Patents

Literature

50results about How to "Smooth panning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

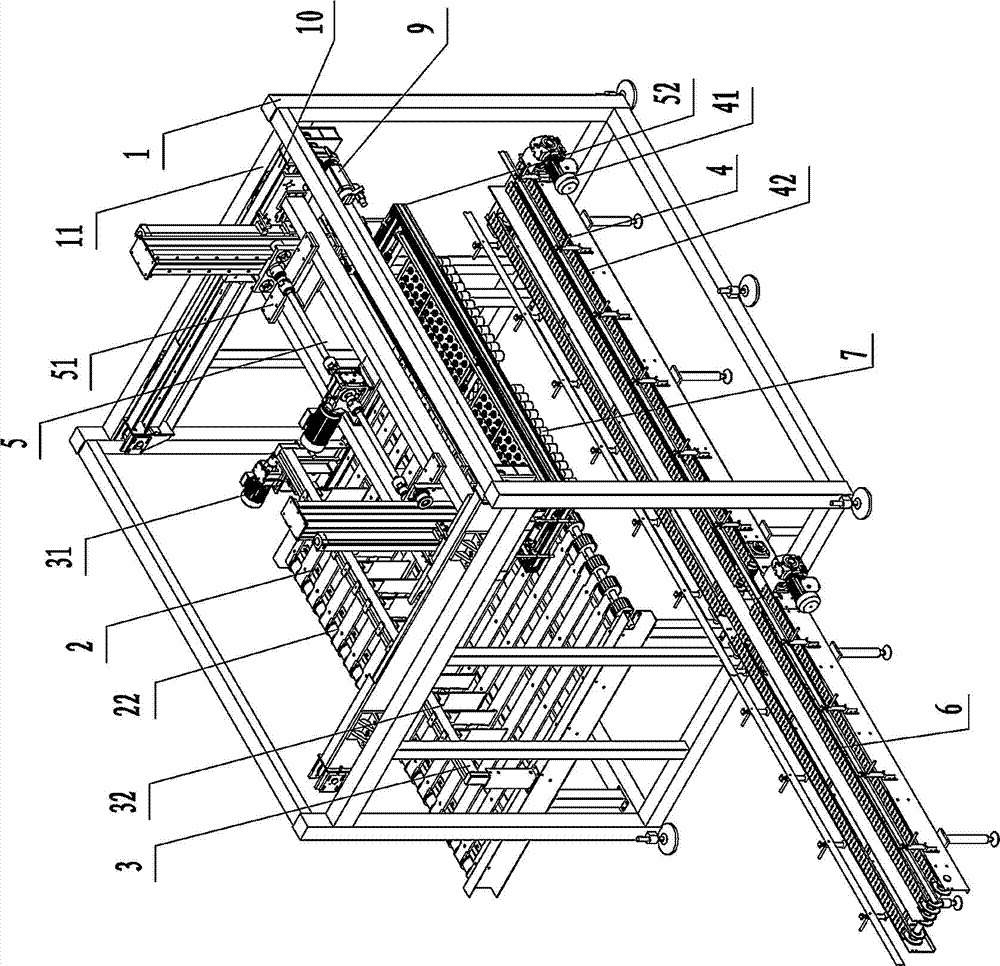

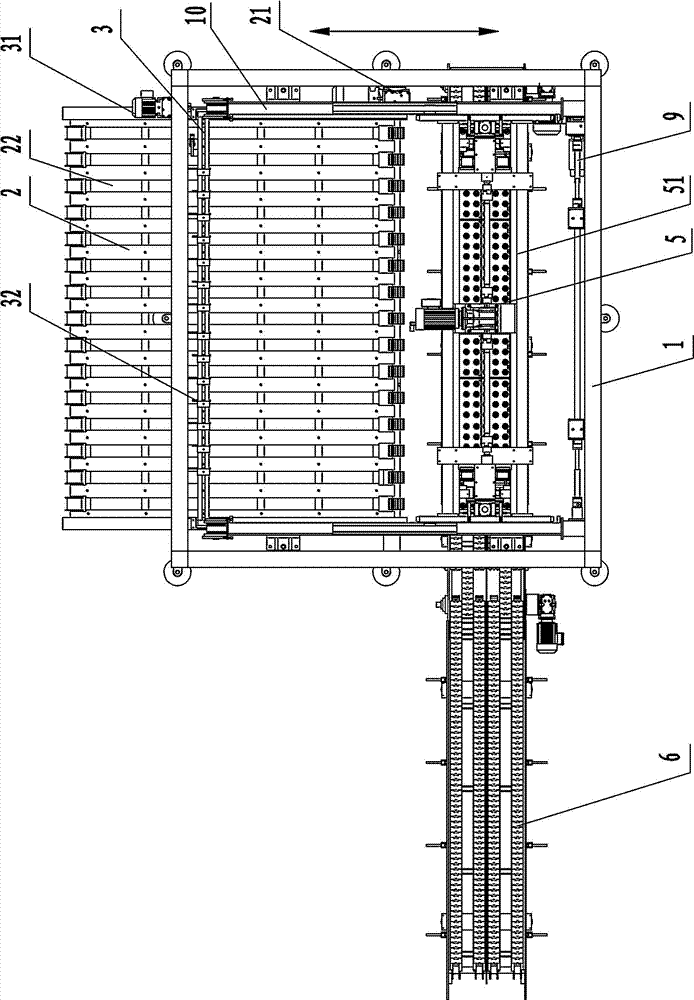

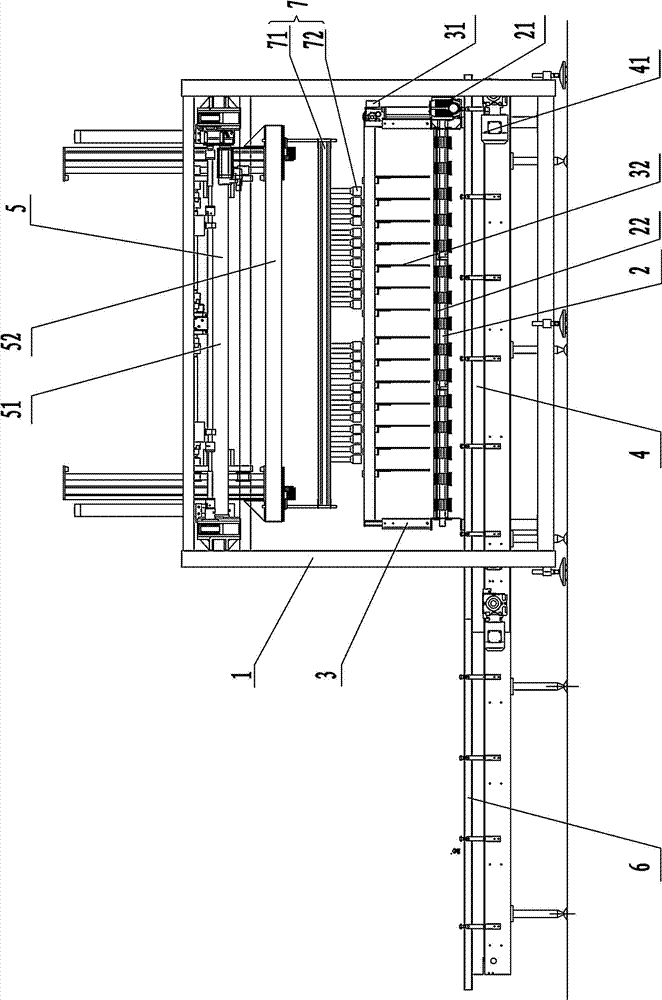

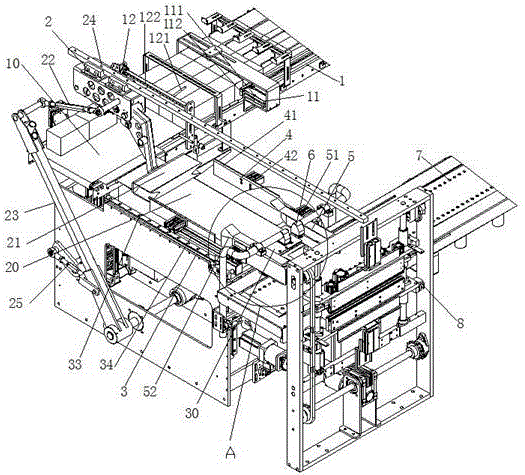

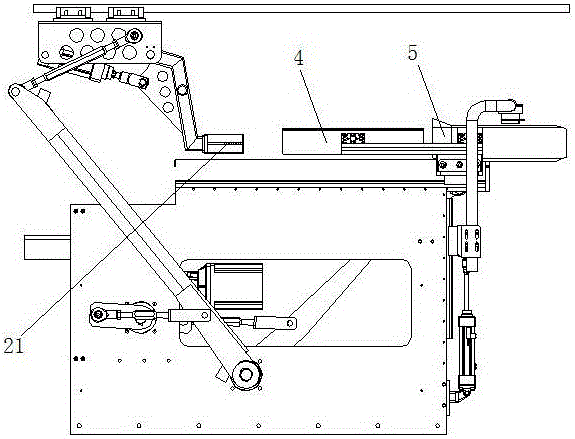

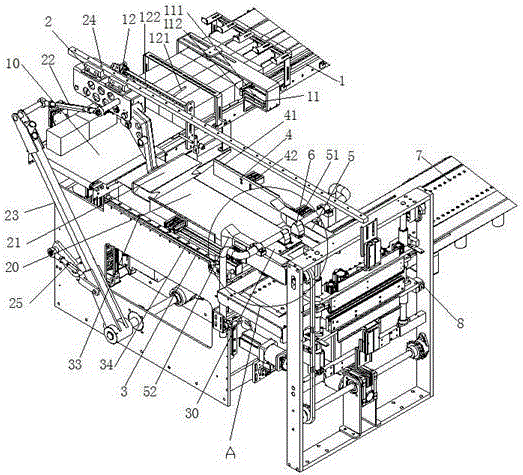

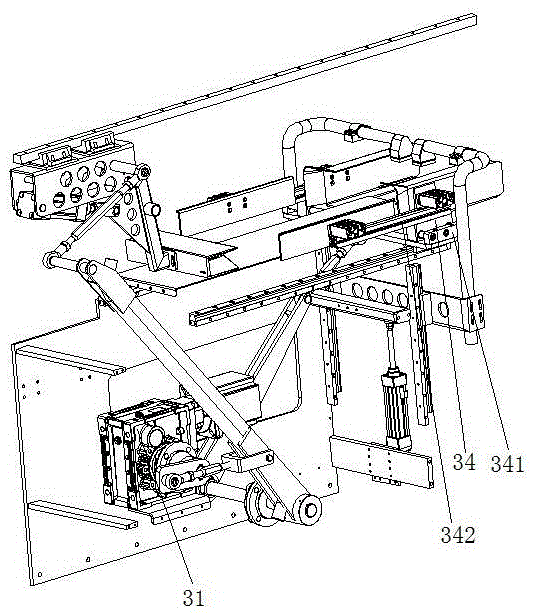

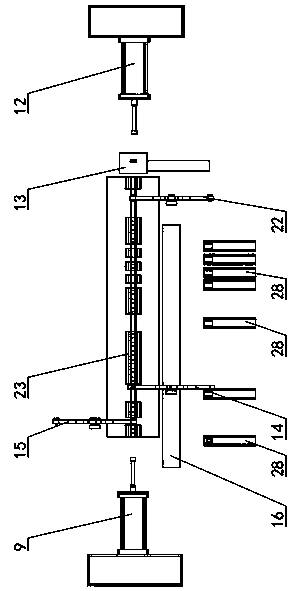

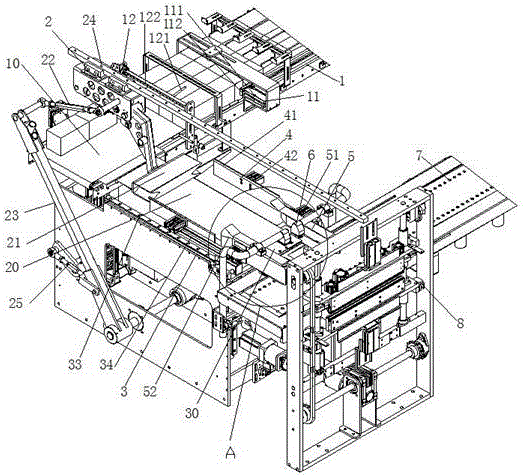

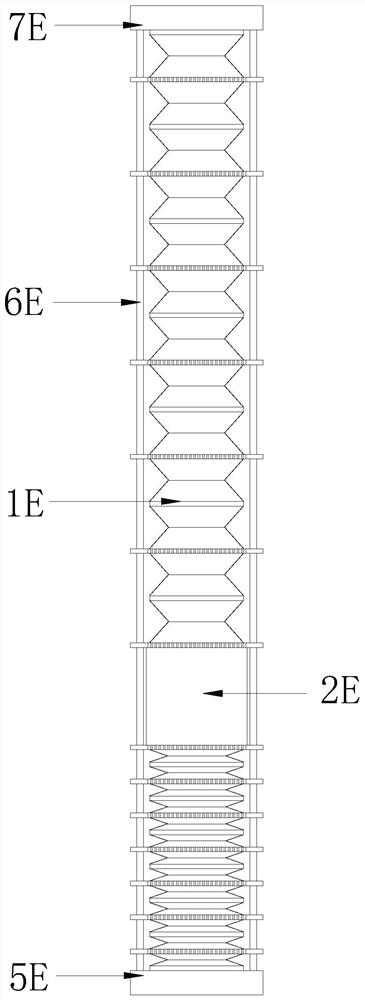

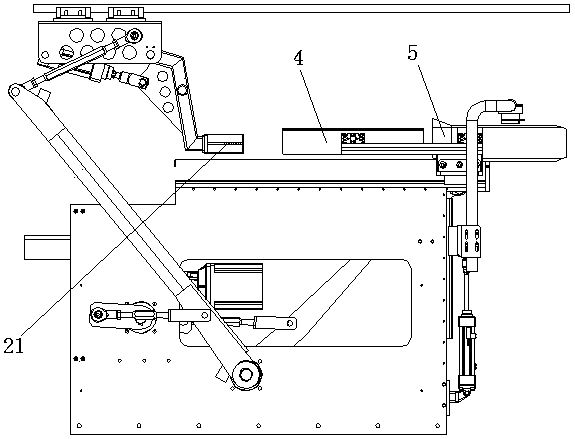

Automatic incasing machine

The invention discloses an automatic incasing machine which comprises a rack, a bottle conveying device, a case conveying device and a bottle moving device, wherein the bottle conveying device, the case conveying device and the bottle moving device are arranged on the rack; and the machine is characterized in that the bottle moving device comprises a translational frame and a bottle grasper installing frame, the translational frame is arranged on the rack and can be driven to horizontally move back and forth, the bottle grasper installing frame is arranged on the translational frame and can be driven to lift upwards and downwards, and the bottle grasper installing frame is provided with a bottle grasper. According to the automatic incasing machine, the bottle moving device is subjected to horizontal moving and vertical lifting through controlling the bottle grasper installing frame and the bottle grasper, stable in running and accurate in control, and in the process of horizontal moving and vertical lifting, bottles on the bottle grasper are uneasy to shake, so that a situation that bottles shake in the process of moving can be effectively avoided, and bottles move smoothly, and therefore, the incasing quality and the quality of bottled products can be ensured.

Owner:广东轻工机械二厂智能设备有限公司

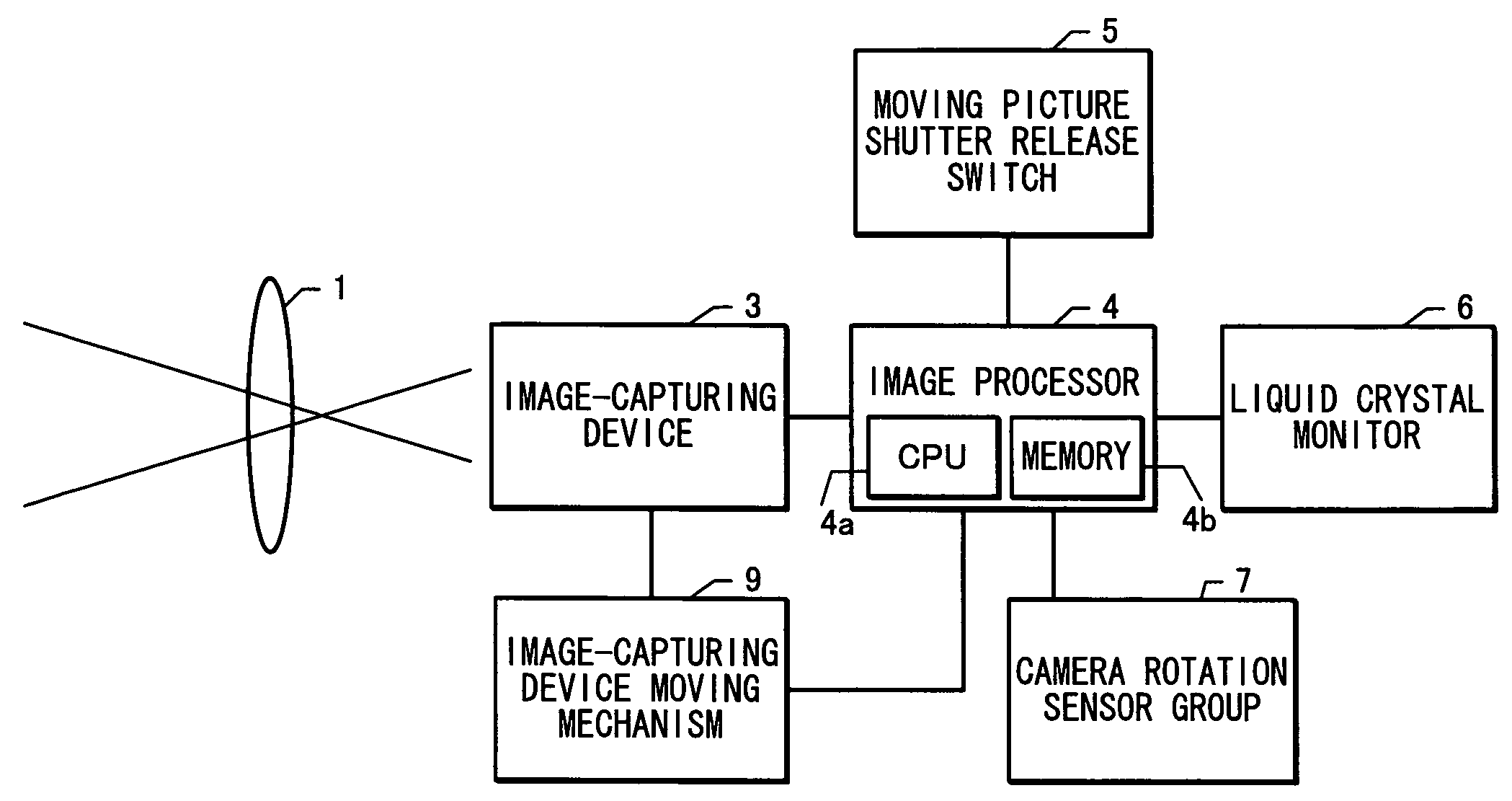

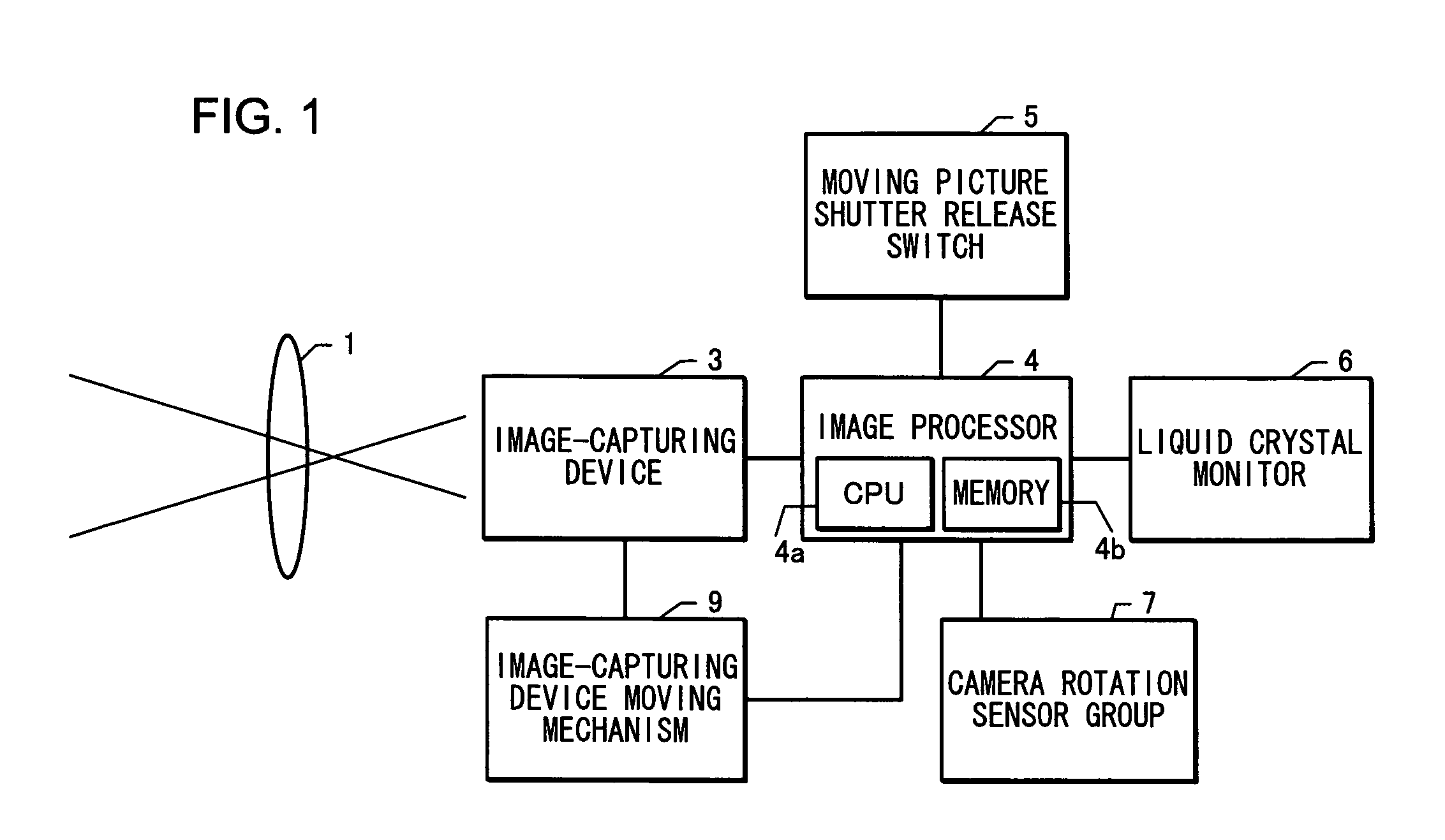

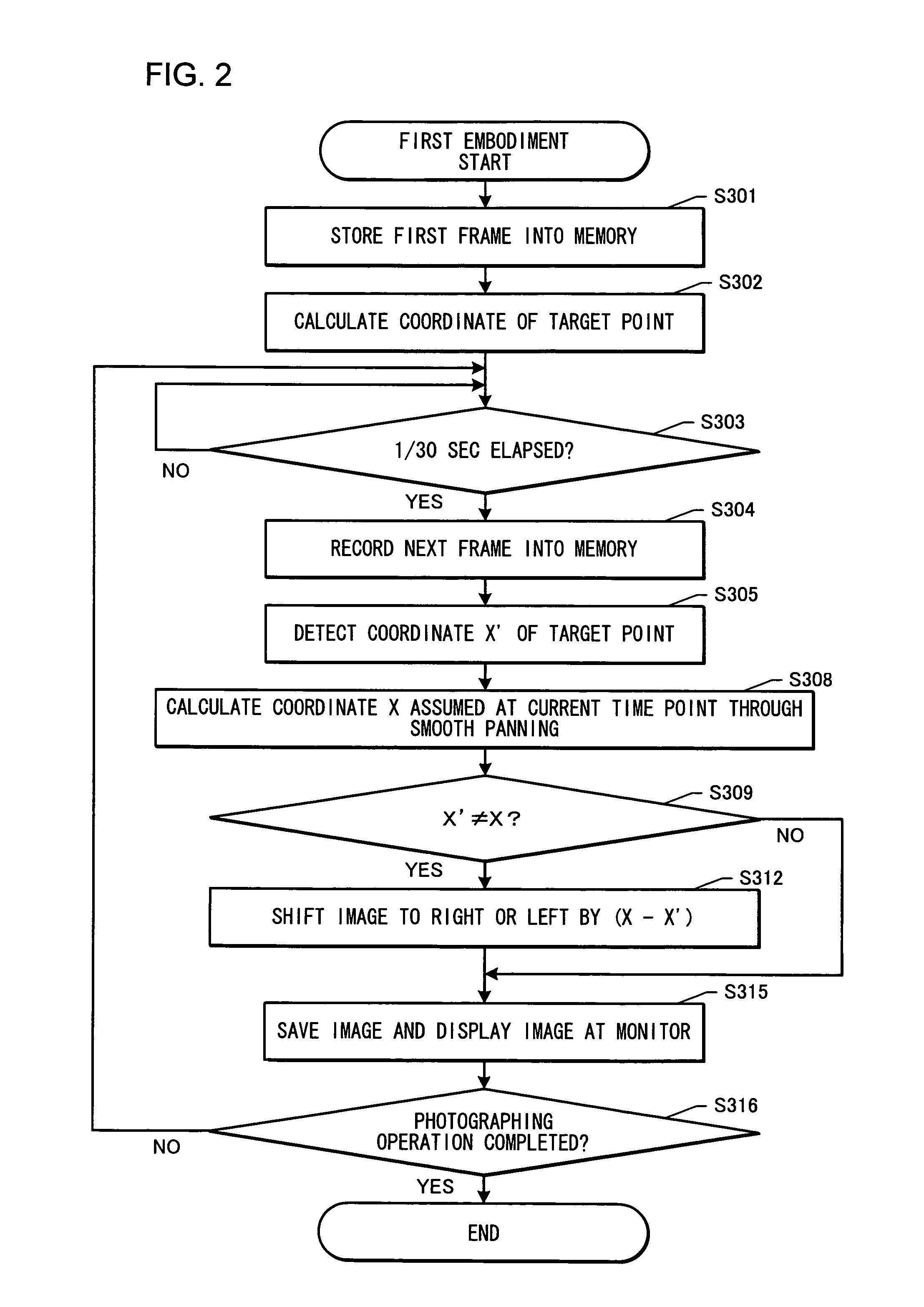

Camera enabling panning and moving picture editing program product

InactiveUS7593038B2Smooth panningOptimal speed and accelerationTelevision system detailsPicture signal generatorsComputer graphics (images)

