Totally-enclosed large differential pressure open-close glasses valve

A large pressure difference, fully enclosed technology, applied in the field of valves and valves, can solve problems such as inability to operate under pressure, achieve smooth lateral transposition, achieve smooth opening and closing, and reduce procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

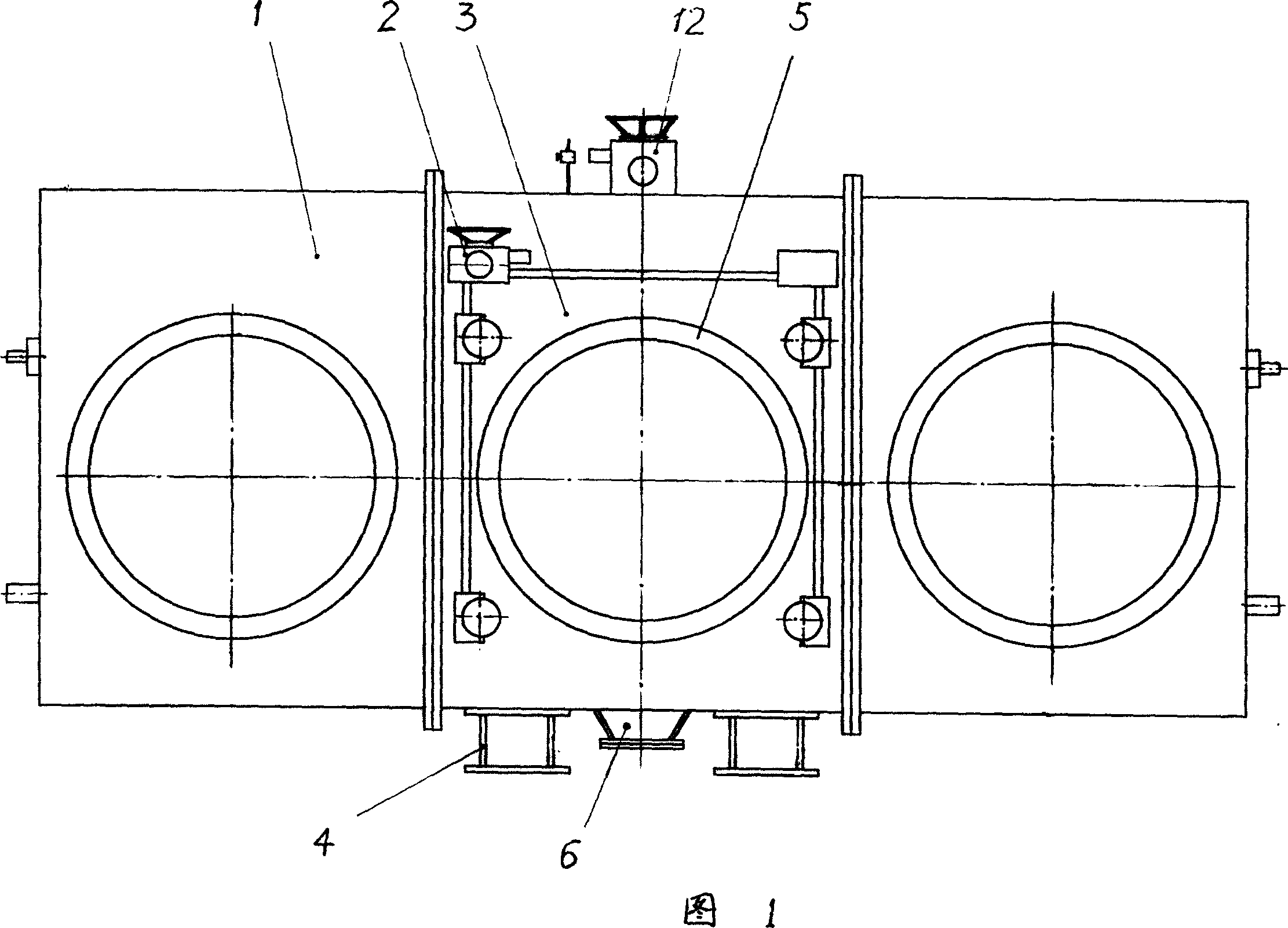

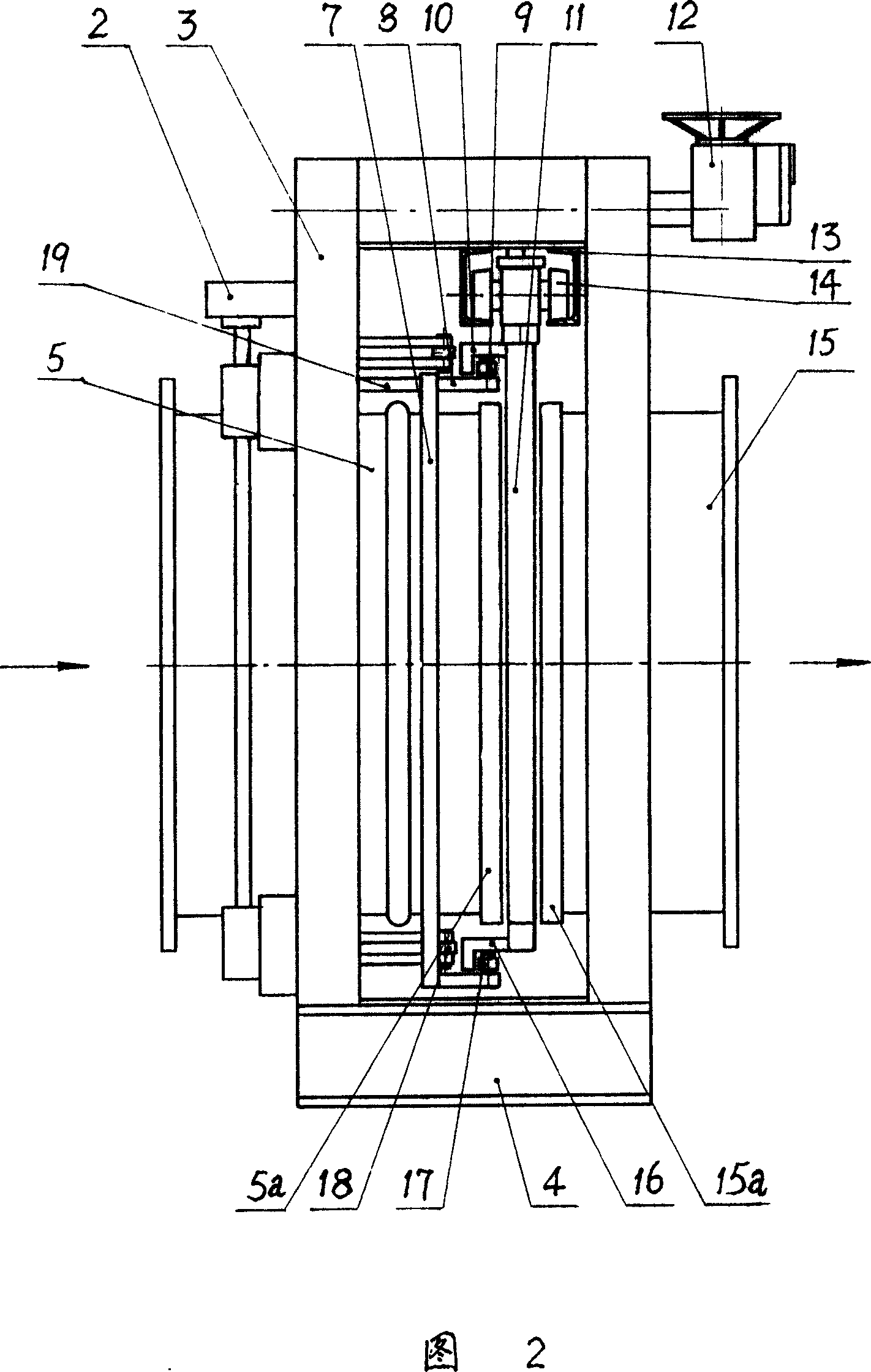

[0021] As shown in the figure, the overall structure of the spectacle valve of the present invention basically adopts the structural form of the existing fully enclosed horizontal spectacle valve, that is, a fixed valve body 15 and a movable valve body 5 with bellows are connected at the front and rear ends of the main valve box 3 (Fig. 2), respectively seal and connect an auxiliary valve box 1 (Fig. 1) on both sides of the main valve box 3, the bottom surface of the main valve box 3 is connected with a base 4, and is provided with an ash outlet 6; A valve plate 11 (Fig. 2) is clamped between the valve seat 15a of 15 and the valve seat 5a of the movable valve body 5. A valve plate compression and release mechanism is installed on the main valve box and the movable valve body, a valve plate transposition and lateral movement mechanism is installed on the top surface of the main valve box and the valve plate, and a valve plate pressure bearing is installed in the main valve box 3...

