Material holding and conveying device of prefabricated bag packaging machine

A conveying device and packaging machine technology, applied in packaging and other directions, can solve the problems of shortening the holding stroke, low packaging efficiency, poor packaging effect, etc., and achieve the effect of shortening the holding stroke, improving packaging efficiency, and improving packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

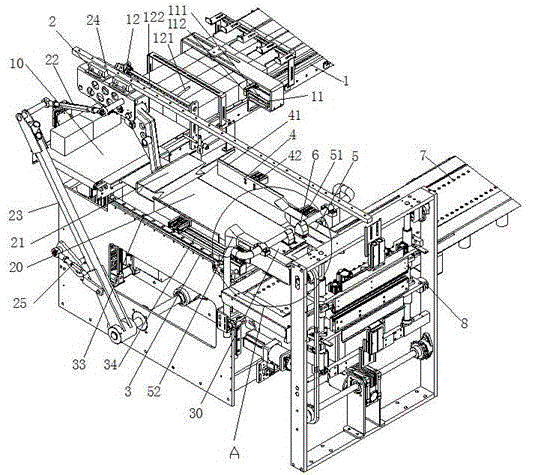

[0088] The material holding and conveying device of the prefabricated bag packaging machine includes a translation mechanism 3 and a holding mechanism 9 connected to the translation mechanism 3. The holding mechanism 9 reciprocates along the material running direction under the action of the translation mechanism 3.

[0089] Including a translation mechanism and a holding mechanism connected to the translation mechanism. The holding mechanism reciprocates along the material running direction under the action of the translation mechanism. The holding mechanism can effectively support the holding material, whether it is a regular material or an irregular bulk. The material can be used, and there will be no vibration during the material conveying process. The material conveying is more stable than the clamping mechanism, and it will not cause clamping and squeezing of the material, which improves the conveying efficiency of the material. The holding mechanism plays a role in the trans...

Embodiment 2

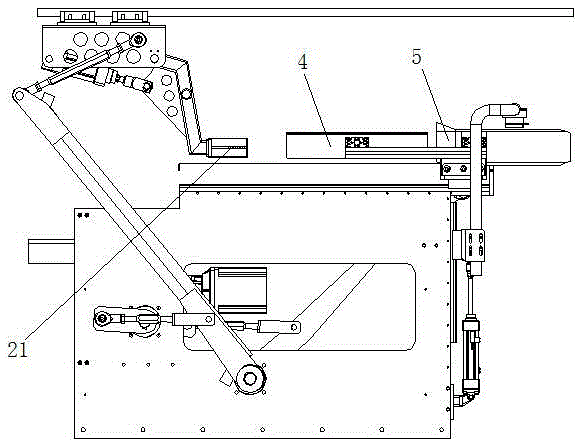

[0091] The material holding and conveying device of the prefabricated bag packaging machine includes a translation mechanism 3 and a holding mechanism 9 connected to the translation mechanism 3. The holding mechanism 9 reciprocates along the material running direction under the action of the translation mechanism 3.

[0092] The holding mechanism includes a first holding side plate 911, a second holding side plate 912, and a holding bottom plate 92 for holding materials. The first holding side plate 911 is connected to one side of the holding bottom plate 92. The second holding side plate 912 is connected to the other side of the holding bottom plate 92, and the holding bottom plate 92 is arranged horizontally.

[0093] The first holding side plate 911 and the second holding side plate 912 are arranged parallel to each other on the holding bottom plate 92.

[0094] It includes a first holding side plate, a second holding side plate, and a holding bottom plate for holding materials. T...

Embodiment 3

[0096] The material holding and conveying device of the prefabricated bag packaging machine includes a translation mechanism 3 and a holding mechanism 9 connected to the translation mechanism 3. The holding mechanism 9 reciprocates along the material running direction under the action of the translation mechanism 3.

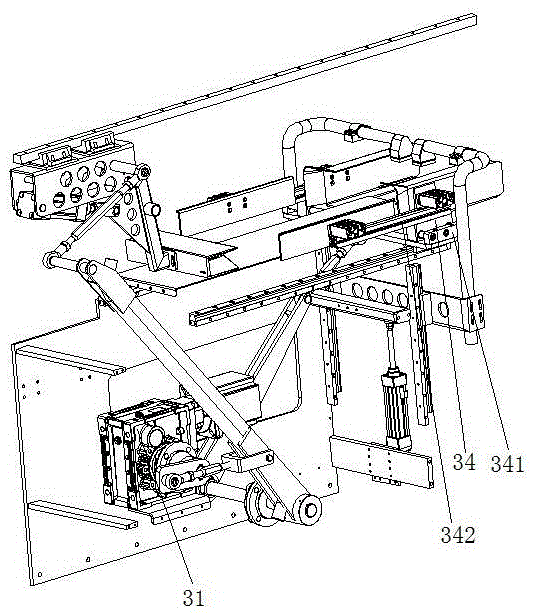

[0097] The holding mechanism includes a first holding side plate 911, a second holding side plate 912, and a holding bottom plate 92 for holding materials. The first holding side plate 911 is connected to one side of the holding bottom plate 92. The second holding side plate 912 is connected to the other side of the holding bottom plate 92, and the holding bottom plate 92 is arranged horizontally.

[0098] The first holding side plate 911 and the second holding side plate 912 are arranged parallel to each other on the holding bottom plate 92.

[0099] It also includes a first holding support plate 93 and a second holding support plate 94. The first holding support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com