Owner:NIKON CORP

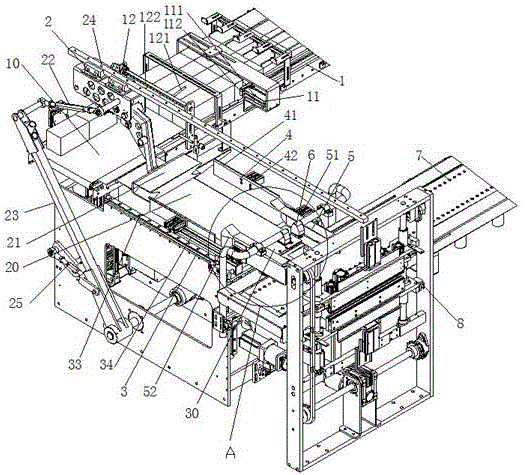

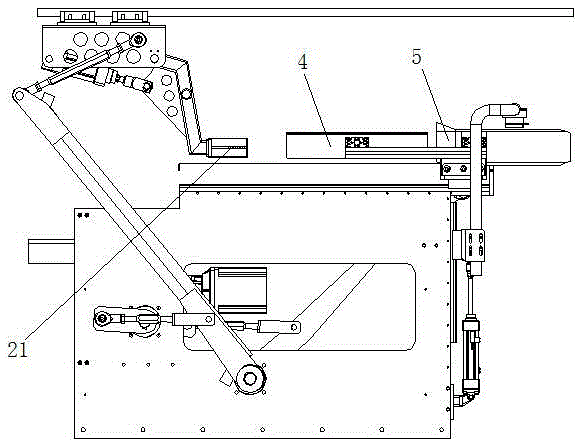

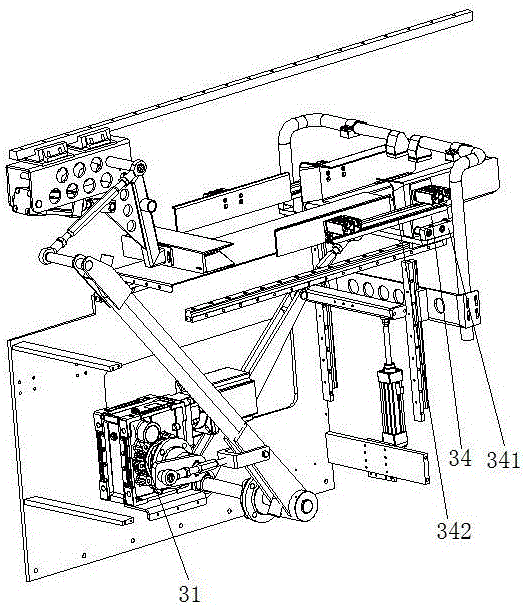

Control system of prefabricated bag packing machine

ActiveCN105857649AShort tripPrevent the situation of dumpingSolid materialRolling paperControl system

The invention discloses a control system of a prefabricated bag packing machine and relates to the technical field of mechanical control of packing machines. The control system of the prefabricated bag packing machine comprises a feeding mechanism, a pushing mechanism, a bag stretching mechanism, a bag opening mechanism and a bag conveying mechanism and is characterized by further comprising a clamping mechanism and a translation mechanism. The control system of the prefabricated bag packing machine is applicable to packing machines for packing via prefabricated bags such as small packing machines, medium packing machines and large packing machines and the like; meanwhile, the control system of the prefabricated bag packing machine is also suitable for packing materials such as facial tissues, flat paper, paper towels, blocky foods, drugs, roll paper, unpackaged foods and the like. Through the control system of the prefabricated bag packing machine, the problems that processes in single station of the prefabricated bag packing machine are complex, various packing actions are needed, the travel distance among the stations is long, the equipment occupied area is large, the material is irregular and is easy to pour, the prefabricated bags are easy to break, the material-pushing travel distance is long, the packing effect is poor, and the packaging efficiency is low in the prior art can be solved.

Owner:上海松川峰冠包装自动化有限公司

Material conveying and pushing method for prefabricated bag packaging machine

ActiveCN105691676ARealize the action of opening and opening bagsReduce processIndividual articlesRisk strokeSingle station

The invention discloses a material conveying and pushing method for a prefabricated bag packaging machine and relates to the technical field of packaging machine packaging processes. The material conveying and pushing method includes the steps that materials are conveyed to a to-be-clamped station; the materials conveyed to the to-be-clamped station are conveyed to a to-be-pushed station in a clamped manner; in the process of conveying the materials to the to-be-clamped station or the to-be-pushed station, prefabricated bags are conveyed to a bag opening station and opened on the bag opening station; the prefabricated bags are opened while the materials on the to-be-clamped station are conveyed to the to-be-pushed station in the clamped manner; in the material pushing process, the prefabricated bags and the materials move in the opposite directions; and the materials are pushed into the prefabricated bags moving in the direction opposite to the material pushing direction, and the prefabricated bags containing the materials in a wrapping manner are pushed to the assigned positions in the original material pushing direction. The material conveying and pushing method for the prefabricated bag packaging machine can solve the problems that by means of a prefabricated bag packaging machine in the prior art, the working procedures of a single station are complex, the number of the packaging actions is large, the stroke among different stations is long, the area occupied by equipment is large, material dumping occurs easily and the prefabricated bags are broken easily due to the fact that materials are irregular, the material pushing stroke is long, the packaging effect is poor, and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

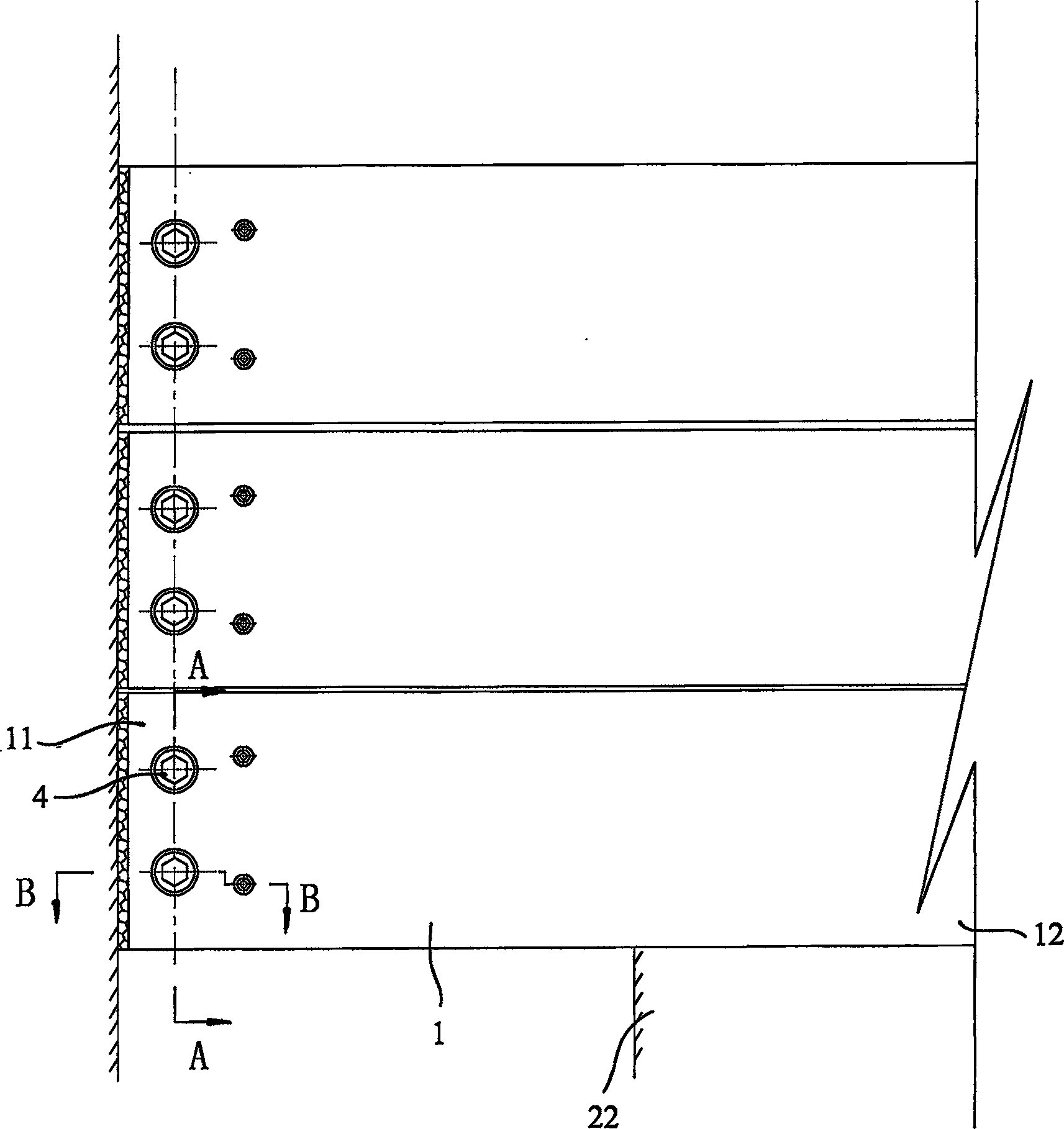

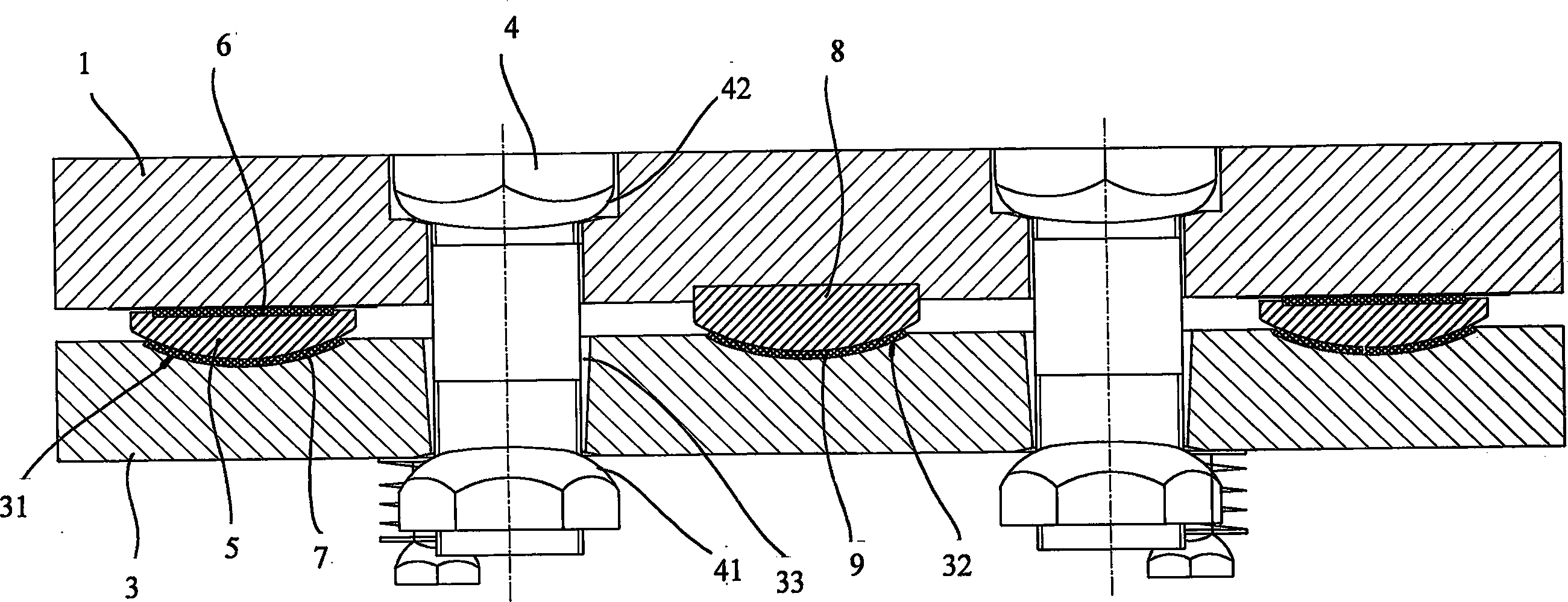

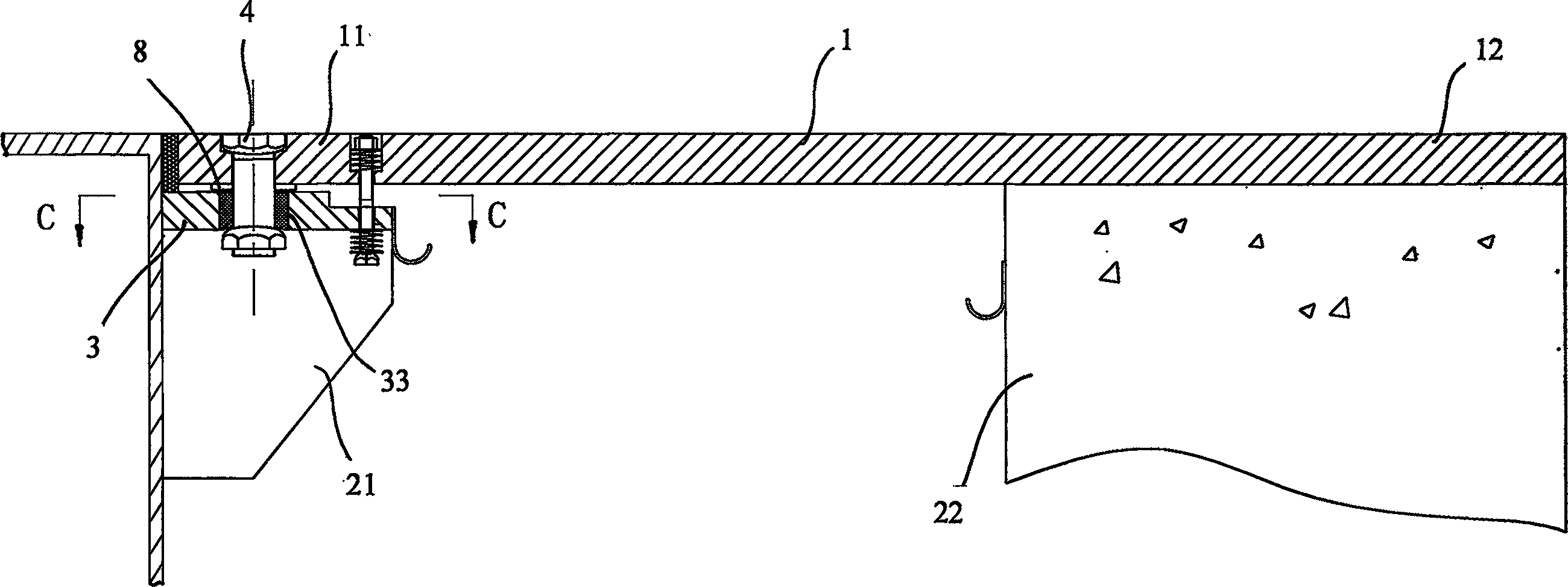

Bridge expansion joint installation of possessing multidirectional displacement capabilities

A bridge expansion joint device with multidirectional shift ability is prepared as fixing the first end of over joint plate on the first beam, placing the second end on the second beam and enabling said plate to relatively move on said beam, setting bottom support board fixed on the first beam under the first end of said plate, connecting said plate with bottom support board by bolt, setting intermediate block with spherical surface at bottom between said plate and said board, setting planar sliding plate above intermediate block being set with spherical sliding plate at its bottom.

Owner:徐斌

Material clamping and conveying method for prefabricated bag packaging machine

The invention discloses a material clamping and conveying method for a prefabricated bag packaging machine, and belongs to the field of material packaging. The material clamping and conveying method is characterized by comprising the following steps: a, a material is fed by a material feeding mechanism to a to-be-clamped station, and clamped by the two sides in the horizontal material conveying direction of a clamping mechanism; b, the clamped material is conveyed to a to-be-pushed station, and a prefabricated bag is expanded by a bag expanding mechanism; and c, the material conveyed to the to-be-pushed station is pushed by a material pushing mechanism, and meanwhile the prefabricated bag is driven by the bag expanding mechanism to move opposite to the pushed material. By adoption of the material clamping and conveying method, the material can be pushed by the material pushing mechanism into the prefabricated bag continuously, and the continuous degree of material conveying and pushing is high. Besides, the material clamping and conveying method has the characteristics that the conveying and packaging stroke is short, and the packaging efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

Material packaging method for prefabricated bag packaging machine

ActiveCN105691677AHigh degree of continuityImprove packaging efficiencyIndividual articlesEngineeringPacking method

The invention discloses a material packaging method for a prefabricated bag packaging machine, and belongs to the technical field of material packaging. The material packaging method comprises the following steps: material clamping or holding, prefabricated bag expanding, material pushing and prefabricated bag removing, wherein in the material clamping or holding process, a material is clamped or held under the action of a clamping mechanism or a holding mechanism, and conveyed to a to-be-pushed station; in the prefabricated bag expanding process; the left and right sides of the bag mouth of the prefabricated bag are expanded under the action of a bag expanding mechanism; in the material pushing process, the material moves under the action of a material pushing mechanism in the direction of the bag mouth of the prefabricated bag to the bottom of the prefabricated bag, and continues being pushed along with the prefabricated bag; and in the prefabricated bag removing process, after moving to the bottom of the prefabricated bag, the material continues being pushed by the material pushing mechanism, and then is removed from the bag expanding mechanism. By adoption of the material packaging method, the material can be pushed by a material pushing head into the prefabricated bag continuously, and the continuous degree of material conveying and pushing is high. Compared with a conventional packaging method, the material packaging method provided by the invention has the advantages that the conveying and packaging stroke is shorter, and the packaging efficiency is higher.

