Hanging device in a freight car

A technology for carriages and trucks, which is applied to vehicles for freight, motor vehicles, transportation and packaging, etc., can solve the problems of occupying space, low stability of hanger placement, and non-compact internal structure of the carriage, and achieves high applicability, High stability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

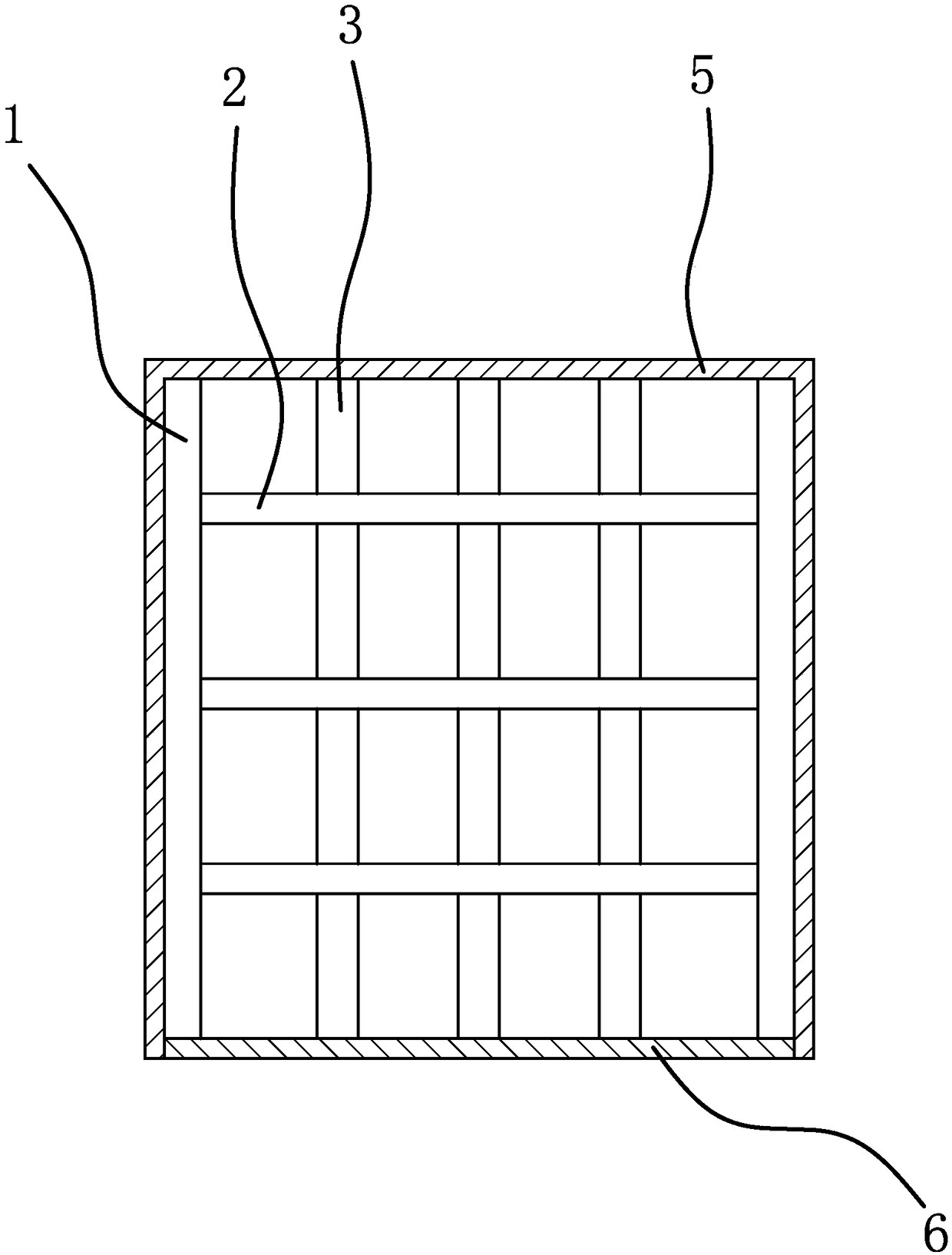

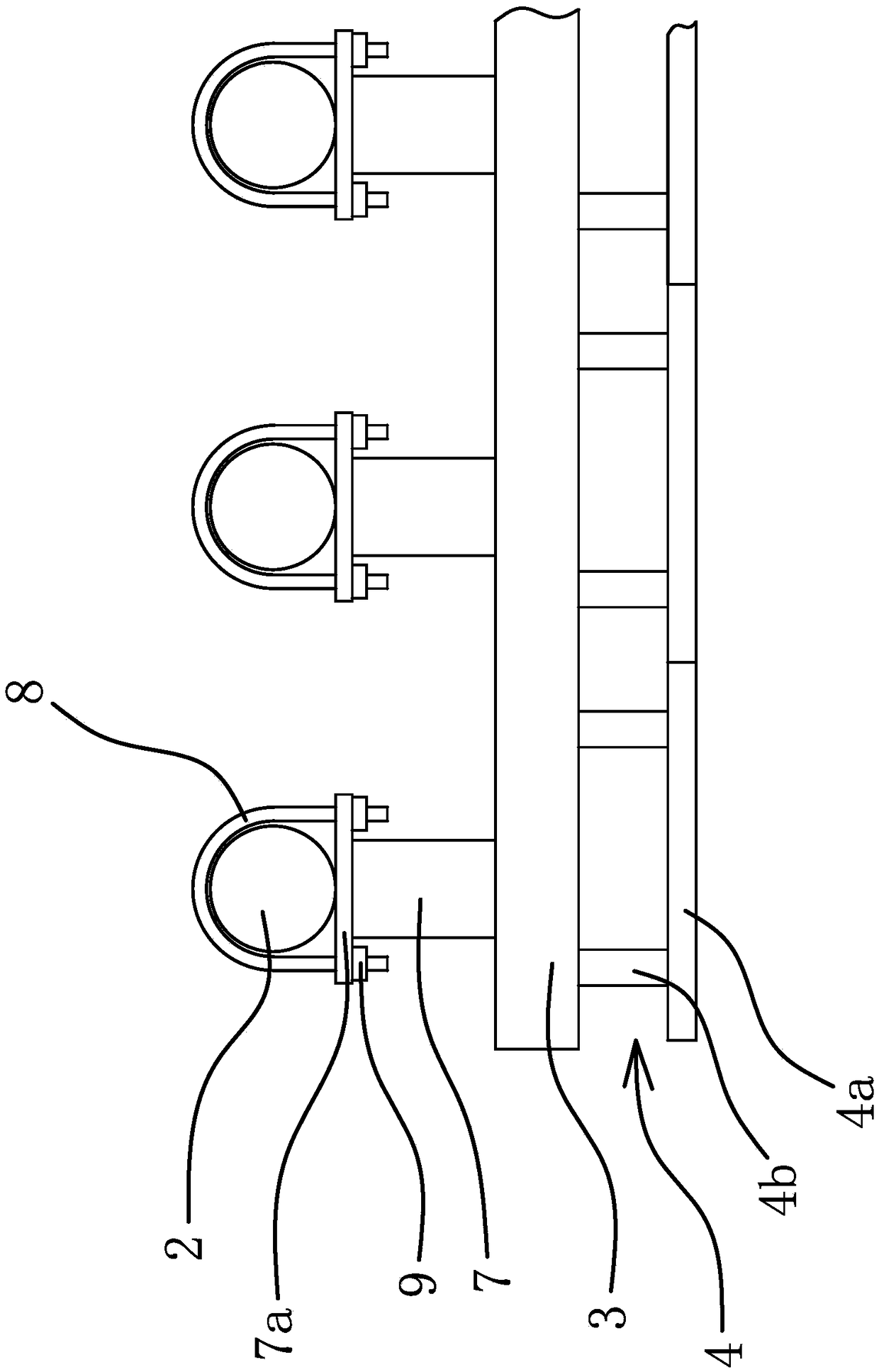

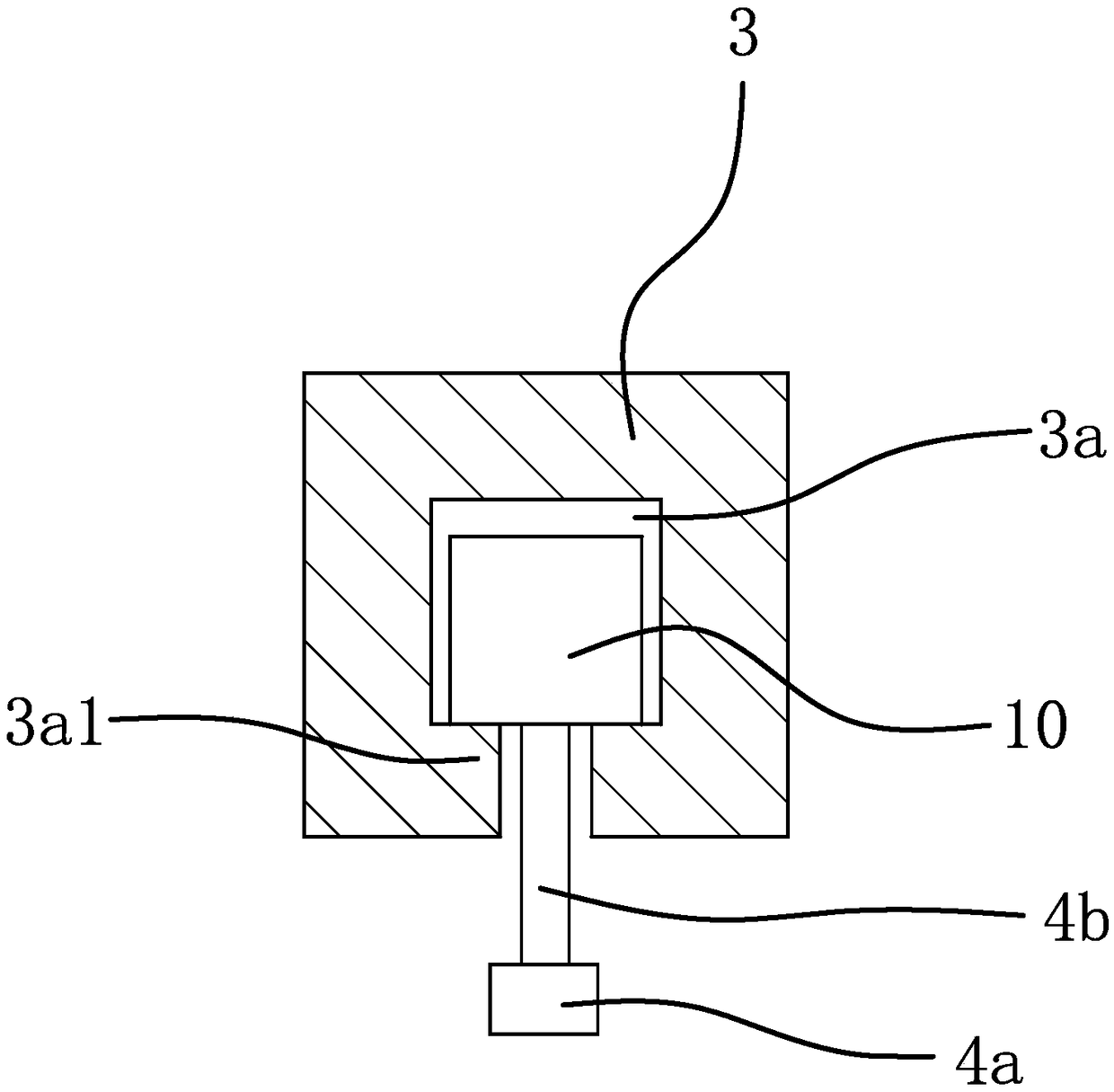

[0035] like figure 1 and figure 2 and image 3 As shown, the hanging device in the truck compartment includes a crossbeam 1, a longitudinal beam 2, a rail bar 3 and a hanger 4, and the number of the above-mentioned crossbeams 1 is two and the two crossbeams 1 are fixedly connected to two rails in the top of the carriage 5 respectively. At the side, the above-mentioned longitudinal beam 2 and the crossbeam 1 are vertically arranged and the two ends of the longitudinal beam 2 are fixedly connected to the two crossbeams 1 respectively, the upper part of the above-mentioned guide rail bar 3 is fixedly connected with the longitudinal beam 2, and the above-mentioned hanger 4 is located at the lower part of the guide rail bar 3 And between the two, there is a guide structure that can make the hanger 4 translate along the guide rail bar 3 .

[0036] The number of the hangers 4 is several and after the hangers 4 are pressed against each other in turn, the frontmost hanger 4 abuts ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com