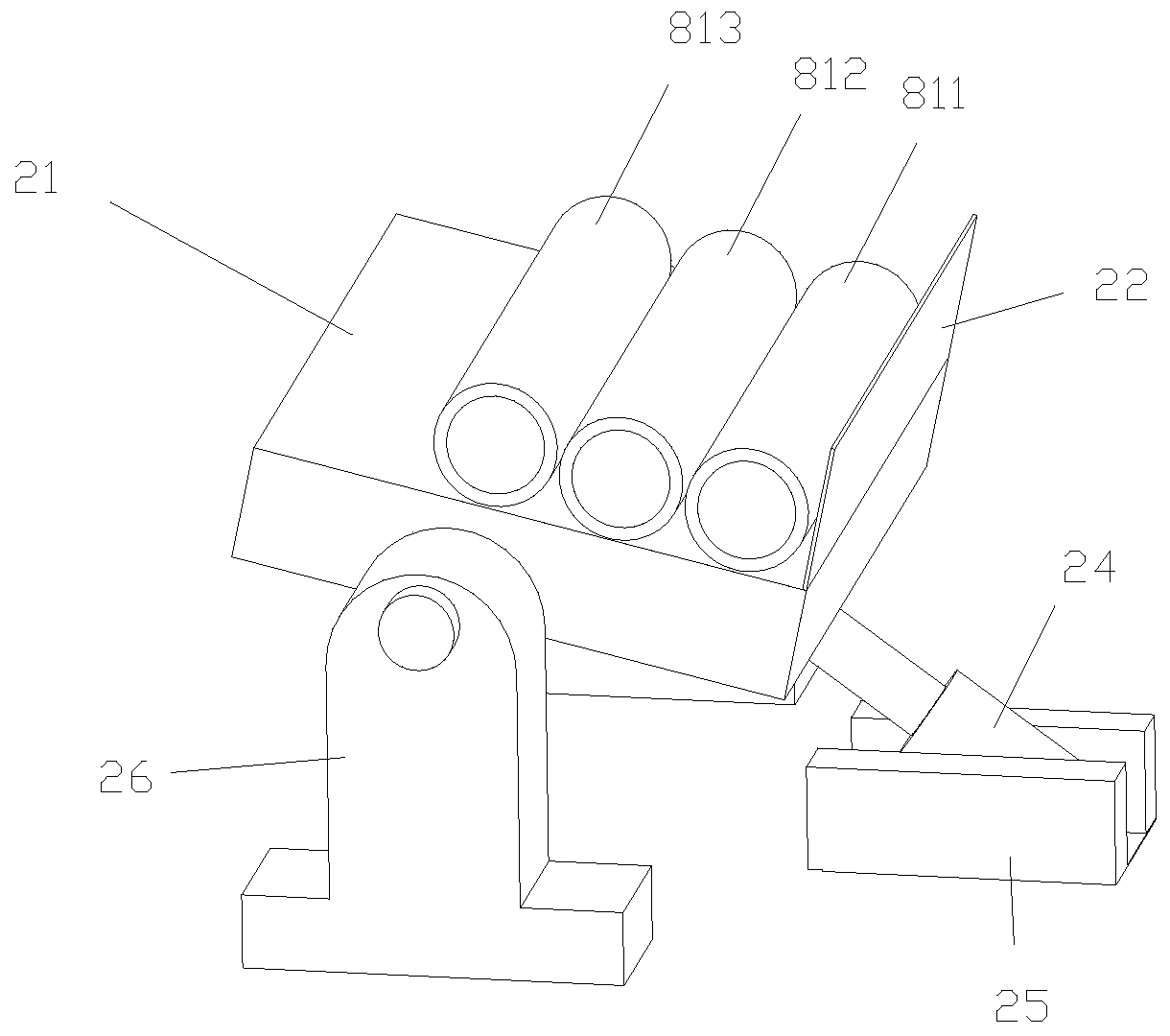

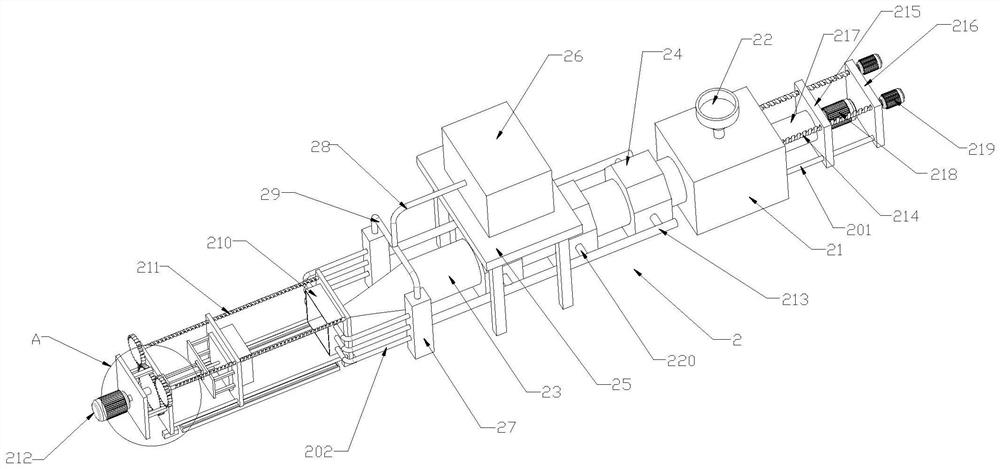

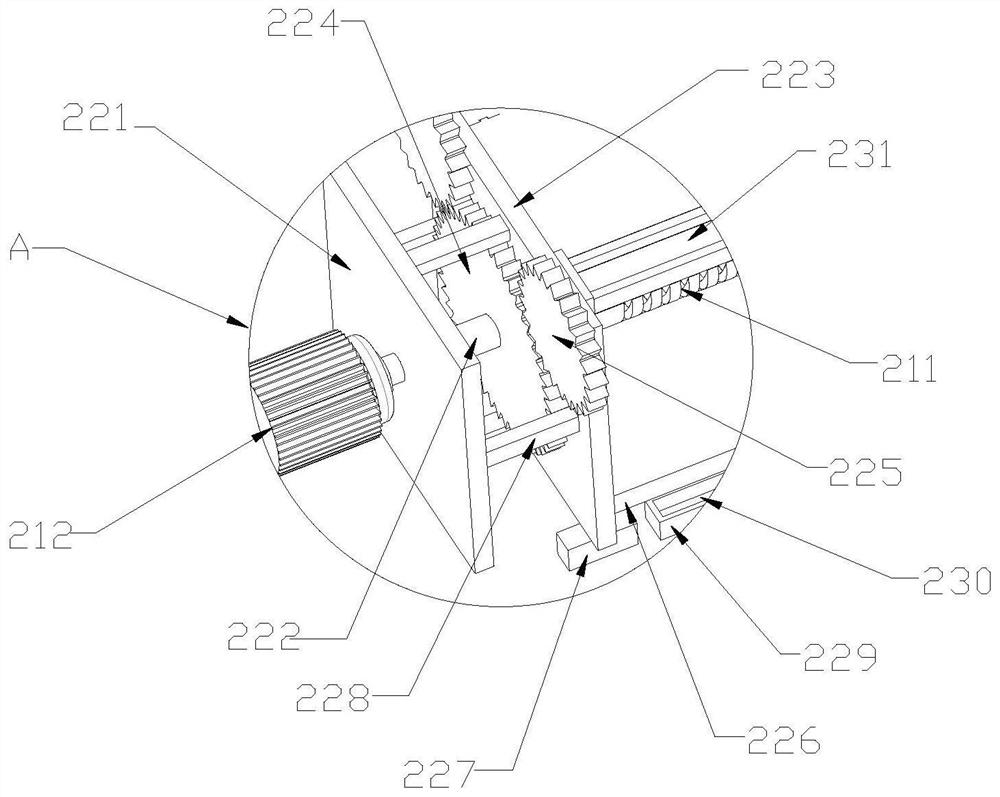

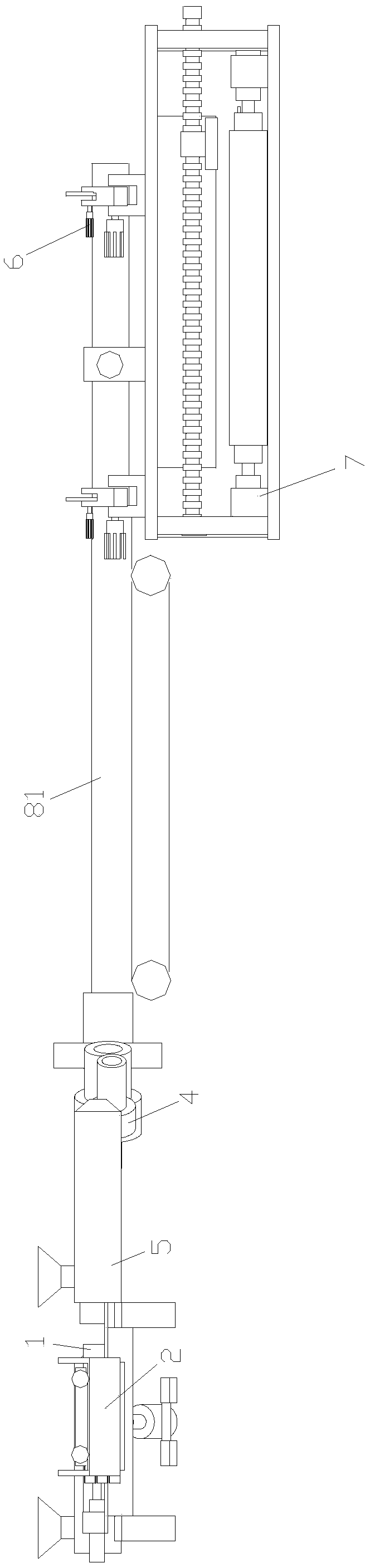

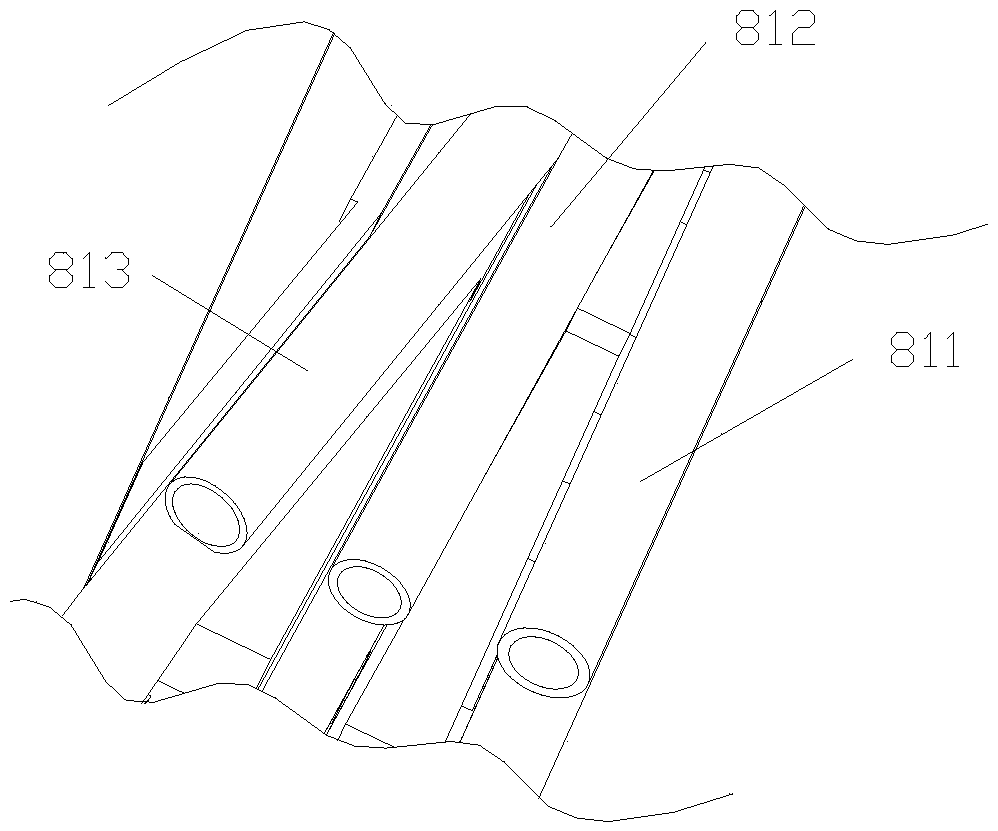

Composite steel pipe processing mechanism, structurally reinforced drainage pipe processed by this mechanism

ActiveCN108819159BImprove neatnessImprove feeding efficiencyCoatingsTubular articlesPolyvinyl chlorideManganese

The invention discloses a structure-reinforced drainage pipe. The structure-reinforced drainage pipe comprises a steel billet pipe and a resin material layer which is extruded on the outer surface ofthe steel billet pipe. A resin material comprises the