Owner:上海松川峰冠包装自动化有限公司

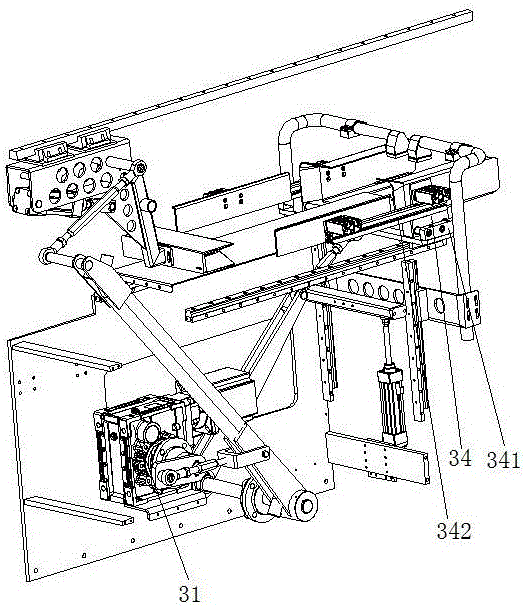

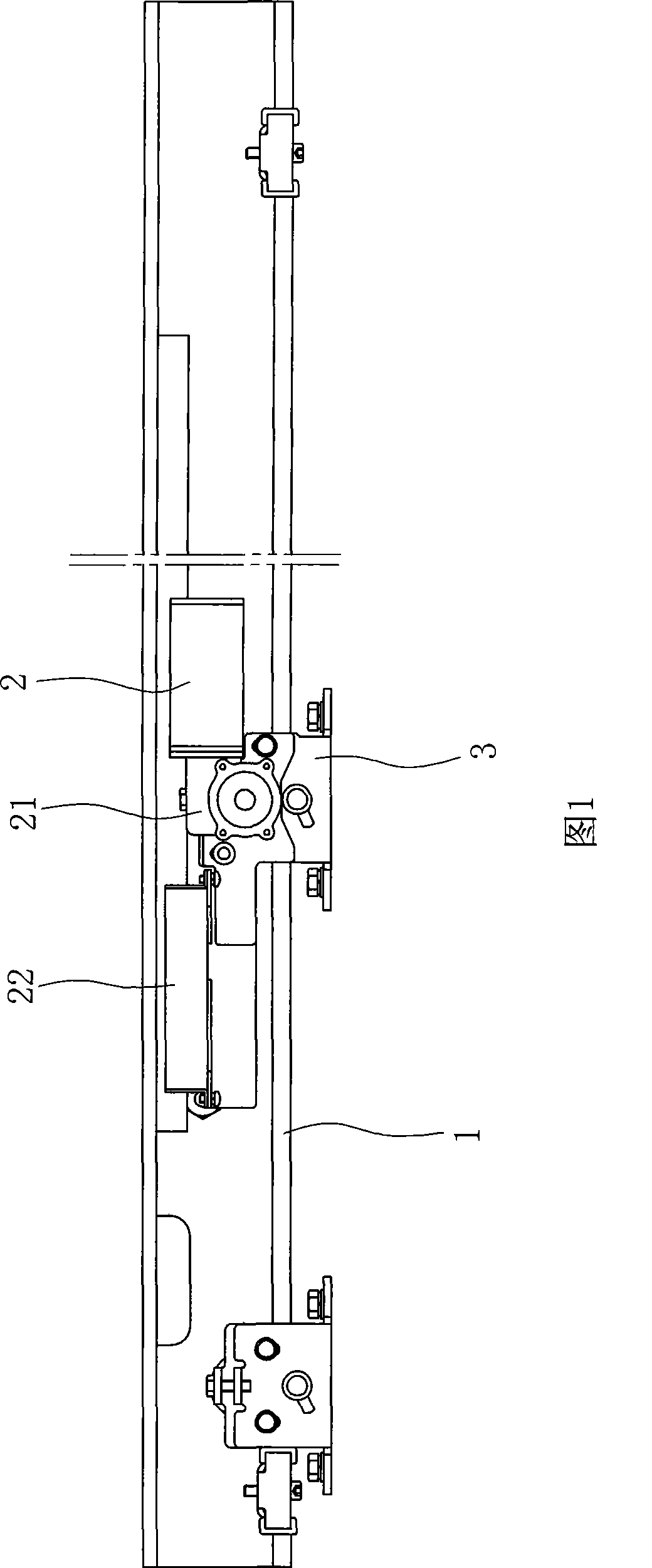

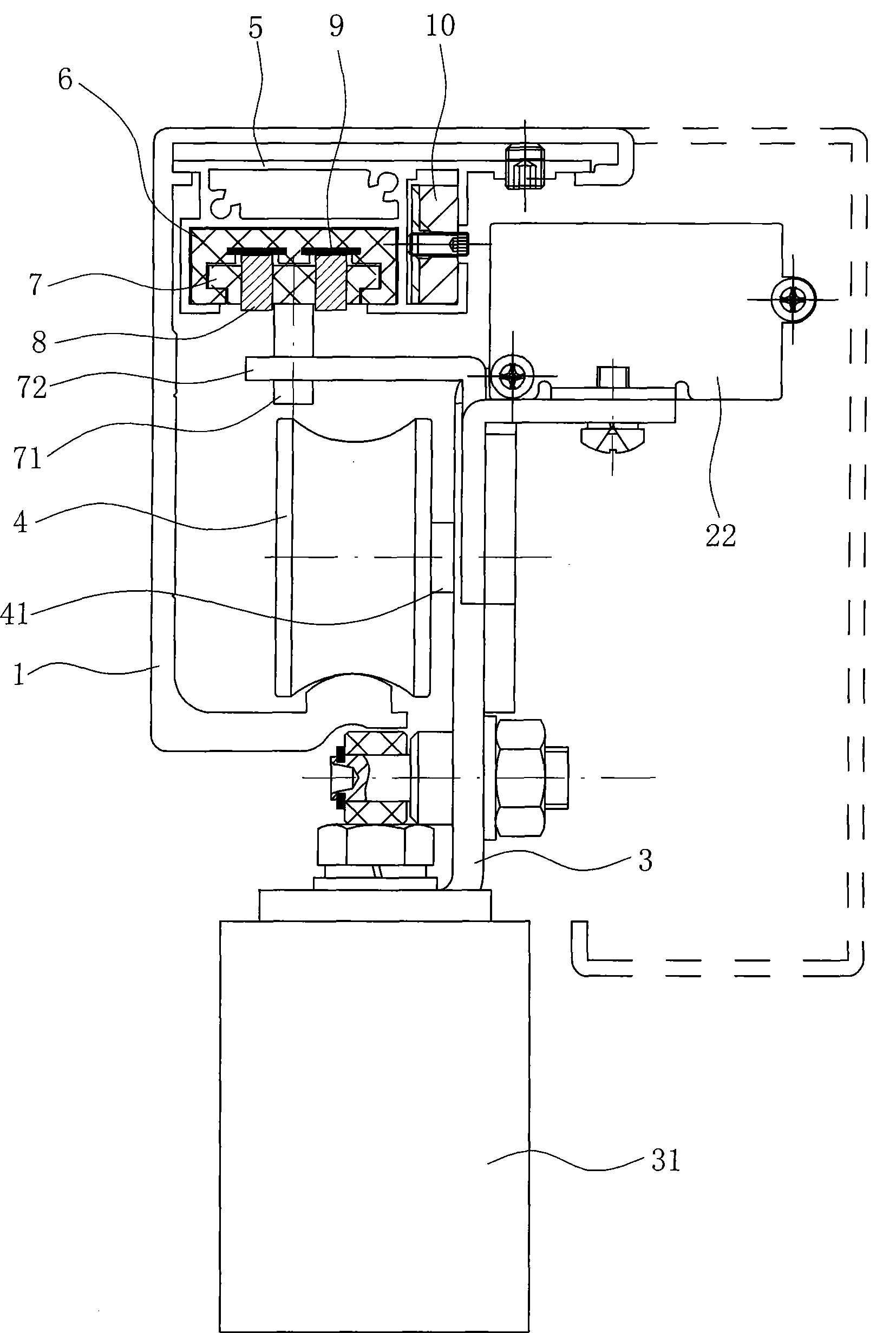

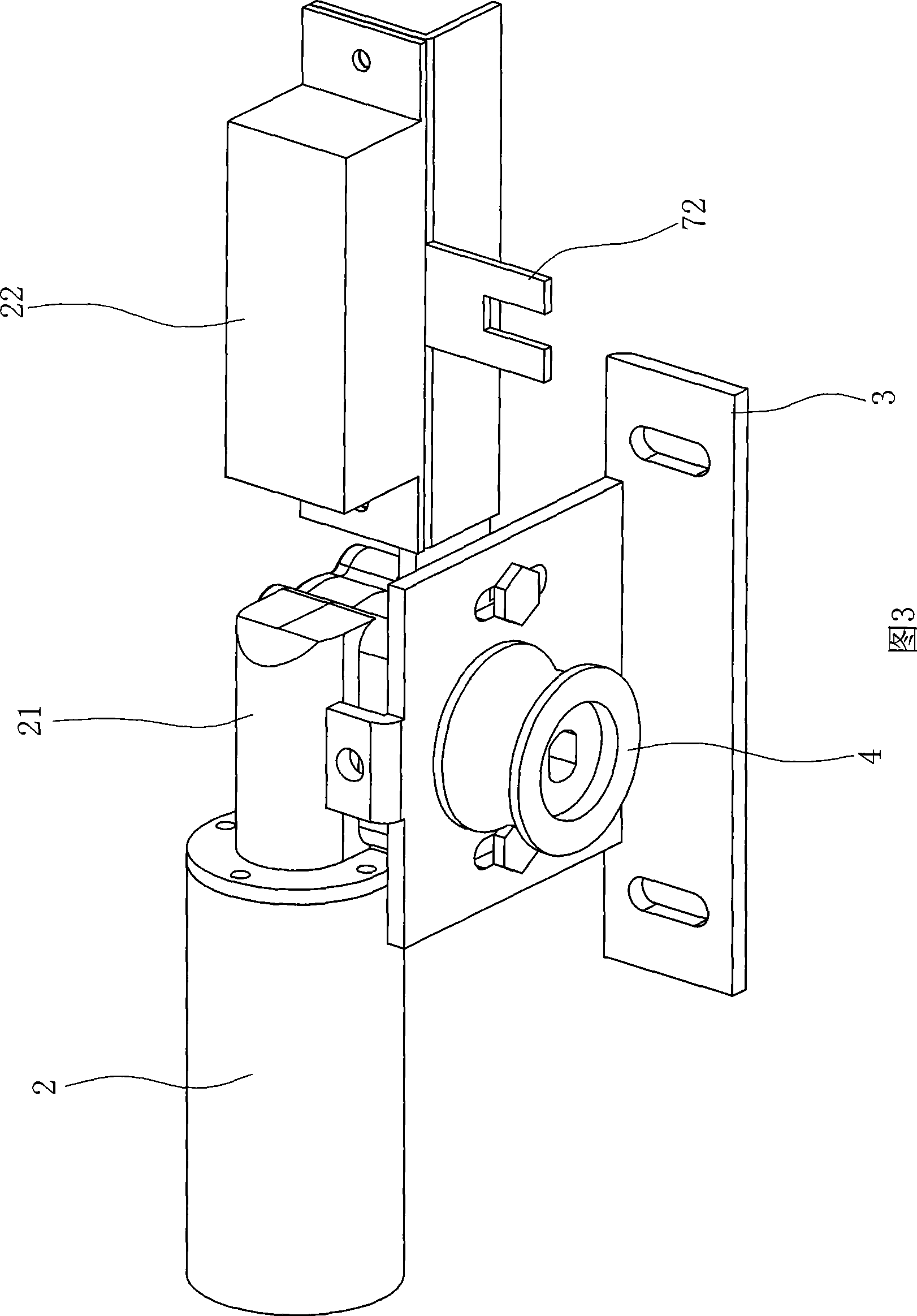

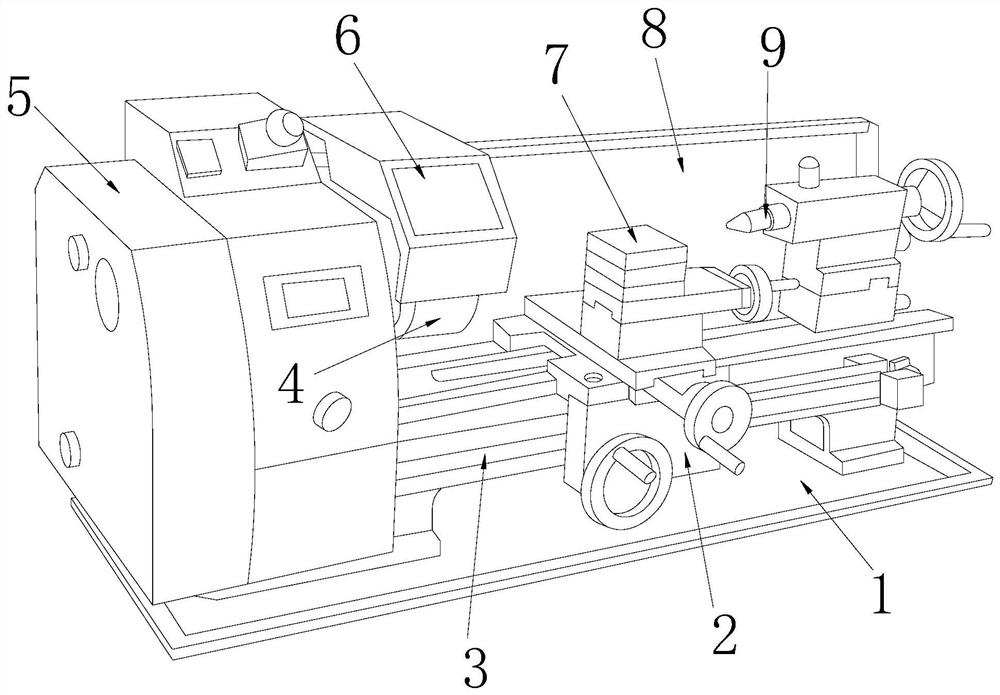

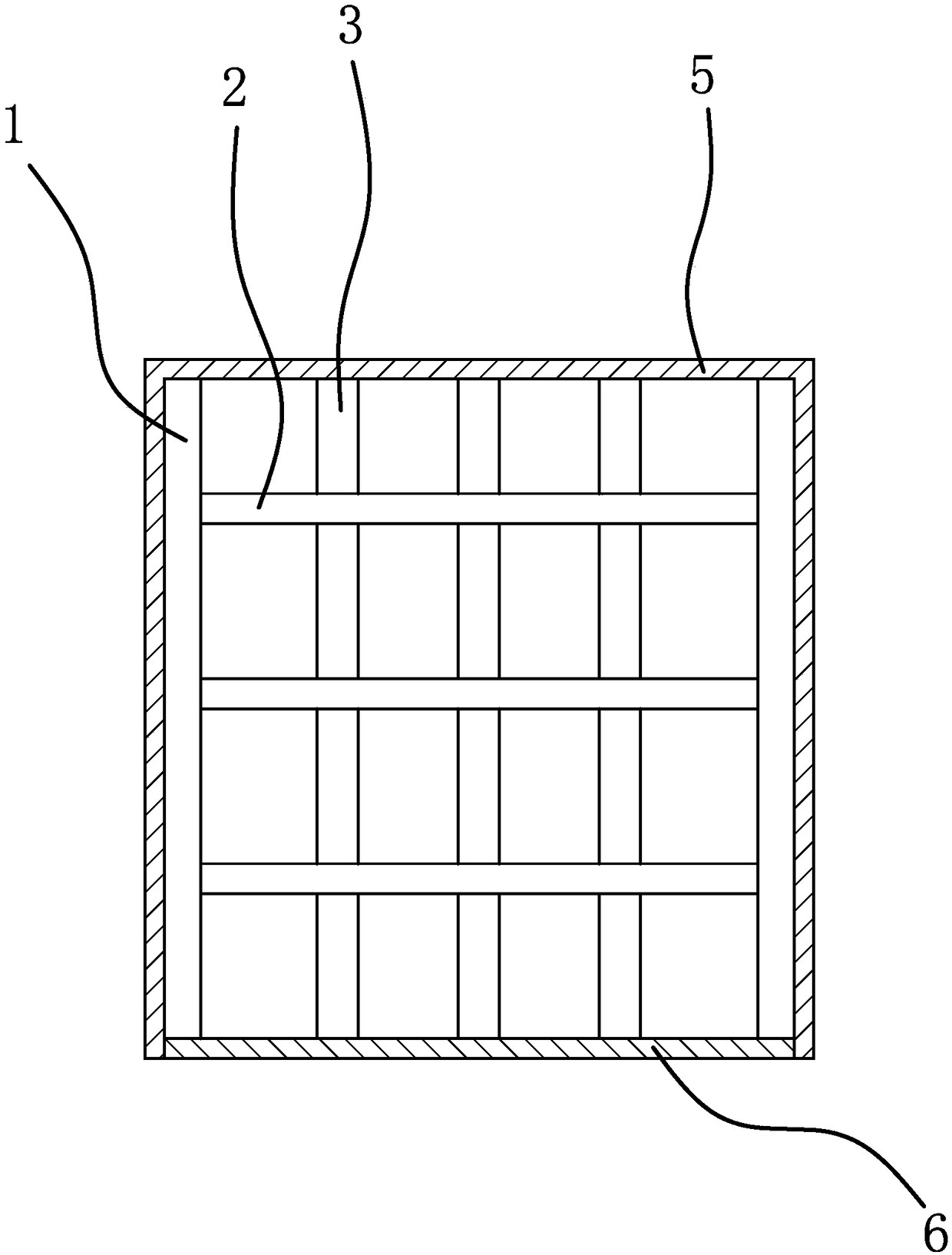

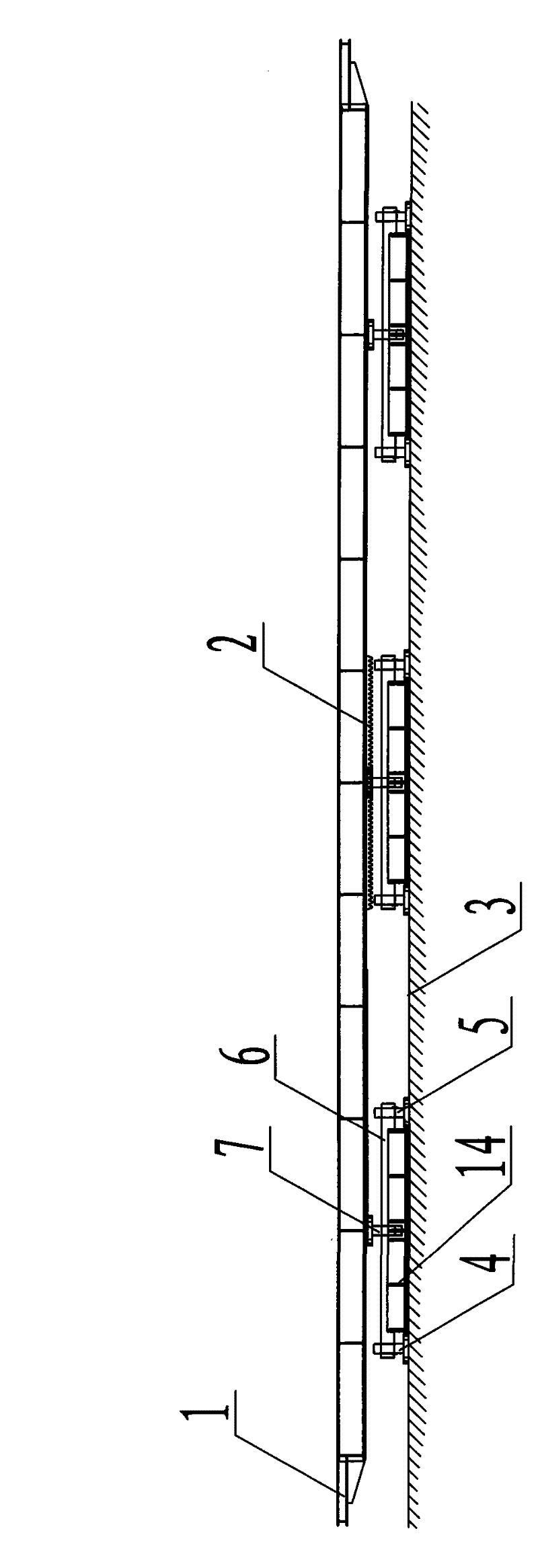

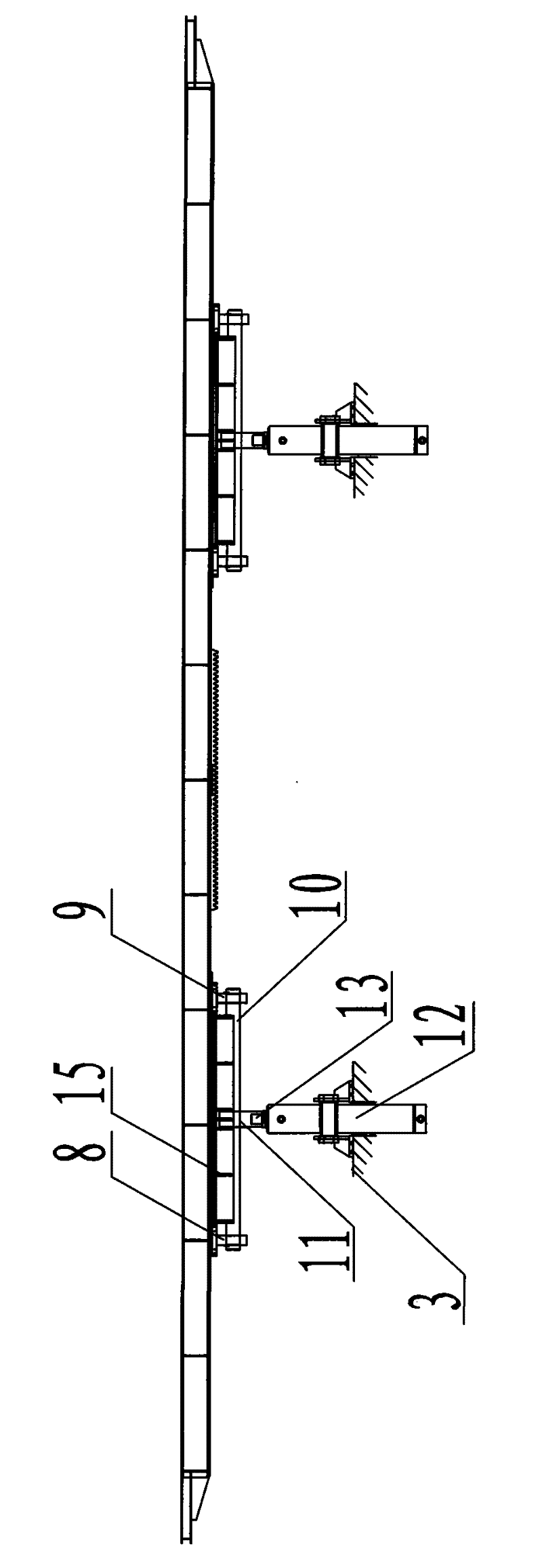

Mobile drive deivce

InactiveCN101424152ASmooth panningReduce working noisePower-operated mechanismElectric machineryElectrical and Electronics engineering

The invention discloses a movable driving device which comprises a motor (2), a guide rail (1) and a hanging bracket (3), an roller wheel (4) and a movably power supply device, wherein the output end of the motor (2) is in driving connection with the roller wheel (4); the movably power supply device comprises a pedestal (5), an insulated sliding seat (6); two parallel conductive strips (9) and an insulated movable block (7) moving with the motor (2) together; a pair of conductive brushes (8) are arranged on the insulated movable block (7); the bottoms of the conductive brushes (8) are contacted with the surfaces of the two conductive strips (9) respectively. Compared with the prior art, the movable driving device has smoother translation motion and low working noise; through the movable power supply device, the motor on the move obtain continuous power supply so as to realize the technical proposal; the movable driving device is quite suitable for an automatic door; meanwhile, the movable driving device has a compact structure and more reliable performance and needs no transmission mechanism or a belt, thereby effectively reducing production cost.

Owner:林万炯

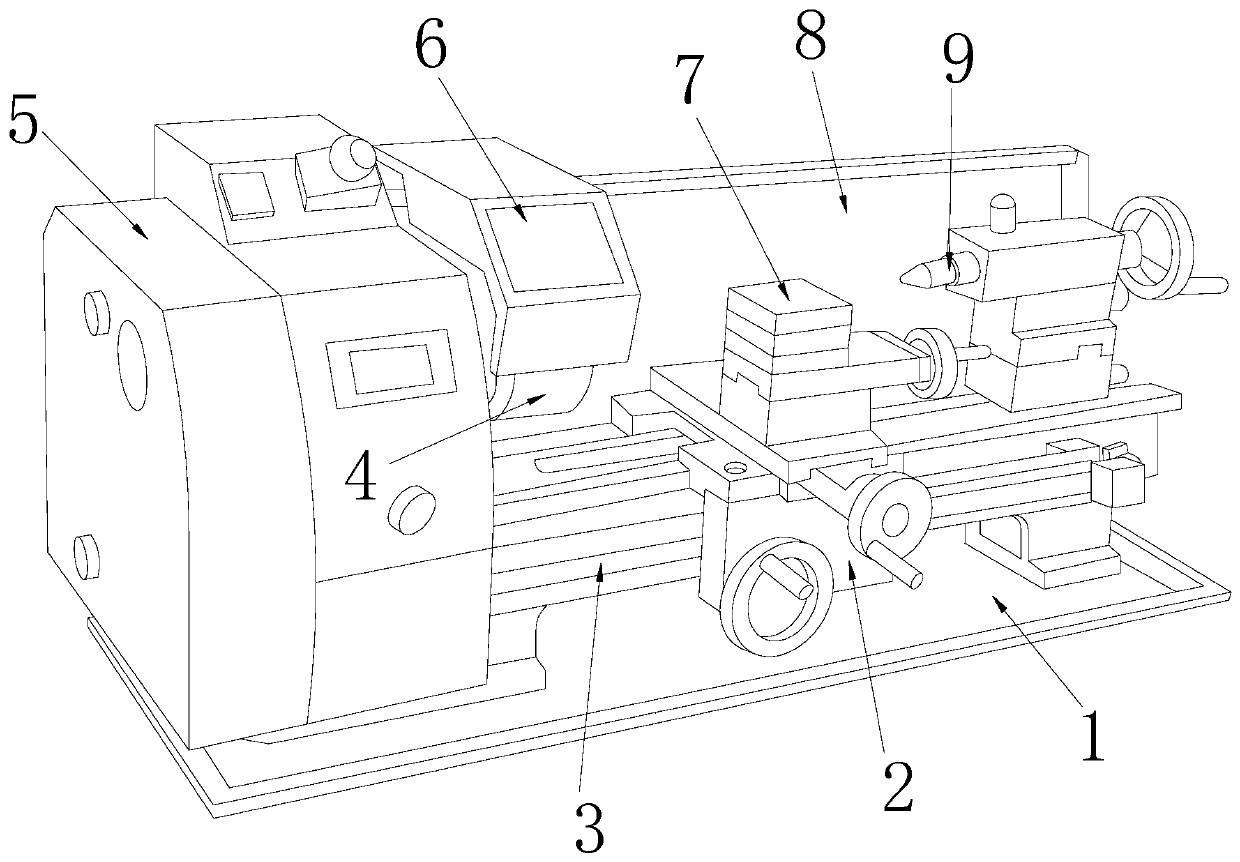

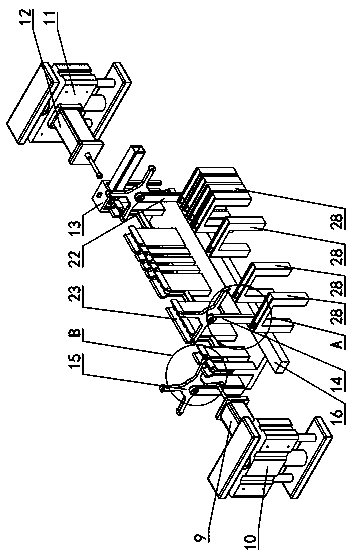

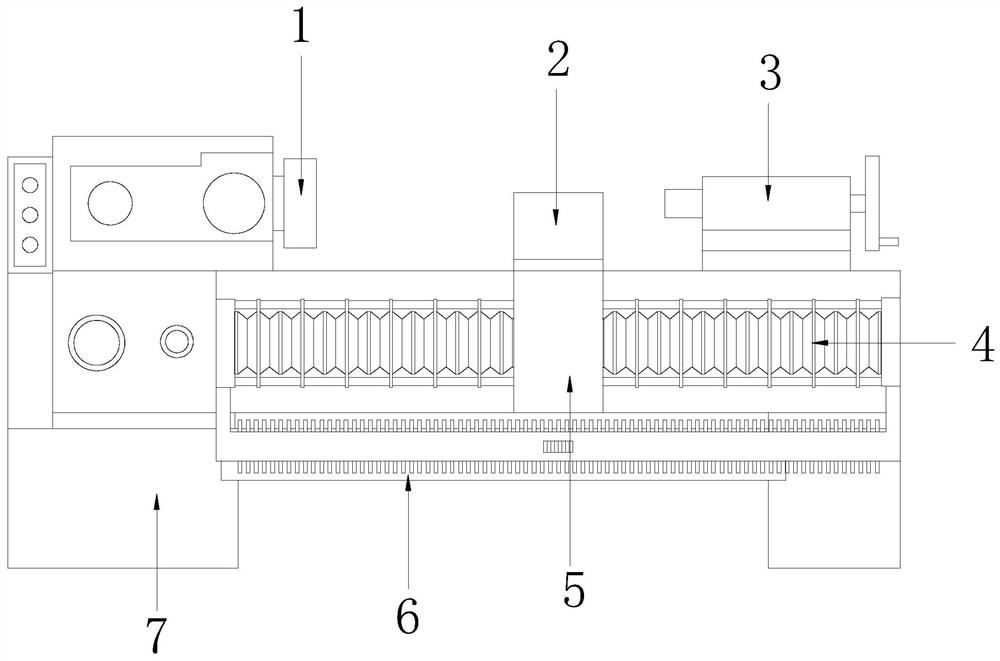

Numerical control lathe

ActiveCN111299618AAvoid exposureAvoid adsorptionAutomatic/semiautomatic turning machinesTool holdersNumerical controlScrew thread

The invention discloses a numerical control lathe. The numerical control lathe comprises a base, a moving module, a lead screw module, a chuck, a lathe body, a dustproof cover, a lathe cutter frame, aprotecting plate, and a tail frame top car mechanism; the lathe body is arranged on the base; and the protecting plate is fixed on the lathe body. Compared with the prior art, the numerical control lathe has the beneficial effects that: the lead screw module adopts a novel structure configuration; a lead screw can be hidden to prevent exposing outside, so that chips generated by lathe processingand external dust are effectively prevented from falling into a thread groove of the lead screw, blockage of the thread groove of the lead screw is prevented, scaling of the thread groove is prevented, translation of the moving module is smooth, and the lead screw has no need to be cleaned and descaled; and the blade mounting base adopts a novel structure configuration, implements multiple fixation to effectively prevent looseness of bolts and blades, so that processing of processed parts by the blades is facilitated.

