Quenched coke receiving slot translating and laterally turning-over device

A technology of coke quenching and jacking device, used in the cooling of coke, coke oven, petroleum industry, etc., can solve the problems of translation operation, affecting normal work, easy deformation of the sliding block, etc., to achieve smooth translation, improve service life, Effective and reliable effect of rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

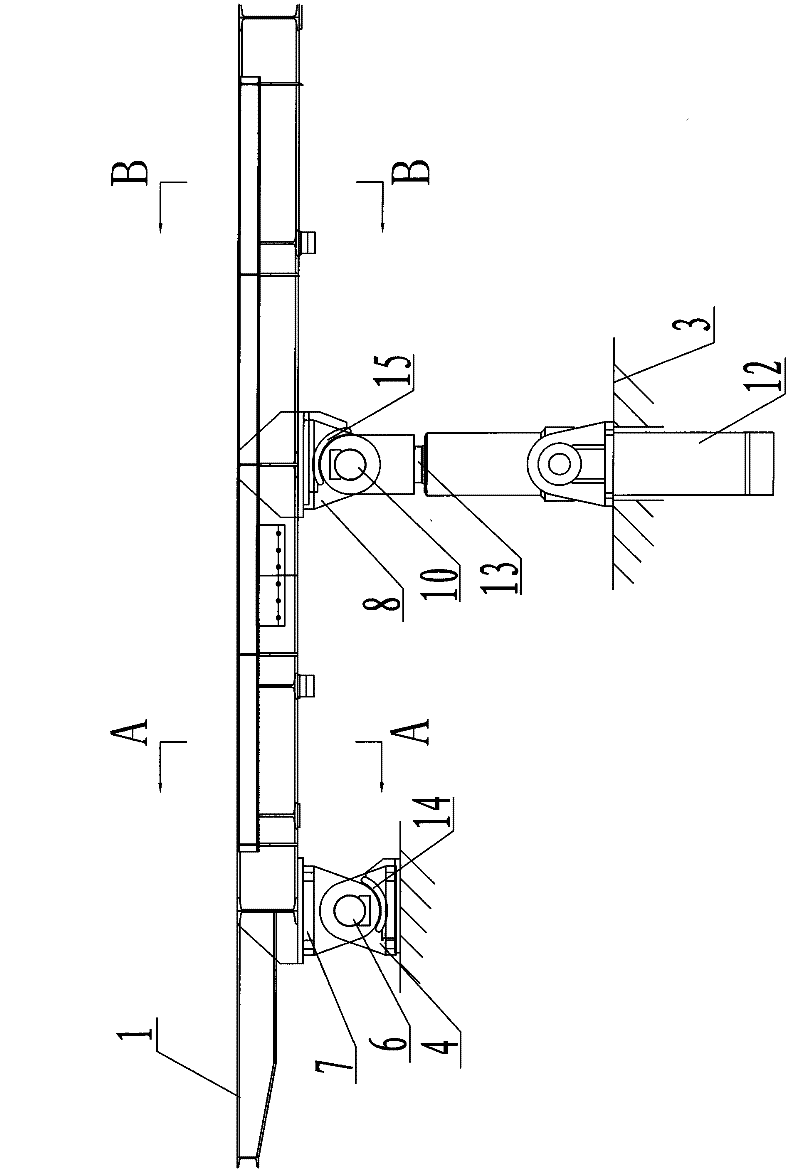

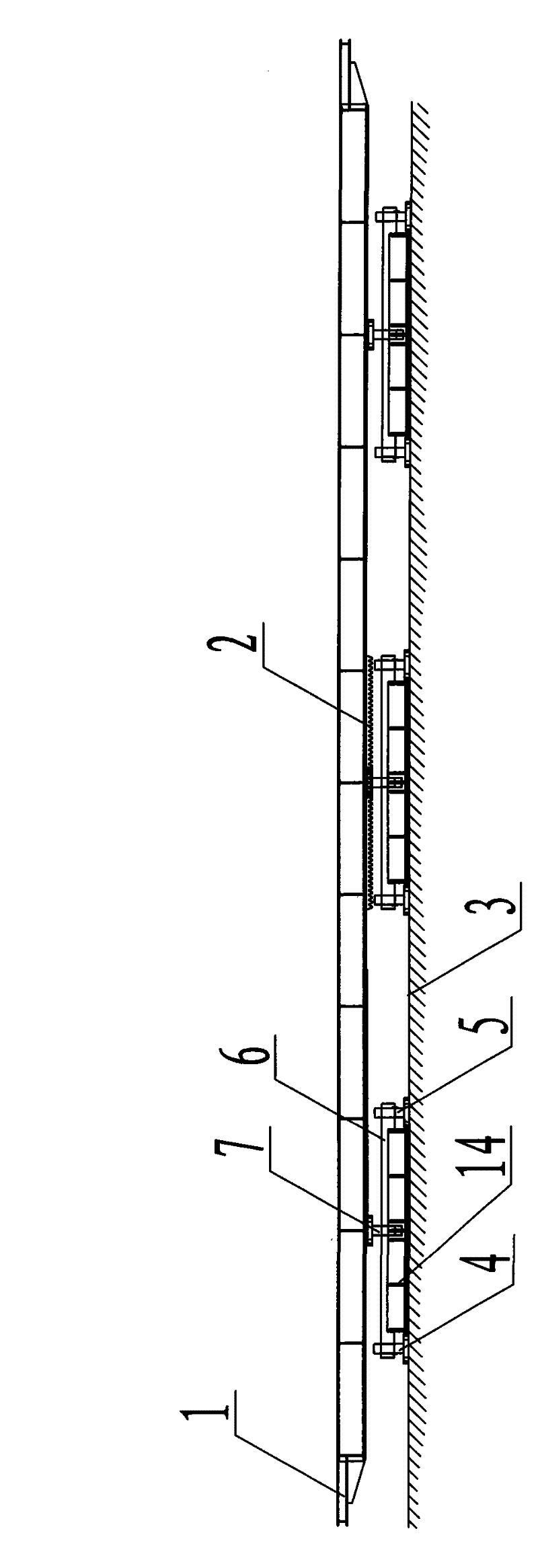

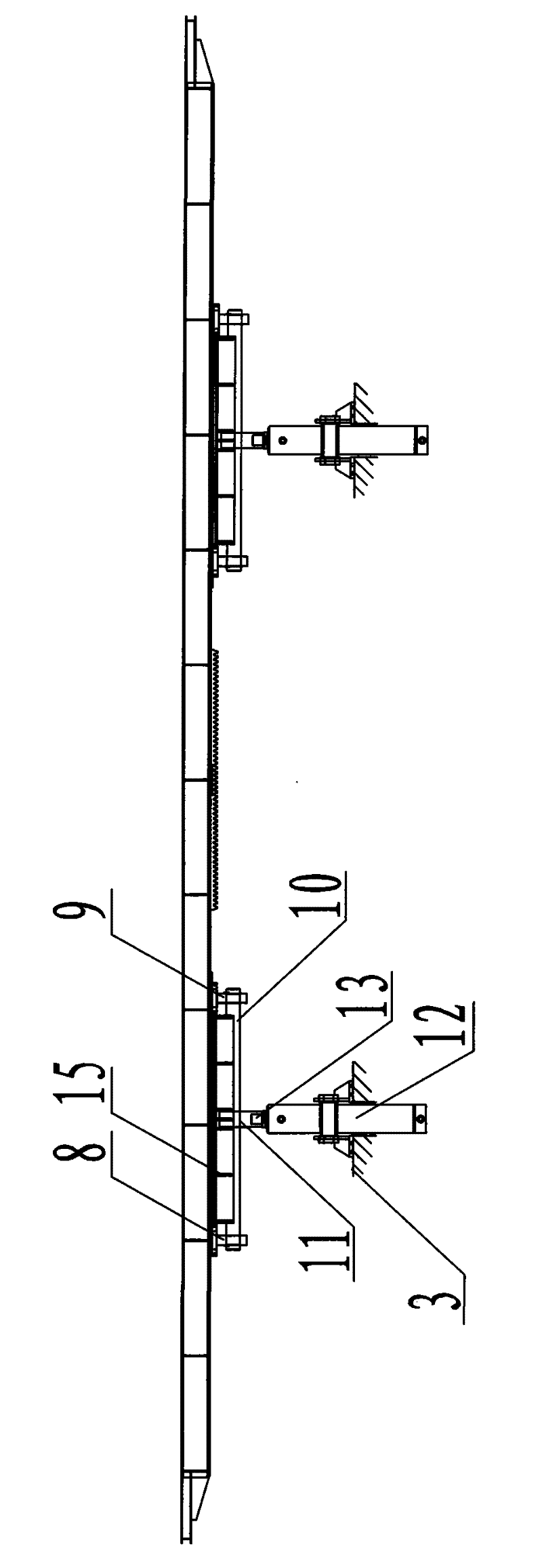

[0013] Such as figure 1 , figure 2 As shown, the translation and rollover device connected to the quenching tank includes: connected to the quenching tank 1, a transmission rack 2 is fixedly installed at the lower end of the quenching tank 1, and the transmission rack 2 is connected with the transmission mechanism. A number of rotating support devices are provided on the bottom end of the coke quenching tank 1 described above. The structure of the rotating support device includes: a first fixed seat 4 and a second fixed seat 5 fixedly arranged on the machine base 3, A first hinge shaft 6 is fixedly arranged between the first fixed seat 4 and the second fixed seat 5. The first hinge shaft 6 cooperates with the first support 7 fixedly arranged on the bottom of the coke quenching tank 1. The first support 7 is sleeved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com