following raw materials by weight: 60-85 parts of polypropylene resin, 20-30 parts of polyvinyl chloride resin, 3-8 parts of barium sulfate, 12-17parts of glass fibers, 11-17 parts of calcium carbonate and 2-5 parts of titanium dioxide. The steel billet pipe consists of the following components by weight: 2-3 parts of carbon, 4-5 parts of silicon, 15-18 parts of manganese, 12-15 parts of nickel, 0.1-0.4 part of sulfur, 0.3-0.5 part of phosphorus, 0.3-1 part of vanadium and 70-90 parts of iron. The invention further discloses a composite steel pipe processing mechanism. The structure-reinforced drainage pipe disclosed by the invention has the advantages of high strength and large binding strength.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

Forming device for smart meter housing

ActiveCN113021748BImprove neatnessReduce the waste of manpower and material resourcesEdge grinding machinesTime integral measurementMaterial resourcesSmart meter

Owner:浙江能兴电气科技有限公司

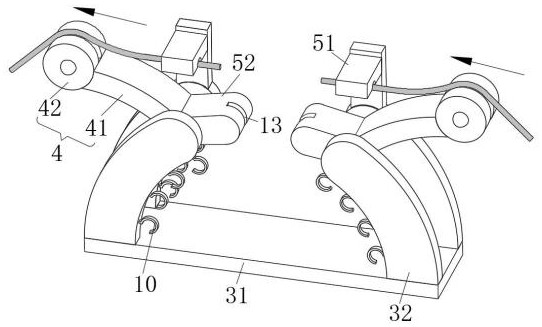

Premade Bag Packaging Machine

ActiveCN105691713BShorten the timePrevent the situation of dumpingPackagingReciprocating motionSingle station

A prefabricated bag packaging machine. A clamping and conveying device is disposed between a to-be-clamped station (10) and a bag opening station (30); the clamping and conveying device comprises a clamping mechanism (4) and a translation mechanism (3); and the translation mechanism (3) drives the clamping mechanism (4) to perform reciprocating motion in the material clamping and conveying direction. The prefabricated bag packaging machine resolves the problems in the prior art of complex working procedures of a single station, the great quantity of packaging actions, long travel distance among stations, large area occupied by the devices; easy overturning of materials due to the irregular materials, easy breaking of prefabricated bags, long travel distance of material pushing, poor packaging effect and low packaging efficiency of the existing prefabricated bag packaging machine.

