Patents

Literature

87results about How to "Translation stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

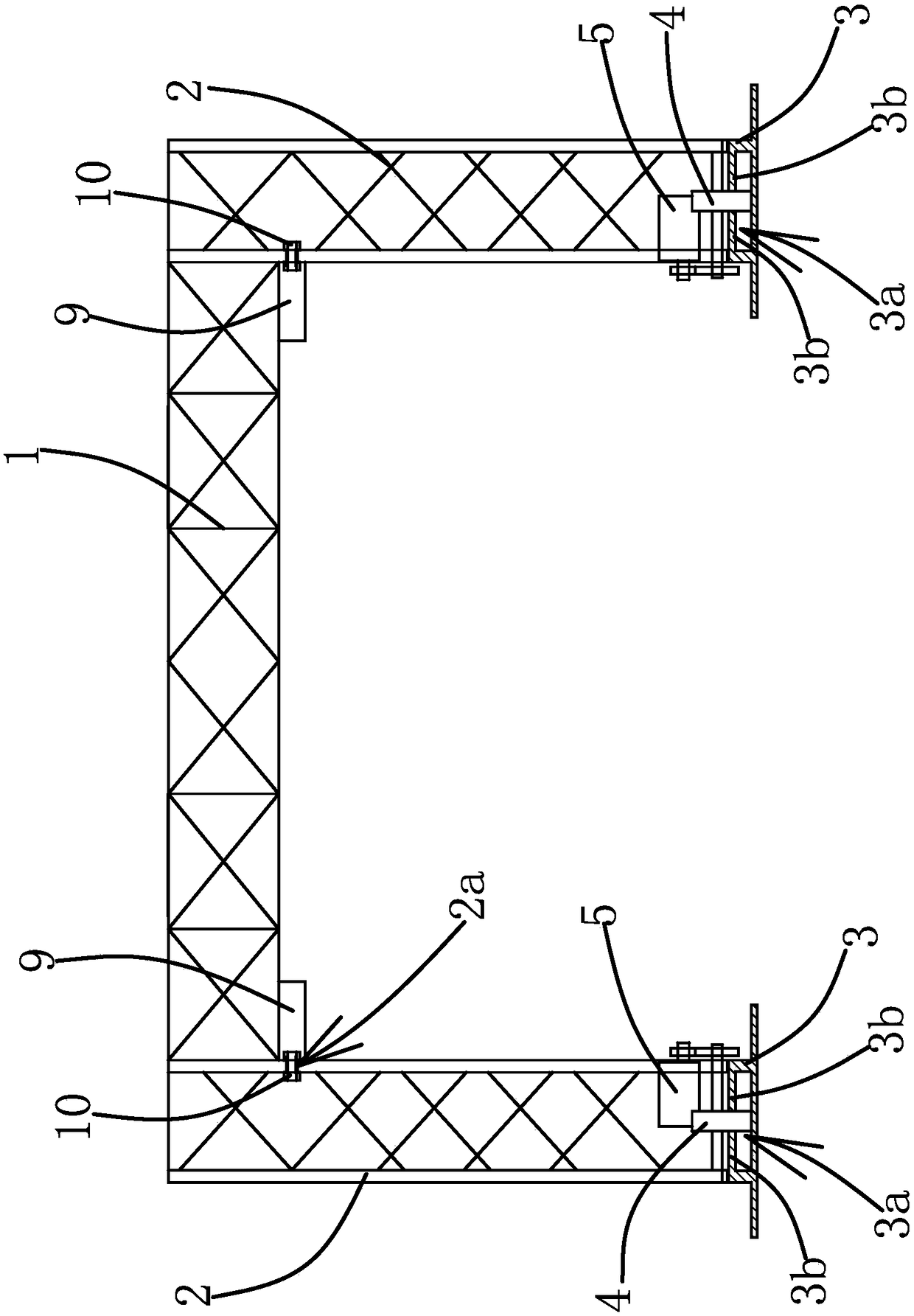

Steel truss girder assembling, erecting and construction process

ActiveCN103614969AThe construction process steps are simpleSimple and fast operationBridge erection/assemblyButtressSupporting system

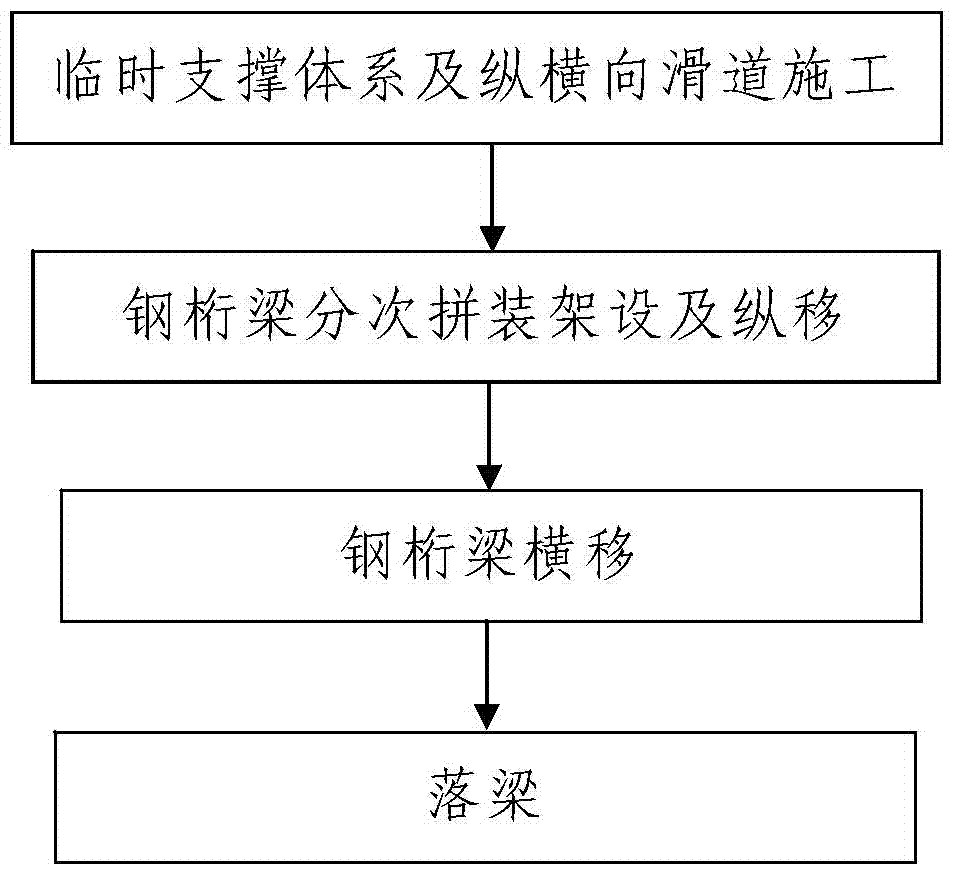

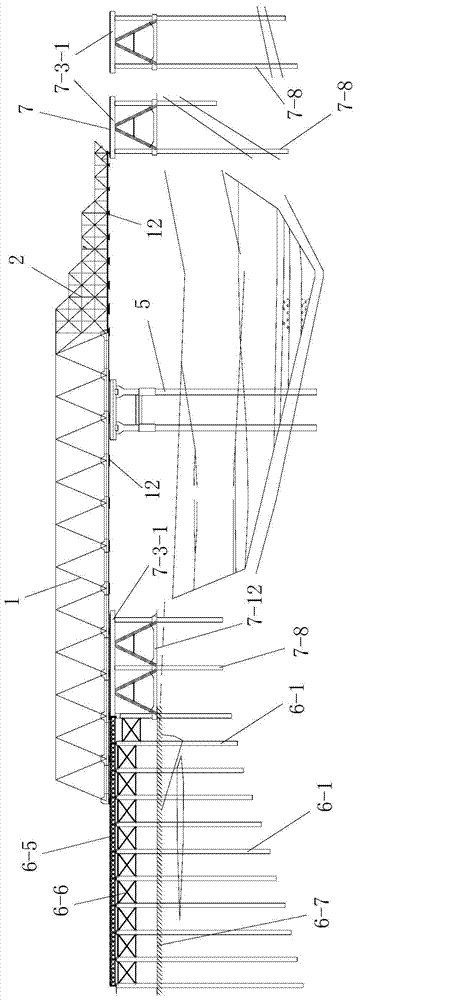

The invention discloses a steel truss girder assembling, erecting and construction process. A steel truss girder is a girder body, the front end and the rear end of an erected steel truss girder are supported on a first permanent buttress and a second permanent buttress respectively, the steel truss girder is formed by splicing a plurality of steel truss girder segments in an end-to-end mode, and the first permanent buttress and the second permanent buttress are located on the two sides of a main riverway of a river respectively. Assembling and erecting of the steel truss girder include the first step of construction of temporary supporting systems, longitudinal sliding rails and transverse sliding rails, the second step of assembling, erecting and longitudinal moving of the steel truss girder at different times, the third step of transverse moving of the steel truss girder and the fourth step of setting of the girder, wherein in the first step, the temporary supporting systems are constructed on one side of the first permanent buttress and on one side of the second permanent buttress respectively, the two longitudinal sliding rails used for the steel truss girder to move longitudinally and the two transverse sliding rails used for the steel truss girder to move transversely are distributed on the temporary supporting systems; in the second step, the steel truss girder segments are assembled more than once from front to back and are longitudinally moved many times. The steel truss girder assembling, erecting and construction process is simple in process, reasonable in design, convenient to achieve, good in construction effect and little in construction difficulty, and the assembling and erecting processes of the steel truss girder can be conveniently and quickly achieved.