Owner:邵阳永腾金属制品有限公司

Material conveying method for prefabricated bag packing machine

The invention discloses a material conveying method for a prefabricated bag packing machine, and belongs to the technical field of material packing. The material conveying method is characterized by comprising the following steps that (a), material after being held or clamped is conveyed to a station to be pushed in the opening direction of a prefabricated bag; (b), the left side and the right side of the prefabricated bag are opened; (c), the material is pushed on the station to be pushed, the precast bag is moved, the material and the prefabricated bag perform opposite motion, and the material is pushed into the prefabricated bag; (d), the material is pushed to the bottom of the prefabricated bag, and the material continues moves along with the prefabricated bag in the pushed direction; (e), next material is cyclically conveyed according to the steps. The material conveying method disclosed by the invention has the characteristics that the material pushing serialization degree is high, the conveying and packing distance is short, the materials cannot fall, and the conveying and packing efficiency is high.

Owner:上海松川峰冠包装自动化有限公司

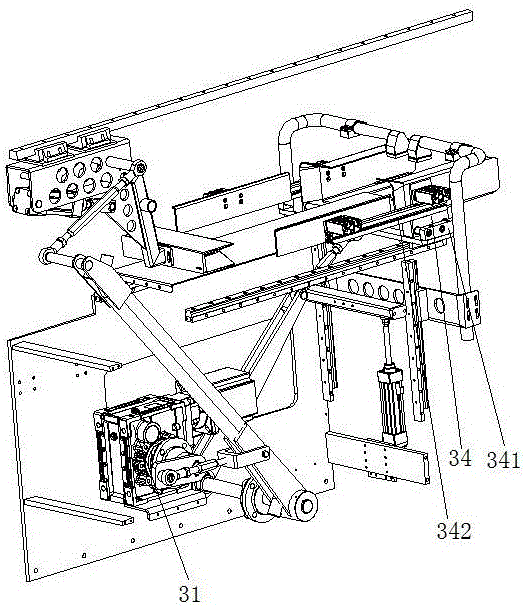

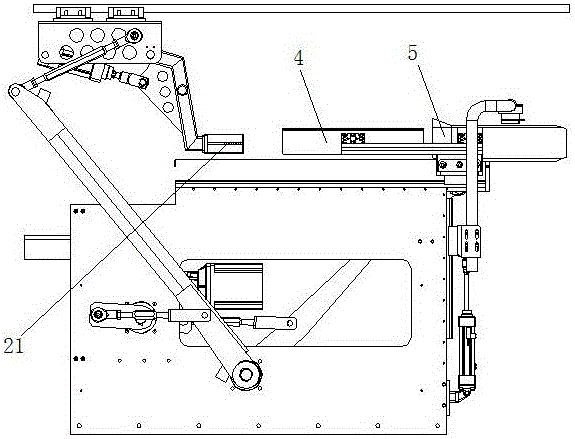

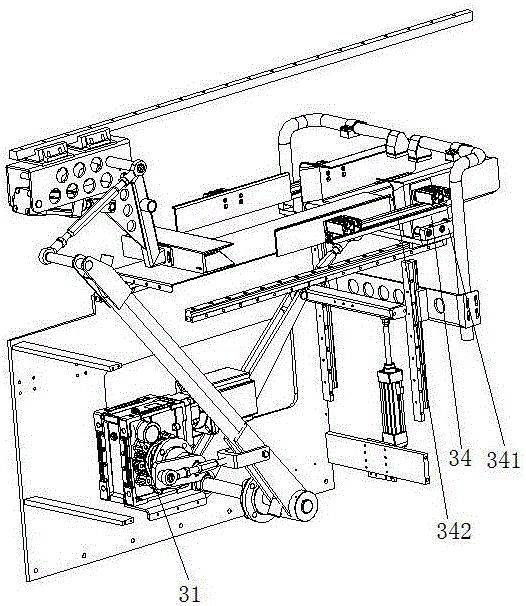

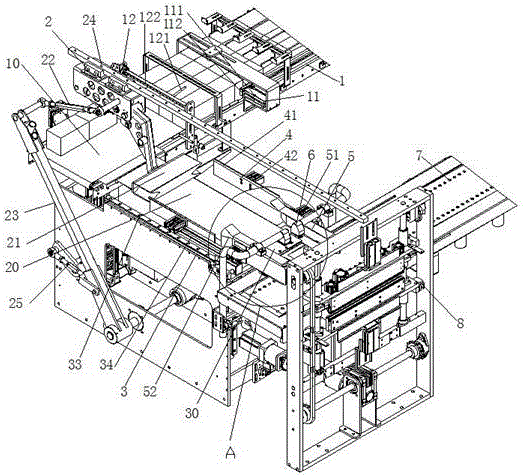

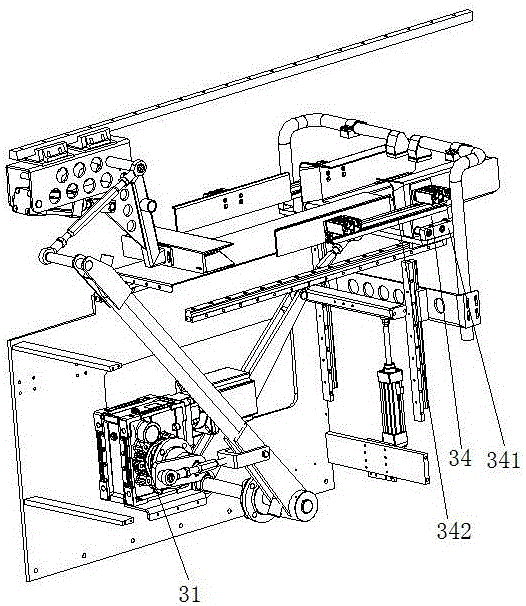

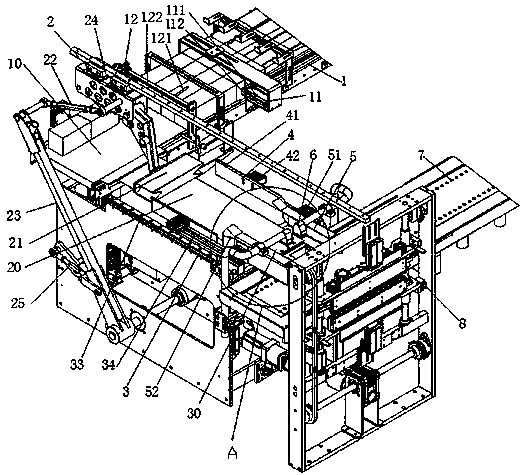

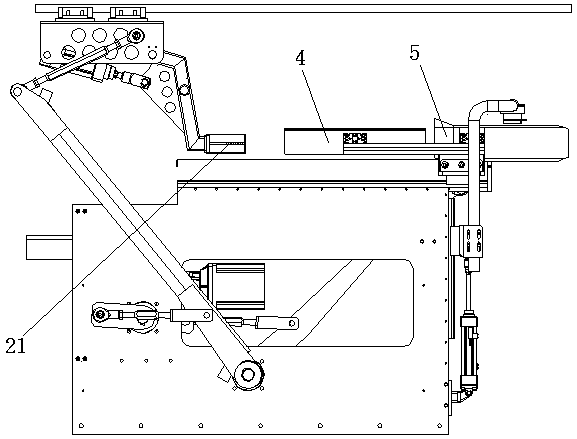

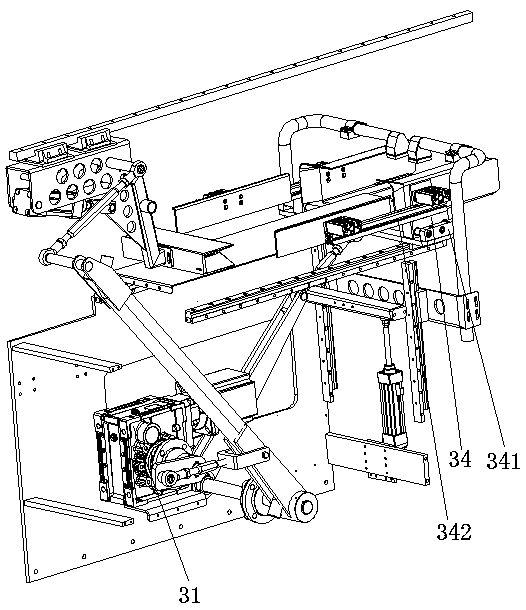

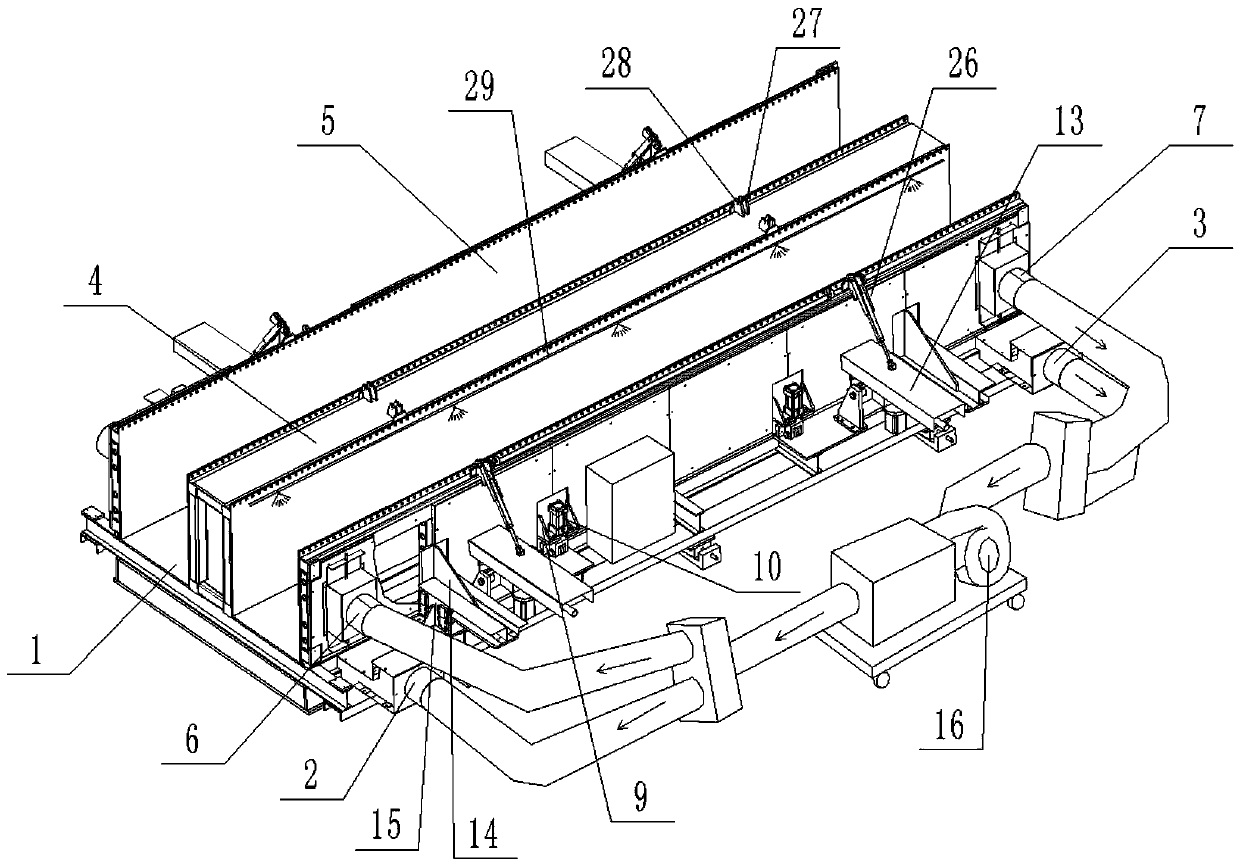

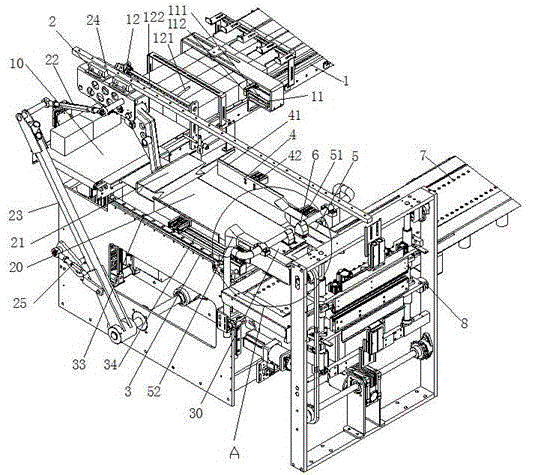

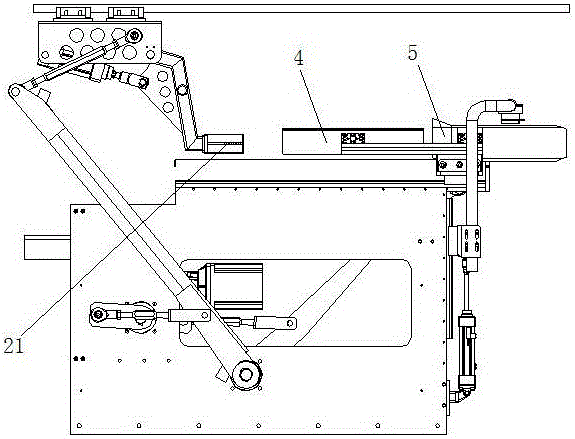

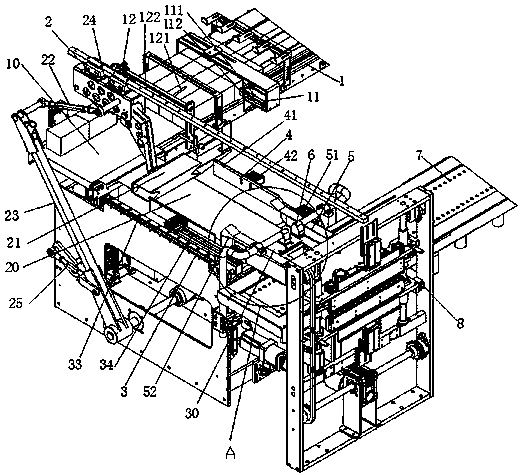

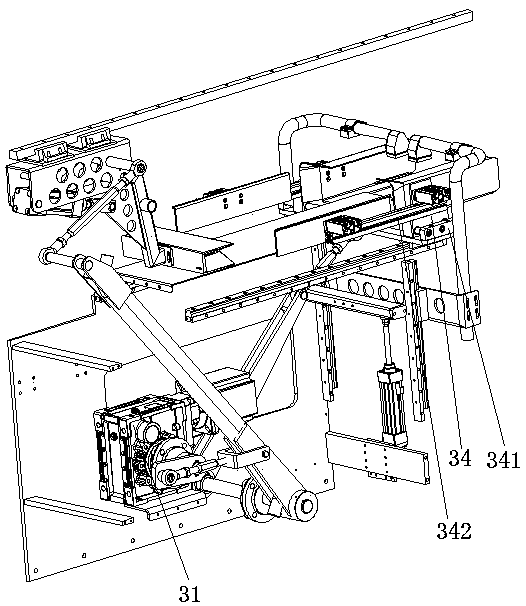

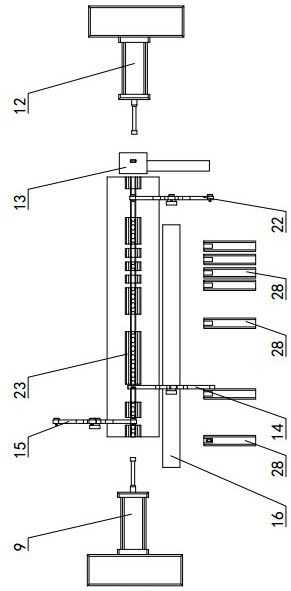

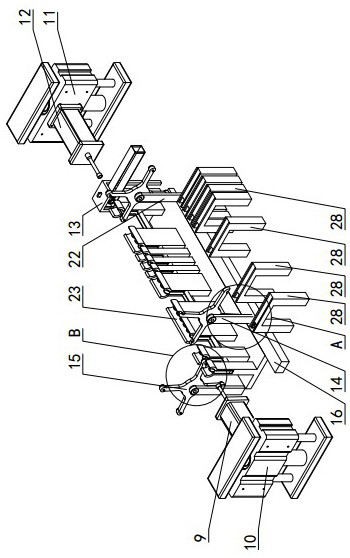

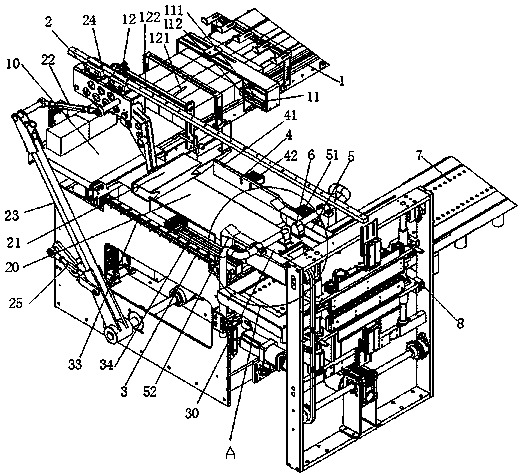

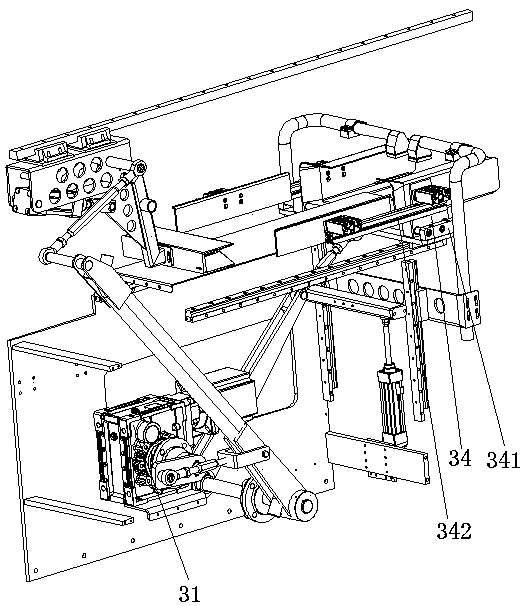

Prefabricated bag packaging machine

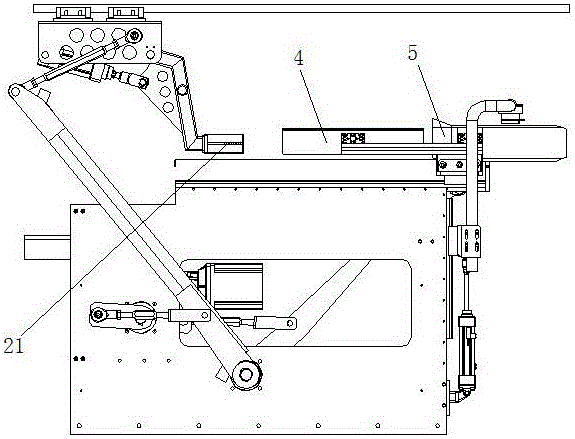

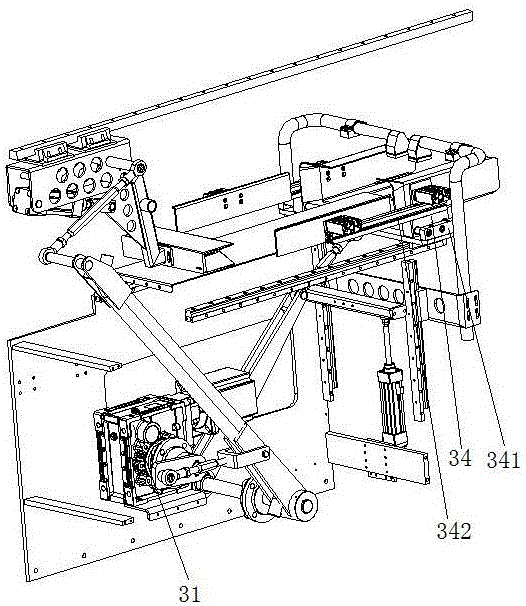

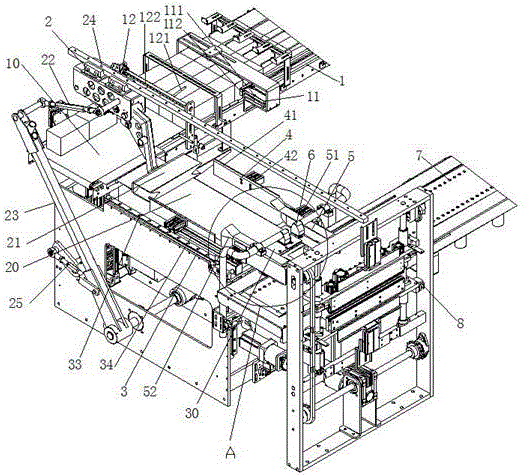

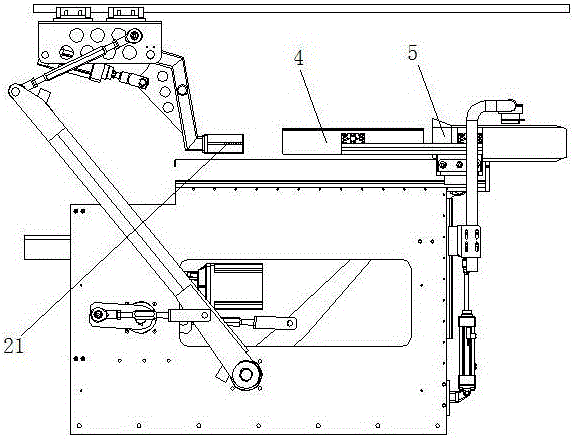

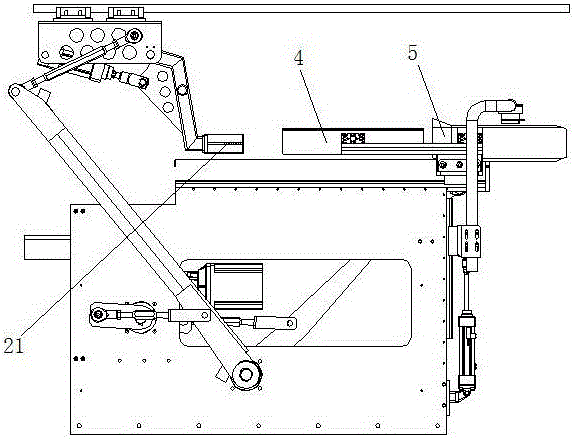

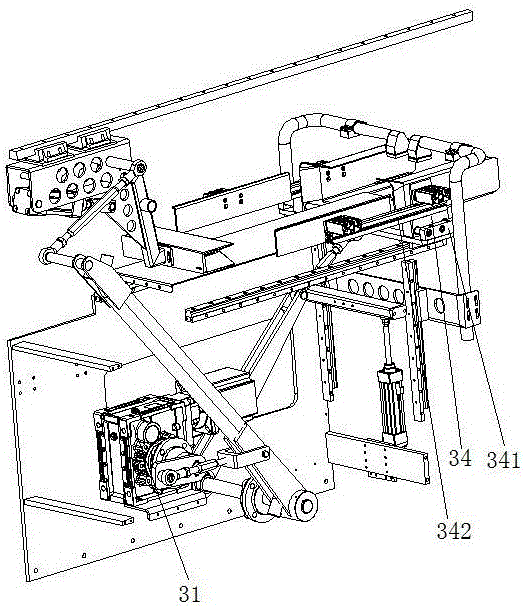

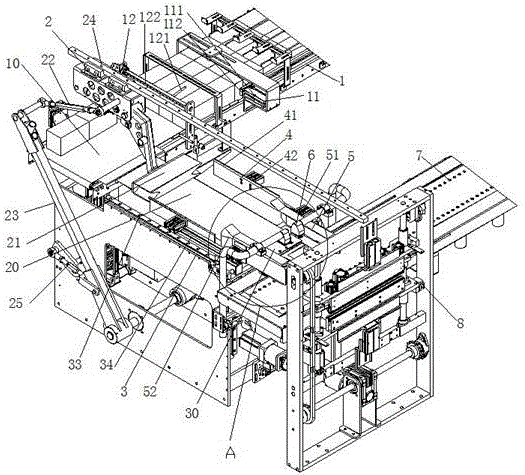

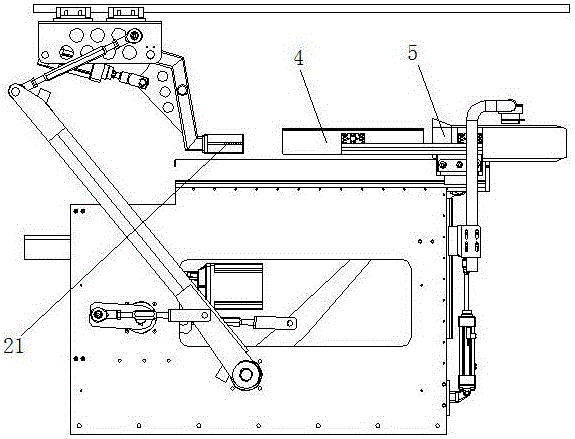

ActiveCN105691713ASolve complexitySolve problems with more motionPackagingReciprocating motionEngineering