Owner:上海松川峰冠包装自动化有限公司

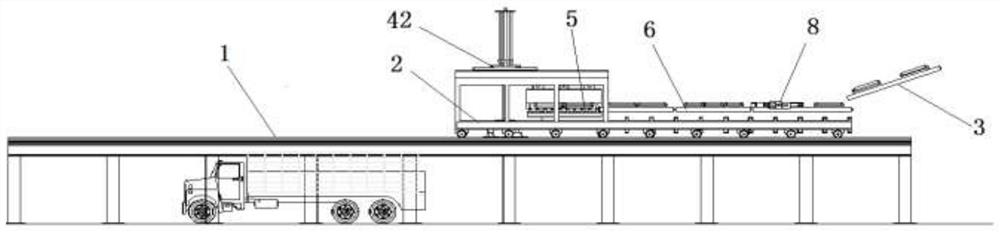

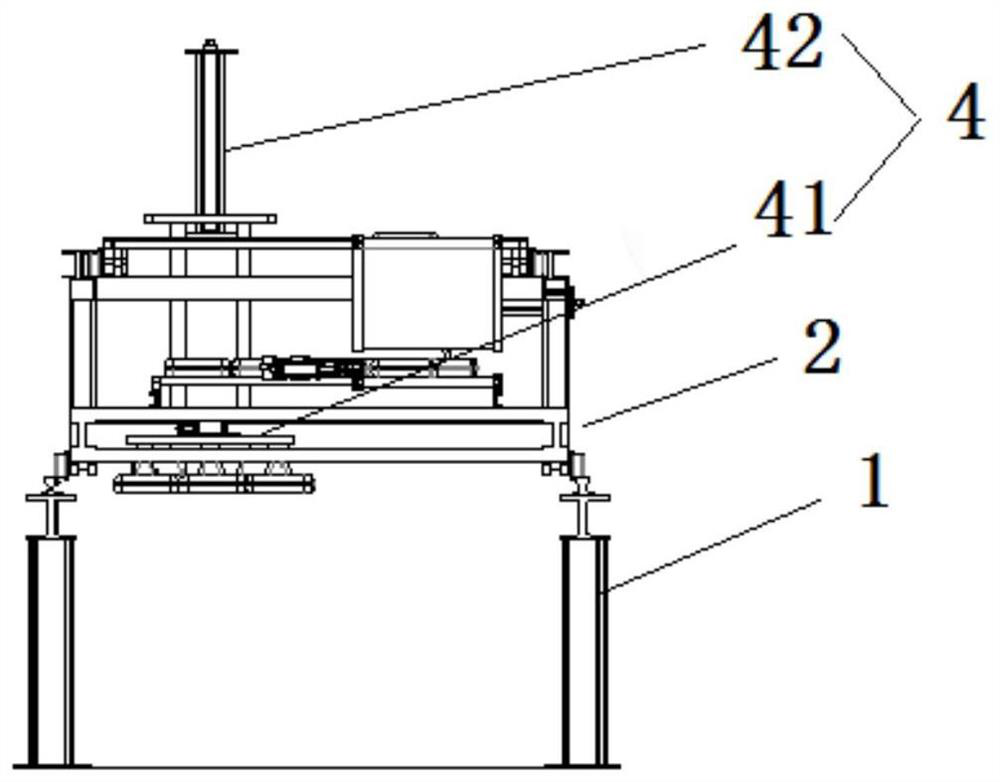

A truss loading system

ActiveCN109051874BImprove loading speedImprove neatnessStacking articlesDe-stacking articlesClassical mechanicsEngineering

Owner:芜湖固高自动化技术有限公司

Machining mechanism for inner-outer double-layer anti-corrosive stainless steel drainage pipes, and machining method thereof

ActiveCN108673148AImprove neatnessAchieve high integrationOther manufacturing equipments/toolsMaterials sciencePush out

The invention discloses a machining mechanism for inner-outer double-layer anti-corrosive stainless steel drainage pipes. The machining mechanism comprises a stainless steel pipe billet feeding device, an alignment push-out device, a multidirectional pipe guide device, a die head, an extruder, a cutting blanking device and a lining compounding device. The invention further discloses a method for machining stainless steel pipe billets by virtue of the machining mechanism for the inner-outer double-layer anti-corrosive stainless steel drainage pipes. The machining mechanism and the method have the advantages of achieving inner-side and outer-side continuous loading, increasing the loading efficiency, and realizing high integration for equipment.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com