Bag opening device for prefabricated bag packaging machine

A packaging machine and prefabricated bag technology, applied in packaging and other directions, can solve the problems of short conveying and packaging strokes, prefabricated bags easily broken, low packaging efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

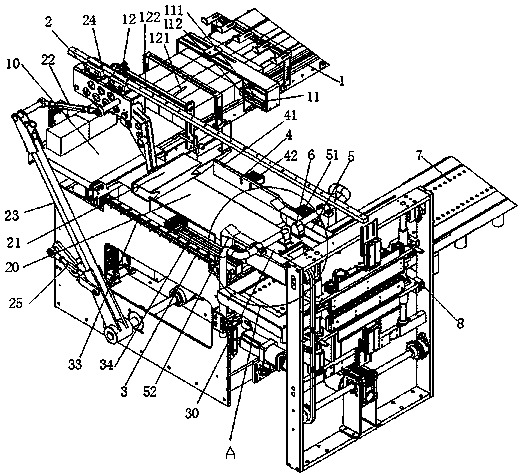

[0073] The bag stretching device of the prefabricated bag packaging machine includes a translation mechanism 3 and a bag stretching mechanism 5 connected to the translation mechanism 3 , and the bag stretching mechanism 5 reciprocates along the material running direction under the action of the translation mechanism 3 .

[0074] It includes a translation mechanism and a bag stretching mechanism connected with the translation mechanism. The bag stretching mechanism reciprocates along the material running direction under the action of the translation mechanism. While the material is being conveyed, the prefabricated bag moves towards the material conveying direction through the stretching mechanism. , shorten the stroke, improve the packaging efficiency, and the bag stretching mechanism runs smoothly under the drive of the translation mechanism, without shaking, which can prevent the bag body from being damaged; it has a high degree of continuous material transportation, short tra...

Embodiment 2

[0076] The bag stretching device of the prefabricated bag packaging machine includes a translation mechanism 3 and a bag stretching mechanism 5 connected to the translation mechanism 3 , and the bag stretching mechanism 5 reciprocates along the material running direction under the action of the translation mechanism 3 .

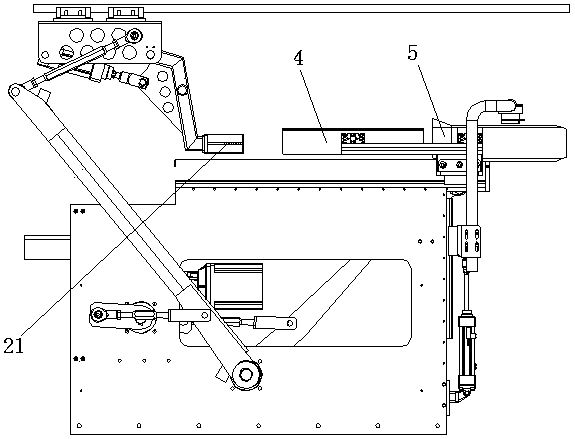

[0077] The bag-opening mechanism includes a bag-opening claw fixedly connected to the translation mechanism 3 and a bag-opening cylinder 51 that drives the bag-opening claw to open or shrink. .

[0078] It includes the bag opening claw fixedly connected to the translation mechanism and the bag opening cylinder that drives the bag opening claw to open or shrink. The bag opening claw makes a linear reciprocating motion along the material running direction under the action of the translation mechanism, and the bag opening claw is driven by the translation mechanism. Movement, while the material is being conveyed, the prefabricated bag is stretched by the opening...

Embodiment 3

[0080] The bag stretching device of the prefabricated bag packaging machine includes a translation mechanism 3 and a bag stretching mechanism 5 connected to the translation mechanism 3 , and the bag stretching mechanism 5 reciprocates along the material running direction under the action of the translation mechanism 3 .

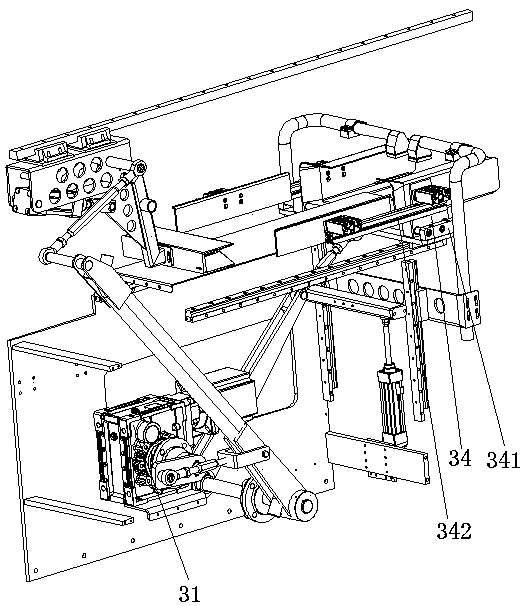

[0081] The bag-opening mechanism includes a bag-opening claw fixedly connected to the translation mechanism 3 and a bag-opening cylinder 51 that drives the bag-opening claw to open or shrink. .

[0082] The bag opening claw comprises two bag opening plates 52, and the two bag opening plates 52 are arranged in parallel.

[0083] The bag-opening claw includes two bag-opening boards, which are arranged in parallel. Compared with the prior art, the contact area between the bag-opening board and the prefabricated bag is larger, and the entire prefabricated bag is arranged in parallel by two The bag stretching boards are stretched at the same time, which will not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com