Steel rolling process and rolling machine

A technology of steel coiling and rounding machine, which is applied in the field of steel processing, and can solve problems such as inconsistency of extrusion force, pressure difference, and influence on coil regularity and wall thickness, so as to improve quality, improve neatness, and good resistance abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A kind of steel coiling process, its step comprises:

[0053] S1 blank processing, cutting the steel material into a blank of required size, specifically, the steps of step S1 blank processing include:

[0054] S11 Scribing, use a talc pen to draw a rectangular marking line on the steel surface according to the marking line of the specified specification;

[0055] S12 cutting, cutting the steel along the marking line to obtain the blank plate, ensuring good parallelism between the blank plate and the edge of the blank plate;

[0056] S13 splicing, welding a plurality of slabs to form a plate-shaped blank, specifically, welding the slabs by electric welding, and then welding along the edges of the slabs to form a welded edge;

[0057] S2 grinding, grinding the plane of the cut blank, and grinding along the edge of the blank to remove burrs, specifically, the specific steps of step S2 grinding include:

[0058] S21 pre-pressing, cold pressing the welding part of the sla...

Embodiment 2

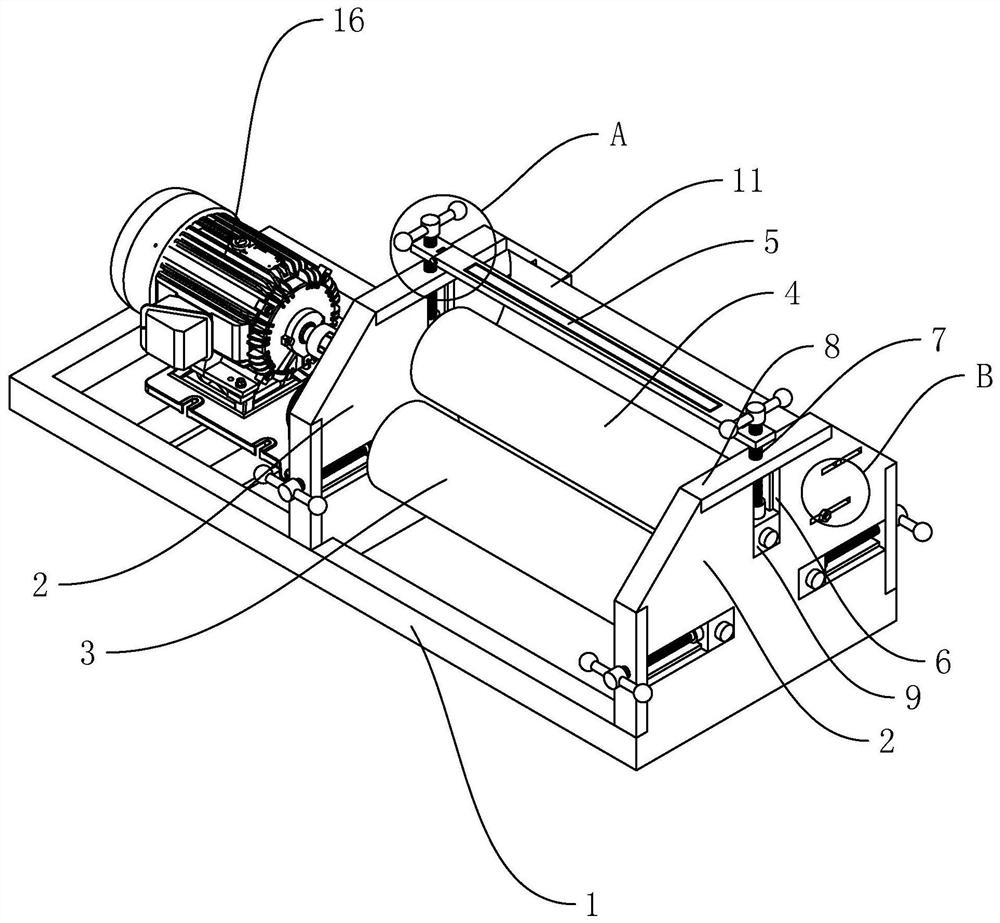

[0067] Embodiment two: if figure 1 and Figure 4 As shown, a steel rolling machine is applied to the steel rolling process in Embodiment 1, including a frame 1, a support frame 2 is fixedly connected to the frame 1, and a plurality of transmission rollers 3 are rotatably connected between the support frames 2 , the support frame 2 is slidingly connected with the pressure roller 4 that is rotationally connected with the support frame 2, and the top of the support frame 2 is provided with an adjustment assembly that is connected with the pressure roller 4 to drive the vertical displacement of the pressure roller 4, and the adjacent adjustment assemblies are hinged There is a balance bar 5, and the frame 1 is fixedly connected with a driving assembly connected with the driving rollers 3 for driving the adjacent driving rollers 3 to rotate in the same direction.