The invention discloses a prefabricated bag packaging machine, and relates to the technical field of packaging machinery. The prefabricated bag packaging machine adopts the structure that a clamping and conveying device is arranged between a to-be-clamped station and a bag opening station; the clamping and conveying device comprises a clamping mechanism and a translation mechanism; and the translation mechanism drives the clamping mechanism to perform reciprocating motion in the material clamping and conveying direction. The prefabricated bag packaging machine provided by the invention solves a plurality of problems in the prior art, for example, the working procedure at a single station of a conventional prefabricated bag packaging machine is complex; the quantity of packaging actions is large; the strokes among various stations are relatively long; the equipment occupied area is large; materials are irregular, and the possibility of material overturning is high; a prefabricated bag is liable to broken; the material pushing stroke is long; the packaging effect is poor; and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

Prefabricated bag packaging method of prefabricated bag packaging machine

ActiveCN105691736BReduce processRealize the action of opening and opening bagsPackagingEngineeringSingle station

The invention discloses a prefabricated bag packaging method for a prefabricated bag packaging machine and relates to the technical field of packaging machine packaging processes. The prefabricated bag packaging method includes the steps that prefabricated bags are conveyed to a bag opening station, opened on the bag opening station and arranged on a bag expanding mechanism of the prefabricated bag packaging machine in a sleeving manner; the prefabricated bags move in the direction opposite to the material movement direction along with the bag expanding mechanism of the prefabricated bag packaging machine; and in the process of opposite movement of the prefabricated bags and the materials, under the action of a material pushing mechanism of the prefabricated bag packaging machine, the materials pushed by the material pushing mechanism are contained in the prefabricated bags in a wrapping manner, and the prefabricated bags containing the materials in the wrapping manner are pushed out under the action of the material pushing mechanism. The prefabricated bag packaging method for the prefabricated bag packaging machine can solve the problems that by means of a prefabricated bag packaging machine in the prior art, the working procedures of a single station are complex, the number of the packaging actions is large, the stroke among different stations is long, the area occupied by equipment is large, material dumping occurs easily and the prefabricated bags are broken easily due to the fact that materials are irregular, the material pushing stroke is long, the packaging effect is poor, and the packaging efficiency is low.

Owner:上海松川峰冠包装自动化有限公司

File scanning device and file input method thereof

PendingCN114615385AAdjustable widthAppropriate widthPictoral communicationComputer hardwareElectronic document

The invention discloses a file scanning device, and relates to the field of file scanning devices. The file scanning device comprises a scanning device, a lifting device, a translation device, a hand wheel device and a supporting device, the scanning device comprises a scanner body and a lifting block, four sets of connecting rods are fixedly connected to the side wall of the scanner body, and the connecting rods are fixedly connected between the scanner body and the lifting block. According to the file scanning device, the shooting visual field and the imaging width of the scanner main body are more suitable, the shooting visual field and the imaging width of the scanner main body can be adjusted by directly rotating the hand wheel main body, the scanner main body can be moved in parallel by using the translation device, and then the scanner main body can continuously shoot files according to the files; and the computer splices the plurality of groups of pictures formed by continuous photographing to form a whole continuous picture and form a finished electronic document.

Owner:青州市中医院

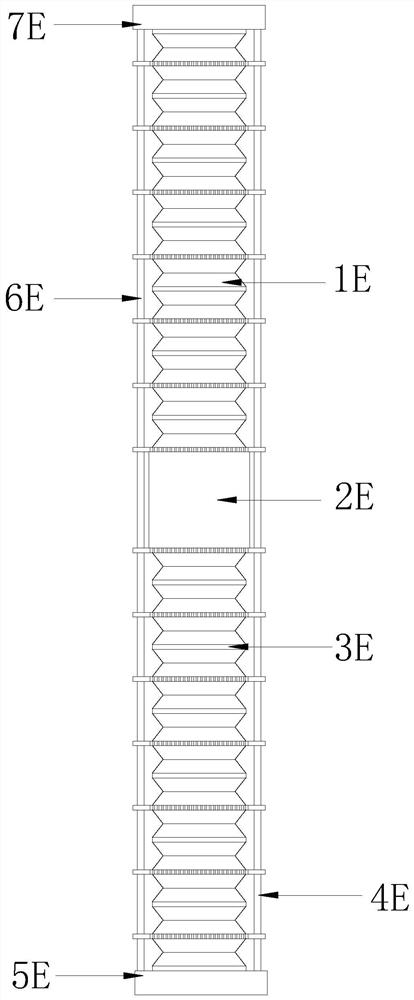

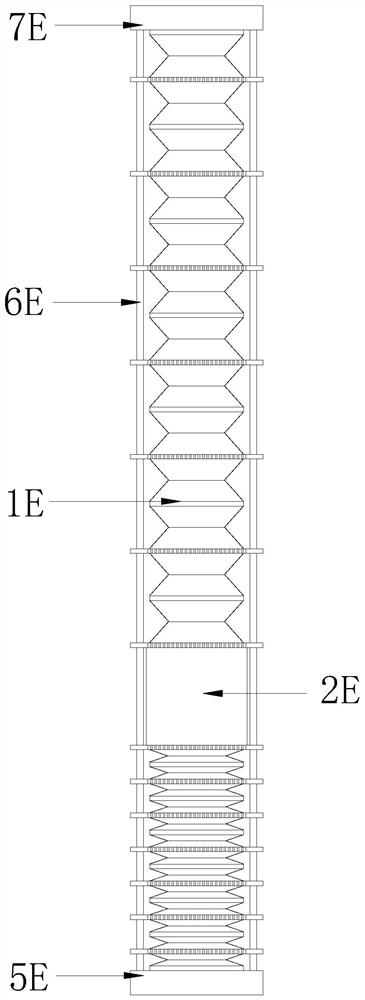

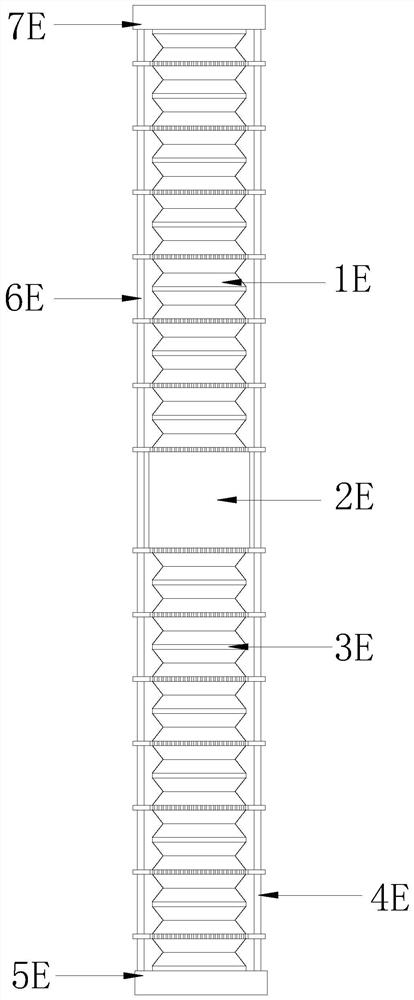

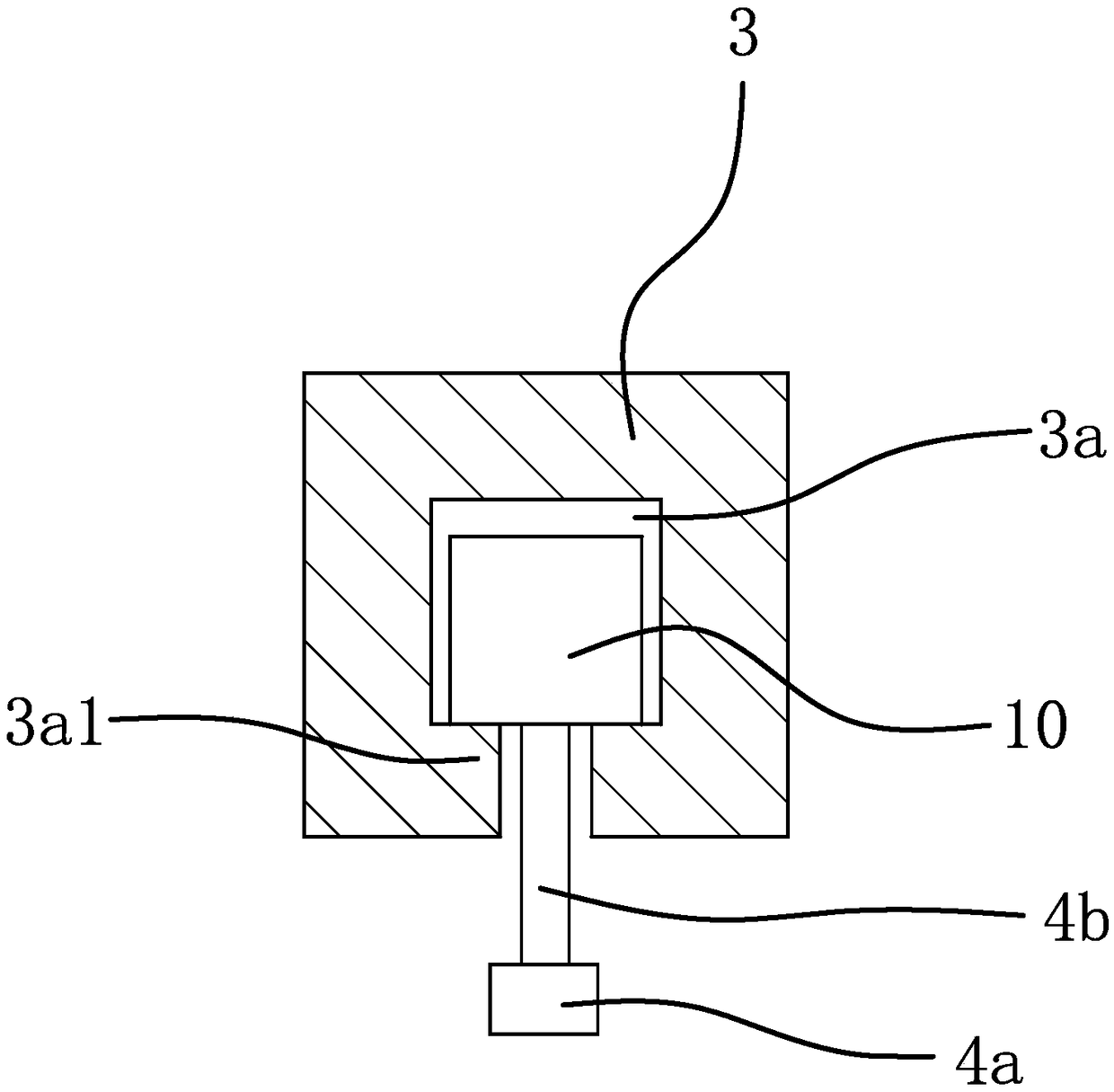

Any-modulus precast concrete beam forming device

PendingCN110202670AIncrease productivitySimple structureMouldsMould fastening meansConcrete beamsRapid prototyping

The invention discloses an any-modulus precast concrete beam forming device which comprises a bottom die, a fixed die, two side dies, side die horizontal moving devices corresponding to the side diesand a heating system. Each side die horizontal moving device comprises multiple sets of horizontal moving driving assemblies and multiple lifting assemblies. Each lifting assembly comprises a fixing seat which is fixedly connected to the corresponding side die. A lifting air cylinder is fixedly connected in each fixing seat. An air cylinder rod of each lifting air cylinder is connected with a wheel fork, wherein a wheel shaft is fixedly connected in the wheel fork, and a wheel is connected to the wheel shaft. The heating system comprises an air heater. The concrete beam forming device is simple in structure, concrete beams with any modulus can be rapidly formed, in addition, after the concrete beams are formed, the concrete beams can also be subjected to heat curing and steam curing, and the production efficiency of the concrete beams is greatly improved.

Owner:重庆恒昇大业建筑科技集团有限公司

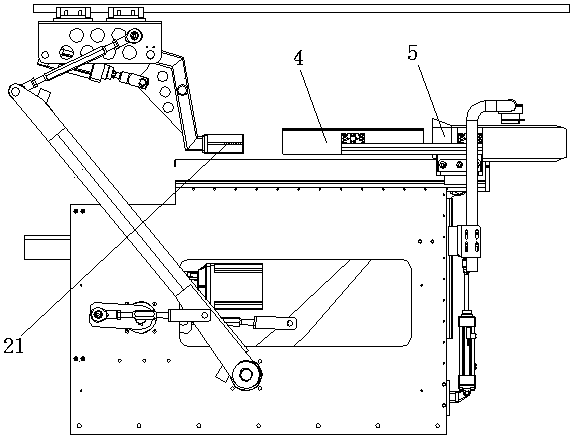

Material holding and conveying device of prefabricated bag packaging machine

ActiveCN105667882AImprove delivery efficiencyShorten holding strokePackagingEngineeringReciprocating motion

The invention discloses a material holding and conveying device of a prefabricated bag packaging machine, and belongs to the technical field of packaging machines. The material holding and conveying device is characterized by comprising a horizontal moving mechanism and a holding mechanism connected with the horizontal moving mechanism; the holding mechanism does the reciprocating motion in the material running direction under the effect of the horizontal moving mechanism. Materials cannot be shaken in the conveying process, and material conveying is more stable compared with that of a clamping mechanism, the materials cannot be clamped and extruded, and the material conveying efficiency is improved; and the holding mechanism does the reciprocating motion in the material running direction under the effect of the horizontal moving mechanism, material conveying and holding are independently matched, the whole holding stroke is shortened, and the follow-up prefabricated bag packaging efficiency can be further improved.