Embodiment 2

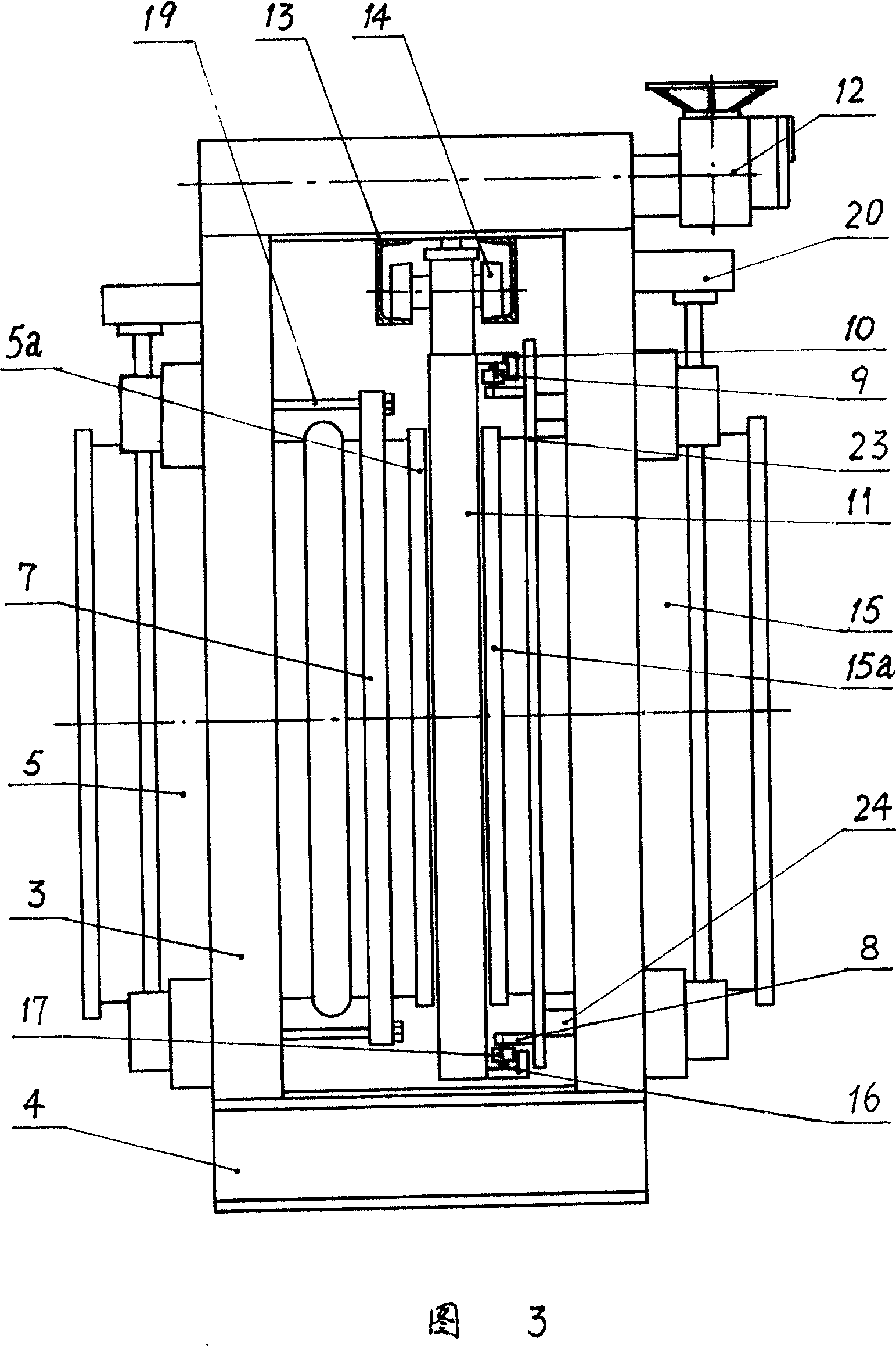

[0031] As shown in FIG. 3 , the basic structure of this embodiment is exactly the same as that of Embodiment 1, except that the pressure-bearing translation mechanism of the valve plate is different. The pressure-bearing translation mechanism of the valve plate in this embodiment is a movable frame plate 23 sleeved on the fixed valve body 15, and a horizontal plate 8 extending toward the direction of the valve plate is respectively connected to the movable frame plate and the lower side. A number of vertical shafts are respectively connected to the top, and rollers 9 and 17 are sleeved on the vertical shafts; an upper corner plate 10 and a lower corner plate 16 are respectively connected on the upper and lower frames of the valve plate 11, and the horizontal plate surfaces of the upper and lower corner plates span the rollers 9 , 17; the vertical plate surface of the upper gusset 10 is positioned between the movable frame plate 23 and the roller 9, and the vertical plate surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com