Owner:NO 1 ENG LIMITED OF CR20G

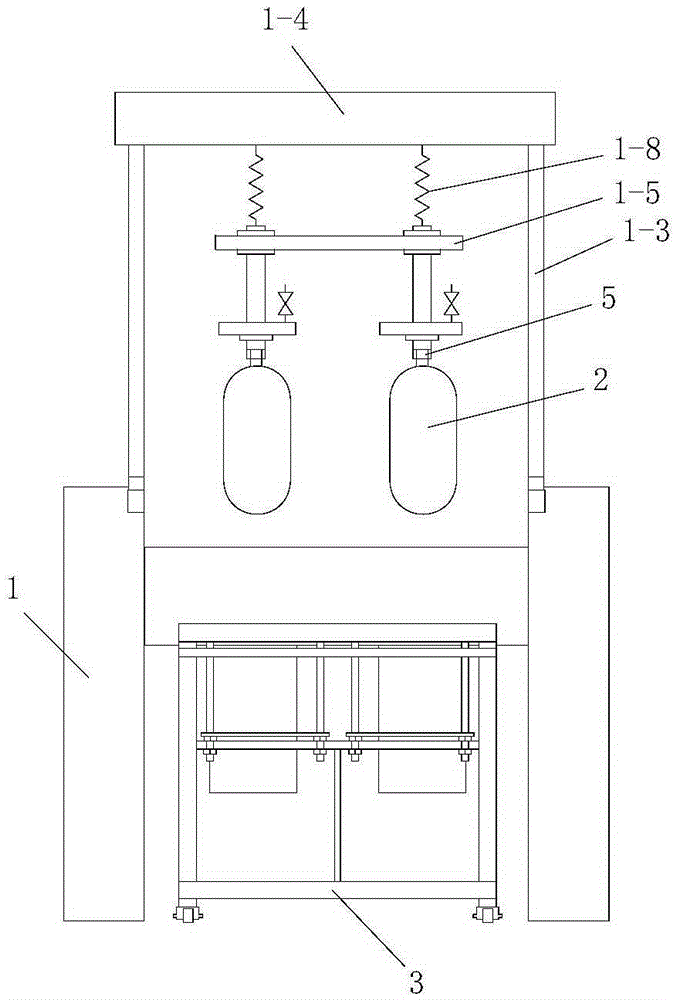

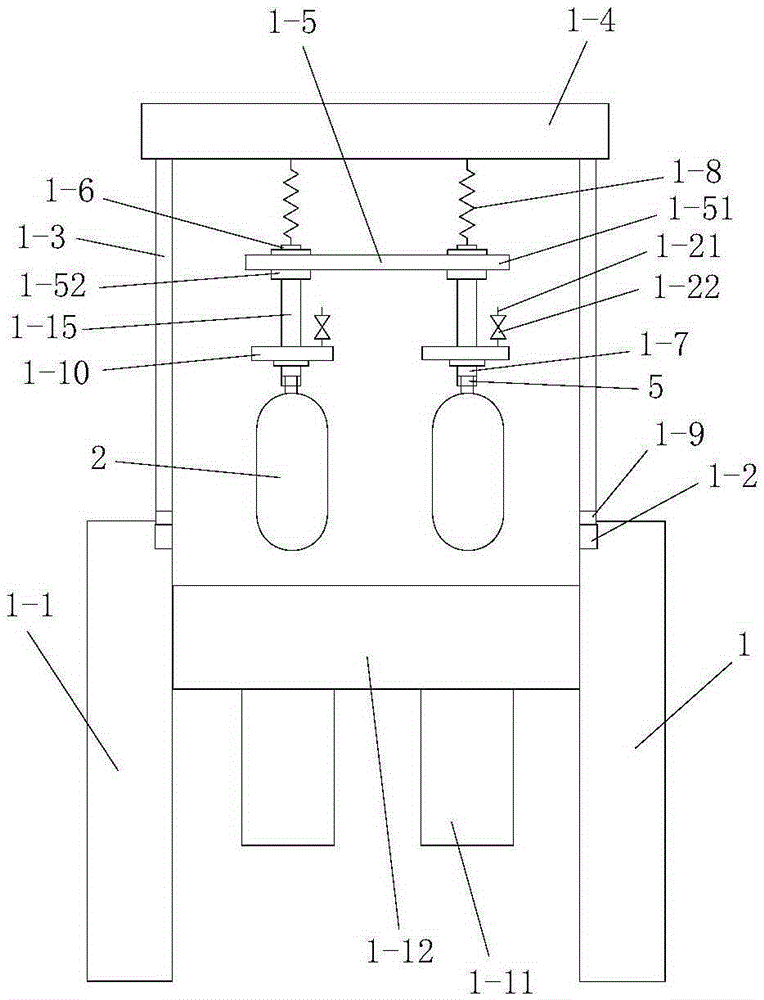

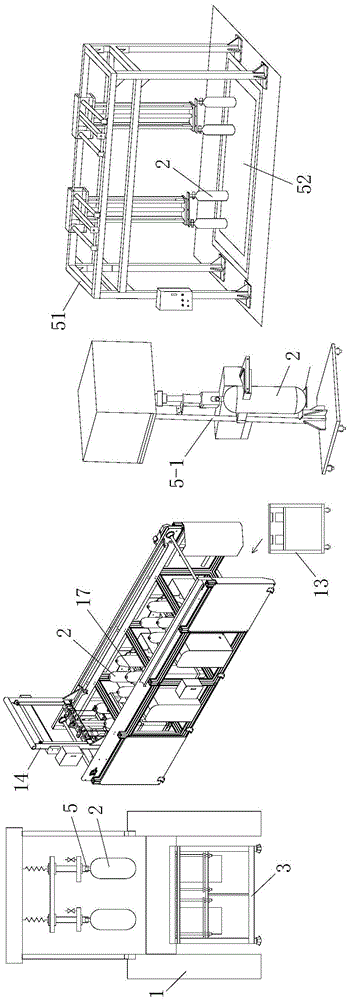

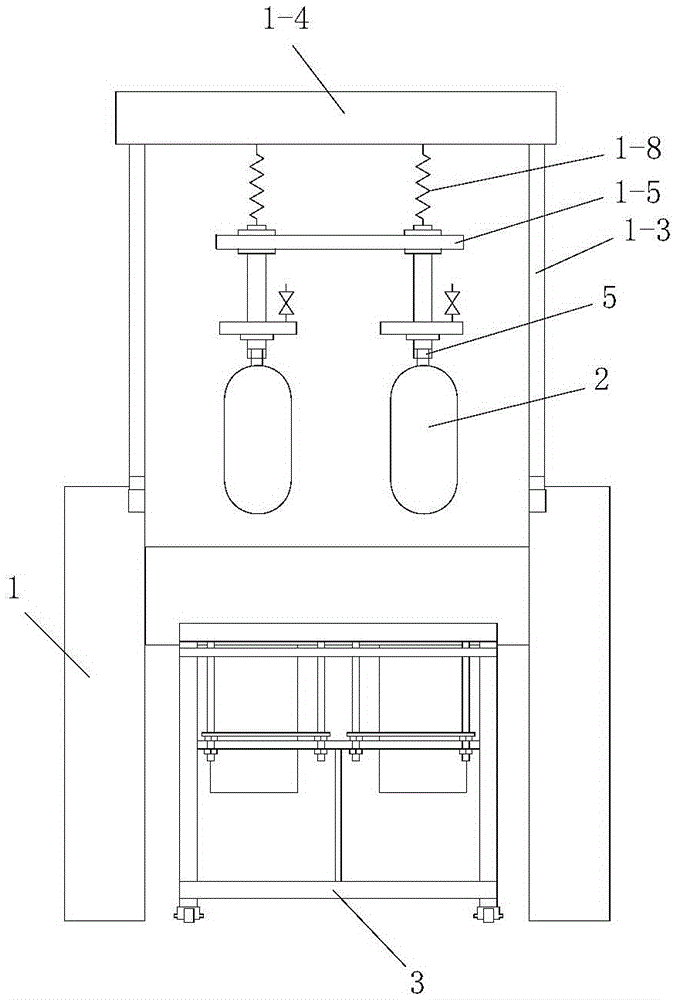

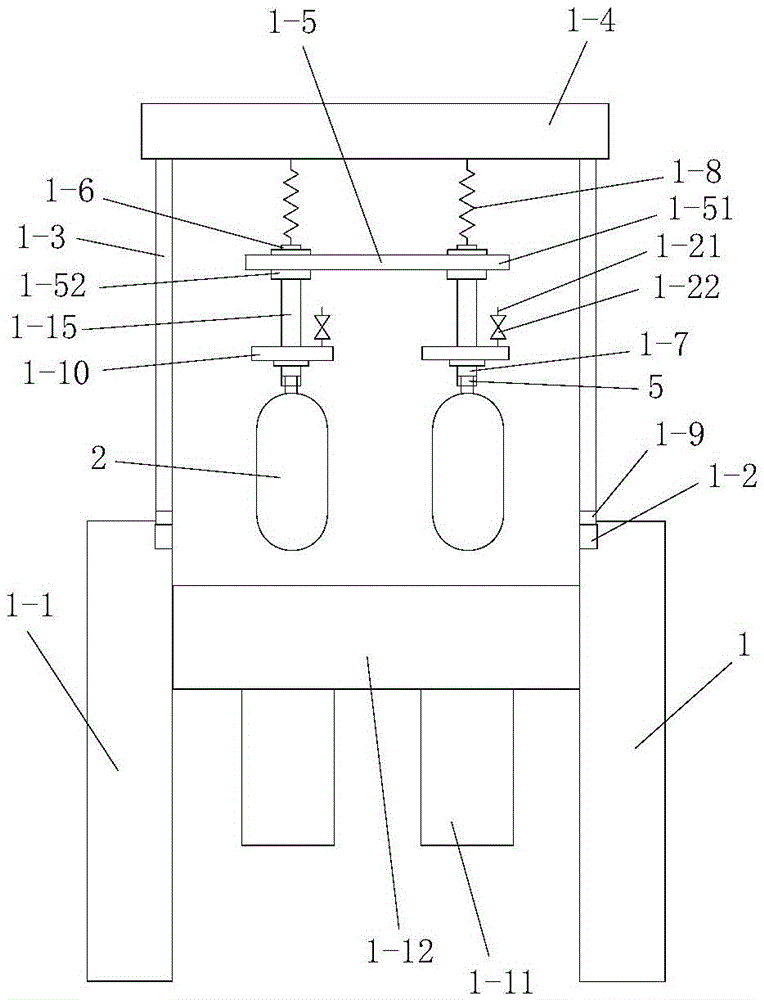

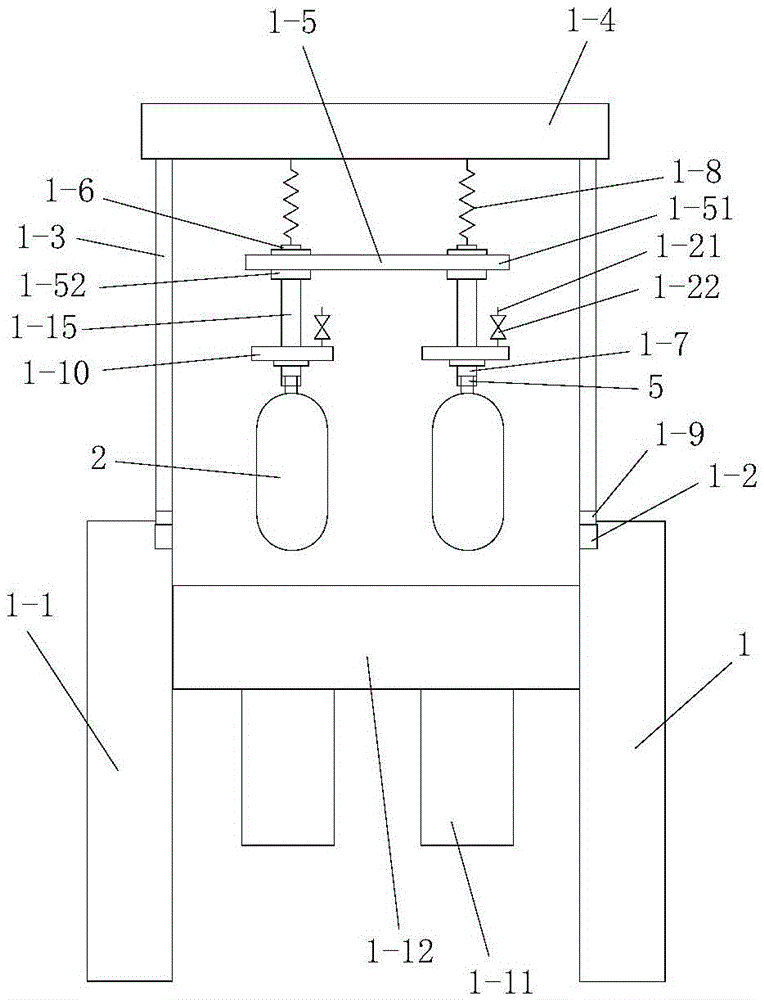

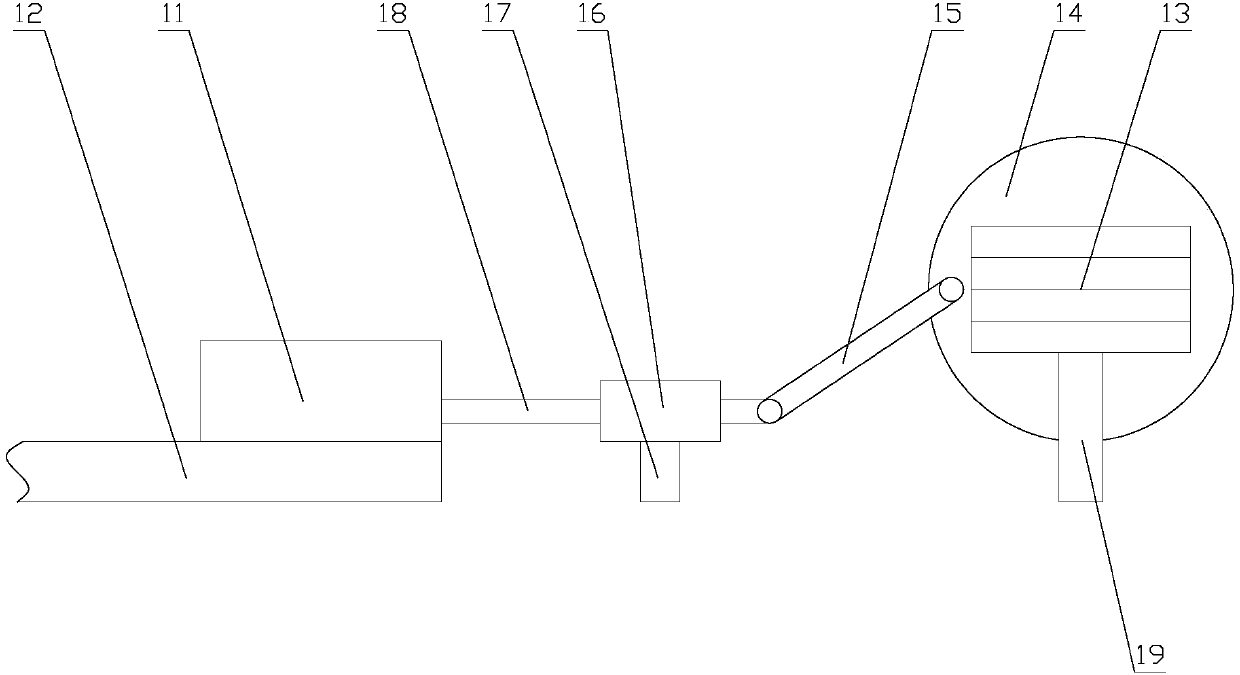

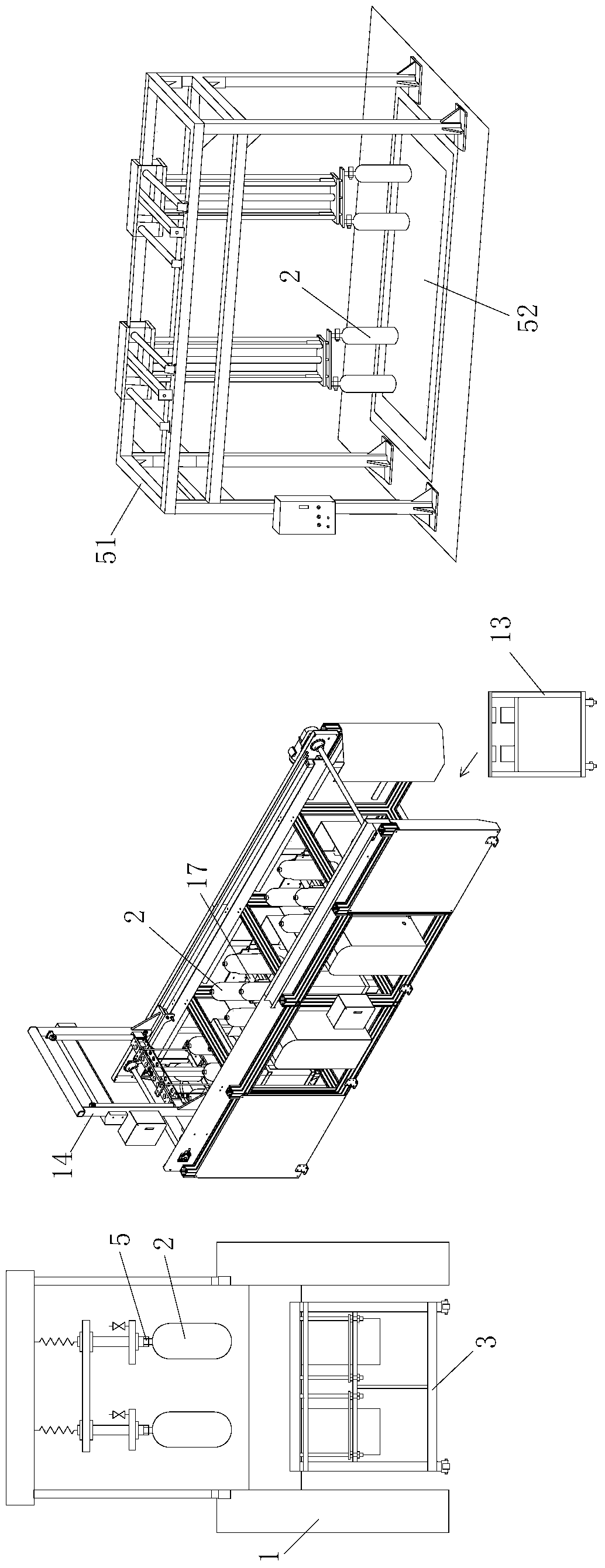

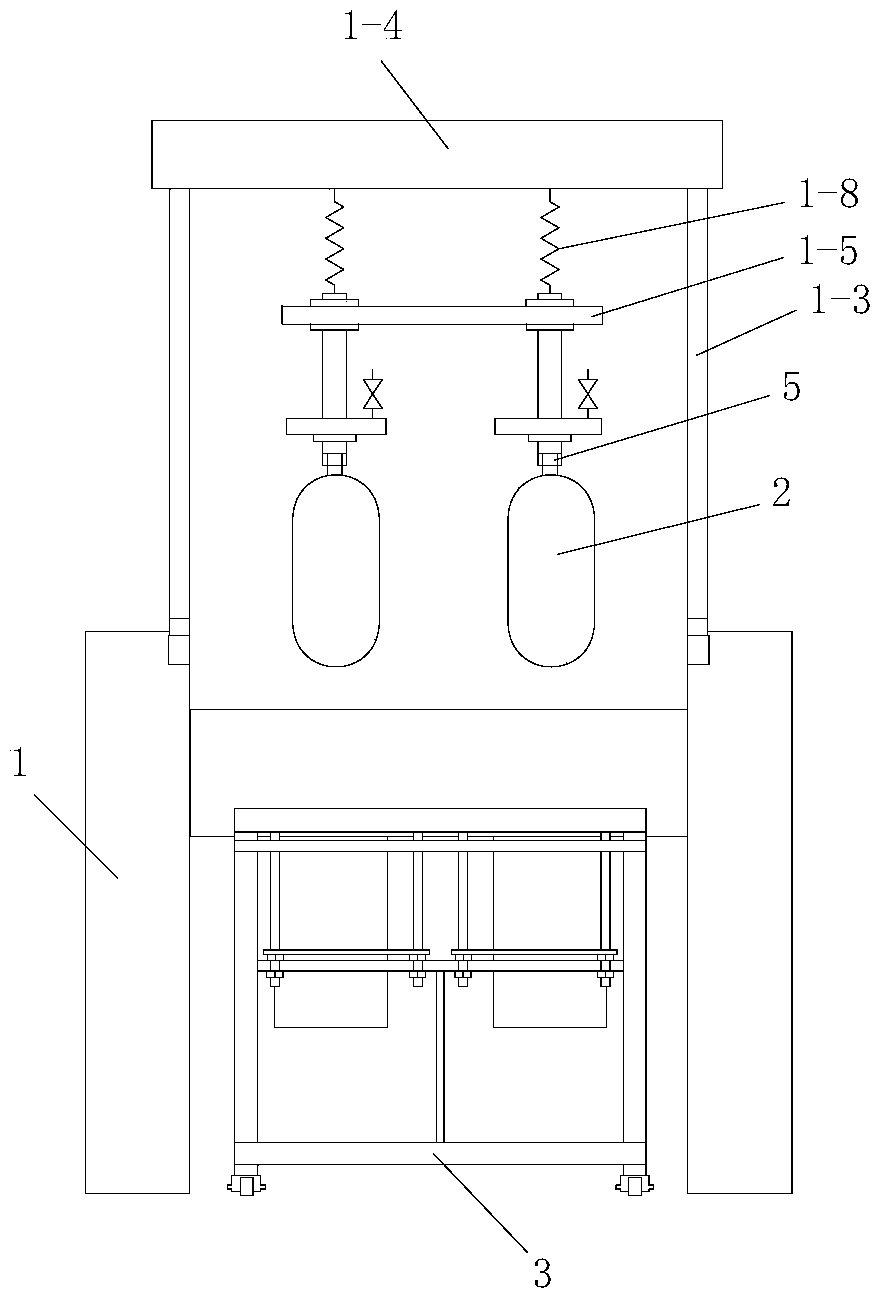

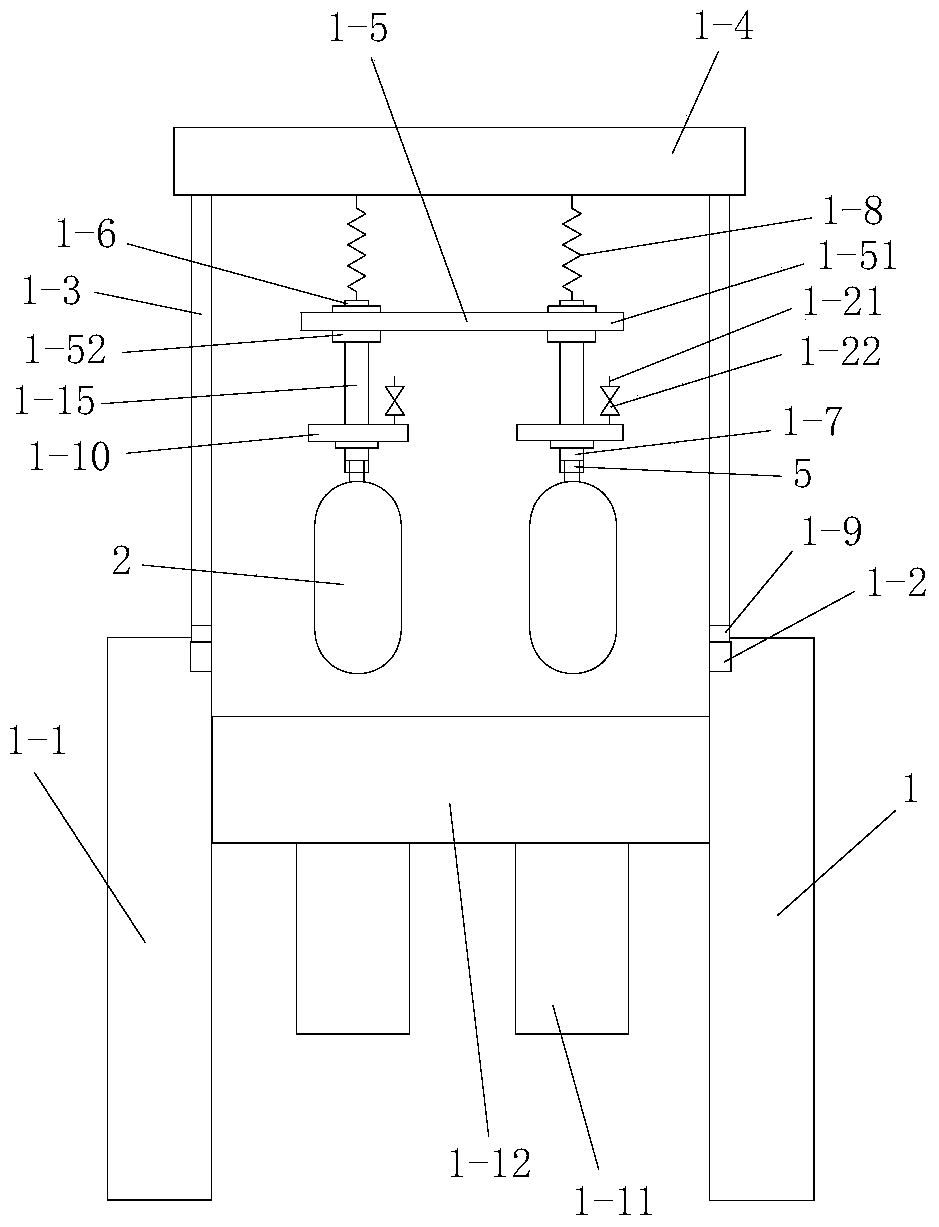

Carbon fiber gas cylinder detection line and carbon fiber gas cylinder detection method

InactiveCN105424489ASimple structureCompact structureDetection of fluid at leakage pointDrying using combination processesFiberCarbon fibers

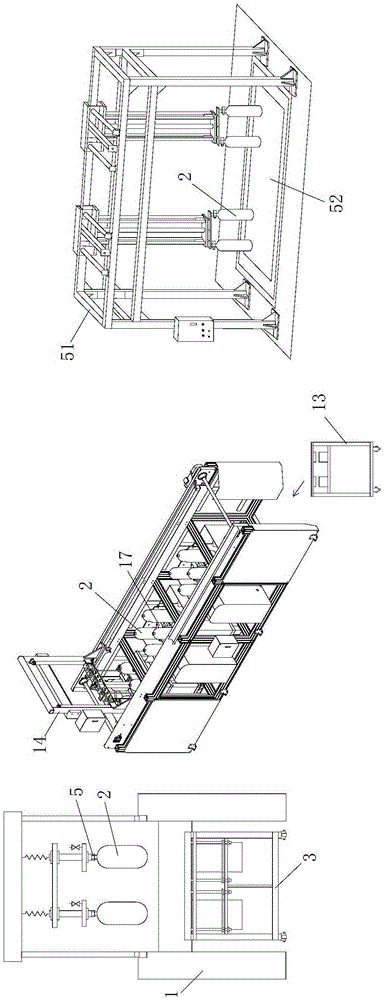

The invention discloses a carbon fiber gas cylinder detection line and a carbon fiber gas cylinder detection method. The detection line includes, in a front-to-back arrangement manner, a water pressure test apparatus, a water pressure auxiliary test apparatus and an air tightness test apparatus. The water pressure test apparatus includes a test rack, a test operation bench, a pressurizing apparatus, a test case installed on the test rack, and test trolleys for stably placing a plurality of to-be-tested gas cylinders. The water pressure auxiliary test apparatus includes a gas cylinder fixture, a transporting trolley, and a gas cylinder water-pouring-away and drying device. The air tightness test apparatus includes an air tightness detection apparatus and a second air supply apparatus for supplying air to the to-be-tested gas cylinders. The air tightness test apparatus is in a cabinet structure or a ground trough structure. The detection method includes the steps of 1) water pressure test; 2) water pouring-away and drying treatment; and 3) air tightness test. The detection line is reasonable in design and simple in operations, is good in use effects, and can easily and quickly complete water pressure test and air tightness test for a plurality of carbon fiber gas cylinders.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