Owner:上海松川峰冠包装自动化有限公司

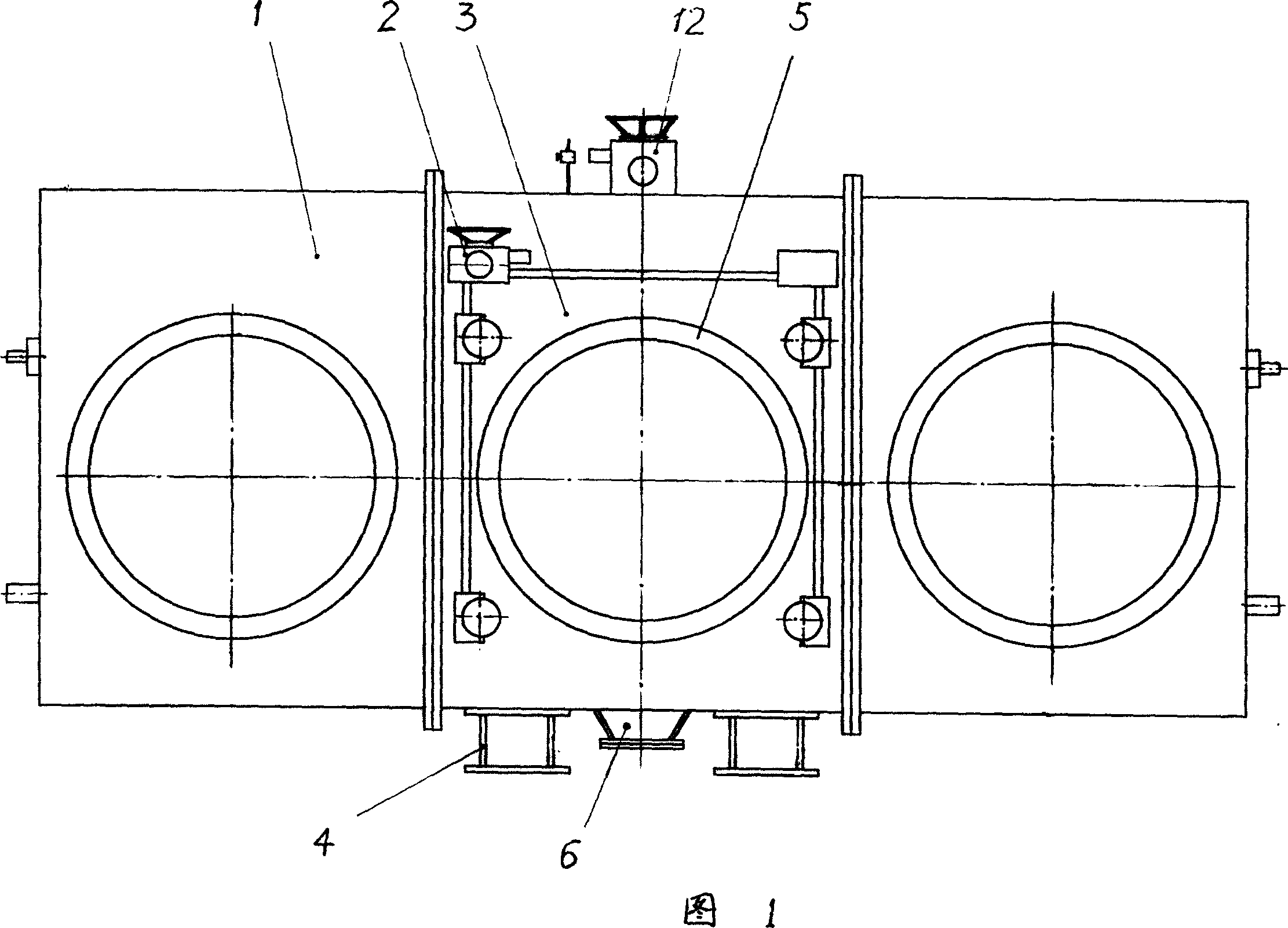

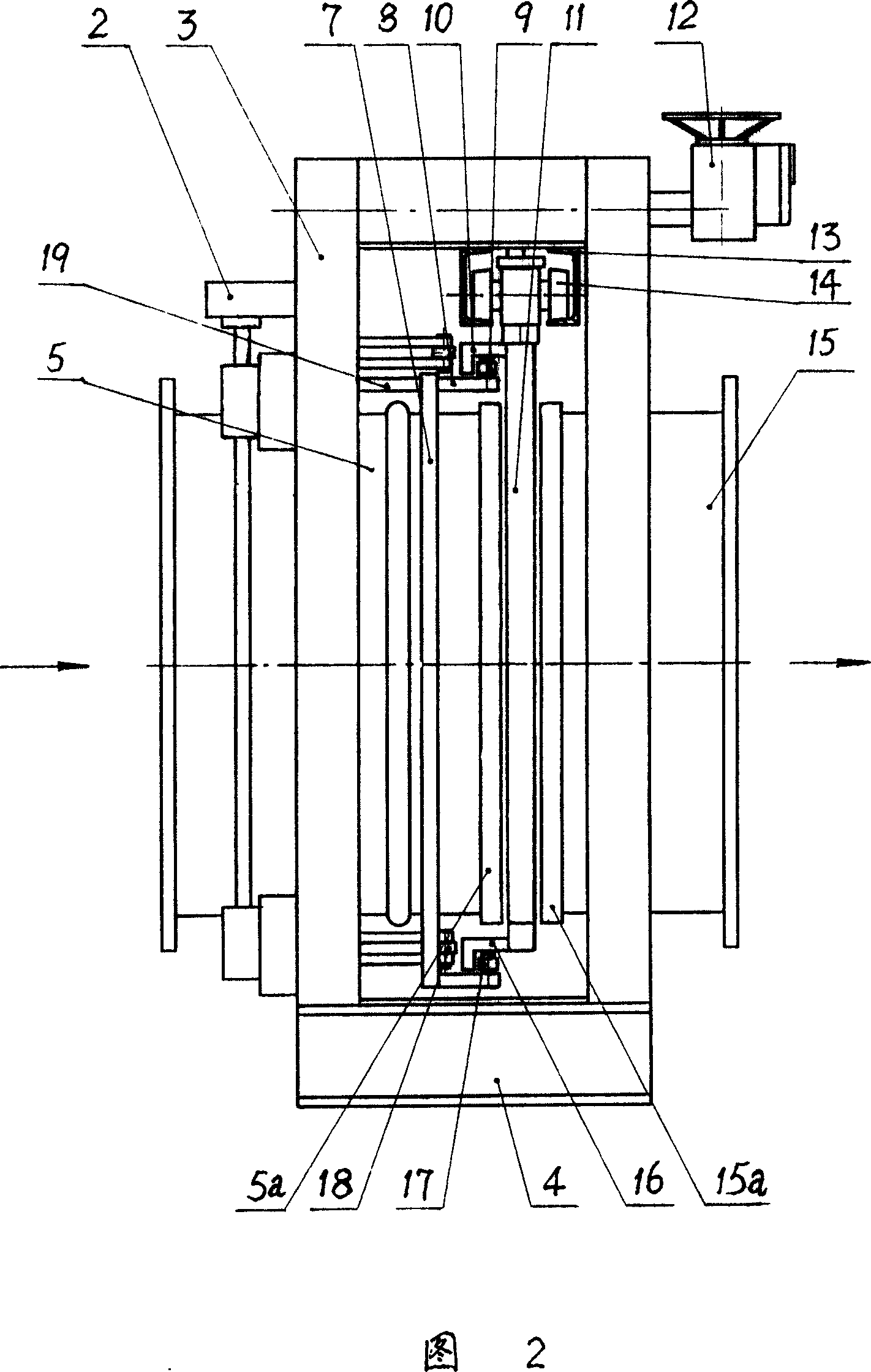

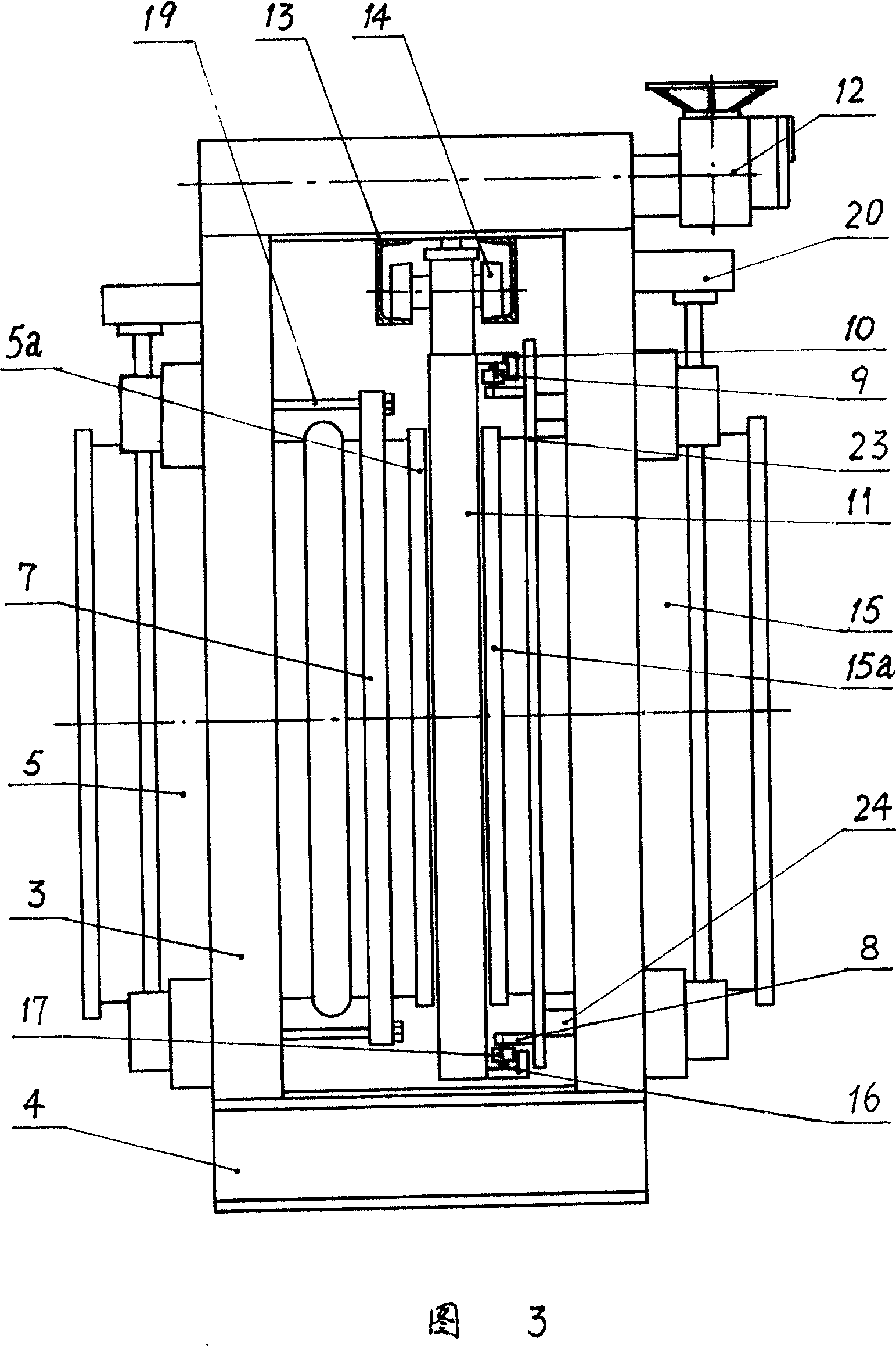

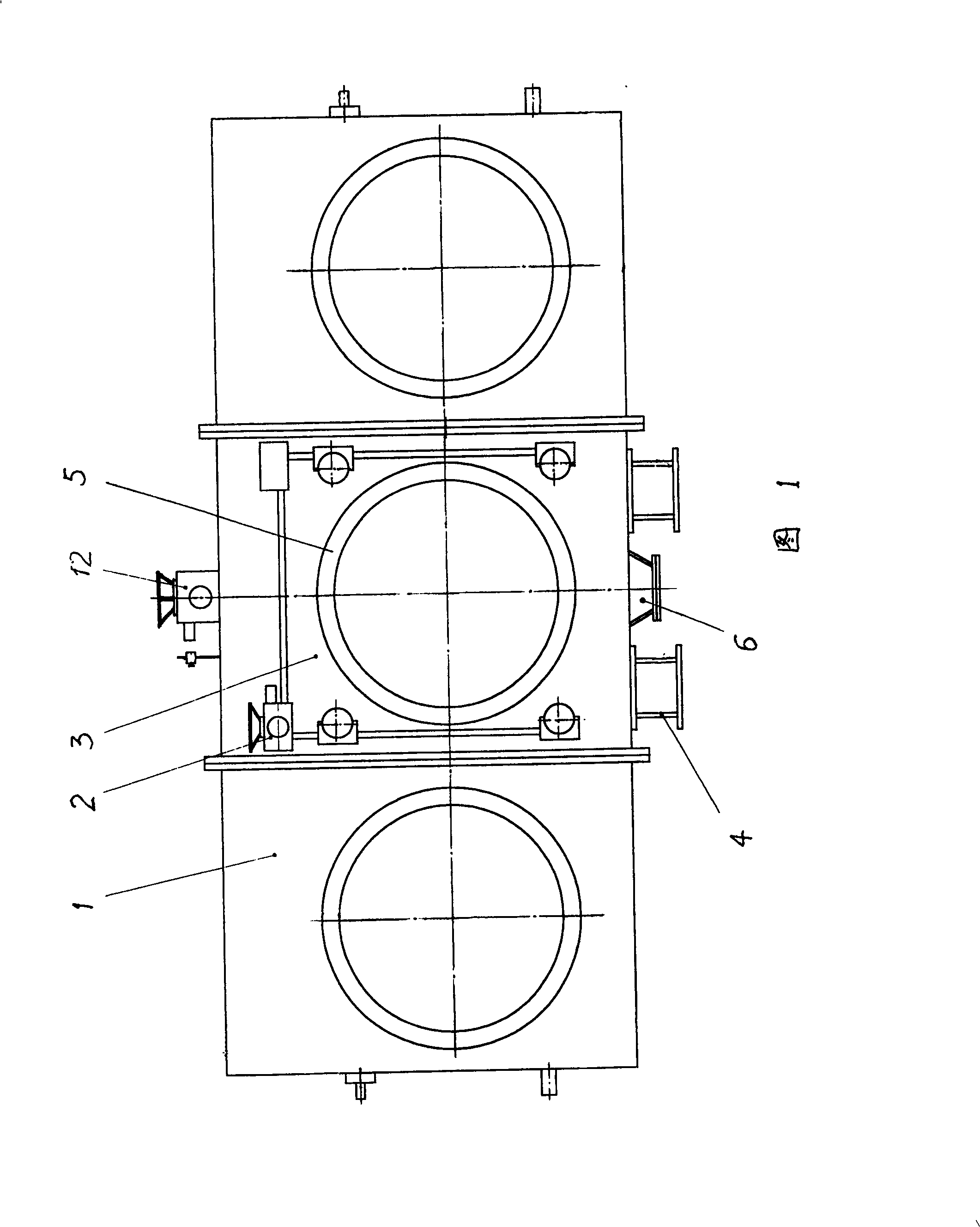

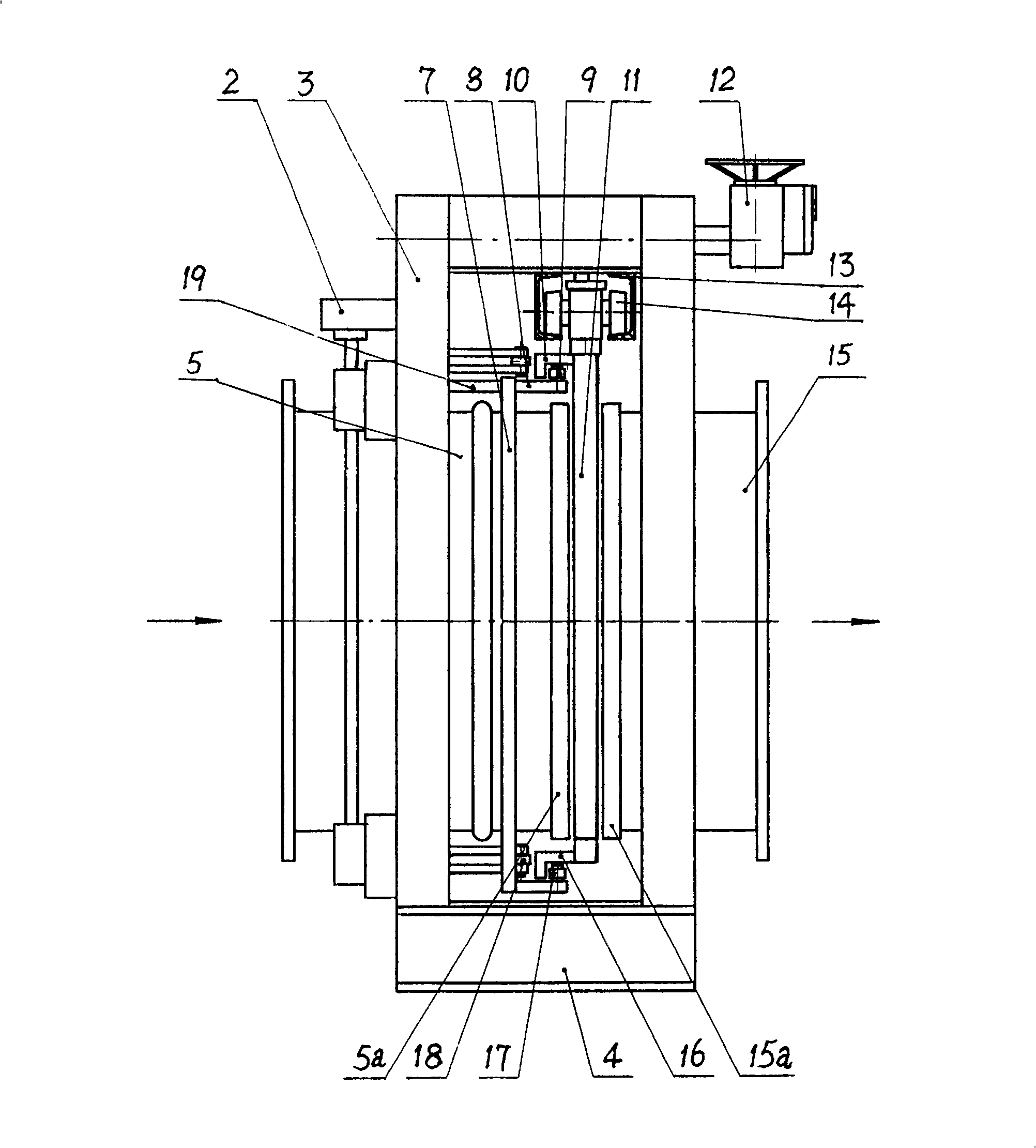

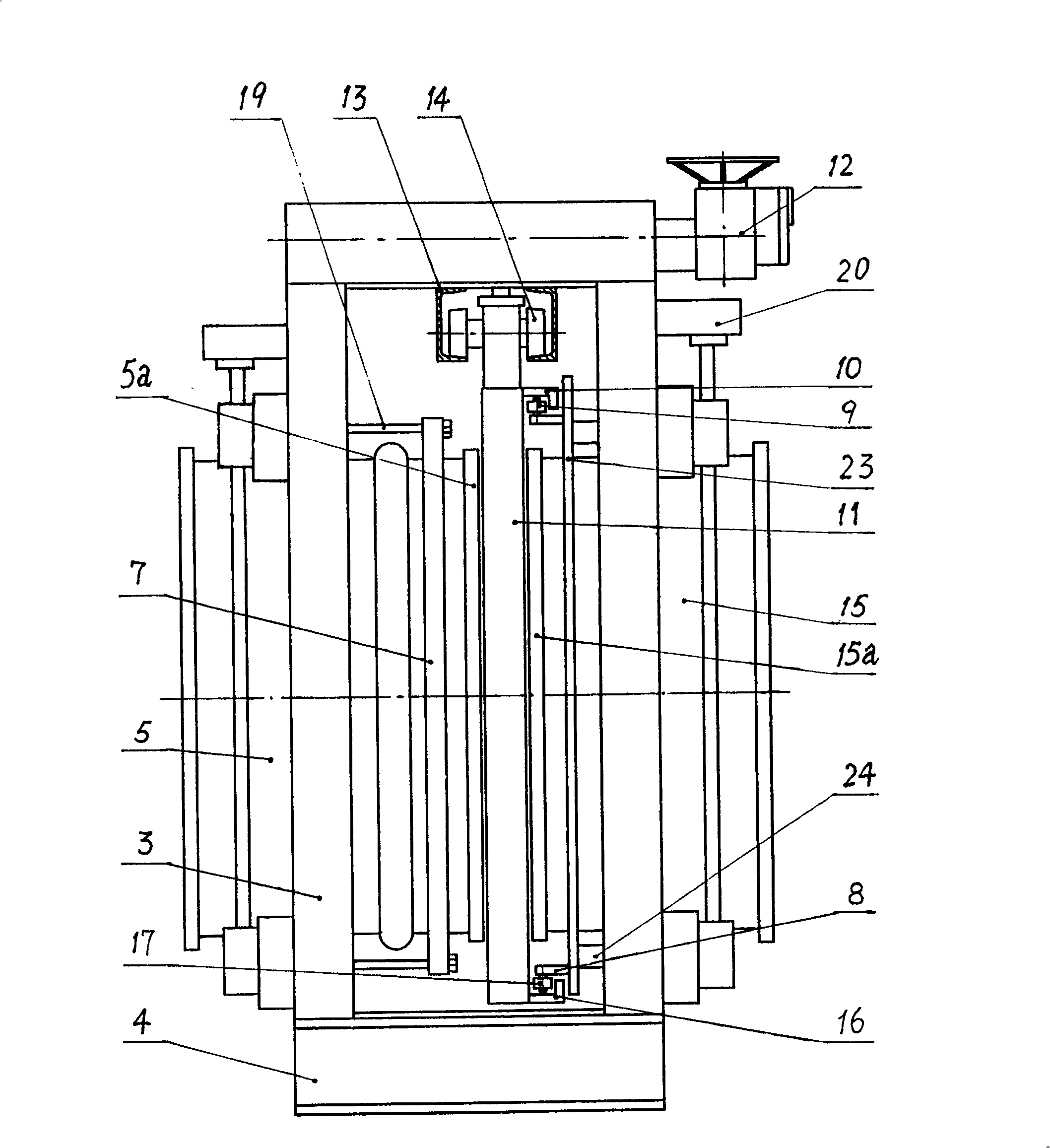

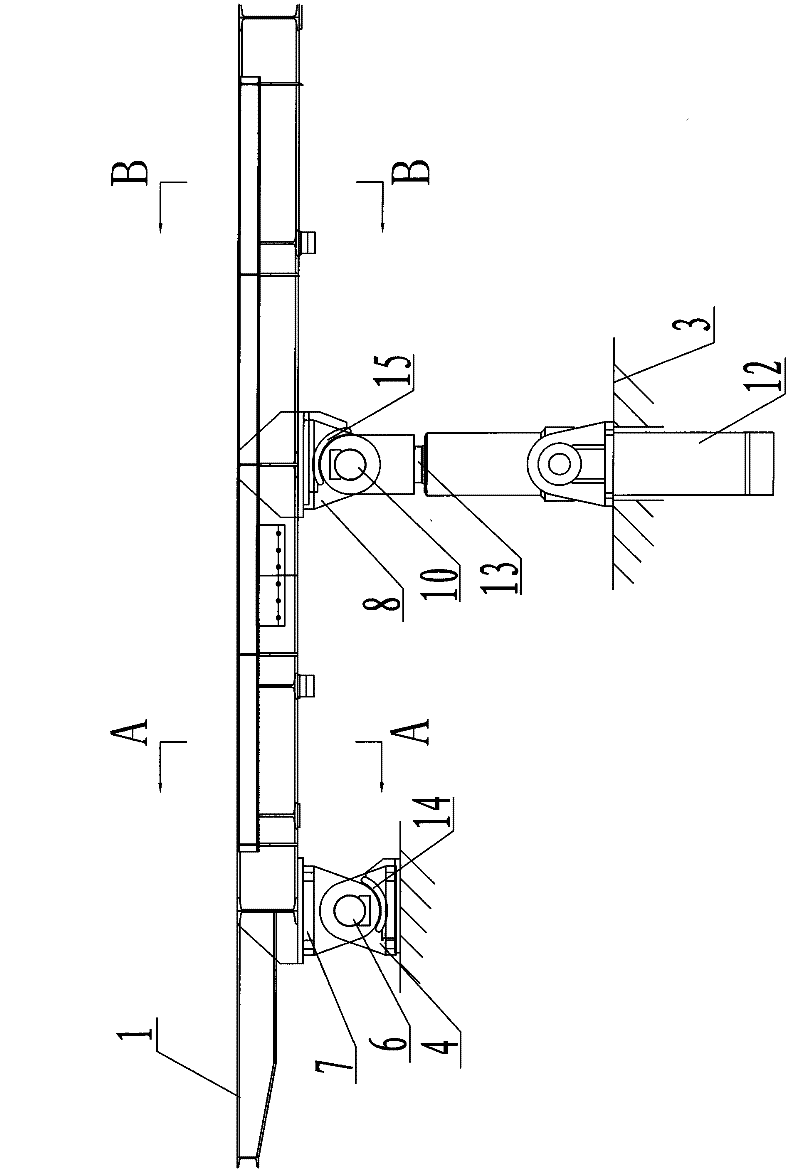

Totally-enclosed large differential pressure open-close glasses valve

InactiveCN101016952APrevent leakageReduce the number of settingsSlide valveDifferential pressureWorking pressure

The invention relates ton a full-seal large-pressure differential glasses valve which uses valve to separate or press the sealing face of valve base, wherein the front and back ends of the main valve box are connected with a stable valve and a movable valve with a corrugated tube, two sides of the main valve box are connected whit a sub valve box, a valve plate with through hole ring and blind hole ring is arranged between the stable valve and the movable valve, a valve plate via a plurality of suspending wheels through at the upper part is suspended on a track at the top of the main valve box, a valve plate press release device is mounted on the main valve box and the movable valve, the top of the main valve box and the valve plate is mounted with a valve plate transverse device, and the main valve box is mounted with a valve plate bearing transverse device. The invention can start and close in pressure with confirmed normal medium pressure to cut off and connect the gas medium in tube.

Owner:邢建栋

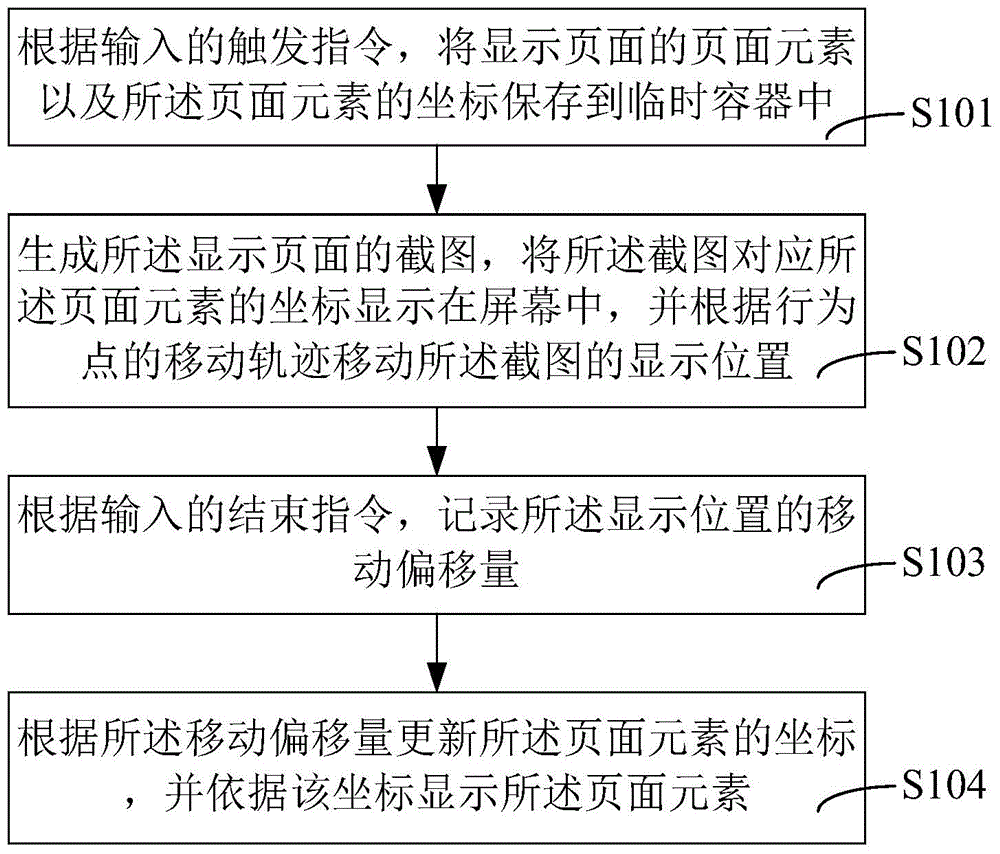

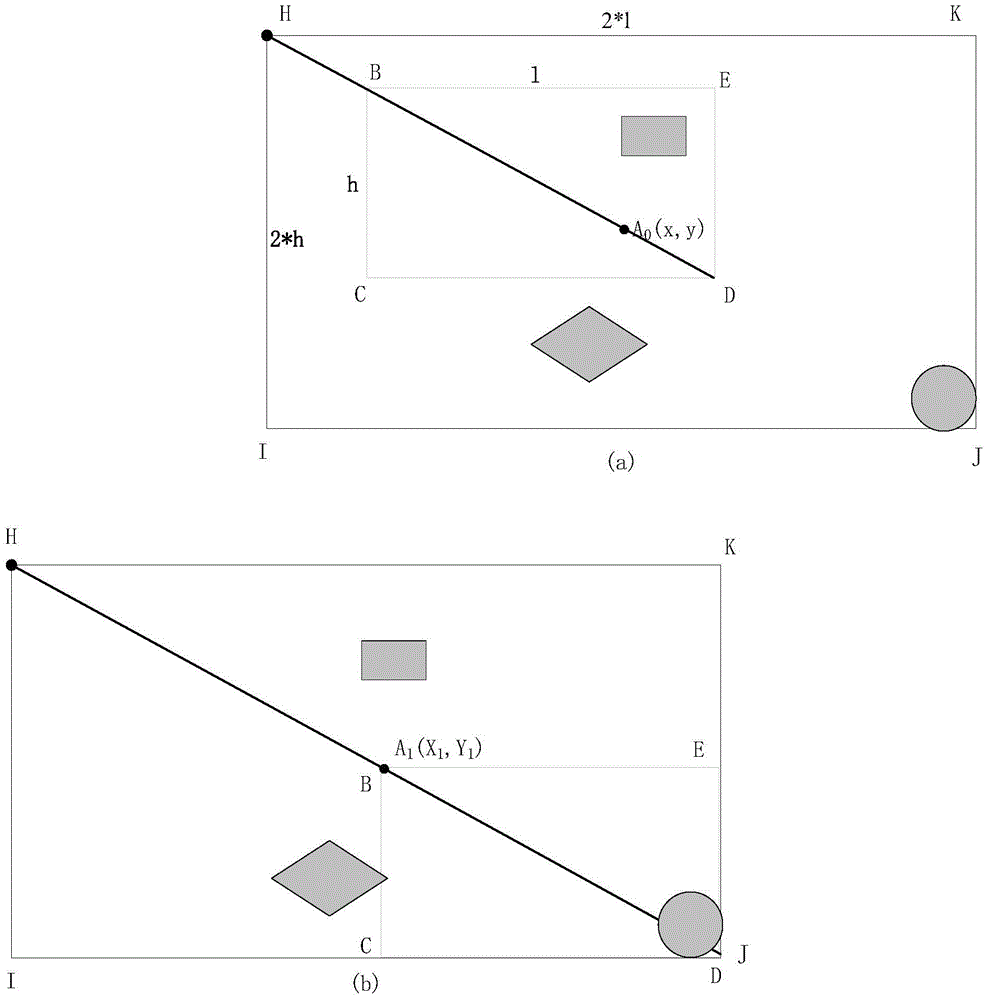

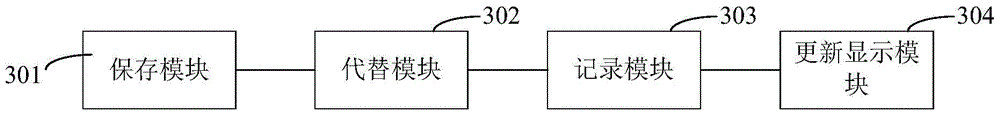

Screen display page translation method and system

ActiveCN104077056BEasy to operateSmooth panningInput/output processes for data processingComputer graphics (images)Translation system

The invention discloses a translation method and a translation system for a page displayed on a screen. The method comprises the steps of: storing the image element of the displayed page and the coordinate of the page element into a temporary container according to an input trigger instruction; generating a printscreen of the displayed page, displaying the printscreen in the screen corresponding to the coordinate of the page element, and moving the display position of the printscreen according to the moving track of a behavior point; recording the movement offset according to an input end instruction; updating the coordinate of the page element according to the movement offset, and displaying the page element according to the coordinate. When in a translation process, the objected to be moved by a user is the printscreen of the displayed page, since the size of the printscreen is far smaller than that of the page element in the displayed page, excessive display card and internal storage resources are not occupied in the translation process, so that the translation process is smooth.