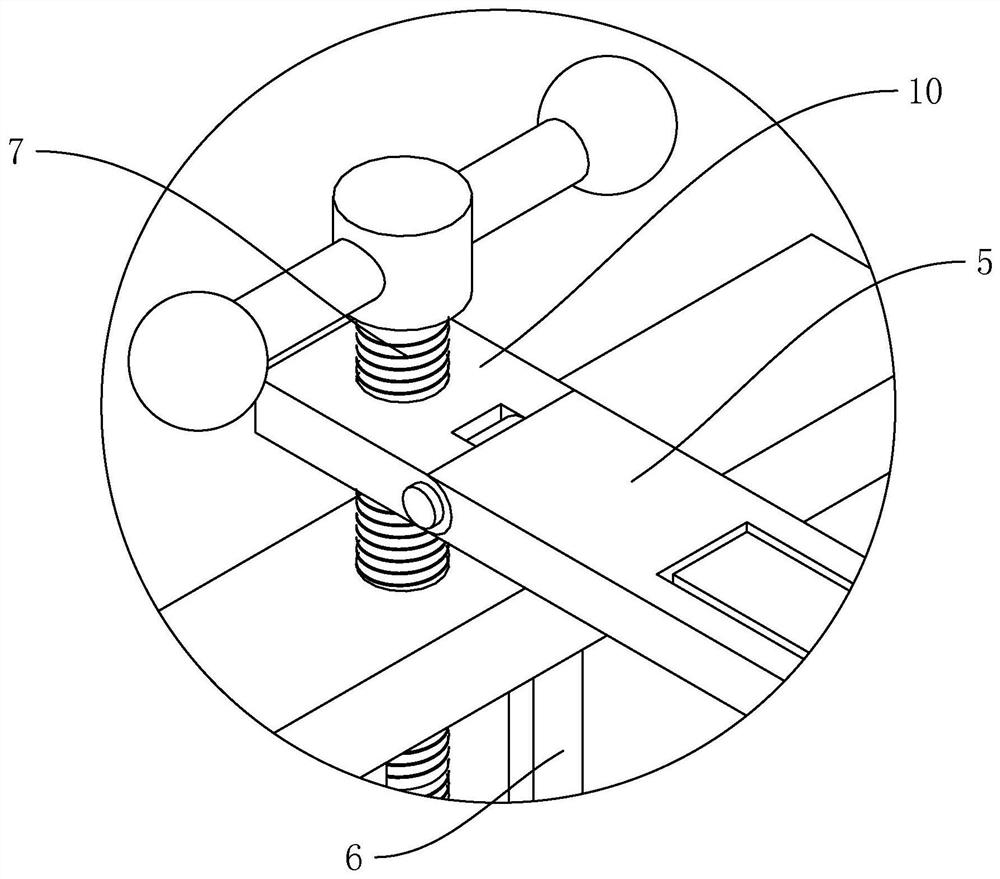

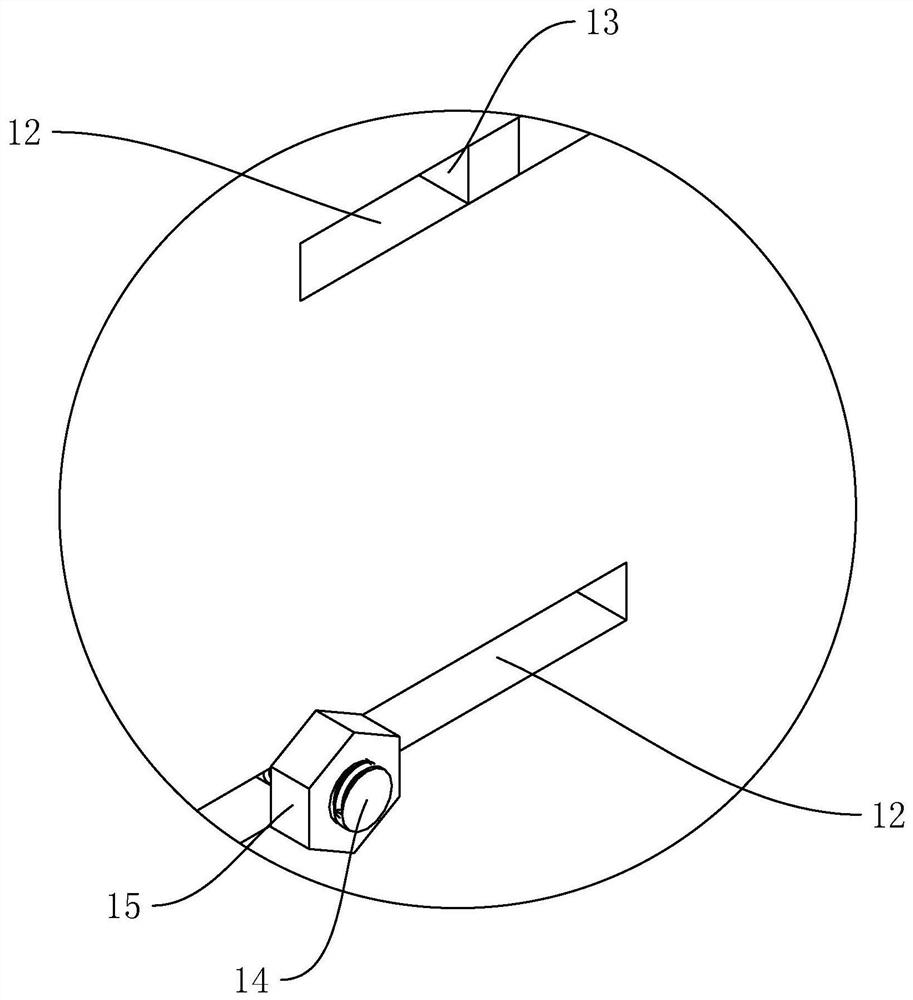

[0068] Such as figure 2 and Figure 5 As shown, the support frame 2 is provided with a vertically arranged slidewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com