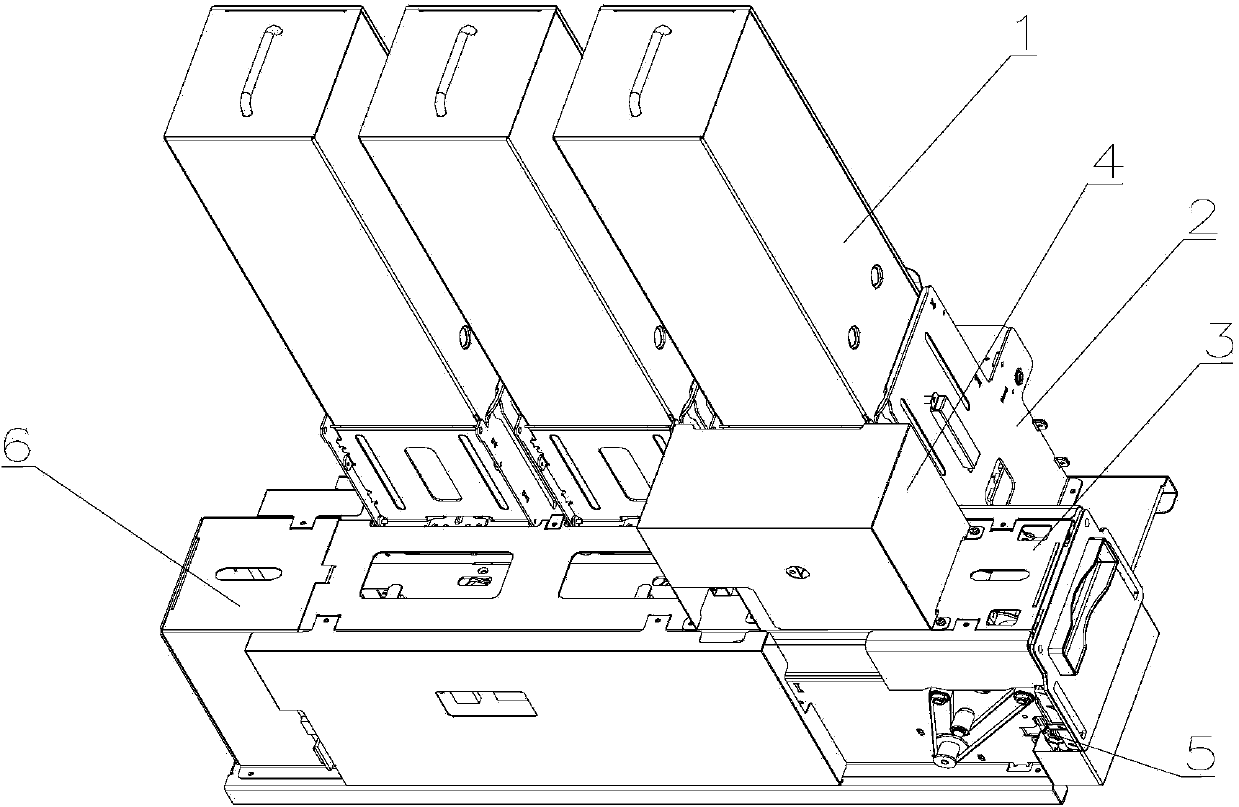

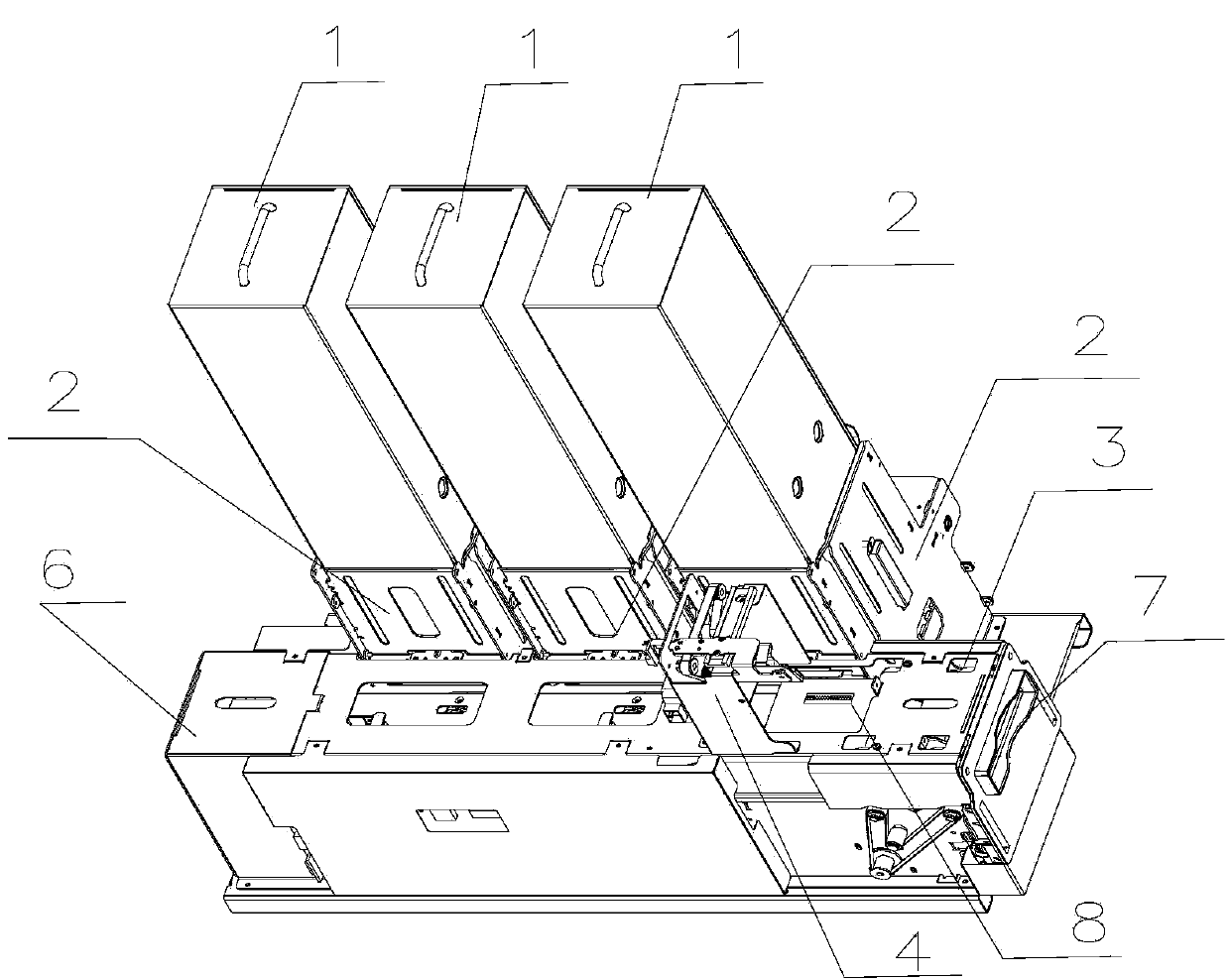

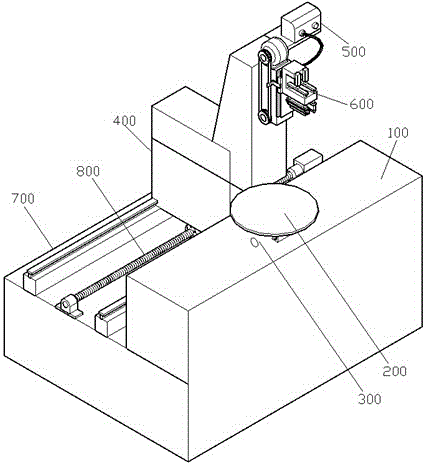

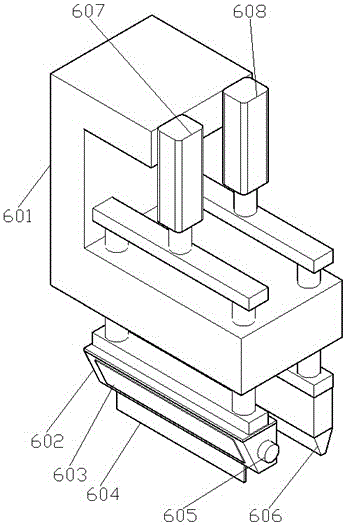

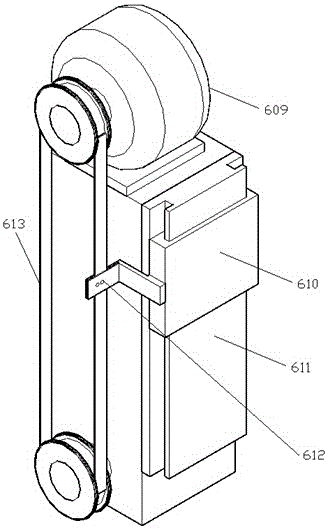

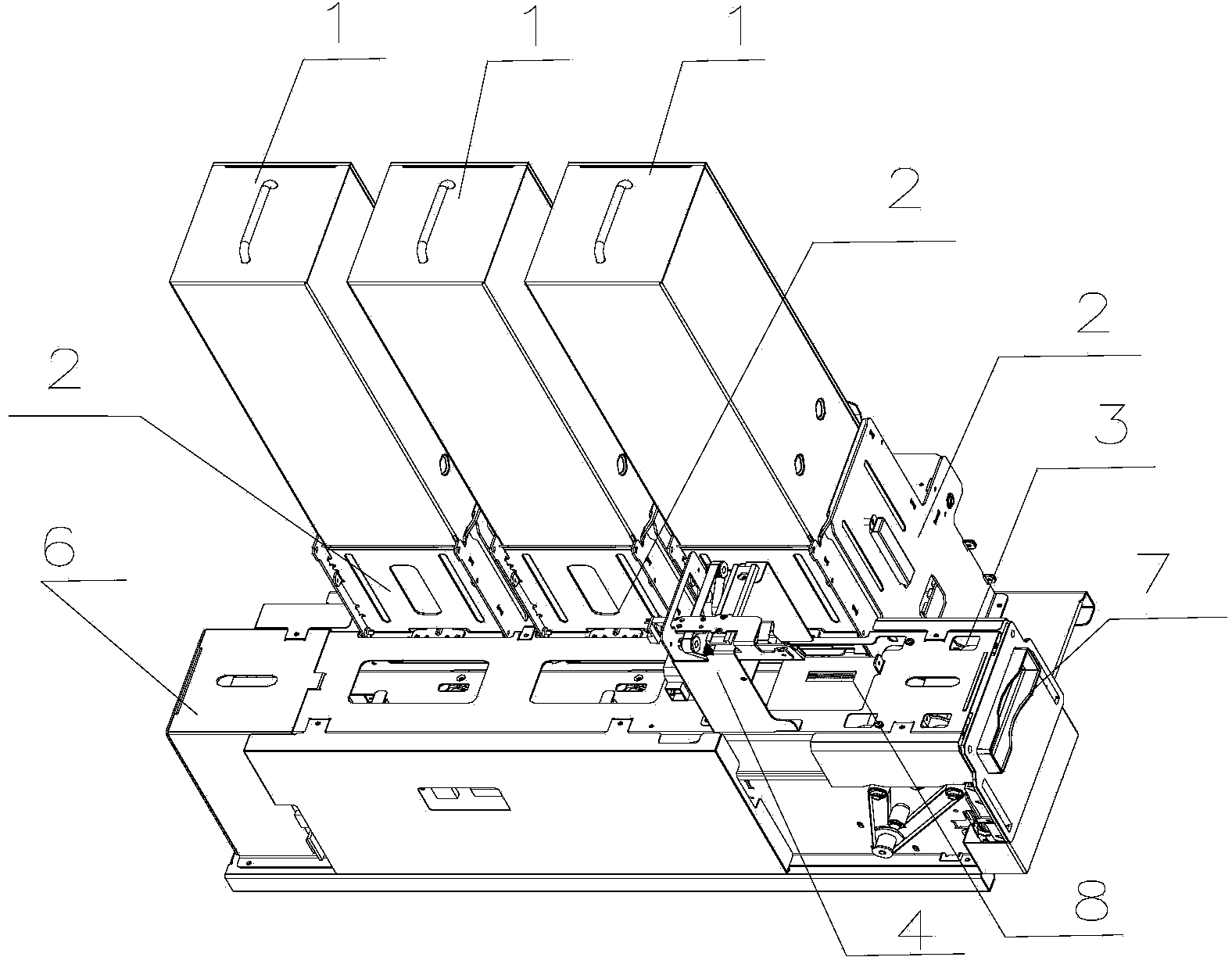

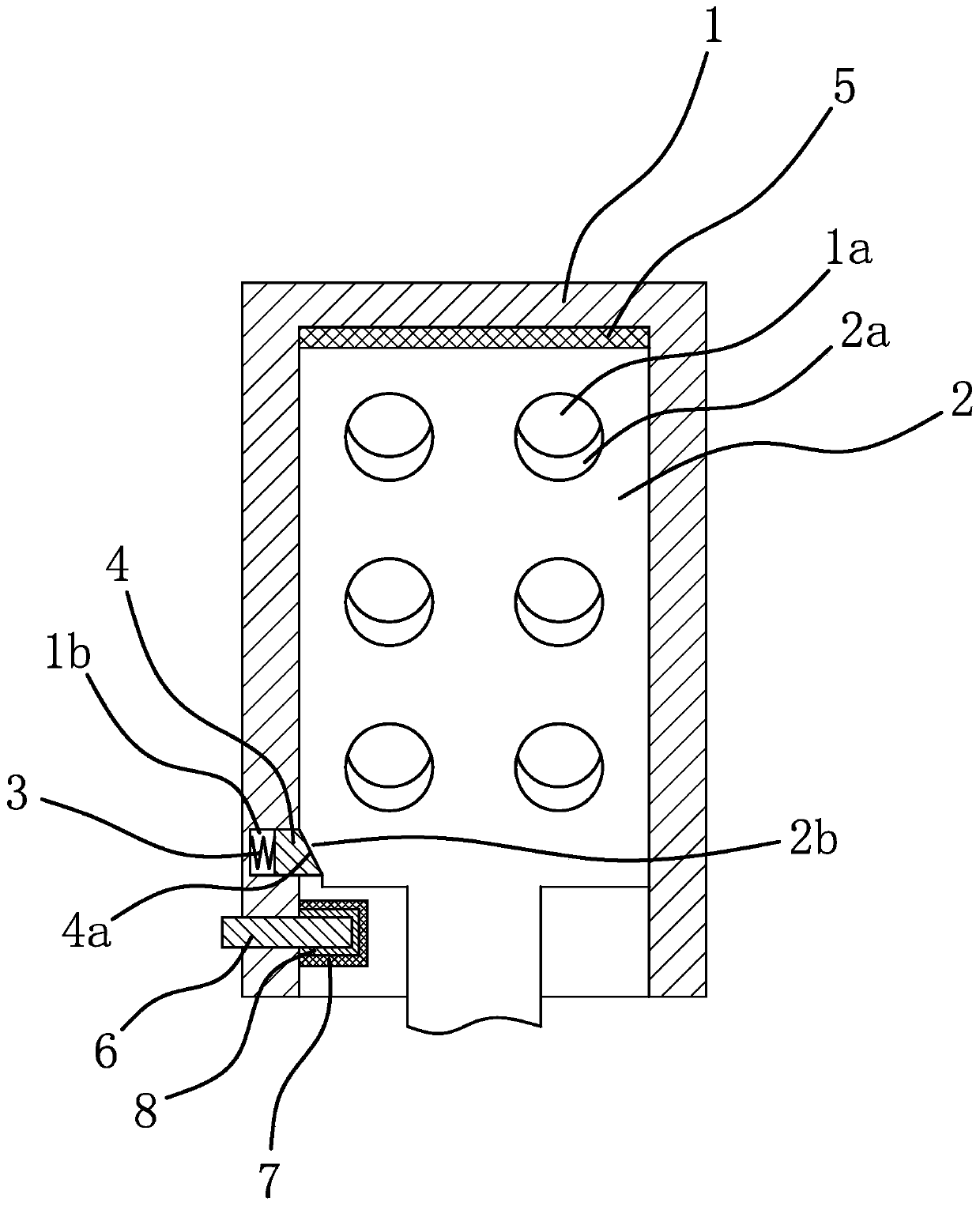

Method for issuing high-capacity internetbank verification modules

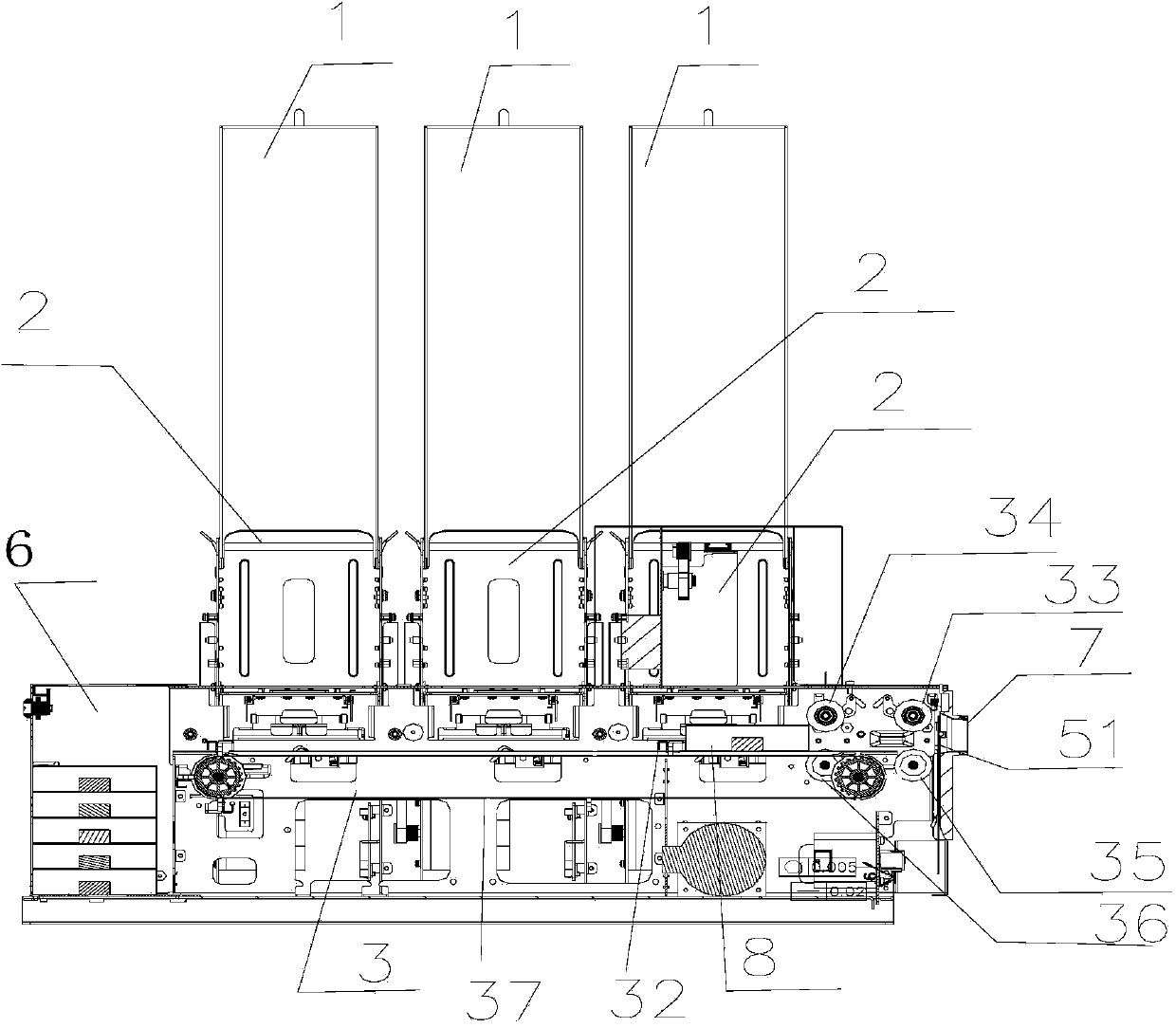

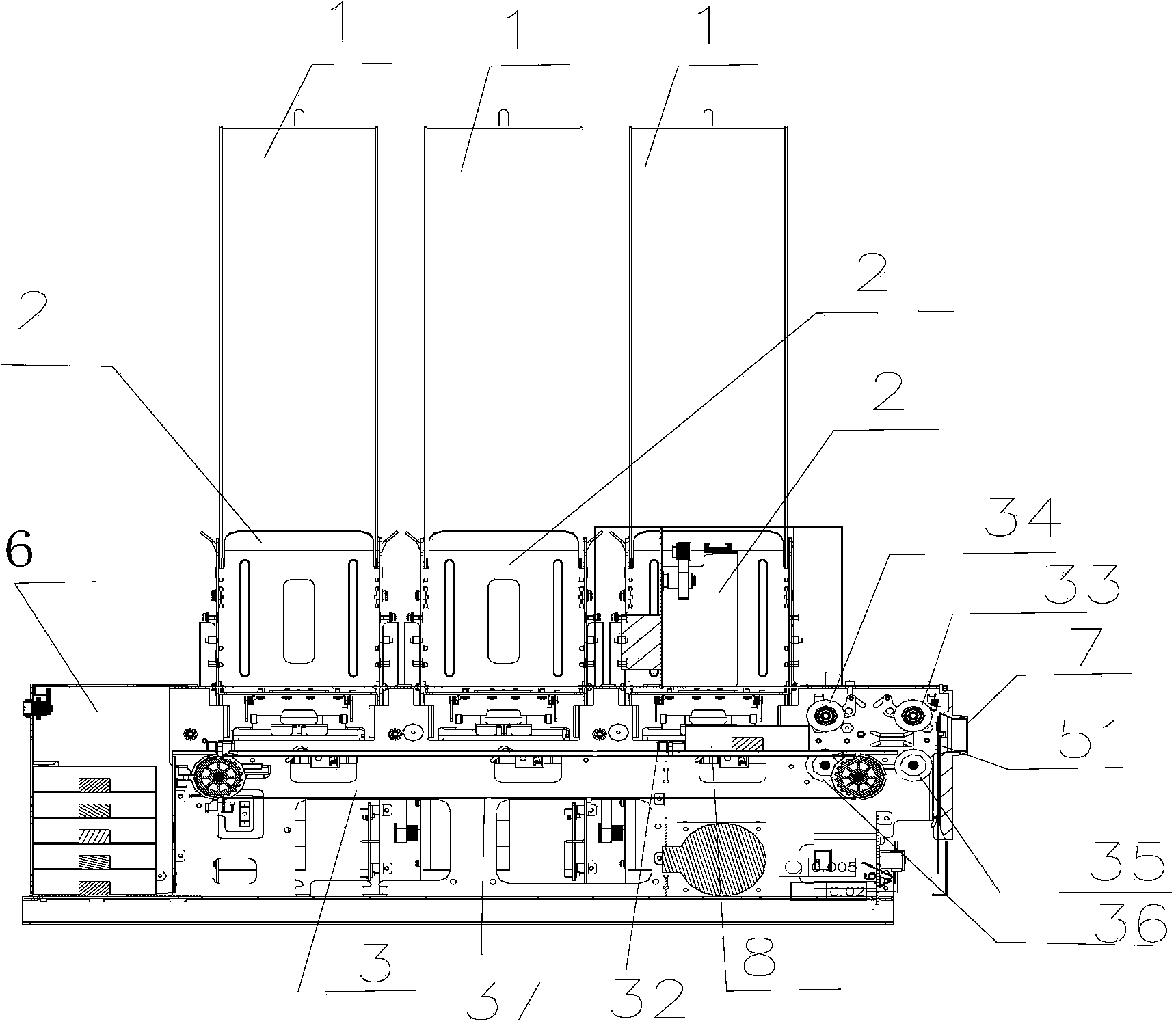

ActiveCN104200241ACompact structureSave spaceComplete banking machinesConveying record carriersLarge capacityAutomation

The invention discloses a method for issuing high-capacity internetbank verification modules. The method includes steps of (1) transmitting any one of KEY boxes stored in storage boxes to a transmission channel in a transmission mechanism by a pushing mechanism, transmitting the KEY box to a gate mechanism from the transmission channel by the transmission mechanism, opening a gate of the gate mechanism to let the KEY box extend out of the gate, and issuing the KEY box to a user; (2) if the user fails to take away the KEY box within a preset time (detecting whether the KEY box is taken away or not by a thru-beam sensor), transmitting the KEY box back to a recovery box through the transmission passage by the transmission mechanism. The method for issuing the high-capacity internetbank verification modules automatically has the advantages of automation and intelligentization and is applicable to issuing high-capacity KEY boxes.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

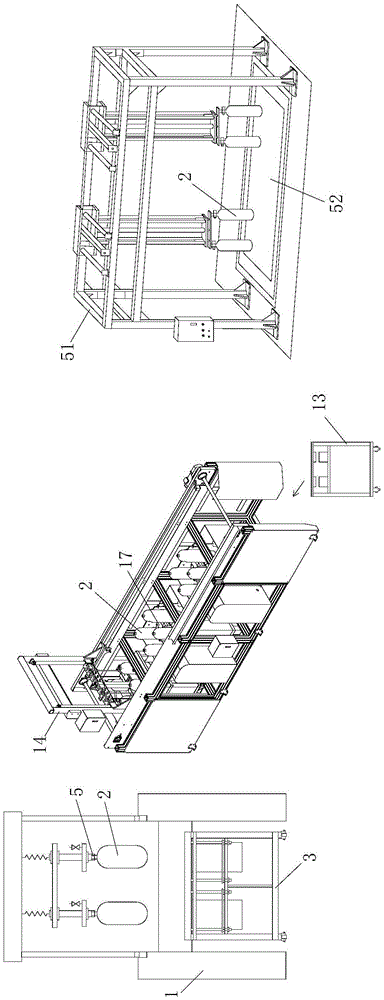

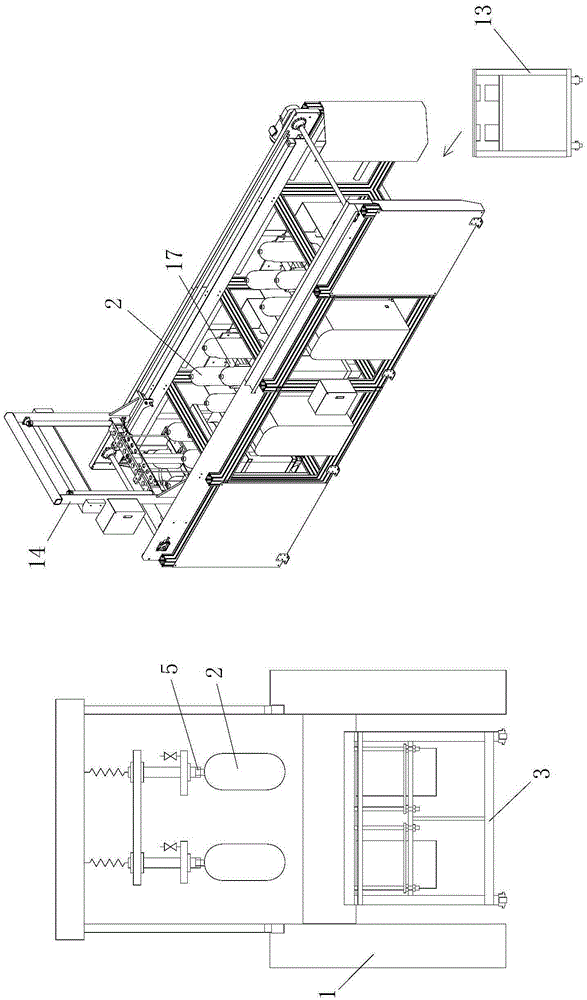

Automatic detection line and detection method of carbon fiber gas bottle

InactiveCN105466786ASimple structureCompact structureDetection of fluid at leakage pointDrying using combination processesEngineeringTest fixture

The invention discloses an automatic detection line and detection method of a carbon fiber gas bottle. The detection line comprises a water pressure testing device, an auxiliary water pressure testing device, a bottle valve loading and unloading machine and an air tightness experiment device, which are arranged from front to back, wherein the water pressure testing device comprises a testing rack, a testing operation platform, a pressurizing device, a testing box and a testing trolley; the auxiliary water pressure testing device comprises a gas bottle clamp, a conveying trolley, and gas bottle water pouring and drying treatment equipment; the bottle valve loading and unloading machine comprises a bottle valve loading and unloading rack, a control cabinet, a gas bottle fixing mechanism and a bottle valve screwing mechanism; the air tightness experiment device comprises an air tightness testing device and a second gas supplying device for supplying gas to a plurality of gas bottles to be tested. The detection method comprises the following steps: 1, testing water pressure; 2, carrying out water pouring and drying treatment; 3, assembling a bottle valve; 4, testing air tightness. The automatic detection line provided by the invention is reasonable in design, simple to use and operate and good in use effect, and can be used for simply, conveniently and rapidly finishing water pressure testing and air tightness testing processes of the plurality of carbon fiber gas bottles.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

Automatic incasing machine

The invention discloses an automatic incasing machine which comprises a rack, a bottle conveying device, a case conveying device and a bottle moving device, wherein the bottle conveying device, the case conveying device and the bottle moving device are arranged on the rack; and the machine is characterized in that the bottle moving device comprises a translational frame and a bottle grasper installing frame, the translational frame is arranged on the rack and can be driven to horizontally move back and forth, the bottle grasper installing frame is arranged on the translational frame and can be driven to lift upwards and downwards, and the bottle grasper installing frame is provided with a bottle grasper. According to the automatic incasing machine, the bottle moving device is subjected to horizontal moving and vertical lifting through controlling the bottle grasper installing frame and the bottle grasper, stable in running and accurate in control, and in the process of horizontal moving and vertical lifting, bottles on the bottle grasper are uneasy to shake, so that a situation that bottles shake in the process of moving can be effectively avoided, and bottles move smoothly, and therefore, the incasing quality and the quality of bottled products can be ensured.

Owner:广东轻工机械二厂智能设备有限公司

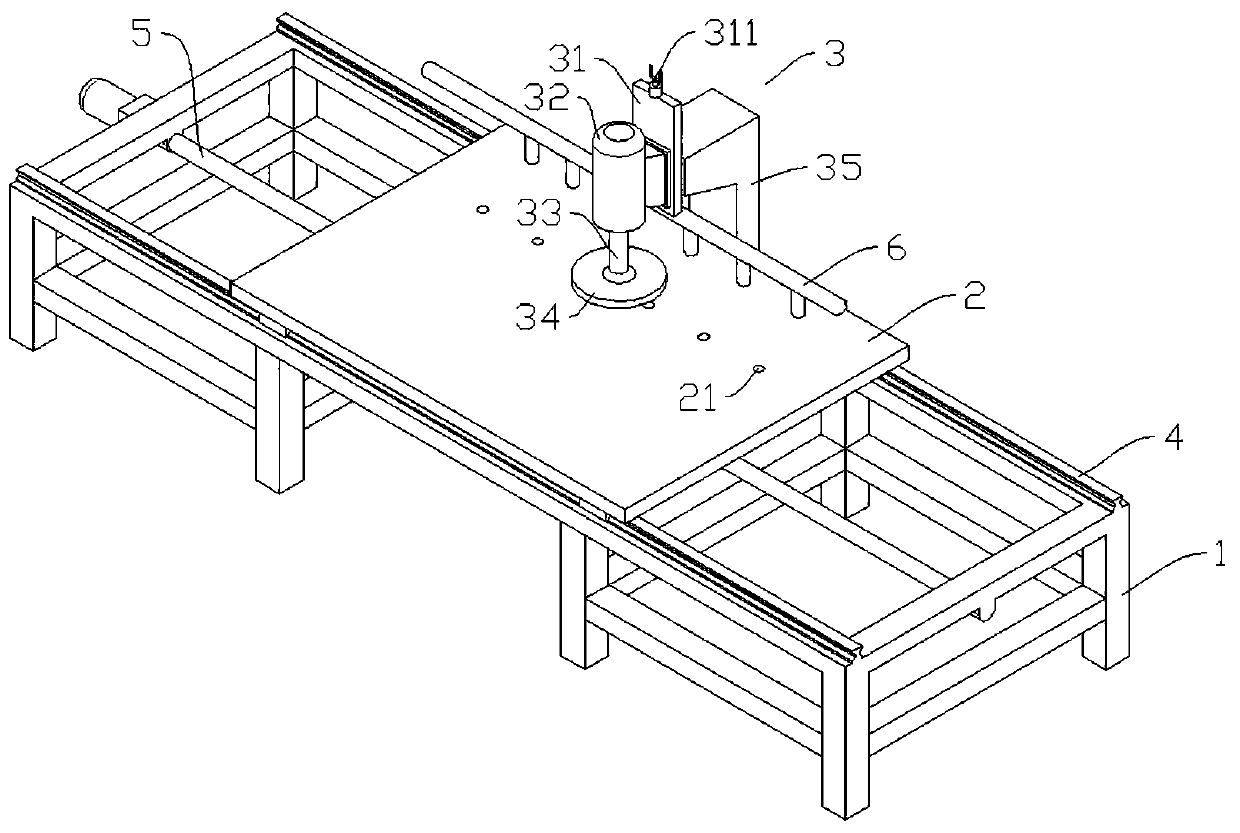

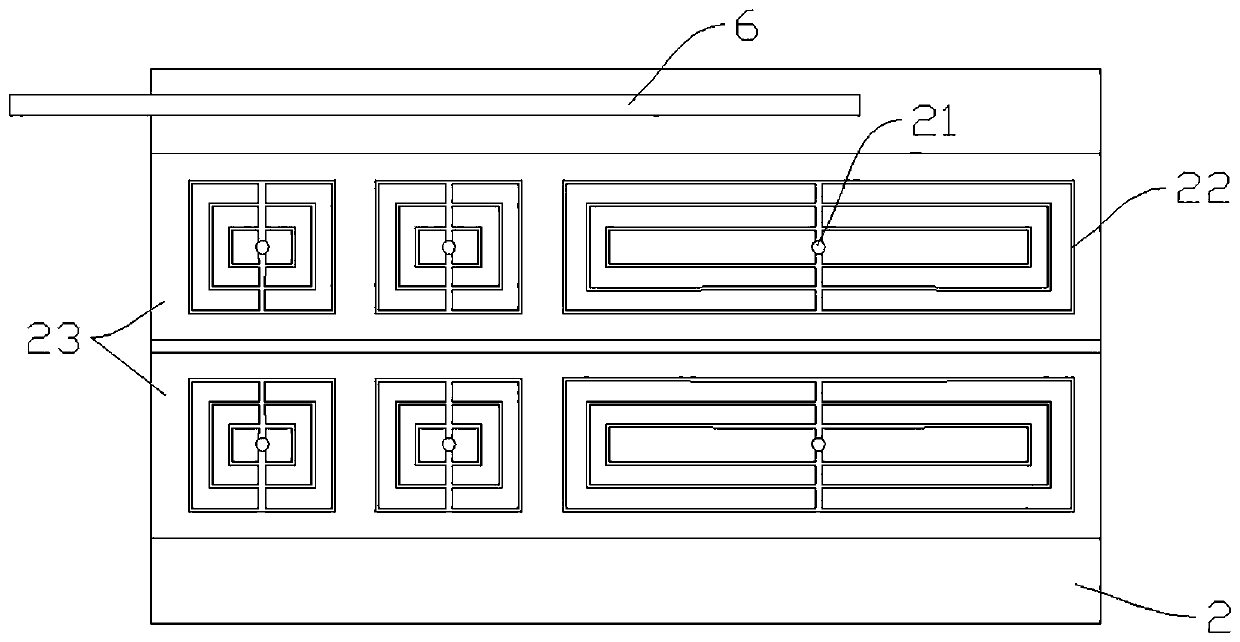

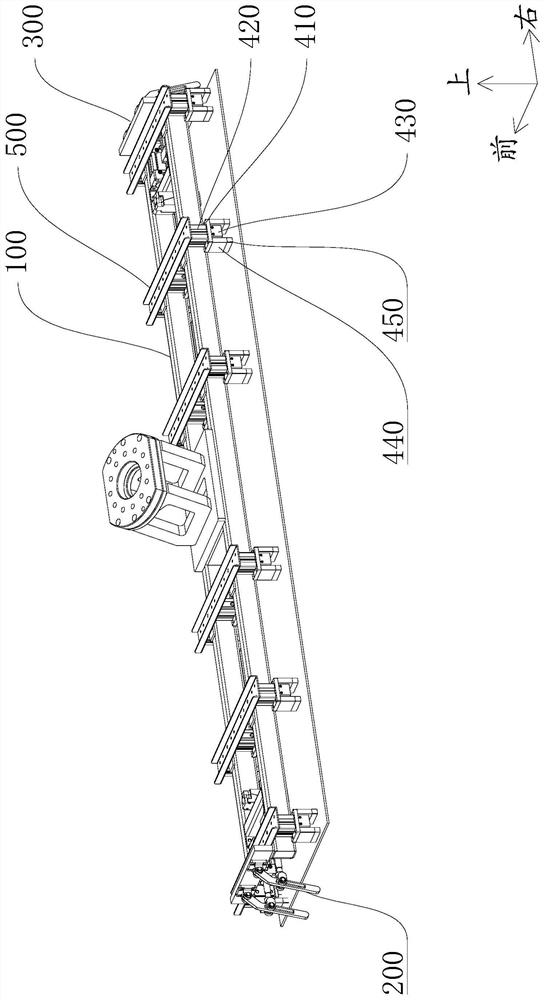

Material conveying system and laser processing equipment

PendingCN110497102AReasonable structural designIncrease production capacityCharge manipulationLaser beam welding apparatusLaser processingTransport system