Owner:GUANGZHOU SHIRUI ELECTRONICS

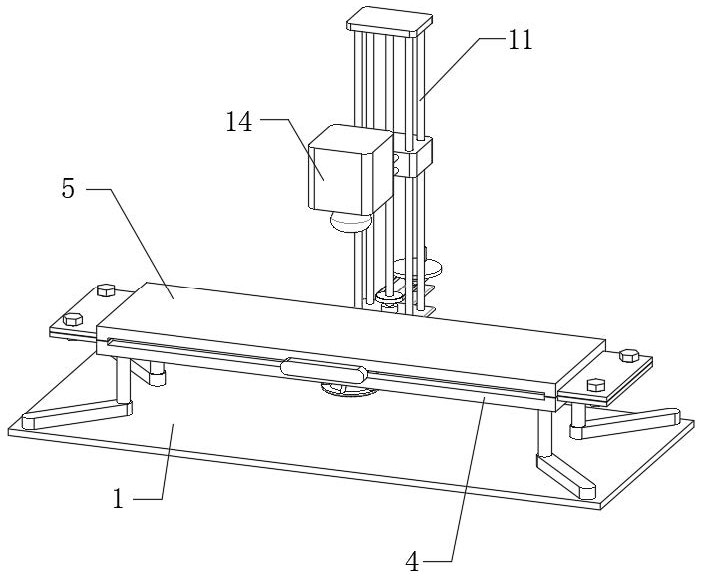

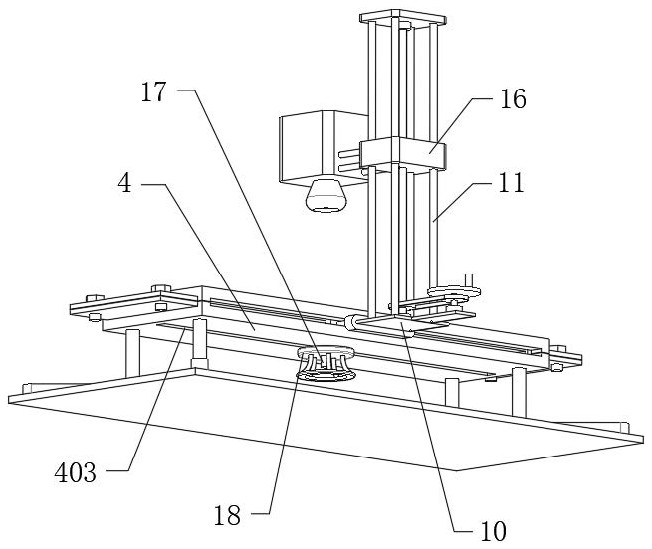

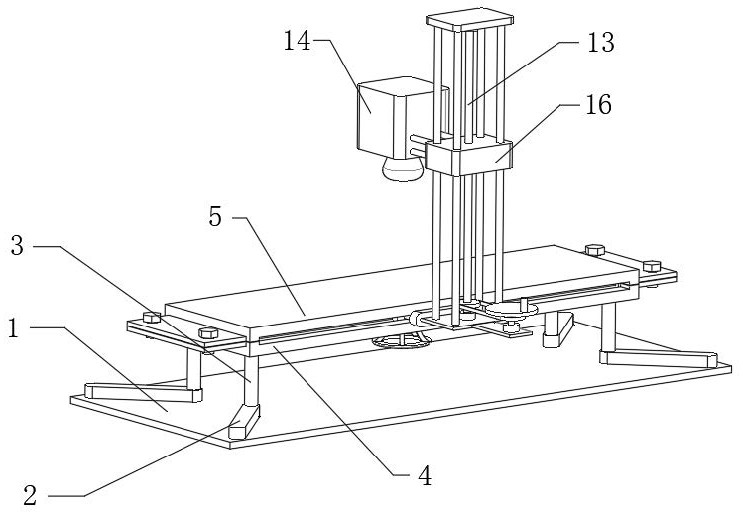

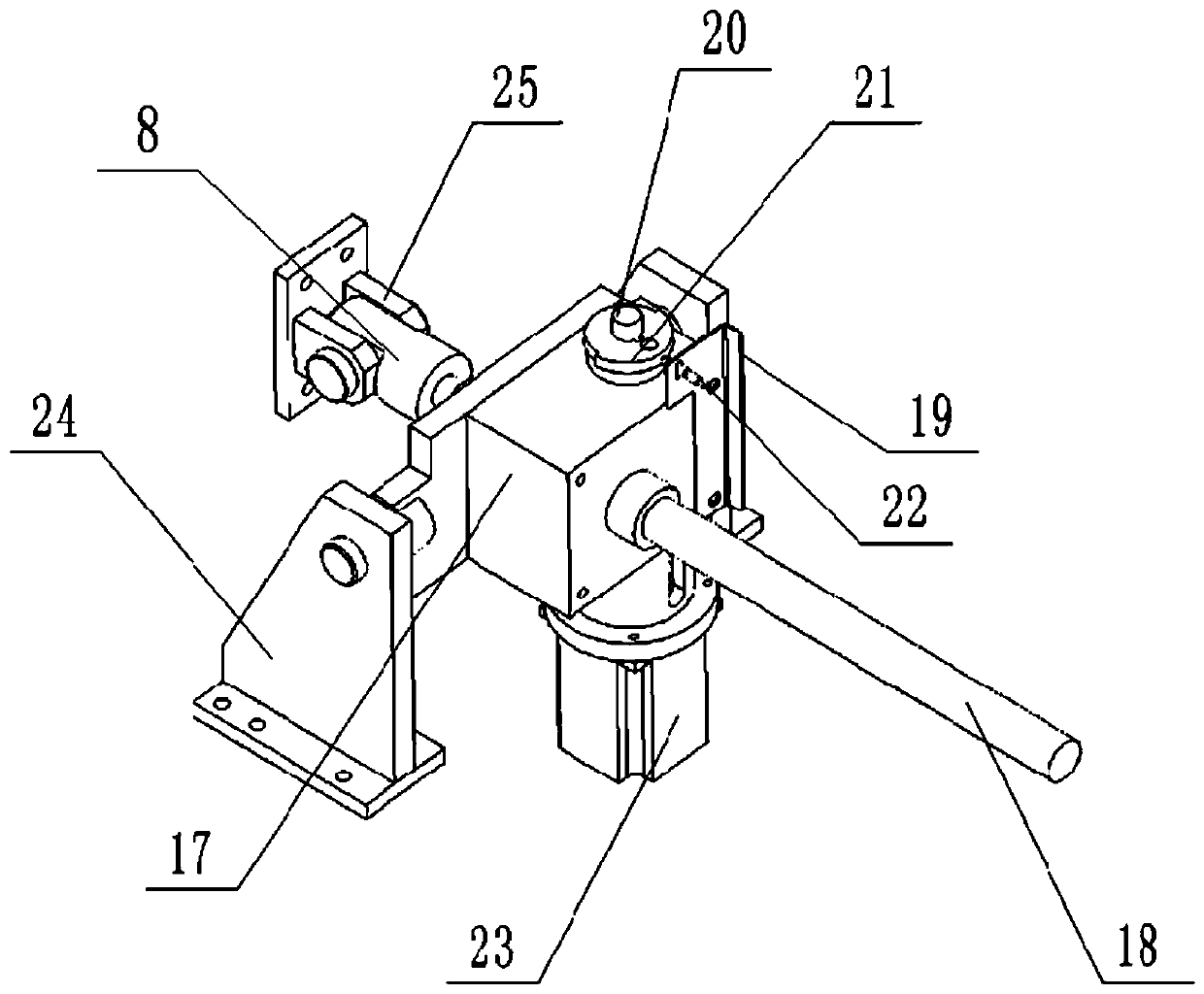

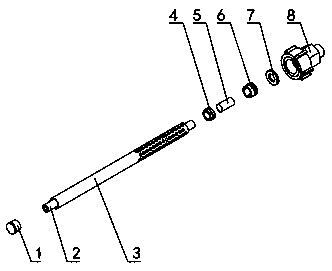

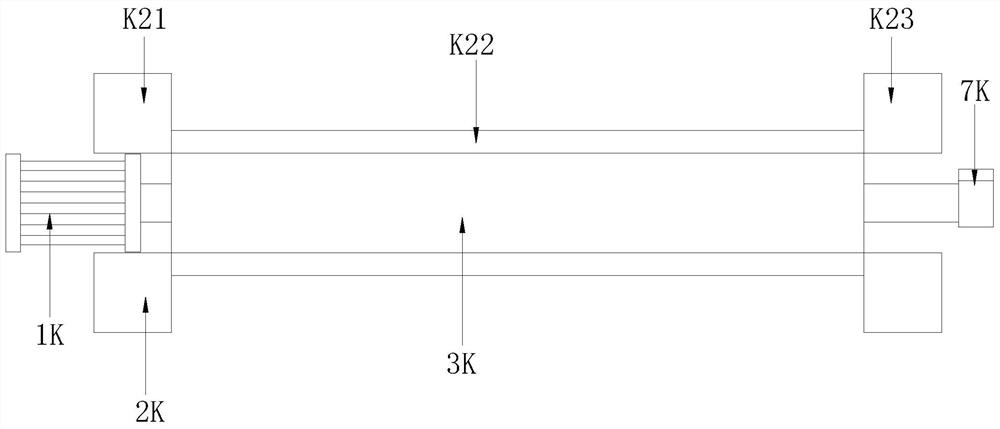

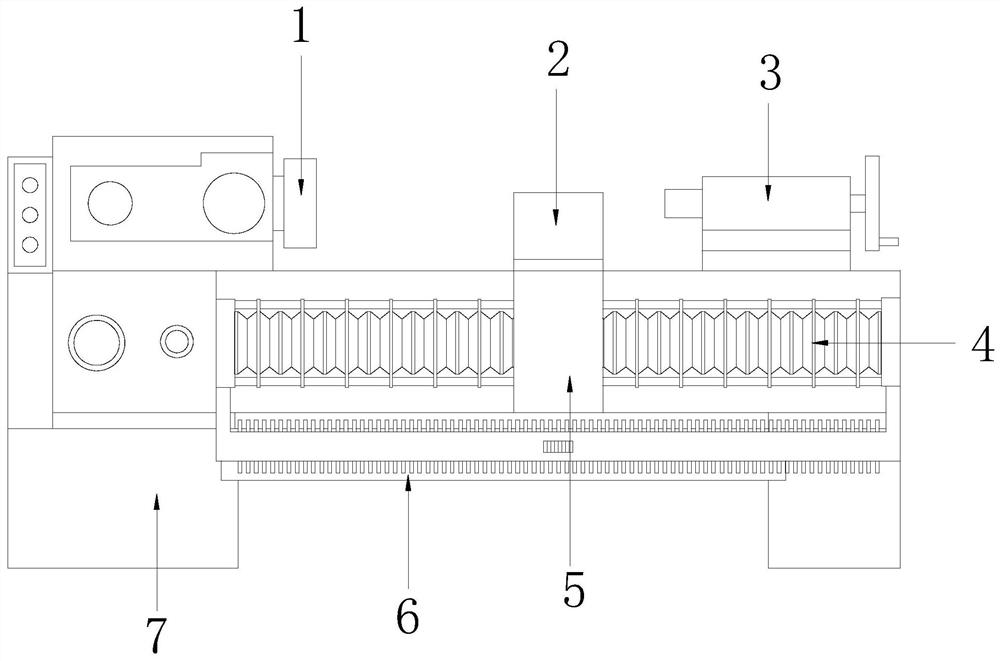

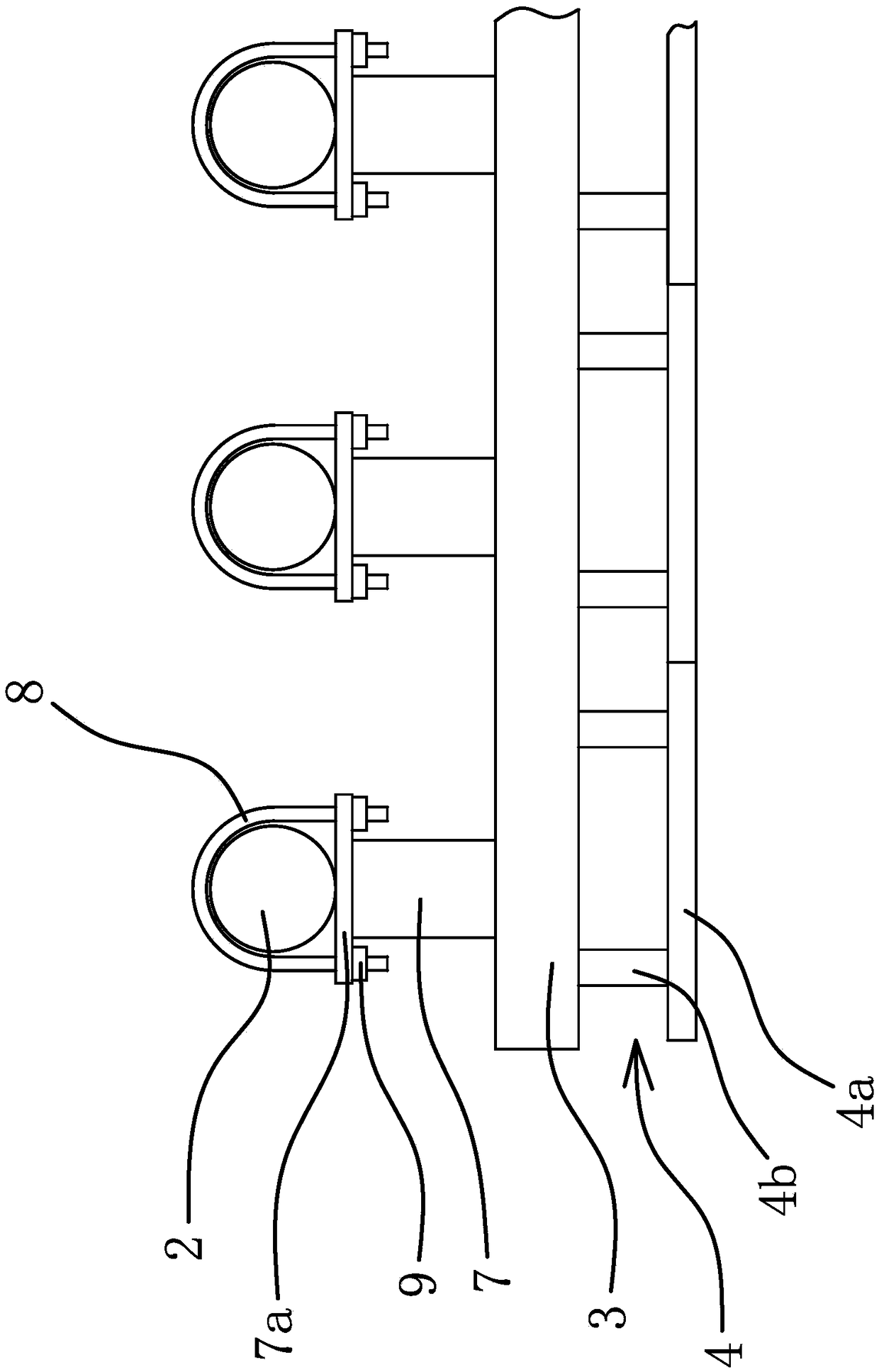

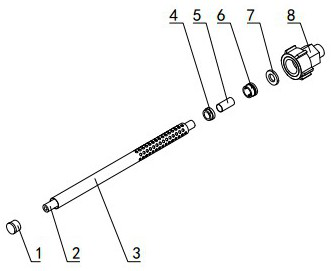

Water heater water pipe assembling device flexible in feeding

ActiveCN110773970AGuaranteed alignmentConvenient thermal connectionMetal working apparatusStructural engineeringMechanical engineering

The invention provides a water heater water pipe assembling device flexible in feeding, and belongs to the technical field of water heater assembling equipment. The water heater water pipe assemblingdevice is characterized by comprising a bearing frame, a bottom seal pushing device, an end pushing device and a feeding device (14), wherein the bottom seal pushing device and the end pushing deviceare symmetrically arranged at the two ends of the bearing frame; a bearing groove is formed in the bearing frame, a bottom seal suction cup used for sucking a bottom seal (1) is arranged on the bottomseal pushing device, and an end suction cup used for sucking an end (8) is arranged on the end pushing device; the feeding device is arranged on one side of the bearing frame, and heat sealing devices are arranged at the two ends of the bearing frame; and the feeding device (14) is mounted on an mounting frame (17) in a sliding manner, and the feeding device (14) is connected with a horizontal moving device (16) for pushing the feeding device (14) to horizontally move in the direction parallel to the bearing groove. By means of the water heater water pipe automatic assembling system, automatic water pipe assembling is achieved, the assembling efficiency is greatly improved, the stability of the quality of an assembled water pipe is guaranteed, and the labor cost is reduced.

Owner:SHANDONG GOLDEN TIDE NEW BUILDING MATERIAL +1

A CNC lathe

ActiveCN111299618BAvoid exposureAvoid adsorptionAutomatic/semiautomatic turning machinesTool holdersNumerical controlScrew thread

Owner:邵阳永腾金属制品有限公司

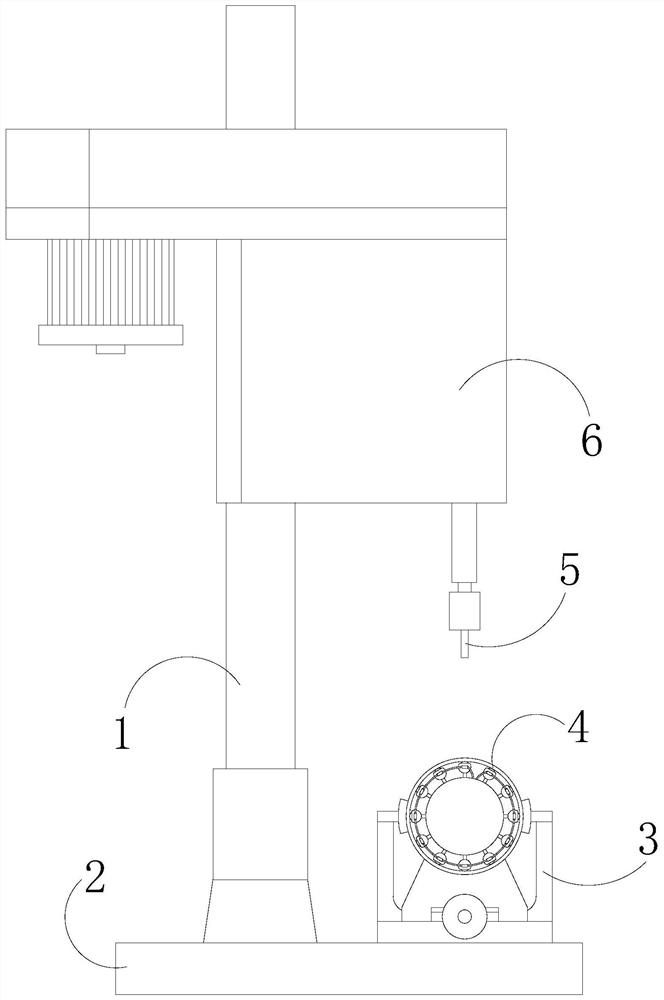

Anti-deformation metal pipe drilling machine

ActiveCN111993132AAccurate displacementEqual spacingFeeding apparatusPositioning apparatusThermodynamicsMachine

The invention discloses an anti-deformation metal pipe drilling machine. The anti-deformation metal pipe drilling machine structurally comprises a stand column, a base, a workbench, a metal pipe, a drill bit and a machine body, wherein the stand column is vertically connected with the base, the machine body is fixed to the stand column, the drill bit is installed on the machine body, the workbenchis arranged below the drill bit, the workbench is fixed to the base, and the metal pipe is placed on the workbench. Compared with the prior art, the anti-deformation metal pipe drilling machine has the beneficial effects that through combined arrangement of a supporting device, a clamp, an L-shaped connecting frame, a foundation seat, a sliding rail assembly and a supporting table, the to-be-drilled part can be internally supported, the supporting stability can be greatly improved through the characteristics and hydraulic pressure of a clockwork spring, a metal pipe is effectively prevented from deforming in the drilling process, meanwhile, the device can adapt to supporting of metal pipes with different calibers, and the application range is wide.

Owner:上海世柯仓储设备工程有限公司

Material holding type conveying method for preformed-bag packer

ActiveCN105752402ADoes not pinch and squeezeImprove delivery efficiencyPackagingEngineeringMechanical engineering

The invention discloses a material holding type conveying method for a preformed-bag packer and belongs to the technical field of material packing. The material holding type conveying method is characterized by including the steps of firstly, conveying materials into a holding mechanism; secondly, conveying the materials by a holding way to a to-be-pushed work station and opening preformed bags by a bag opening mechanism; thirdly, pushing the materials by a pushing mechanism while driving the preformed bags to move opposite the materials by the bag opening mechanism. The material holding type conveying method is adaptable to both regular materials in bulk and irregular materials in bulk; the material holding type conveying way is stabler than the material clamping type conveying way and squeezing of the materials is avoided; thus, material conveying efficiency is improved, and efficiency of preformed bag packing is improved.