The invention discloses a material conveying system and laser processing equipment. The material conveying system comprises a workbench, an objective table, a driving transmission assembly and a feeding and discharging mechanism; the objective table is arranged at the upper end of the workbench and is in transmission connection with the driving transmission assembly arranged on the workbench, andtwo sets of discharging stations which are distributed in parallel are arranged on the objective table; a set of feeding stations is arranged on each of the left side and the right side of the upper portion of the workbench, a set of processing stations is arranged in the middle of the workbench, the driving transmission assembly drives the objective table to move left and right in a reciprocatingmode, the two sets of discharging stations are driven to move in a reciprocating mode between the feeding stations on one side and the processing stations, and when one set of discharging stations islocated at the processing stations, the other set of discharging stations is located at the feeding stations on the side corresponding to the discharging stations; and the two feeding and dischargingmechanisms correspond to the two sets of feeding stations correspondingly, and the feeding and discharging mechanisms are used for feeding materials to the feeding positions and transferring the materials on the feeding positions. The system and the equipment have the advantages that the productivity can be improved, and meanwhile, the bottleneck problem that the production is limited due to thefact that the process of the subsequent stage is balanced is effectively solved.

Owner:WUHAN DR LASER TECH CORP LTD

Carbon fiber cylinder detection system and method

InactiveCN105571949ASimple structureCompact structureDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesFiberCarbon fibers

The invention discloses a carbon fiber cylinder detection system and method. The detection system comprises a hydraulic pressure tester, a hydraulic pressure assisted tester and a tightness tester; the hydraulic pressure tester comprises a test rack, a test operating table, a pressurizing device, a test case mounted on the test rack and a test cart for multiple cylinders to be tested to be placed steadily on; the hydraulic pressure assisted tester comprises a cylinder clamp, a conveying cart and a cylinder emptying and drying apparatus; the tightness tester comprises a tightness test unit and a second gas supply device supplying gas to multiple cylinders to be tested, and the tightness test unit is a cabinet type tightness test unit or a trough type tightness test unit; the method comprises the steps: first, hydraulic pressure testing; second, emptying and drying treatment; third, tightness testing. This system is reasonable in design and simple to operate and effective to use and enables the hydraulic pressure test and tightness test process of multiple carbon fiber cylinders to be finished simply and quickly.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

3D printer

The invention discloses a 3D printer which comprises a translation printer head for assembling a printing head assembly, the translation printer head is driven by a translation assembly, and the translation assembly is assembled to a printer head assembling platform; the printer head assembling platform is provided with a processing platform for assembling a forming platform; the forming platform is driven by a two-dimensional adjustment assembly to achieve two-dimensional movement in the horizontal direction and the vertical direction; the printing head assembly comprises a printing head and an ascending and descending assembly for driving the printing head to ascend and descend; the two-dimensional adjustment assembly comprises a double-cam drive shaft, the double-cam drive shaft rotates along with a planar cam and a cylindrical cam which is fixed to the double-cam drive shaft, the cylindrical cam pushes a horizontal movement sliding block to conduct horizontal linear movement along linear guide rails moving in the horizontal direction, and the planar cam pushes a vertical movement sliding block arranged in the horizontal movement sliding block in a sleeving mode to conduct linear movement in the vertical direction along linear guide rails moving in the vertical direction; the processing platform is assembled to the vertical movement sliding block through a supporting assembly.

Owner:宾向思

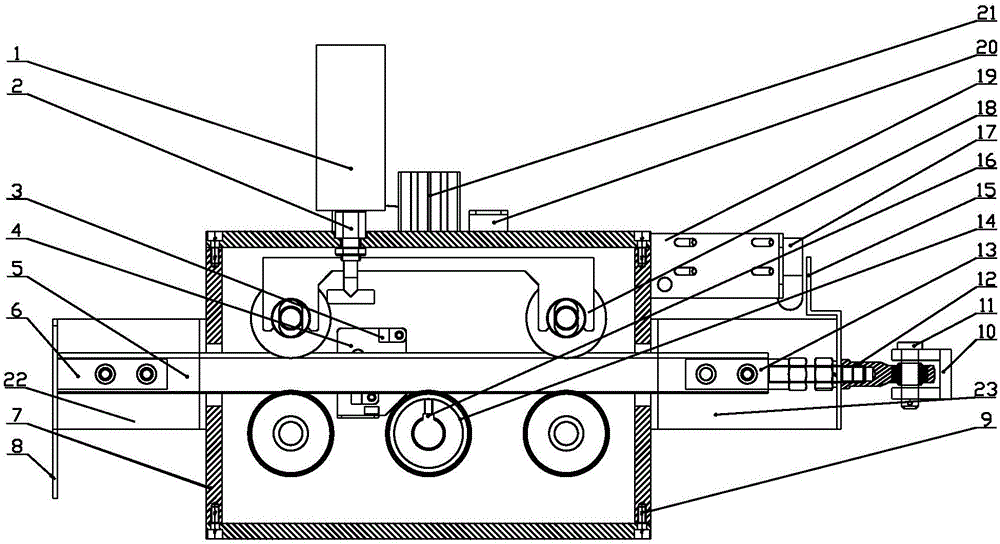

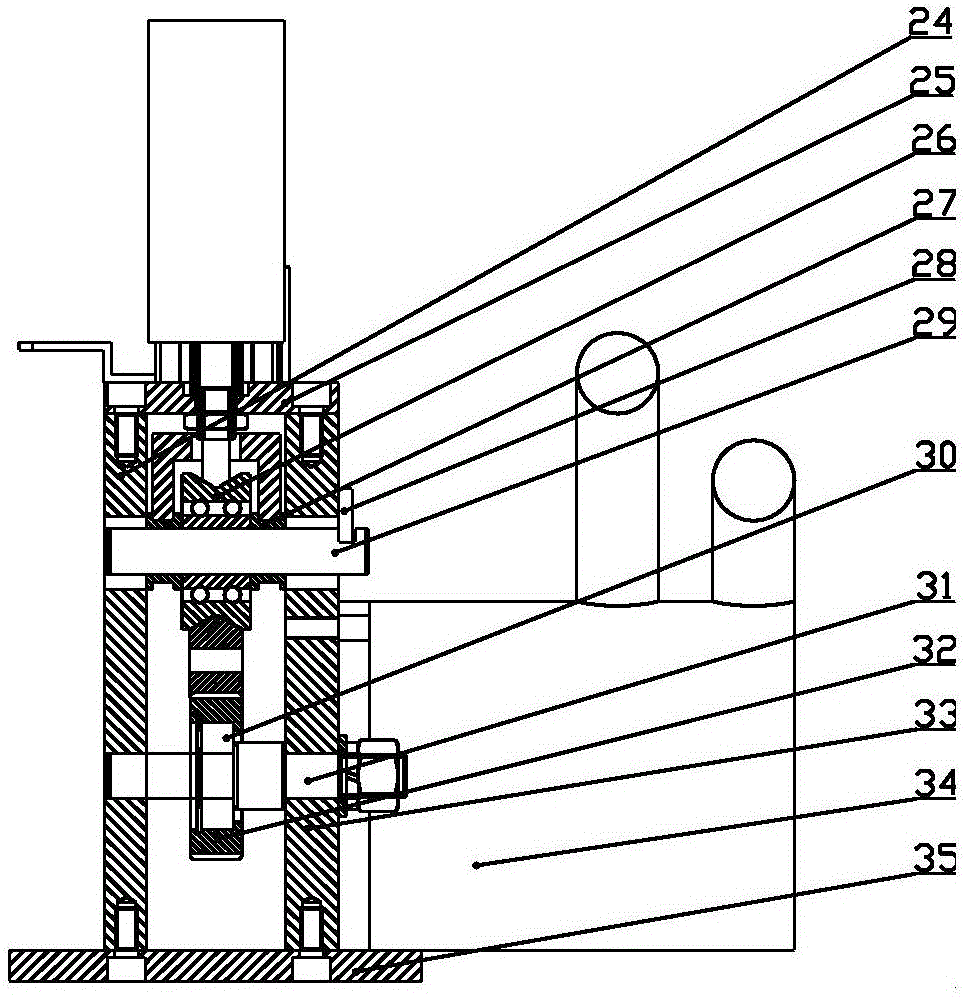

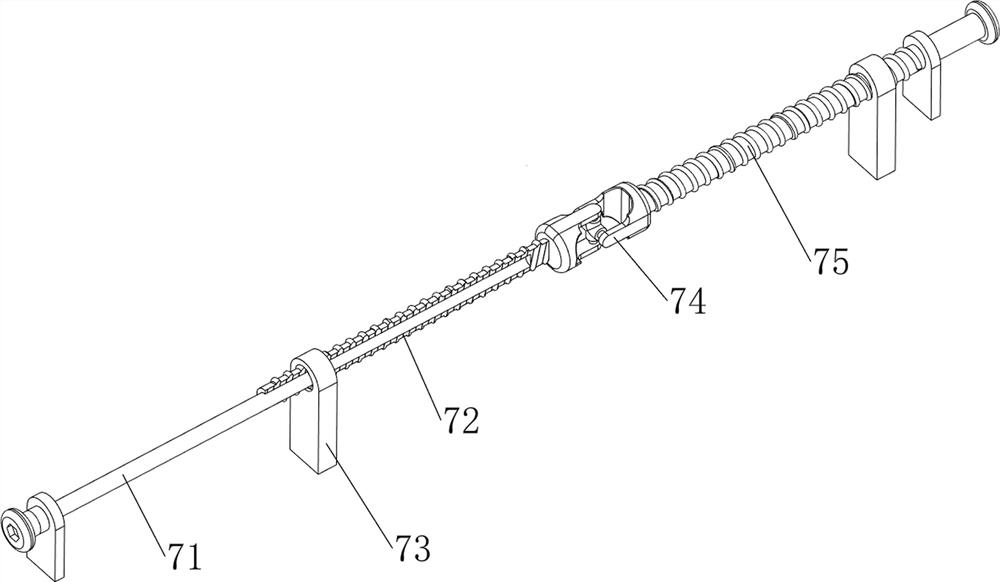

Feeding mechanism of neodymium iron boron magnetic field forming press

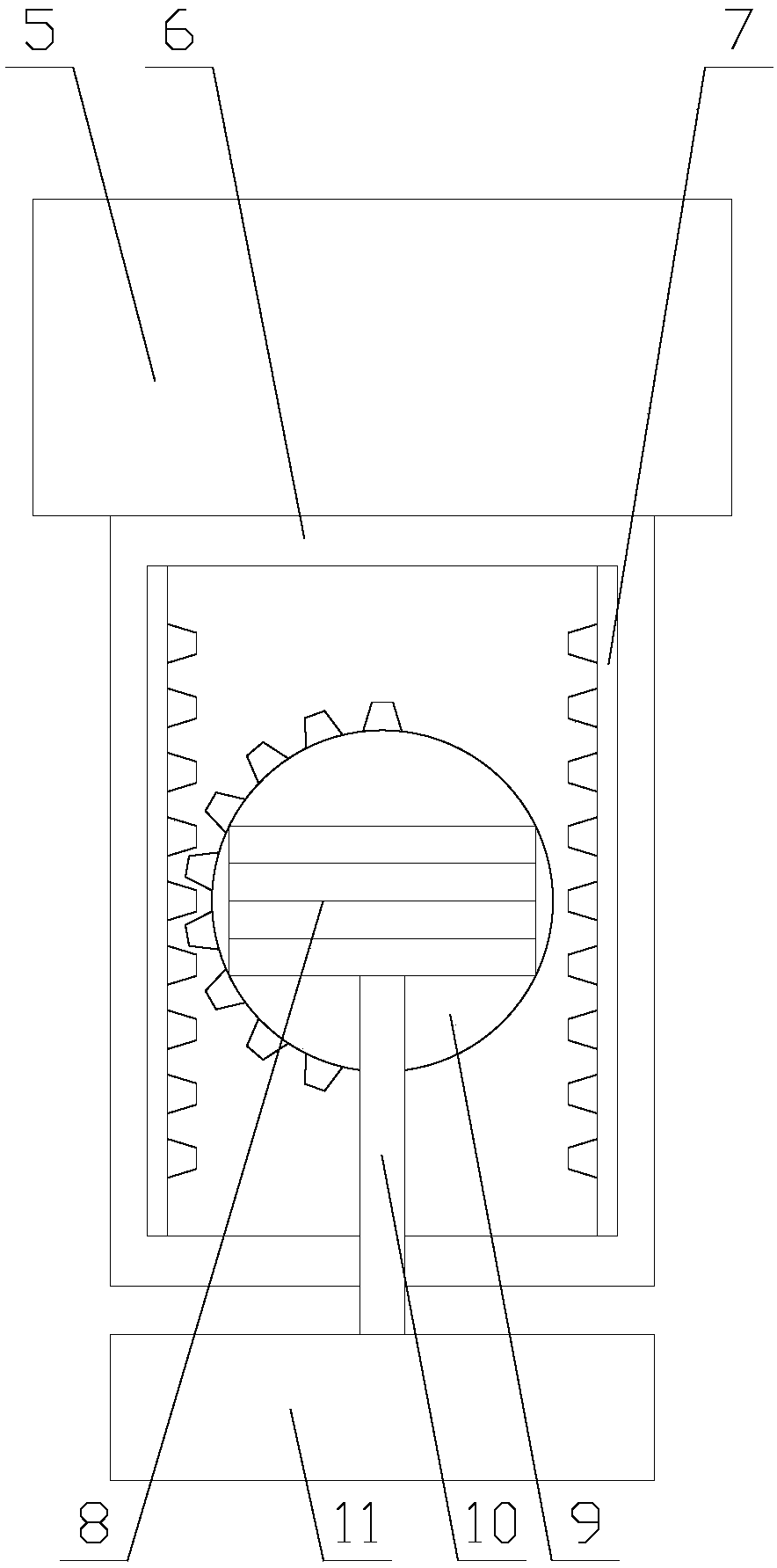

ActiveCN106041066ADrive fastImprove use reliabilityMagnetic materialsFriction gearingsEngineeringNeodymium iron boron

The invention discloses a feeding mechanism of a neodymium iron boron magnetic field forming press. The feeding mechanism comprises a gearbox and a rack penetrating the gearbox. The gearbox is internally provided with a drive gear driven by a servo motor. The drive gear is engaged with one side of the rack. The gearbox is internally further provided with press wheels matched with the other side of the rack. Dust covers in closed connection with the gearbox are arranged at the end portions, stretching out of the gearbox, of the rack. According to the feeding mechanism, a drive mechanism in which the closed gearbox and the rack are matched is adopted for driving a powder box to linearly reciprocate, the dustproof requirement is low, the displacement speed and the stroke precision can be accurately controlled, the drive speed is higher, running is stable and reliable, and the maintenance rate is lower.

Owner:BAIQIDA INTELLIGENT TECH NINGBO CO LTD

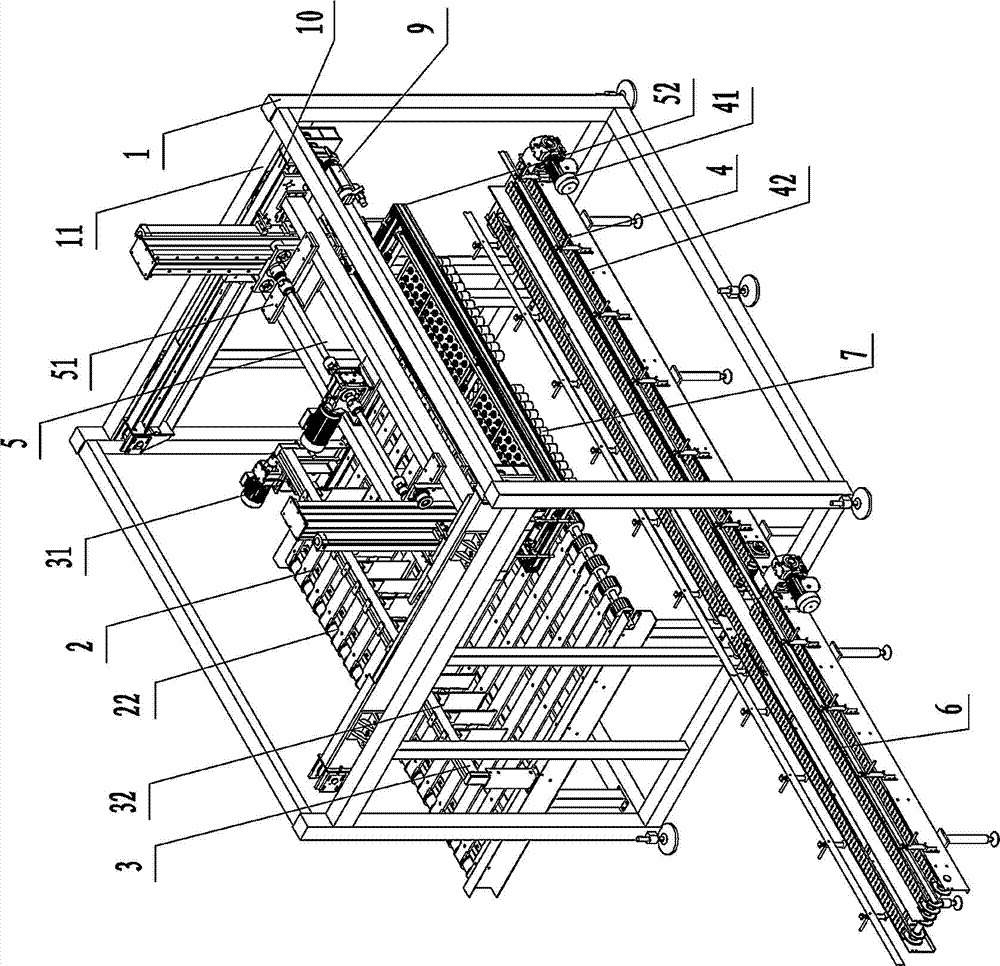

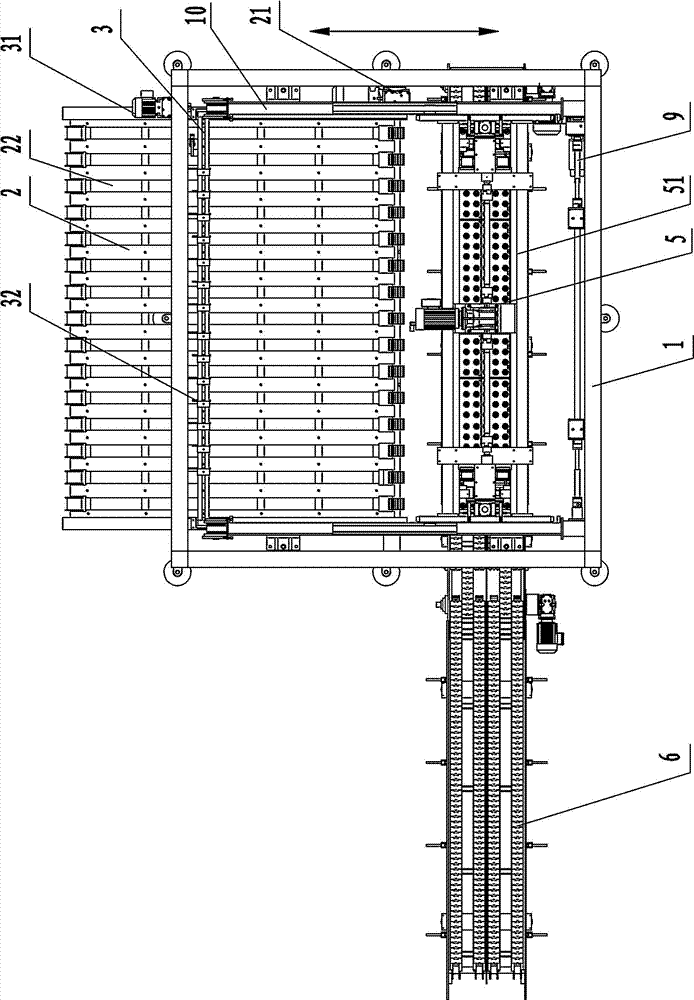

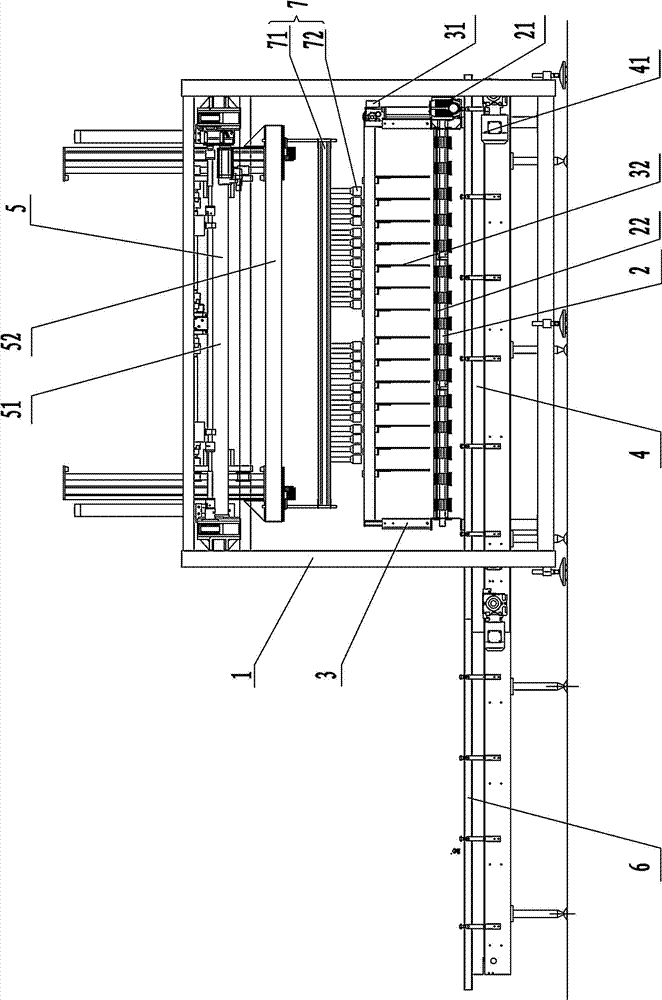

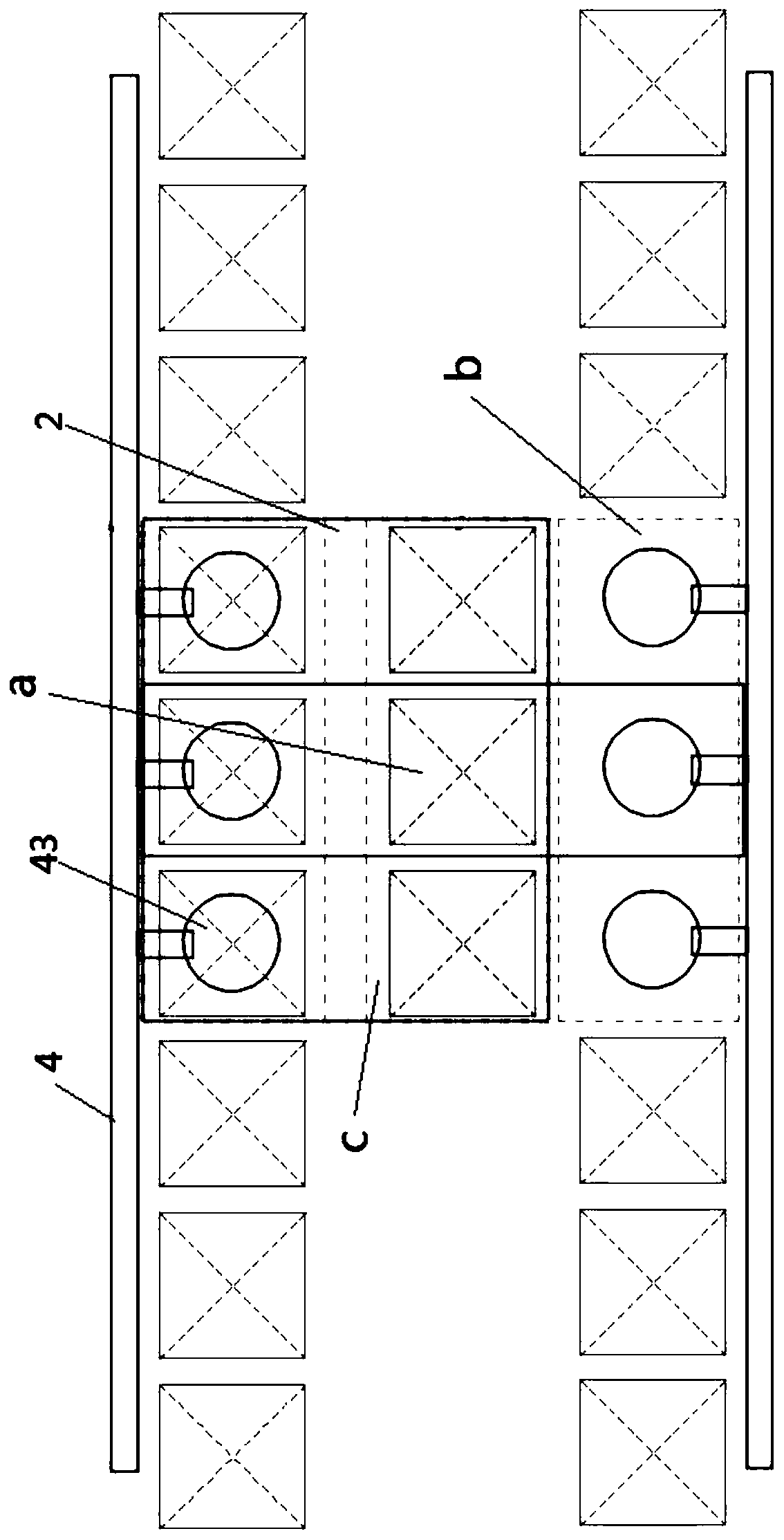

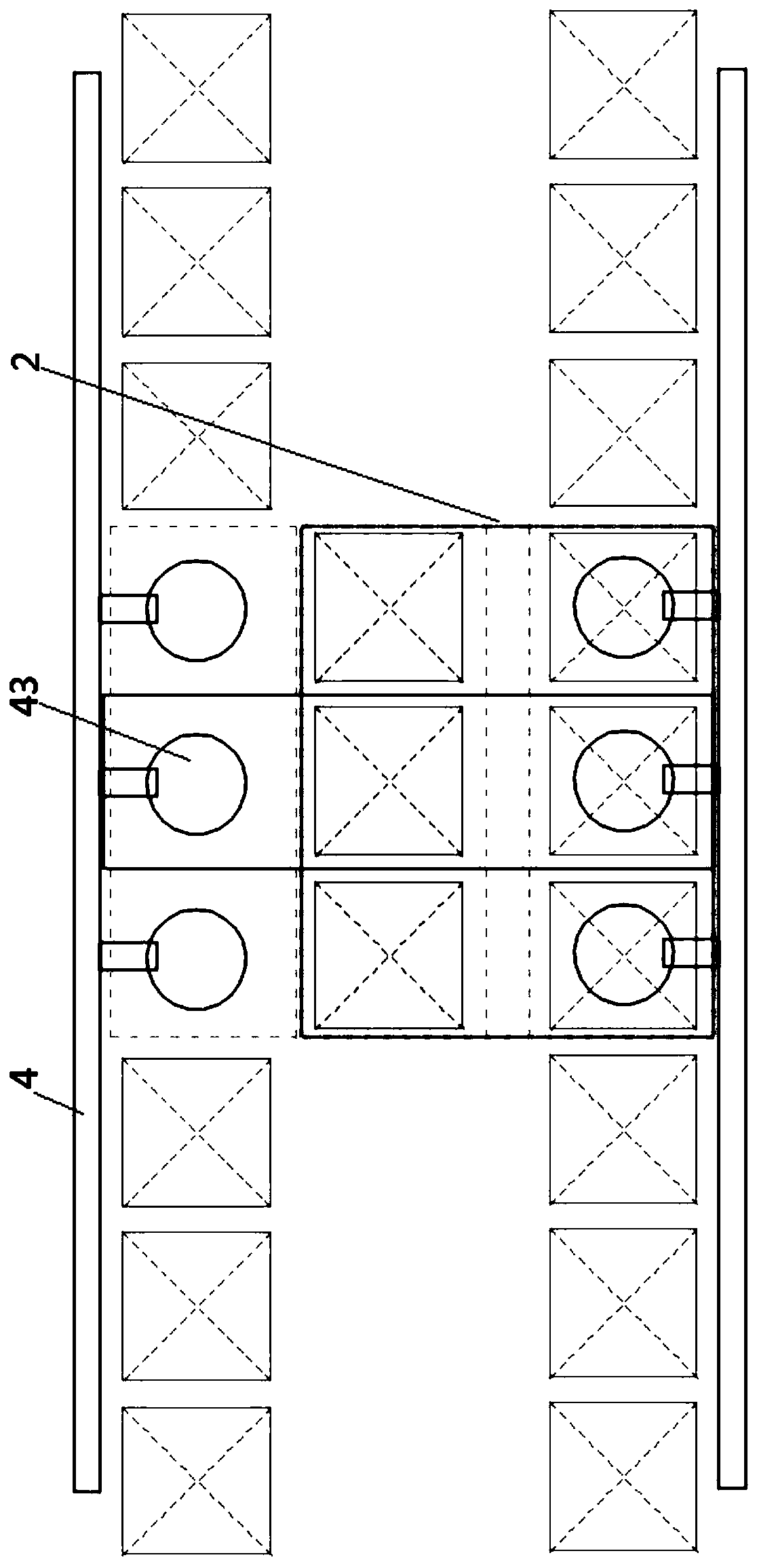

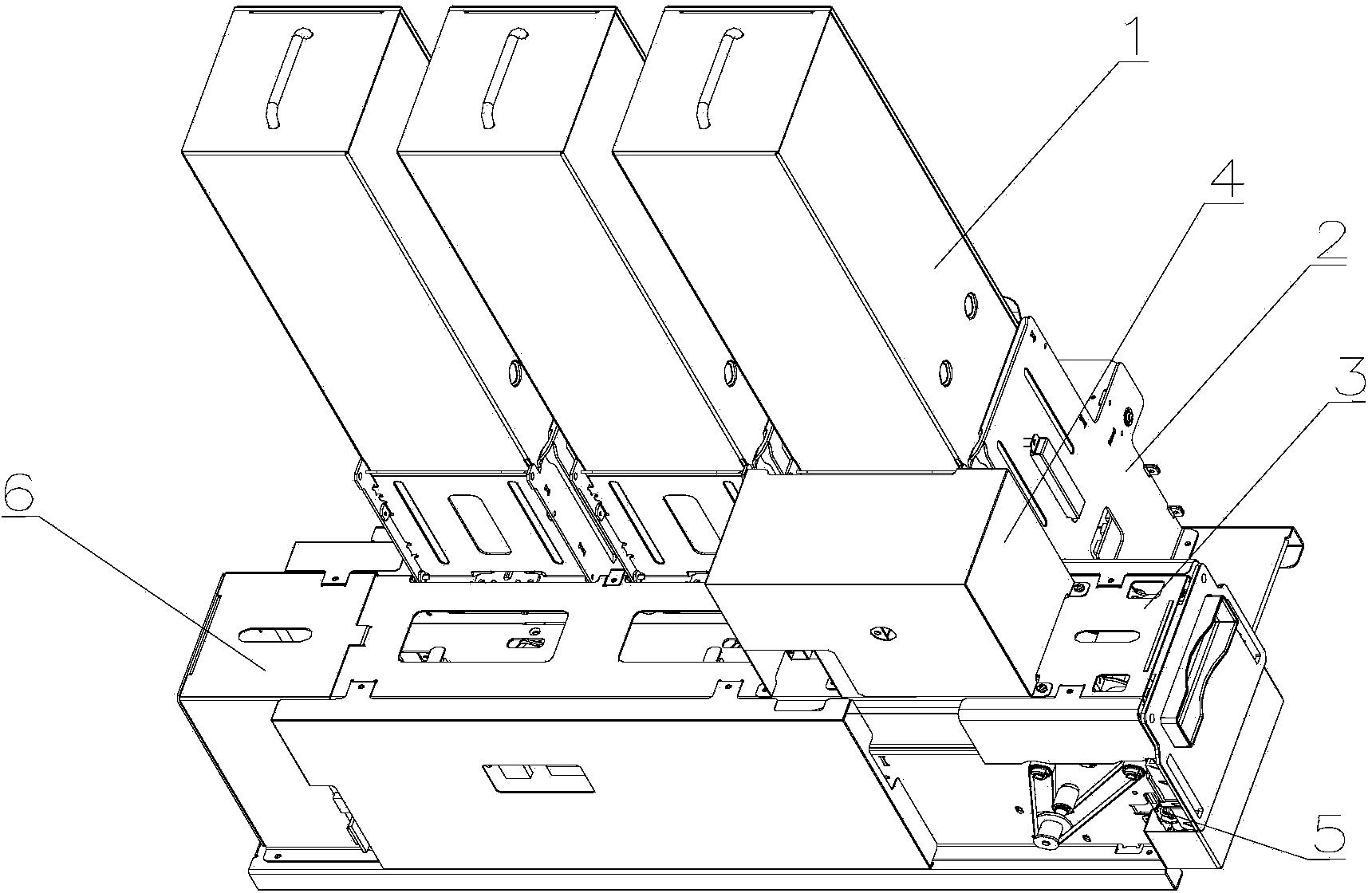

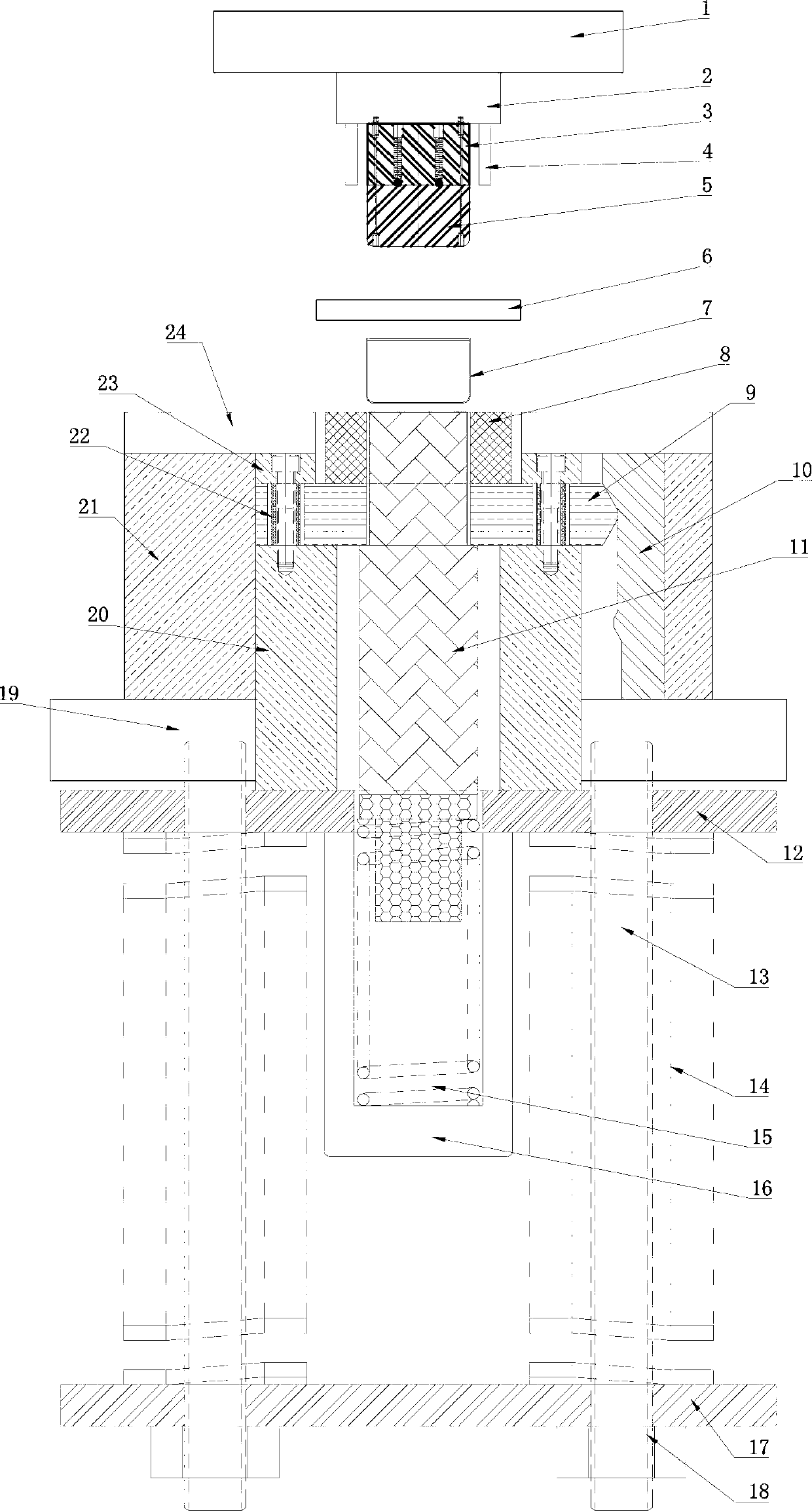

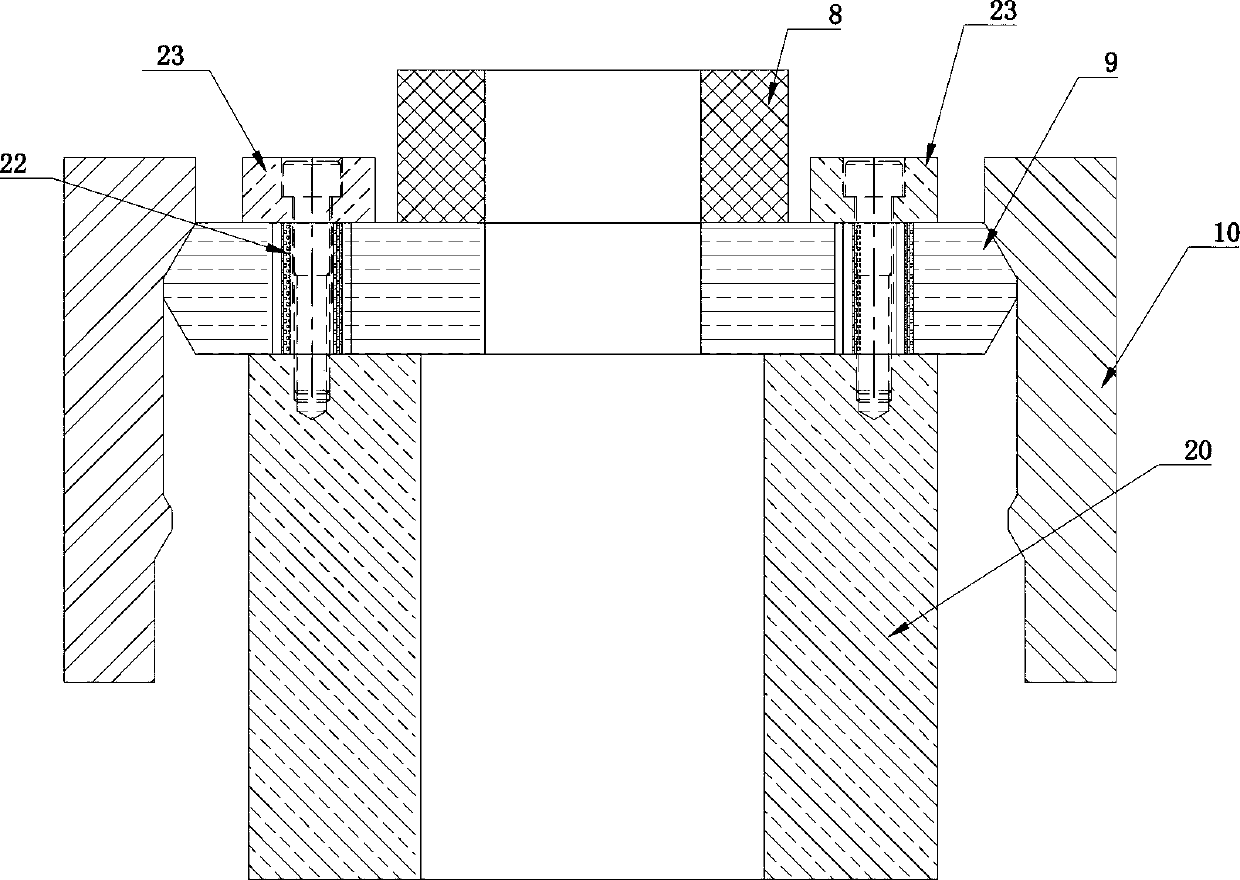

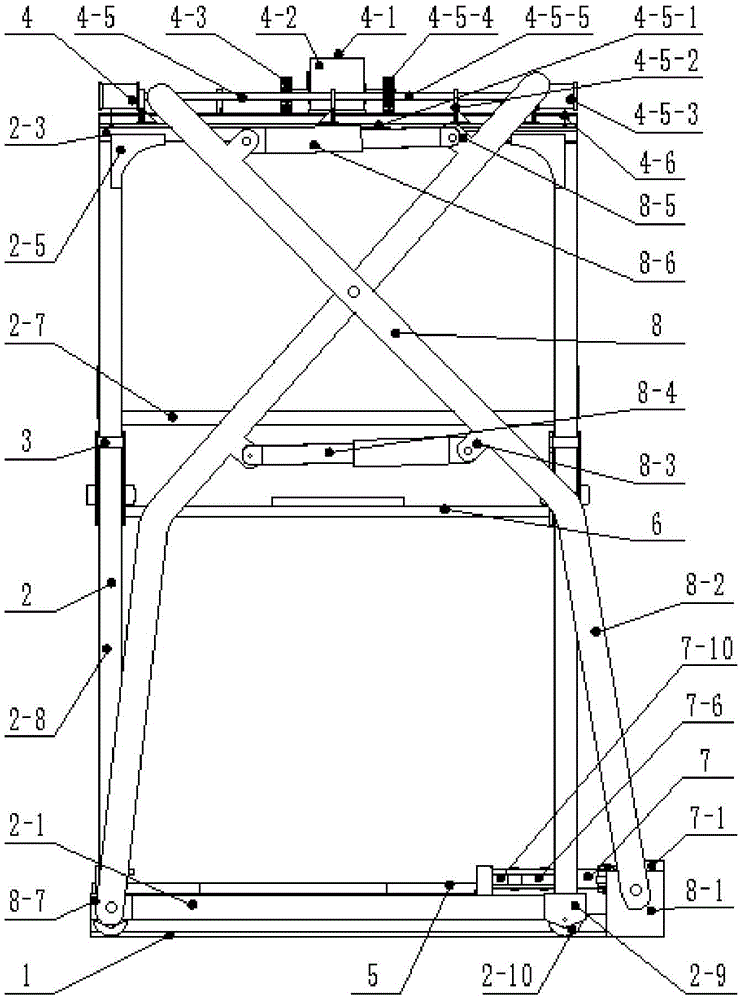

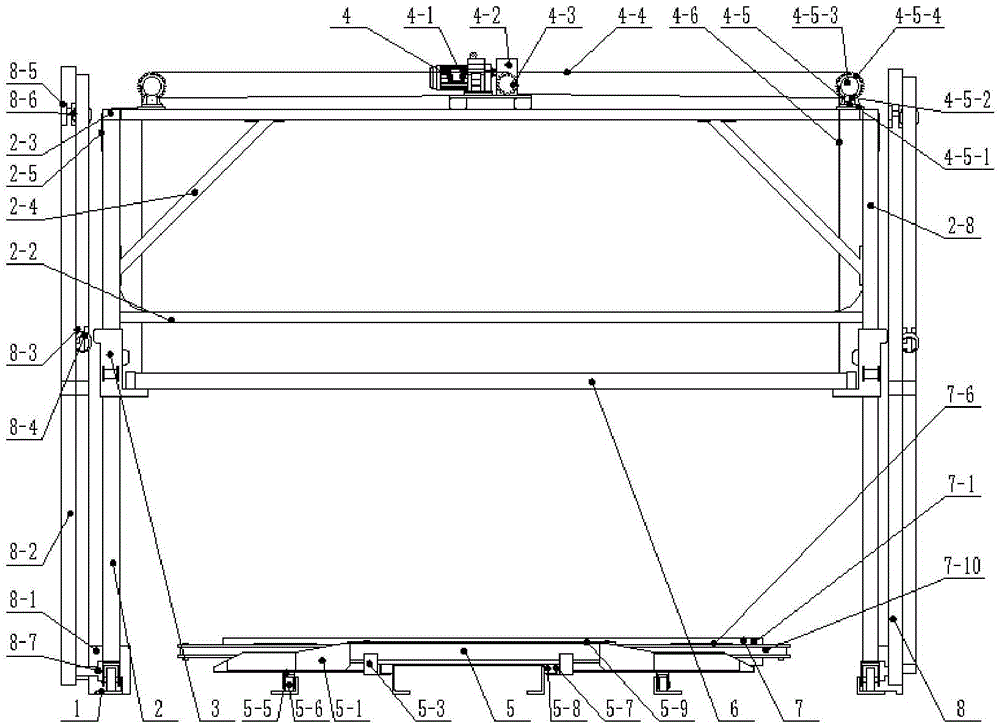

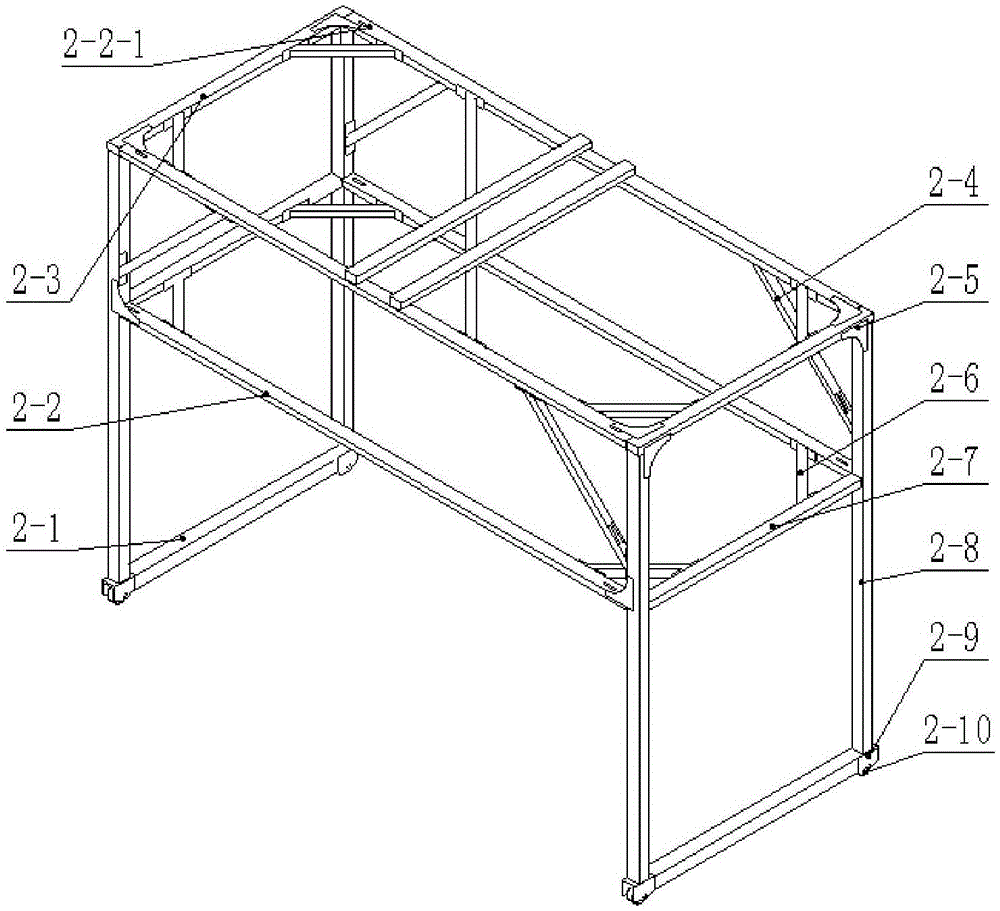

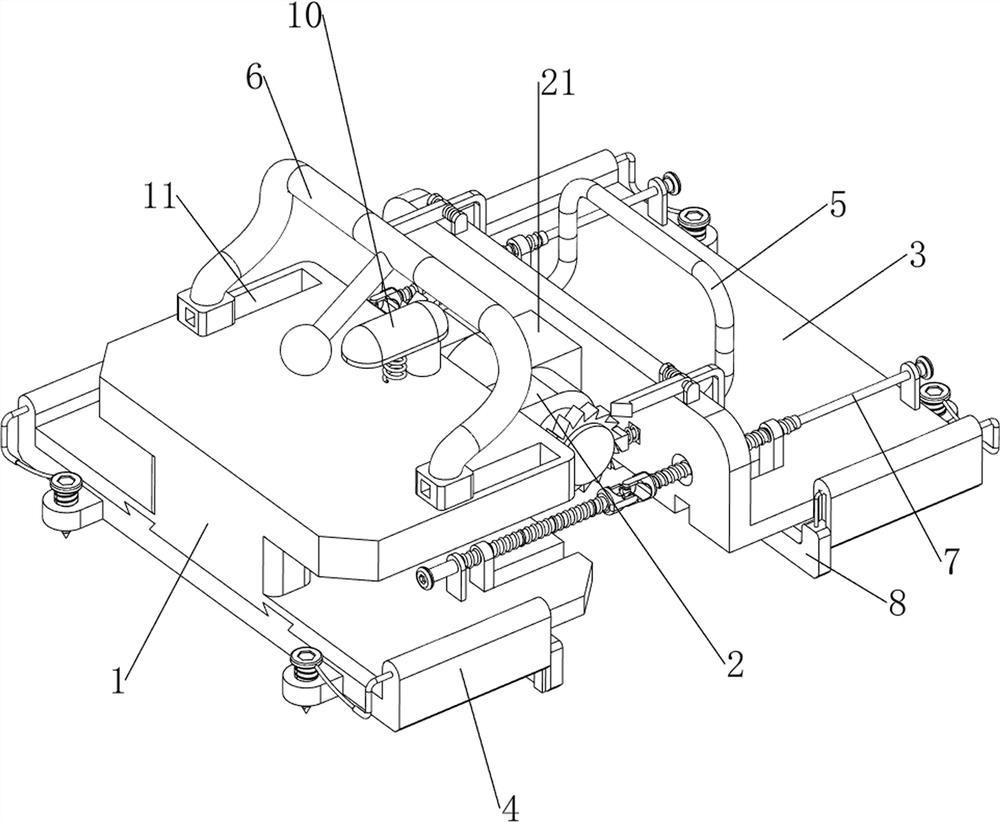

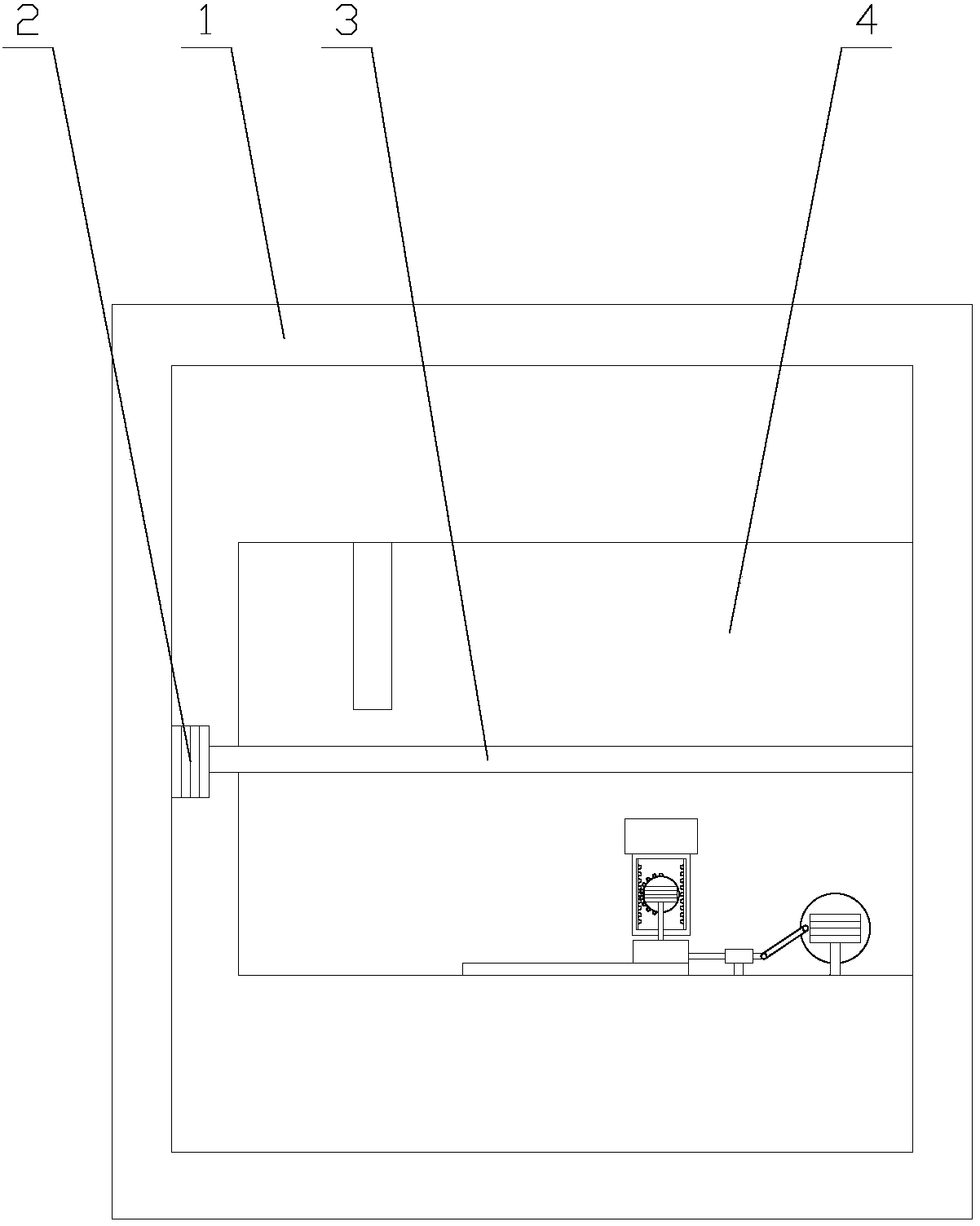

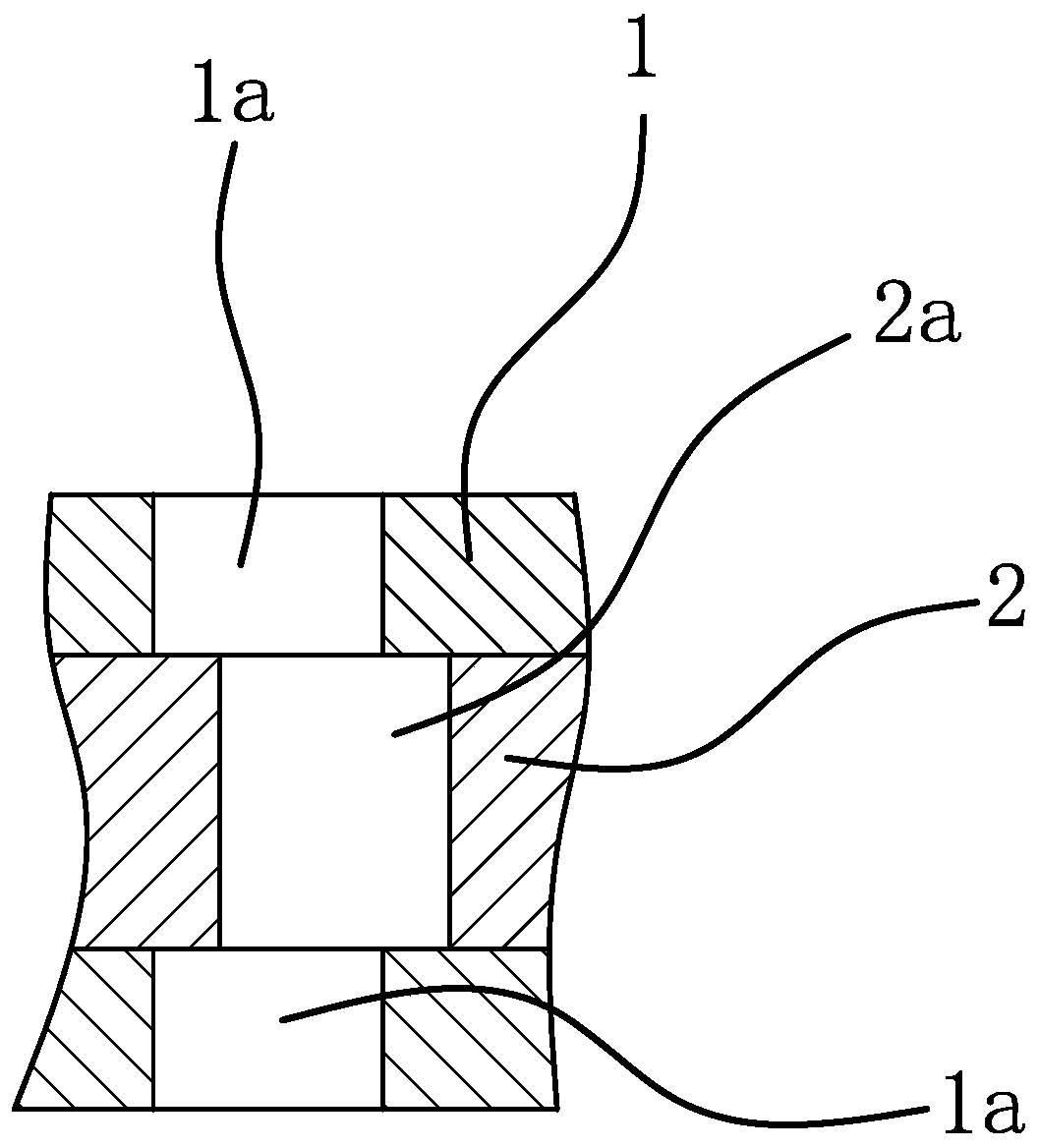

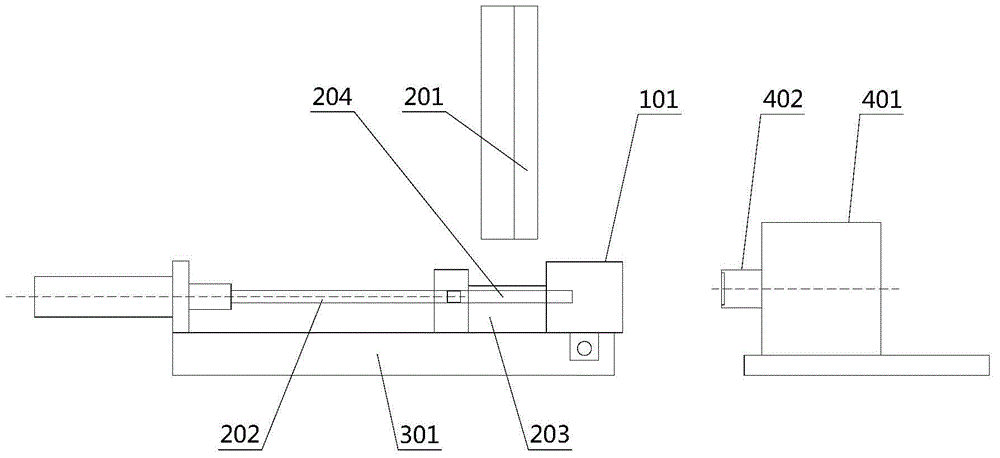

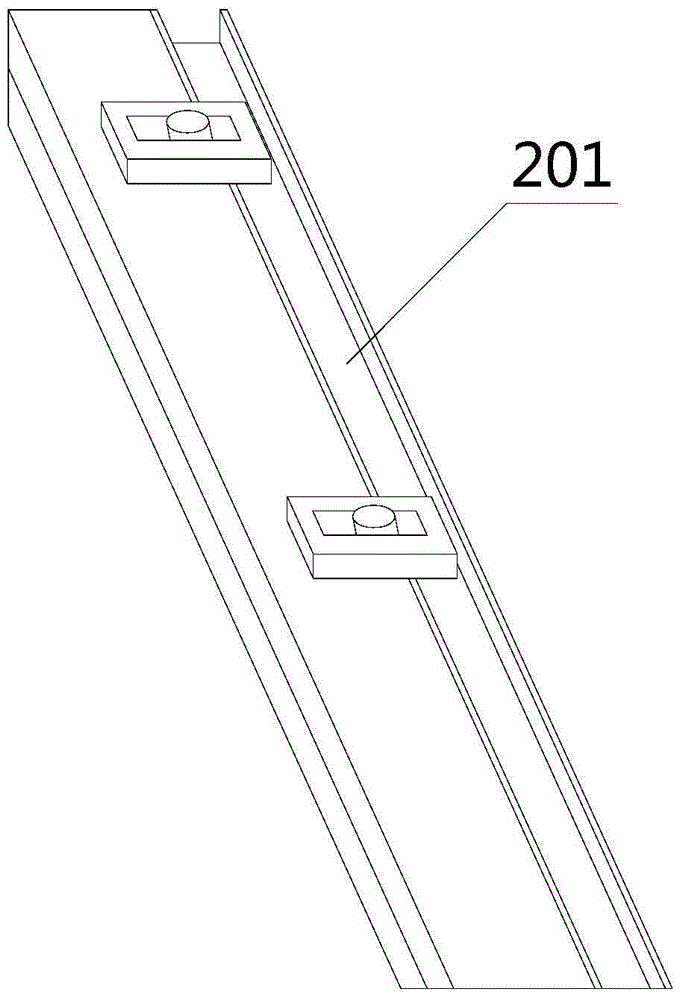

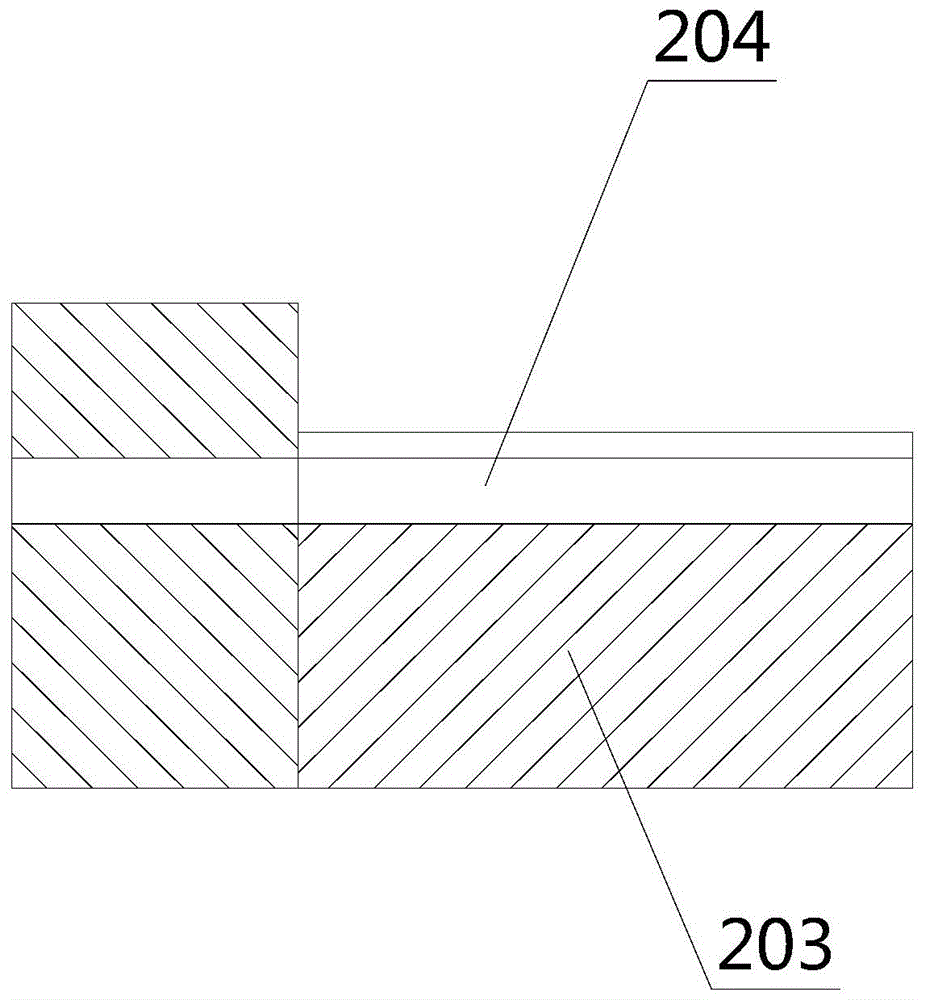

Large-capacity E-bank verification module issuing system for financial self-service system

ActiveCN104239911ACompact structureWon't interfereComplete banking machinesConveying record carriersComputer moduleTransmission channel

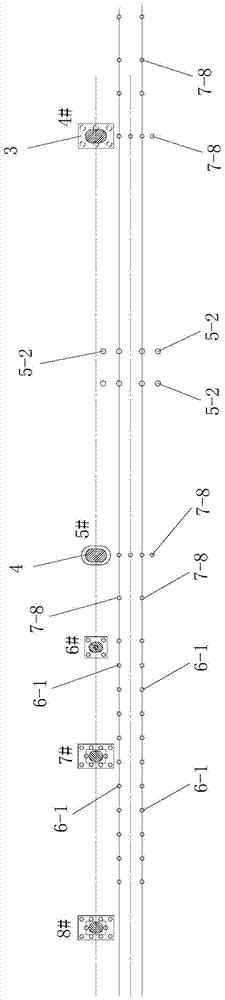

The invention discloses a large-capacity E-bank verification module issuing system for a financial self-service system. The large-capacity E-bank verification module issuing system for the financial self-service system comprises storage boxes (1), pushing mechanisms (2), a transmission mechanism (3), a scanning mechanism (4), a gate mechanism (5) and a recovery box (6). The number of the storage boxes and the number of the pushing mechanisms are both N. A plurality of stacked E-bank verification modules are stored in each storage box, and the pushing mechanisms are used for sending KEY boxes in the storage boxes to a transmission channel in the transmission mechanism. The gate mechanism and the recovery box are arranged at the two ends of the transmission mechanism respectively. The KEY boxes are transmitted to the recovery box to be recovered or transmitted to the gate mechanism to be issued to users by the transmission mechanism. The scanning mechanism is used for scanning