Owner:上海松川峰冠包装自动化有限公司

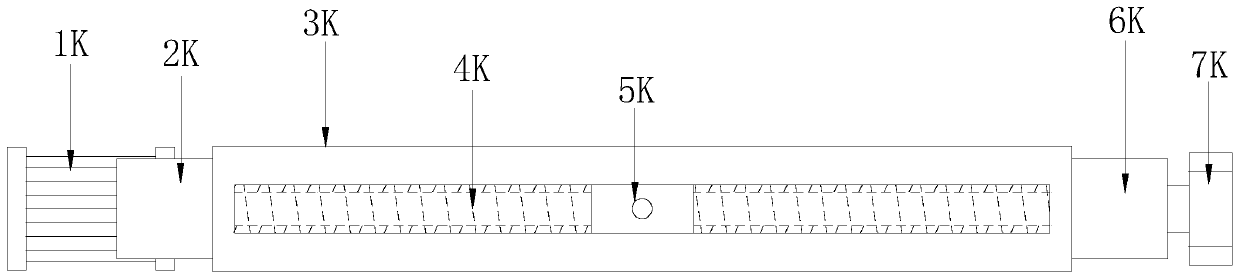

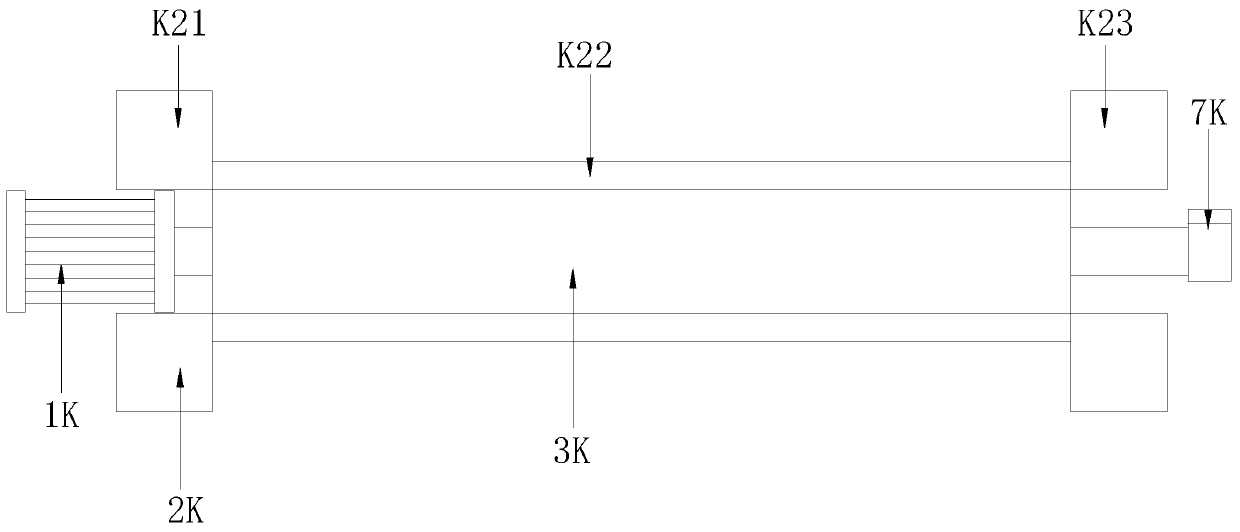

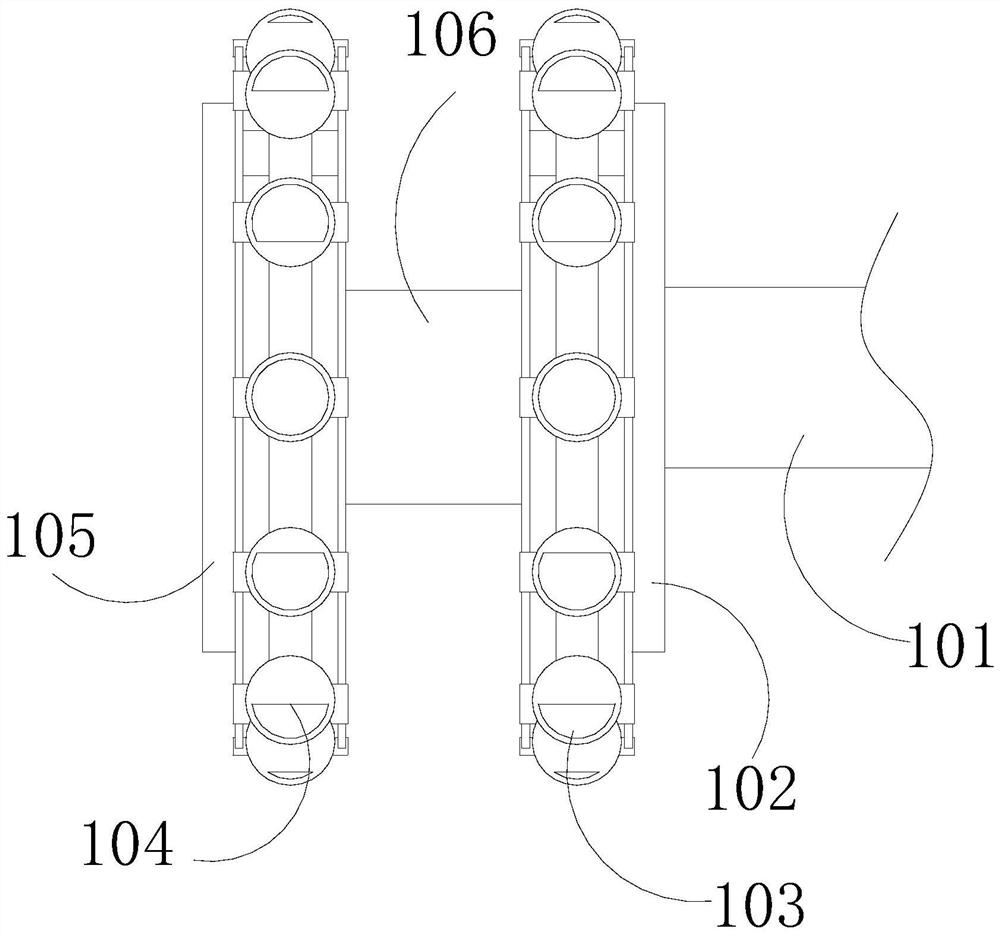

Numerical control turning machining center system and operation method thereof

InactiveCN112894473ASmooth panningHigh precisionMaintainance and safety accessoriesNumerical controlThermal dilatation

The invention discloses a numerical control turning machining center system and an operation method thereof. The numerical control turning machining center system structurally comprises a fixed chuck, a turning device, a movable clamping device, a moving device, a moving base, a water pan and a machine body, wherein the fixed chuck is arranged on one side of the machine body, the movable clamping device is installed on the other side of the machine body, and the turning device is arranged between the fixed chuck and the movable clamping device. Compared with the prior art, the system has the beneficial effects that through combined arrangement of a first corrugated pipe, a nut pair, a second corrugated pipe, a first guide rod, a second fixed base, a second guide rod, a first fixed base, a lead screw and a lead screw cooling mechanism, the lead screw can be hidden, the situation that the lead screw is exposed to the outside, oxidized and rusted is avoided, dirt formed by adhering dust impurities can also be avoided, the screw rod does not need to be cleaned, the maintenance cost is greatly reduced, meanwhile, horizontal movement of the nut pair is smooth, the horizontal movement precision of the nut pair is improved, heat dissipation can be conducted on the lead screw, it is avoided that the horizontal movement of the nut pair is affected due to thermal expansion of a lead screw body, and the turning machining precision is improved.

Owner:钟金梅

A CNC turning machining center equipment

ActiveCN111451834BSmooth panningHigh precisionMaintainance and safety accessoriesThermal dilatationProcessing accuracy

The invention discloses a numerical control turning machining center equipment, the structure of which comprises a fixed chuck, a turning device, a moving clamp device, a moving device, a moving seat, a water tray, and a machine body. One side of the machine body is provided with a fixed chuck, and the other side A movable clamp device is installed, and a turning device is provided between the fixed chuck and the movable clamp device. Compared with the prior art, the beneficial effect of the present invention is that: through the No. 1 bellows, the nut pair, the No. 2 bellows, the No. 1 The combination of guide rod, No. 2 fixed seat, No. 2 guide rod, No. 1 fixed seat, screw rod, and screw cooling mechanism can hide the screw rod to prevent the screw rod from being exposed to oxidation and rust. It avoids dust and impurities from sticking to form dirt, so that the screw rod does not need to be cleaned, which greatly reduces maintenance costs. At the same time, it makes the translation of the nut pair smooth and unimpeded, which is conducive to improving the accuracy of the translation of the nut pair, and can dissipate heat from the screw rod to avoid thermal expansion of the screw rod body. It affects the translation of the nut pair, which is helpful for the turning precision.

Owner:东莞市迪奥数控设备有限公司

Hanging device in a freight car

The invention provides a hanging device in a freight car, belonging to the mechanical technical field. It solves the problem of poor stability in the prior art. The hanging device in the truck compartment comprises a cross member, Side rails, guide rods and hangers, the number of the crossbeams is two and the two crossbeams are fixedly connected at two sides in the top of the carriage, the longitudinal beam and the cross beam are arranged perpendicularly and two ends of the longitudinal beam are fixedly connected on two cross beams respectively, an upper part of that guide rail bar is fixedlyconnected with a longitudinal beam, and the hanging frame is locate at the lower part of the guide rail bar and has a guide structure capable of translating the hang frame along the guide rail bar between the two, the number of the hanging frames is several and the hanging frames are sequentially abutted together, the most front hanging frame is abutted against the inner side wall of the car, andthe most outer hanging frame is abutted against the car door of the car. The hanging device in the truck compartment has high stability.

Owner:ANZHENG FASHION GROUP

Totally-enclosed large differential pressure open-close glasses valve

InactiveCN100451407CDoes not affect lateral transposition movementPrevent leakageSlide valveDifferential pressureWorking pressure

Owner:邢建栋

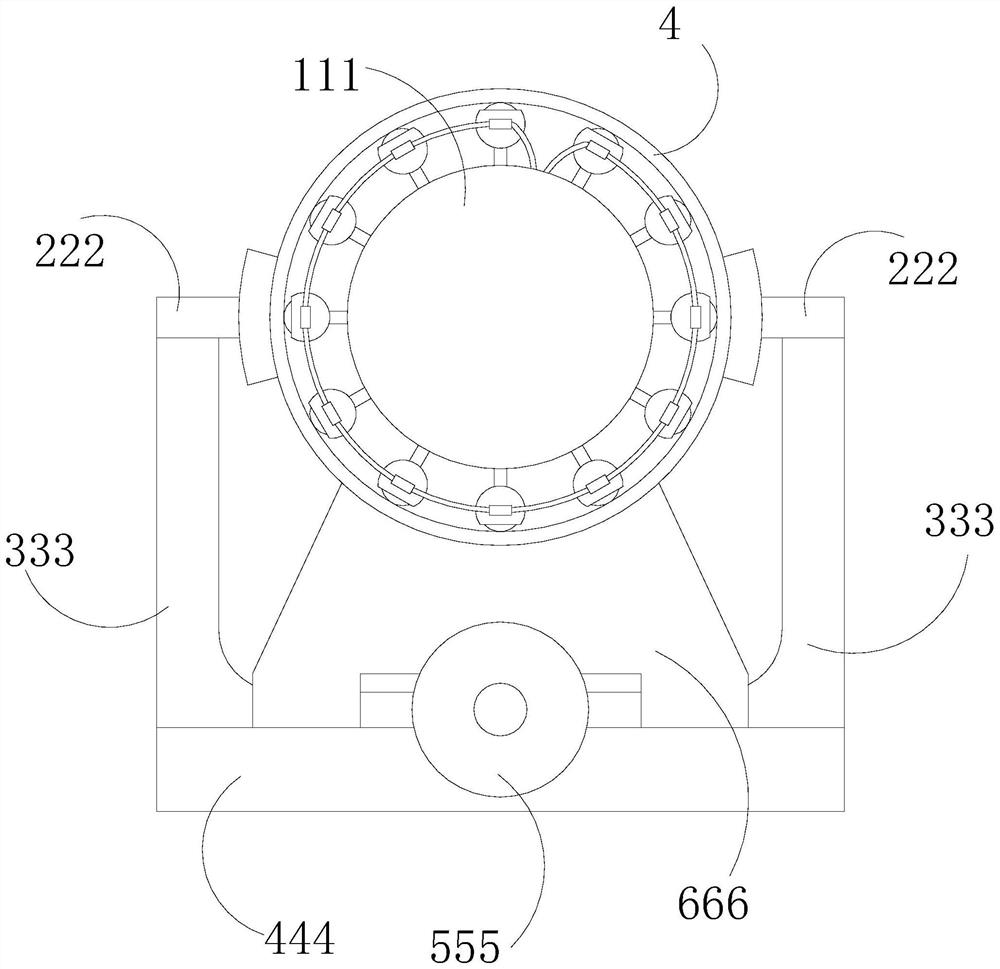

Quenched coke receiving slot translating and laterally turning-over device

The invention discloses a quenched coke receiving slot translating and laterally turning-over device comprising a quenched coke receiving slot. One end of the bottom of the quenched coke receiving slot is provided with a plurality of rotary supporting devices, and the rotary supporting devices comprise a first fixed base and a second fixed base which are fixedly arranged on a stand, wherein a first hinge shaft is fixedly arranged between the first fixed base and the second fixed base, and the first hinge shaft matches with a first support which is fixedly arranged at the bottom of the quenched coke receiving slot. The other end of the bottom of the quenched coke receiving slot is provided with a plurality of jacking devices, and the jacking devices comprise a third fixed base and a fourthfixed base which are fixedly arranged at the bottom of the quenched coke receiving slot, wherein a second hinge shaft is fixedly arranged between the third fixed base and the fourth fixed base and isprovided with a second support which matches with the second hinge shaft, and the second support is connected with the piston rod of an oil cylinder which is fixedly arranged on the stand. The quenched coke receiving slot translating and laterally turning-over device can make the quenched coke receiving slot translate more smoothly and laterally turn over more effectively and reliably.

Owner:ZHANGJIAGANG CHANGLI MACHINERY

Premade Bag Packaging Machine

ActiveCN105691713BShorten the timePrevent the situation of dumpingPackagingReciprocating motionSingle station

A prefabricated bag packaging machine. A clamping and conveying device is disposed between a to-be-clamped station (10) and a bag opening station (30); the clamping and conveying device comprises a clamping mechanism (4) and a translation mechanism (3); and the translation mechanism (3) drives the clamping mechanism (4) to perform reciprocating motion in the material clamping and conveying direction. The prefabricated bag packaging machine resolves the problems in the prior art of complex working procedures of a single station, the great quantity of packaging actions, long travel distance among stations, large area occupied by the devices; easy overturning of materials due to the irregular materials, easy breaking of prefabricated bags, long travel distance of material pushing, poor packaging effect and low packaging efficiency of the existing prefabricated bag packaging machine.

Owner:上海松川峰冠包装自动化有限公司

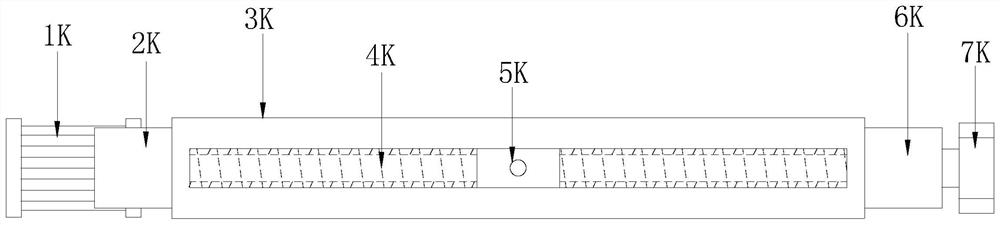

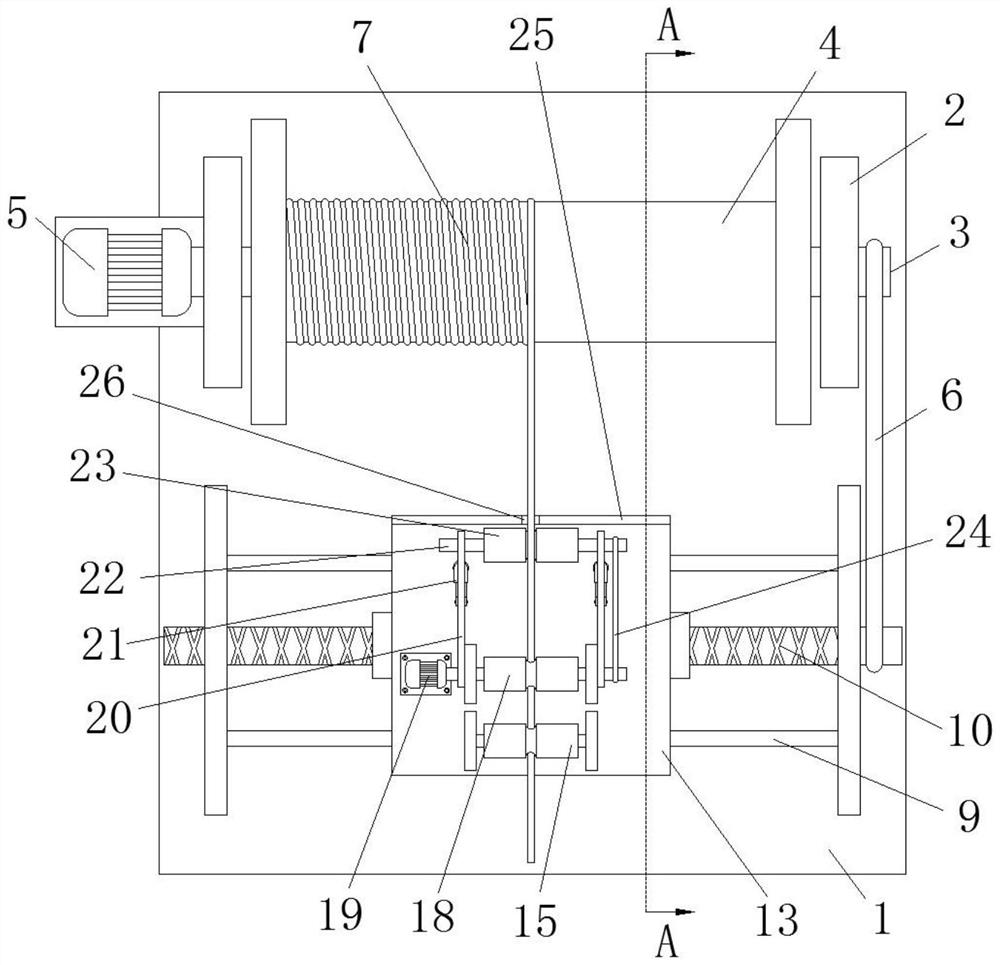

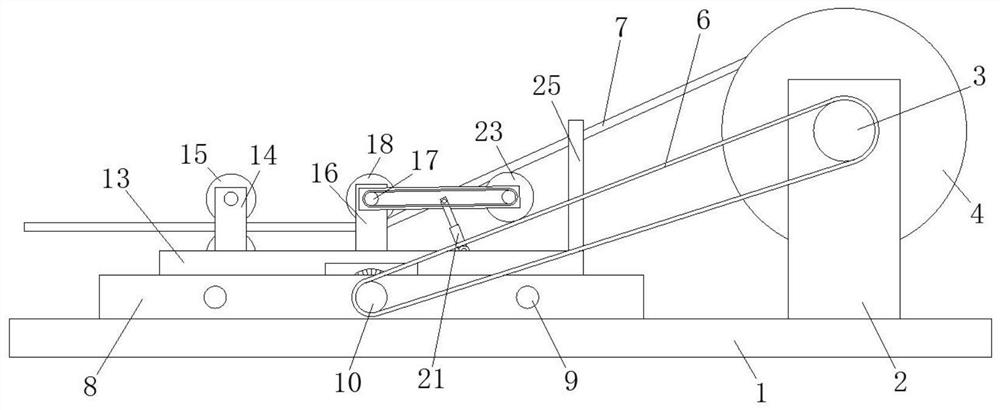

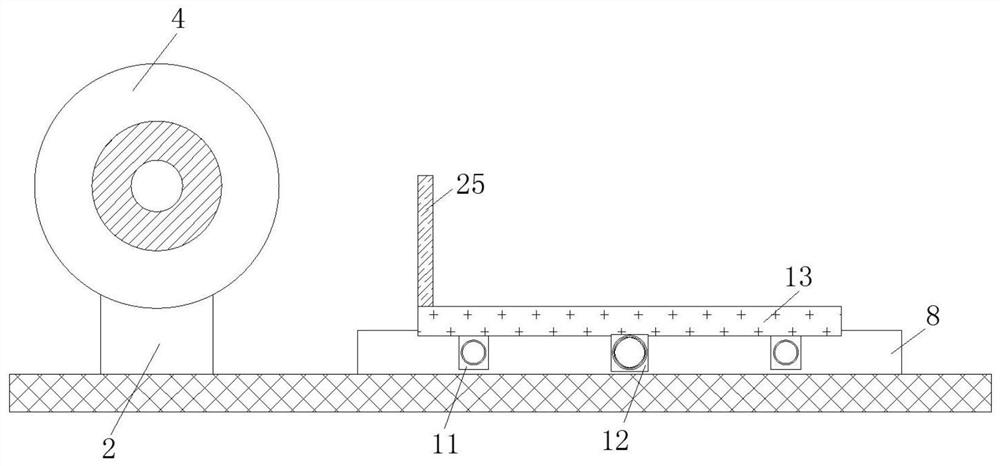

Winding device for armored platinum-rhodium wire production

PendingCN113682881AReduce surface preparation timePrevent affecting the tightness of windingFilament handlingCleaning using toolsForeign matterEngineering

The invention discloses a winding device for armored platinum-rhodium wire production, which comprises a base, a winding mechanism is fixedly connected to the rear side of the top of the base, a first belt is arranged on the right side of the winding mechanism, the first belt is rotationally connected with a reciprocating translation mechanism, a supporting plate is arranged on the top of the reciprocating translation mechanism, a burr removing mechanism is arranged at the top of the supporting plate, and foreign matter blocking mechanisms are arranged on the rear side, the left side and the right side of the top of the supporting plate; and brush plates are fixedly connected to the middle points of the left side and the right side of the supporting plate. The winding mechanism and the reciprocating translation mechanism operate synchronously, so that platinum-rhodium wires are stacked while being wound by a wire winding roller, surface treatment is performed on the platinum-rhodium wires in the winding process, the time required for surface treatment of the platinum-rhodium wires is saved, the production efficiency is improved, and in addition, burrs and other foreign matters are blocked and cleaned through a foreign matter blocking mechanism, so that normal operation of the winding mechanism and the reciprocating translation mechanism is ensured, and the reliability of the device is improved.

Owner:京仪股份有限公司

A water heater water pipe assembly device with flexible feeding

ActiveCN110773970BGuaranteed alignmentConvenient thermal connectionMetal working apparatusThermodynamicsStructural engineering

Owner:SHANDONG GOLDEN TIDE NEW BUILDING MATERIAL +1

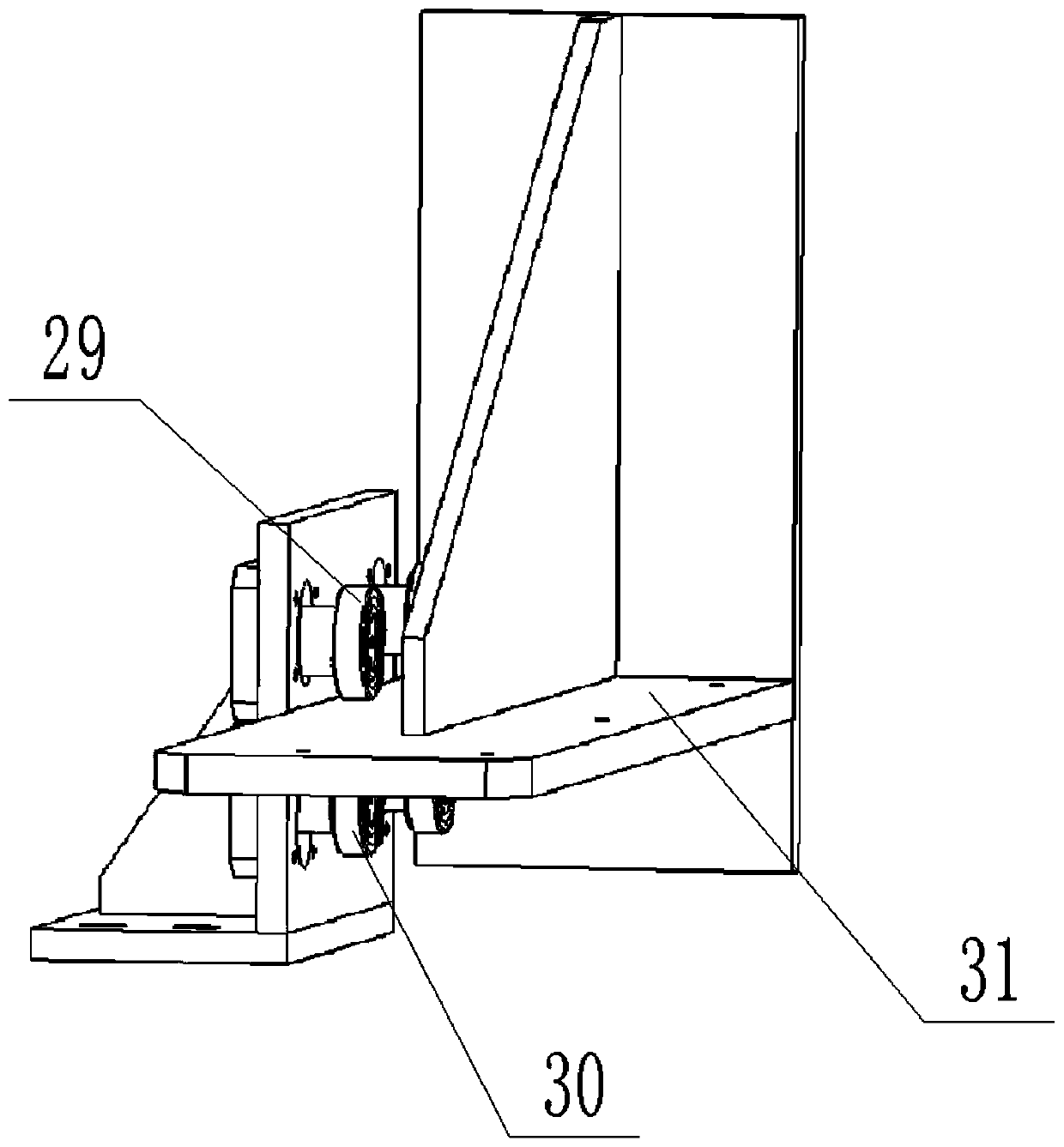

Bag opening device for prefabricated bag packaging machine

The invention discloses a bag opening device of a prefabricated bag packaging machine, and belongs to the technical field of packaging machines. The bag opening device is characterized by comprising a translation mechanism and a bag opening mechanism connected to the translation mechanism, wherein the bag opening mechanism is driven by the translation mechanism to move back and forth in a material operation direction. According to the bag opening device, prefabricated bags are moved in a material conveying direction by virtue of the bag opening mechanism, so that the stroke is shortened, and the packaging efficiency is improved; moreover, the bag opening mechanism is driven by the translation mechanism to stably operate without shaking, so that the bags are prevented from being damaged; and the bag opening device has the characteristics of being high in material conveying continuous degree, short in conveying and packaging stroke, and high in material conveying and packaging efficiency.

Owner:上海松川峰冠包装自动化有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com