the identity identification codes on the KEY boxes which pass through the transmission channel. The large-capacity E-bank verification module issuing system for the financial self-service system can automatically issue the E-bank verification modules, has the advantages of automation and intellectualization, and can support issuing of large-capacity KEY boxes.

Owner:HUNAN GREATWALL INFORMATION FINANCIAL EQUIP

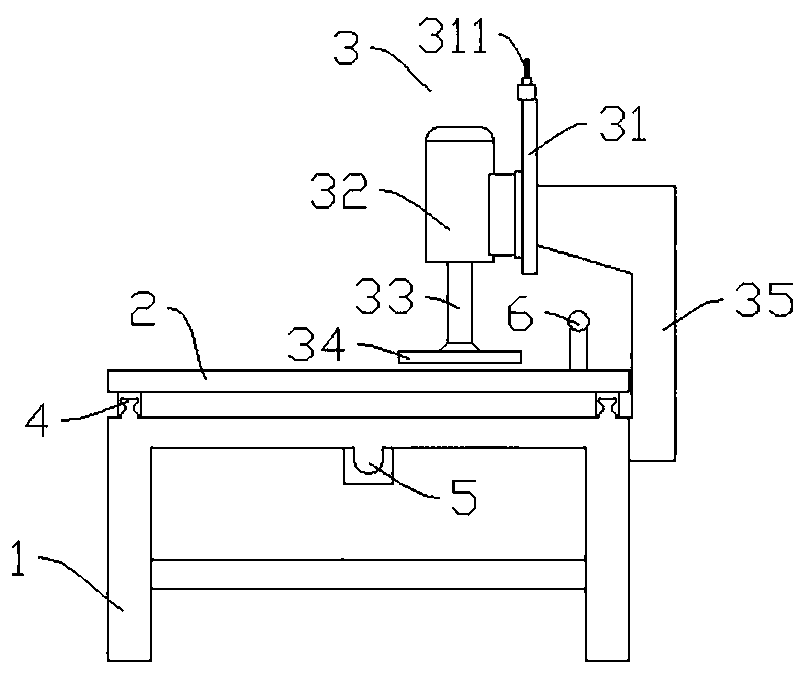

High-precision polishing equipment for graphite slices

PendingCN111531452AAchieve level adjustmentHigh polishing precisionGrinding carriagesPolishing machinesPolishingEngineering

The invention belongs to the technical field of graphite product machining equipment, and particularly discloses high-precision polishing equipment for graphite slices. The high-precision polishing equipment for the graphite slices comprises a rack, a workbench and a grinding assembly. Small holes are formed in the surface of the workbench for vacuumizing to adsorb and fix the graphite slices, double sliding rails and the grinding assembly are arranged on the rack for adjustment of polishing positions, and the relatively high polishing precision is obtained preliminarily; annular channels communicating with the small holes are formed in the peripheries of the small holes to enhance the vacuum adsorption effect, with the arrangement of a concave area of the workbench combined, it is guaranteed that the graphite slices cannot deviate in position in the polishing process, and the polishing precision is improved; and through the three-layer structural design of a metal layer, a rubber layer and a polishing layer of a polishing disc, the stability of the grinding assembly is improved, and the polishing precision is further improved; in addition, the high-precision polishing equipment for the graphite slices also has the characteristics that the operation is easy, the safety is high, the polishing layer can be easily replaced, and the polishing efficiency is high.

Owner:ZHEJIANG HAROG TECH CO LTD

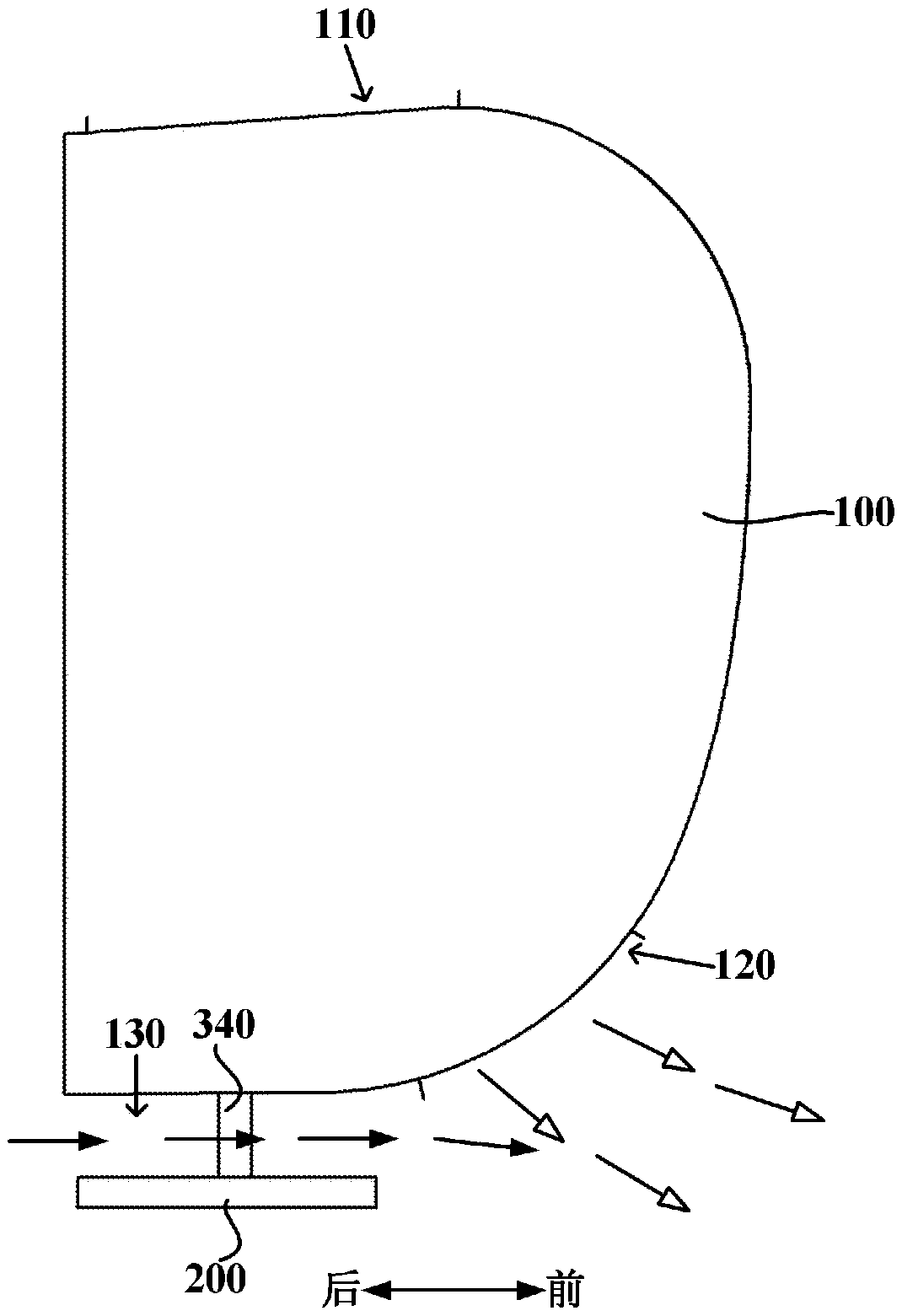

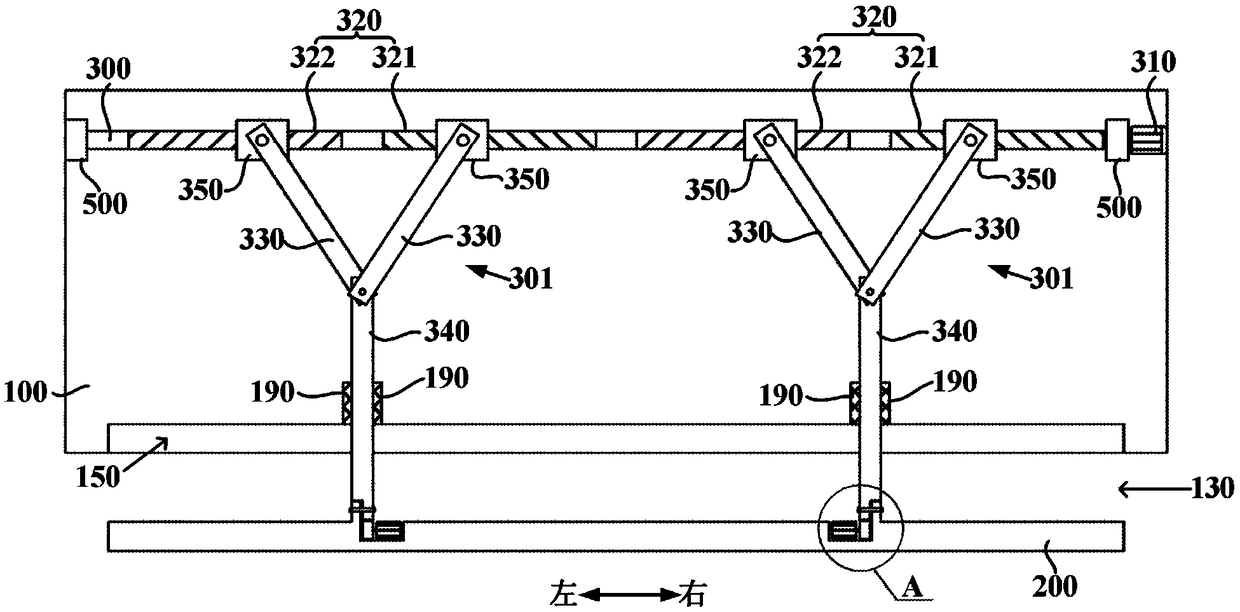

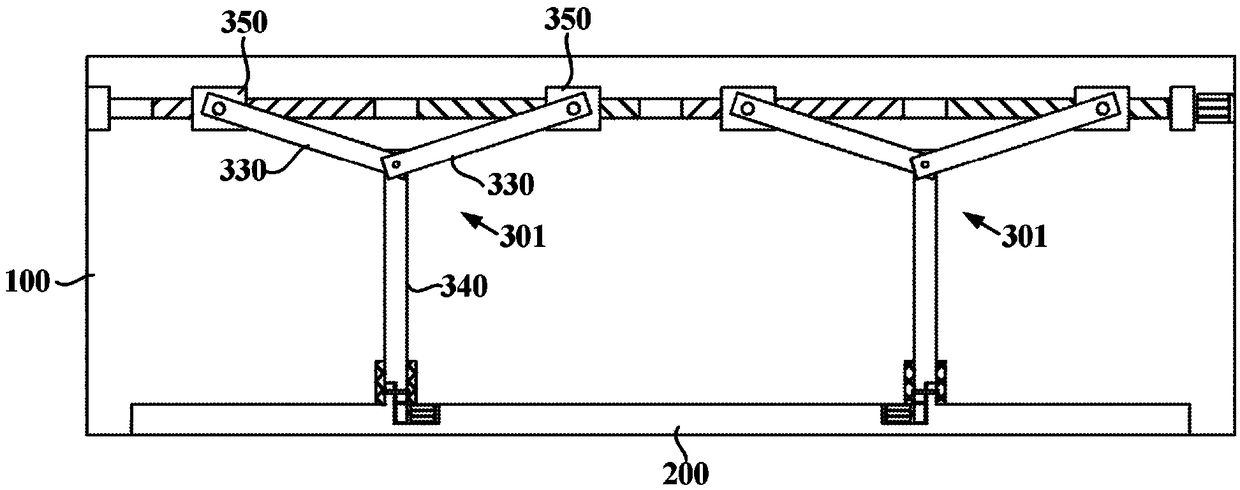

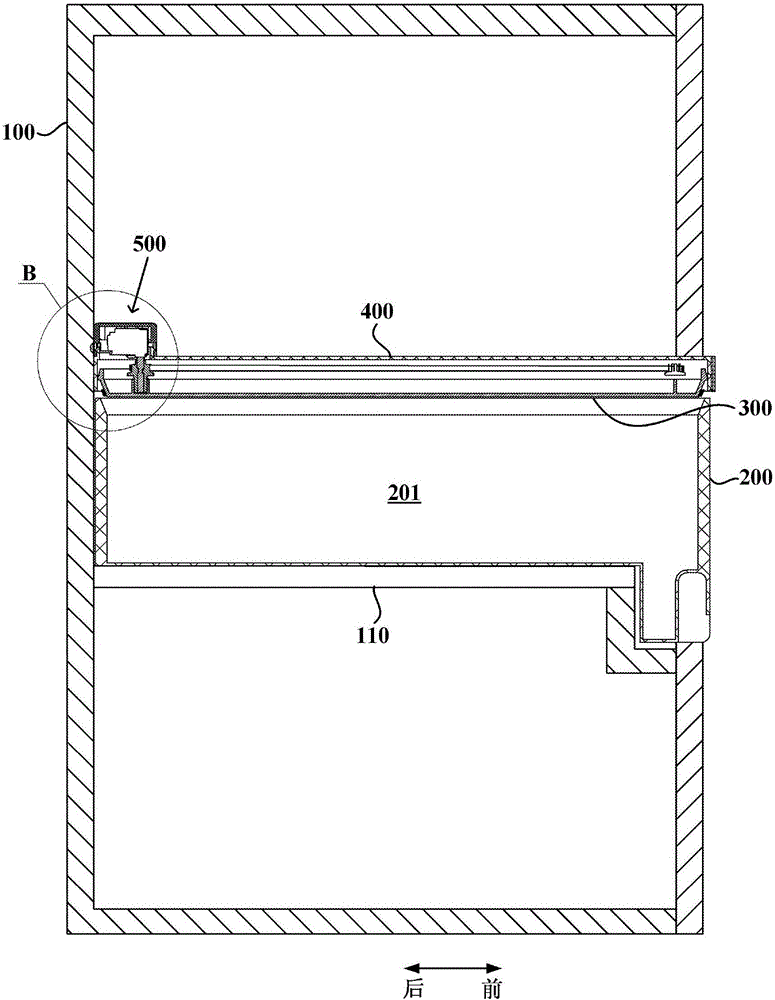

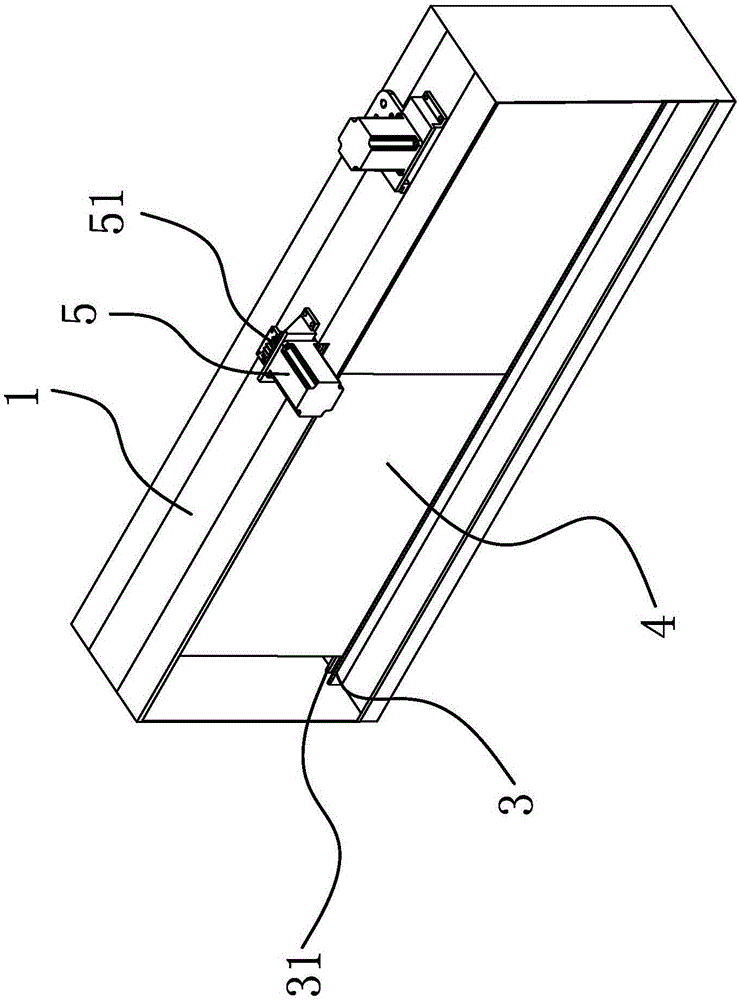

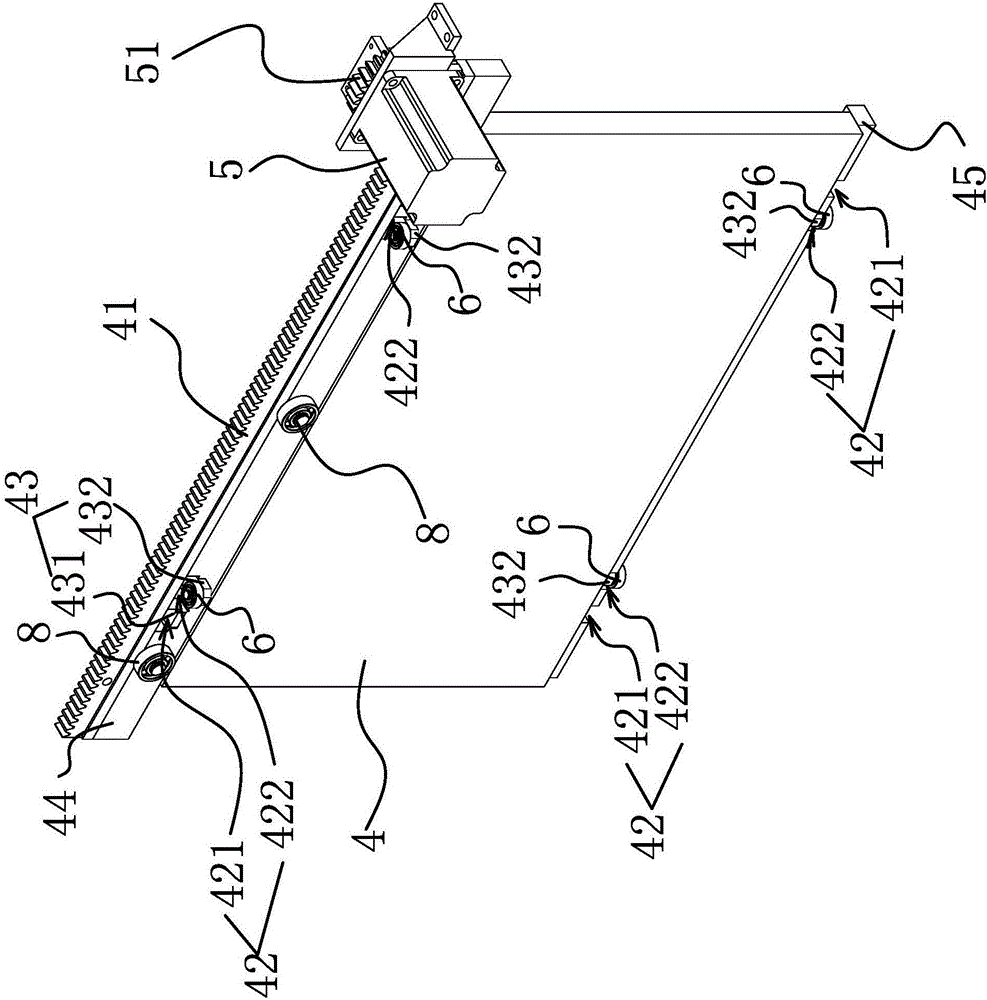

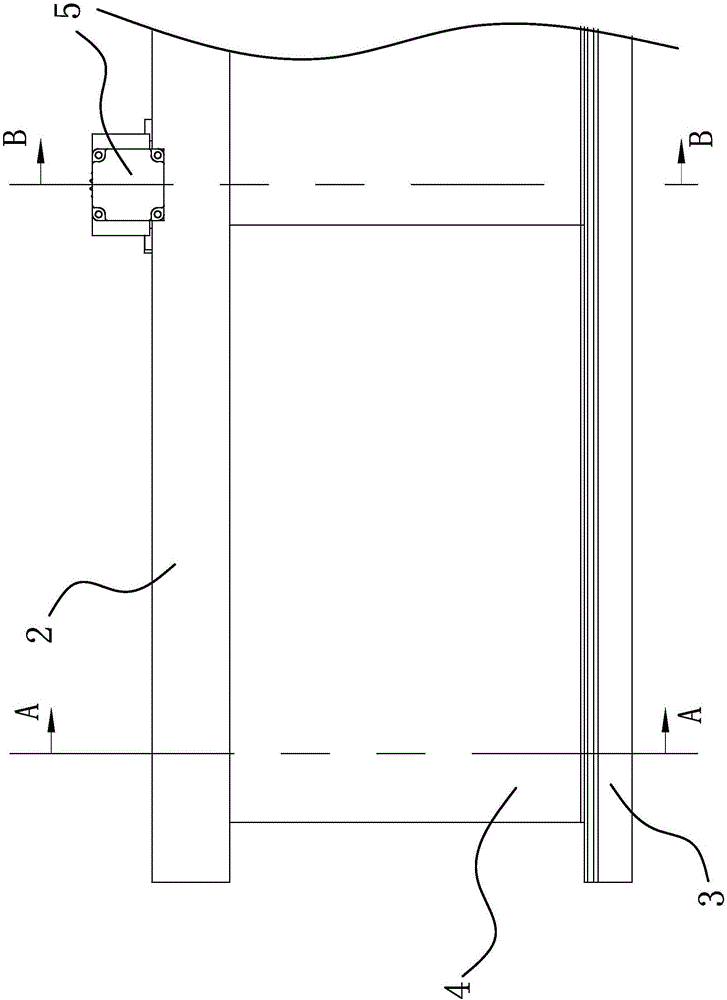

Indoor unit of wall-mounted air conditioner

The invention provides an indoor unit of a wall-mounted air conditioner. The indoor unit comprises a shell, wherein an air outlet is formed in the bottom of the front side of the shell; a drainage plate is arranged below the shell, and a mixed air channel is formed between the drainage plate and the bottom face of the shell, and indoor air flows to the air outlet through the mixed air channel andis mixed with outlet air from the air outlet; a lead screw is parallel to the length direction of the shell, is rotatably installed on the shell and is provided with at least one threaded section group, and each threaded section group comprises a left-handed threaded section and a right-handed threaded section; a first motor is used for driving the lead screw to rotate; at least one bracket assembly comprises two ball sliding blocks which are installed on the left-handed threaded section and the right-handed threaded section correspondingly; the upper ends of two upper rods are hinged to the two ball sliding blocks correspondingly; and the upper end of a lower rod is hinged to the lower ends of the two upper rods, the lower end of the lower rod is connected to the drainage plate, and whenthe lead screw rotates in a positive direction or in a reverse direction, the upper ends of the two upper rods are driven to move transversely in a backward direction or in an opposite direction by the two ball sliding blocks, so that the lower rod is driven to move transversely up and down by the two upper rods, the drainage plate is driven to move transversely up and down, and the overflowing area of the mixed air channel is changed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Battery shell automatic notching die

InactiveCN103341550ANo tiltingTranslation stabilizationShaping toolsStructural engineeringMechanical engineering

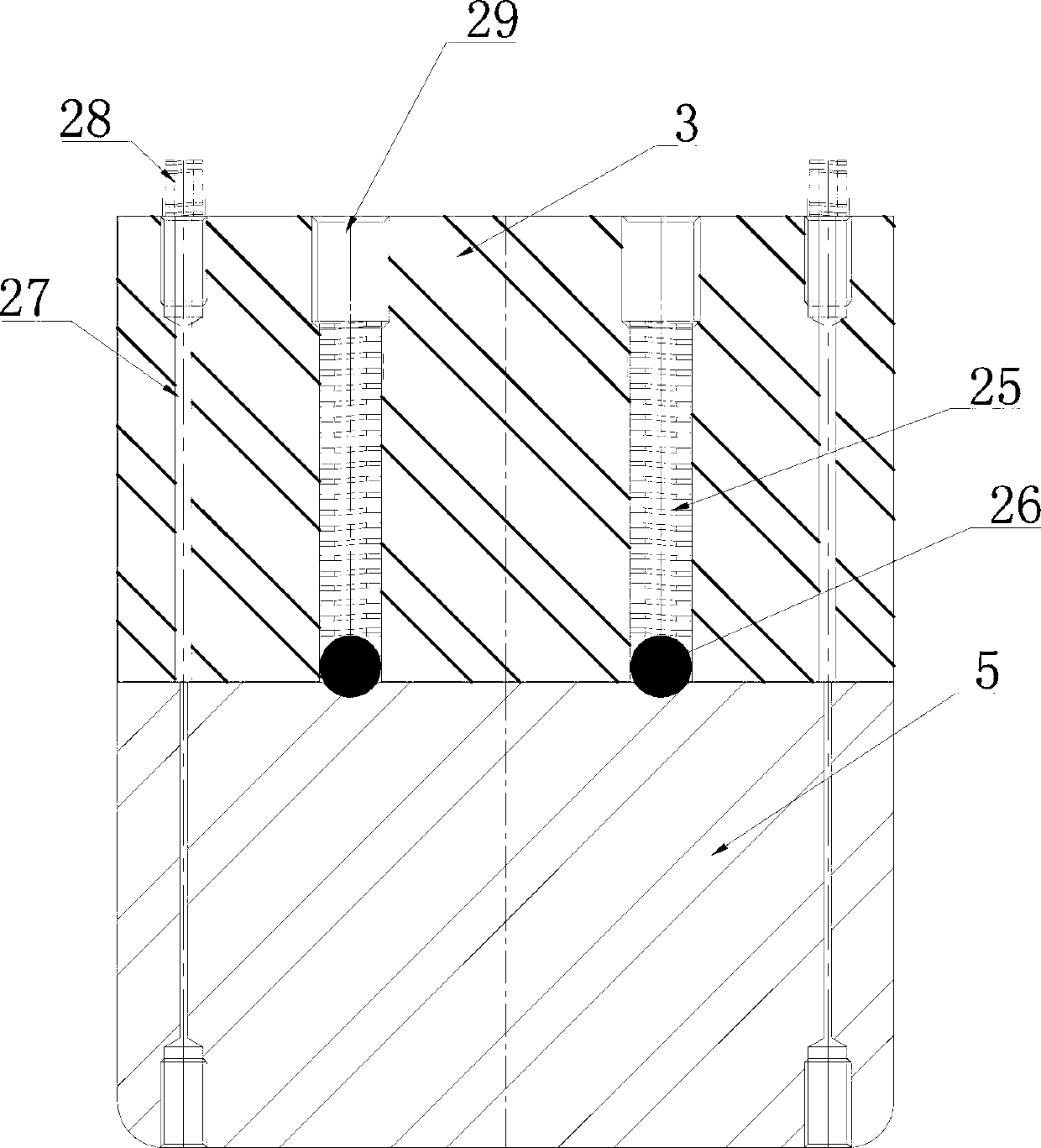

A battery shell automatic notching die comprises an upper die and a lower die. The upper die comprises an upper die plate, a notching male die fixing plate is fixedly connected with the lower face of the upper die plate, the lower face of the notching female die fixing plate is fixedly connected with a notching male die and locating rods, the locating rods are located around the notching male die, and locating cores are movably connected with the lower face of the notching male die in a front-and-back and left-and-right mode. The lower die comprises a lower die plate, a lower die seat is fixedly connected with the upper face of the lower die plate, female die cover plates are fixedly connected with the upper face of the lower die seat, and penetrating holes are formed in the middle of the female die cover plates. The middle part of the lower die seat and the middle part of the lower die plate are movably connected with a lower locating seat together in an up-and-down mode, guiding sliding blocks are arranged on the upper face of the lower locating seat, upper locating rings are arranged on the upper faces of the guiding sliding blocks, the upper locating rings, the guiding sliding blocks and the lower locating seat are fixedly connected through equal-altitude sleeves, guiding sliding rails are arranged between the lower die seat and the lower locating seat, the guiding sliding rails are fixedly installed inside the lower die seat and the upper face of the lower die plate, the guiding sliding blocks correspond to the guiding sliding rails, and the guiding sliding blocks are connected with the guiding sliding rails in an up-and-down sliding mode.

Owner:倪志华

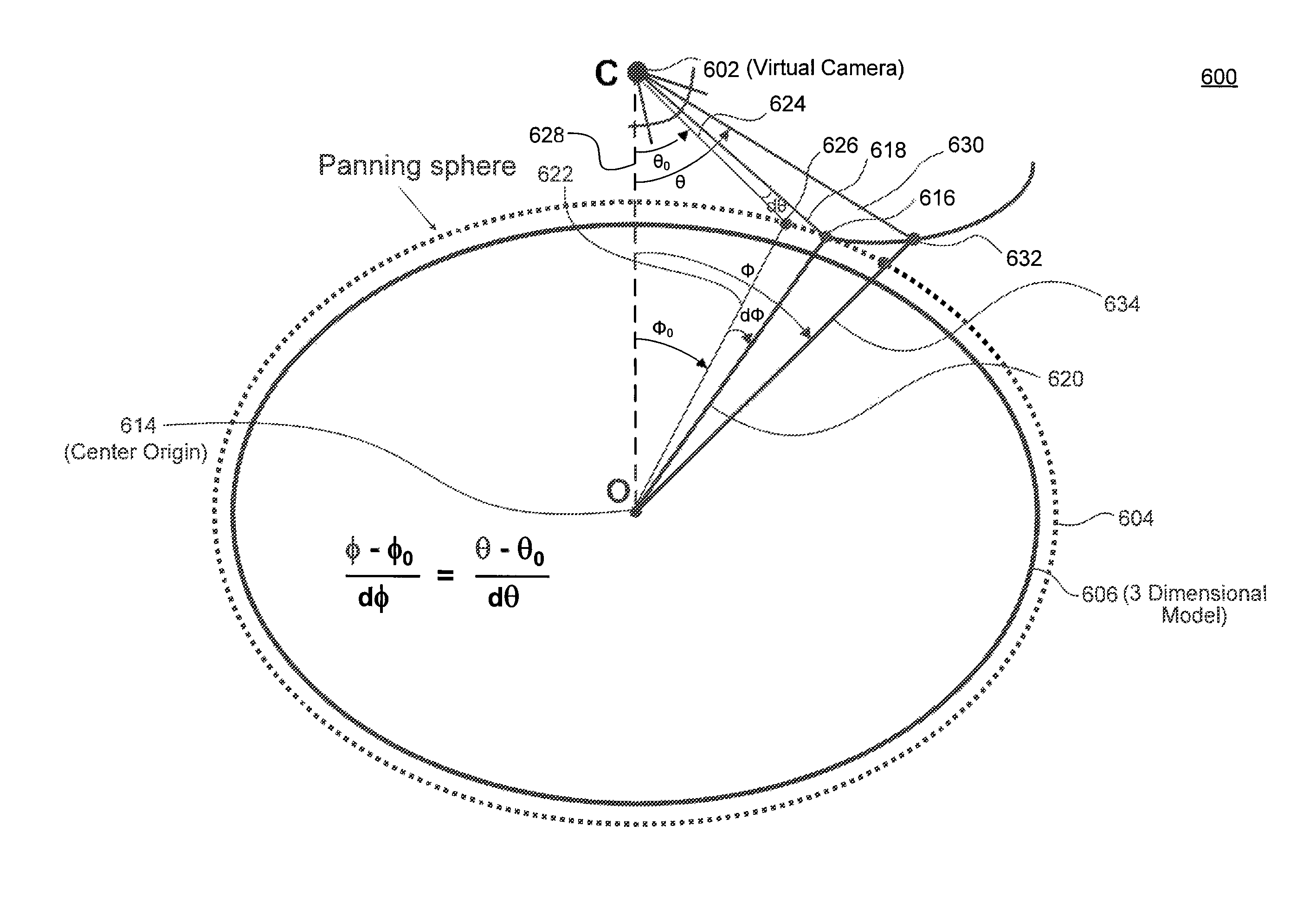

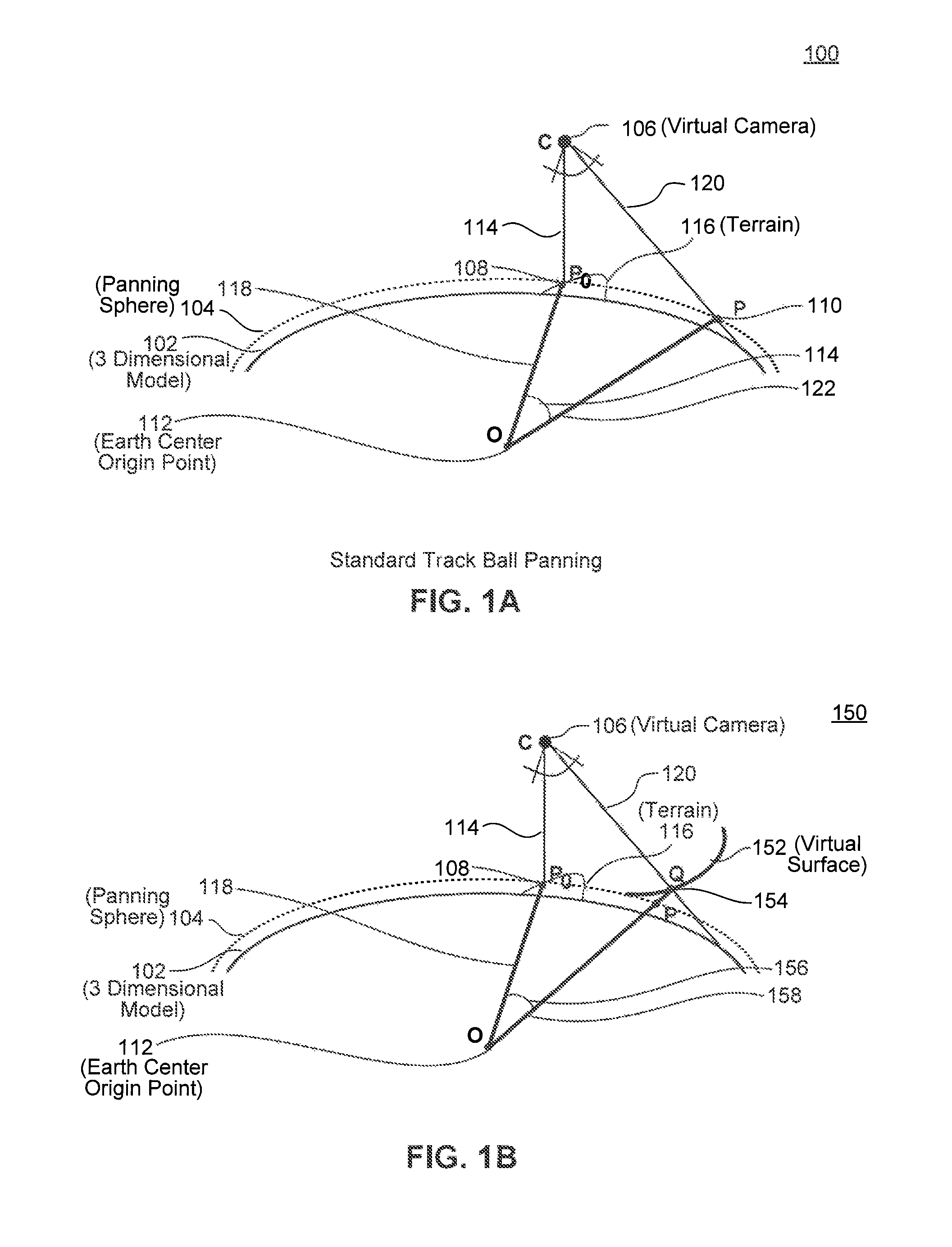

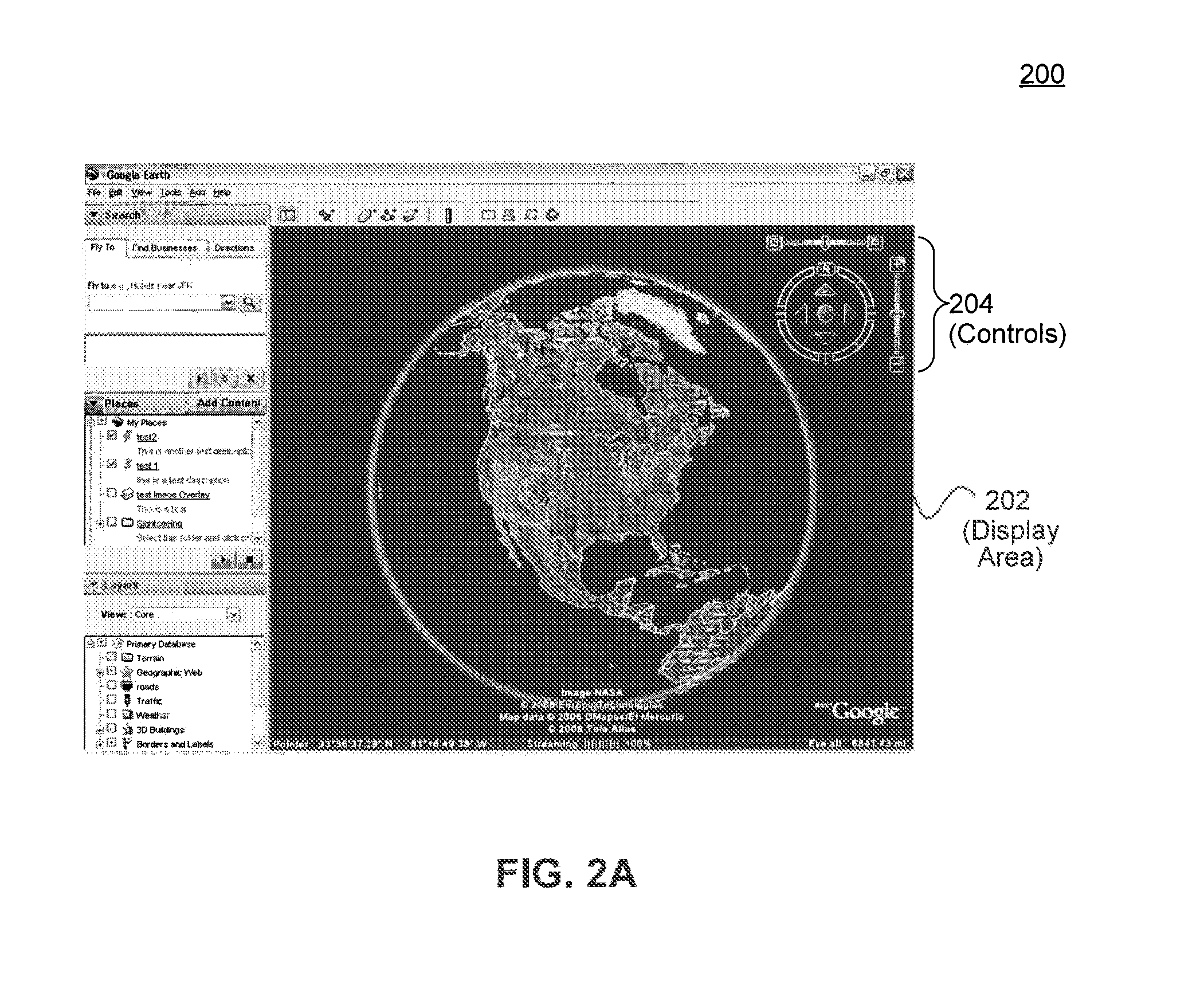

Panning using virtual surfaces

ActiveUS8624926B2Reduce exerciseTranslation stabilizationCathode-ray tube indicatorsInput/output processes for data processingDimensional modelingVirtual camera

Owner:GOOGLE LLC

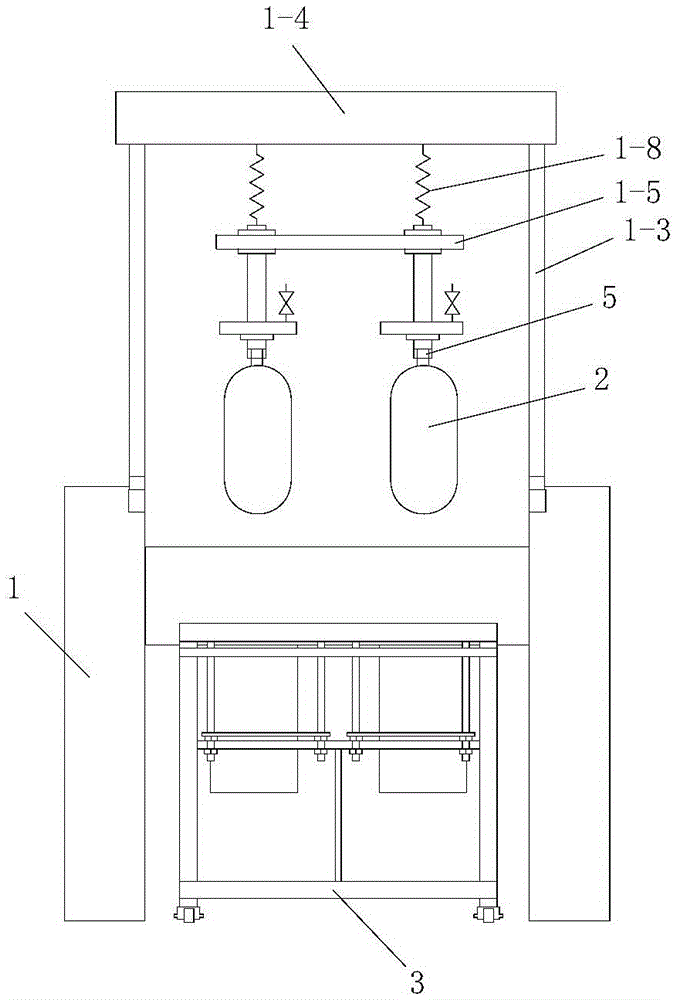

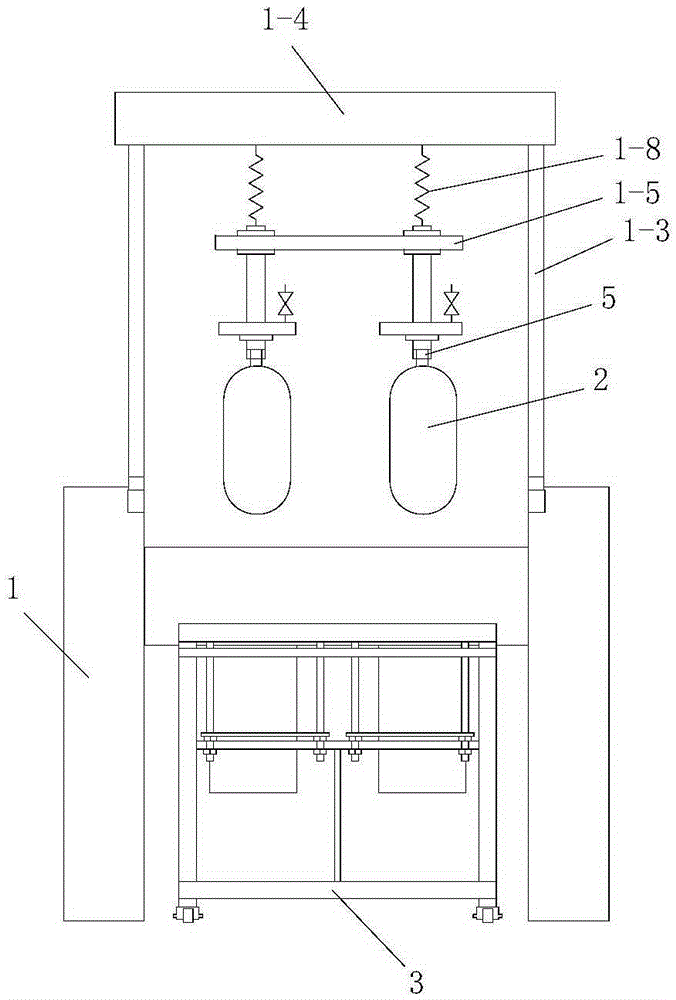

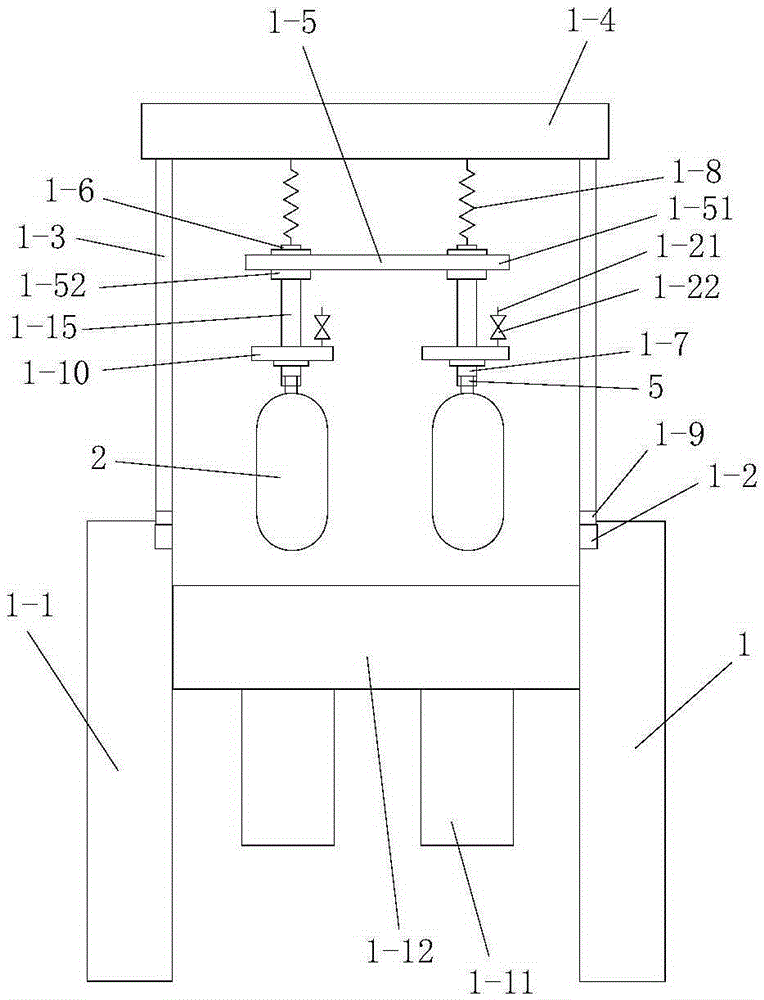

Carbon fiber gas cylinder hydraulic pressure test device and hydraulic pressure test method

InactiveCN105403463ASimple structureCompact structureMaterial strength using tensile/compressive forcesFiberCarbon fibers

The present invention discloses a carbon fiber gas cylinder hydraulic pressure test device and a hydraulic pressure test method, the carbon fiber gas cylinder hydraulic pressure test device comprises a hydraulic pressure test unit for testing deformation and pressure bearing capacity of a plurality of to-be-tested gas cylinders, and a hydraulic pressure auxiliary test unit located in front side of the hydraulic pressure test unit; the hydraulic pressure test unit comprises a test rack, a test console, a pressurization unit, a test case and a test vehicle; the hydraulic pressure auxiliary test unit comprises a gas cylinder fixture, a conveying vehicle and a gas cylinder water-pouring and drying treatment unit for performing water pouring and drying treatment on the to-be-tested gas cylinders, and a horizontal placement platform for horizontal placement of the gas cylinder fixture is arranged on the upper part of the conveying vehicle; and the method comprises the following steps: 1, hydraulic pressure test; and 2, water pouring and drying treatment. The carbon fiber gas cylinder hydraulic pressure test device is reasonable in design, easy to operate and good in use effect, a simultaneous testing process of the deformation and pressure bearing capacity of the plurality of gas cylinders can be completed easily, and the water pouring and drying treatment of the plurality of gas cylinders after testing can be performed easily.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

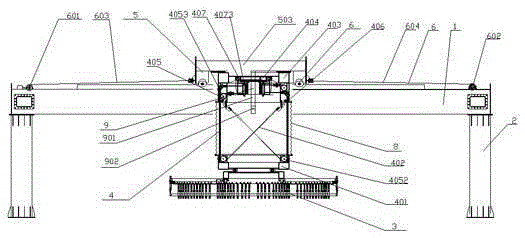

Blank stacking machine

The invention relates to a blank stacking machine. The blank stacking machine comprises a blank stacking device, two cross beams and a vertical column, wherein a lifting device is arranged between the cross beams; a translation device is arranged on the cross beams, and comprises a V-shaped rail, an I-shaped rail and a walking trolley; the walking trolley moves on the V-shaped rail and the I-shaped rail through a V-shaped wheel and an I-shaped wheel; the lifting device comprises a lifting table, a traction rope guide mechanism and a rectangular platform; the guide mechanism comprises a steering wheel, a horizontal wheel and a vertical wheel; one ends of traction ropes are fixed on a fixed hook, and the other ends are wound on a rope winding drum after bypassing through the steering wheel, the vertical wheel and the horizontal wheel in sequence; two traction ropes on the same side surface of the rectangular platform are across arranged; and the rope winding drum is driven by a power device, so that the traction ropes drive the lifting table and the blank stacking device to move up and down. The blank stacking machine is high in synchronization rate, excellent in stability, safe, reliable, simple in structure, convenient for use, dustproof and reduced in enterprise cost through arranging such structures as the translation device and the lifting device.

Owner:河南工创联盟科技有限公司

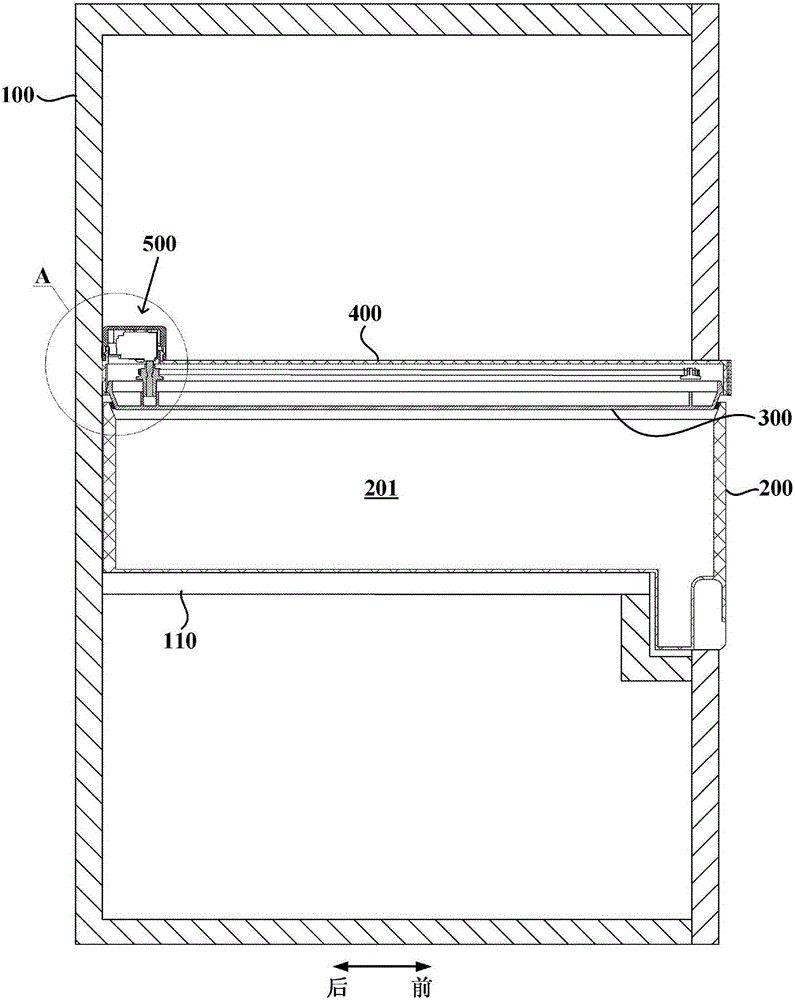

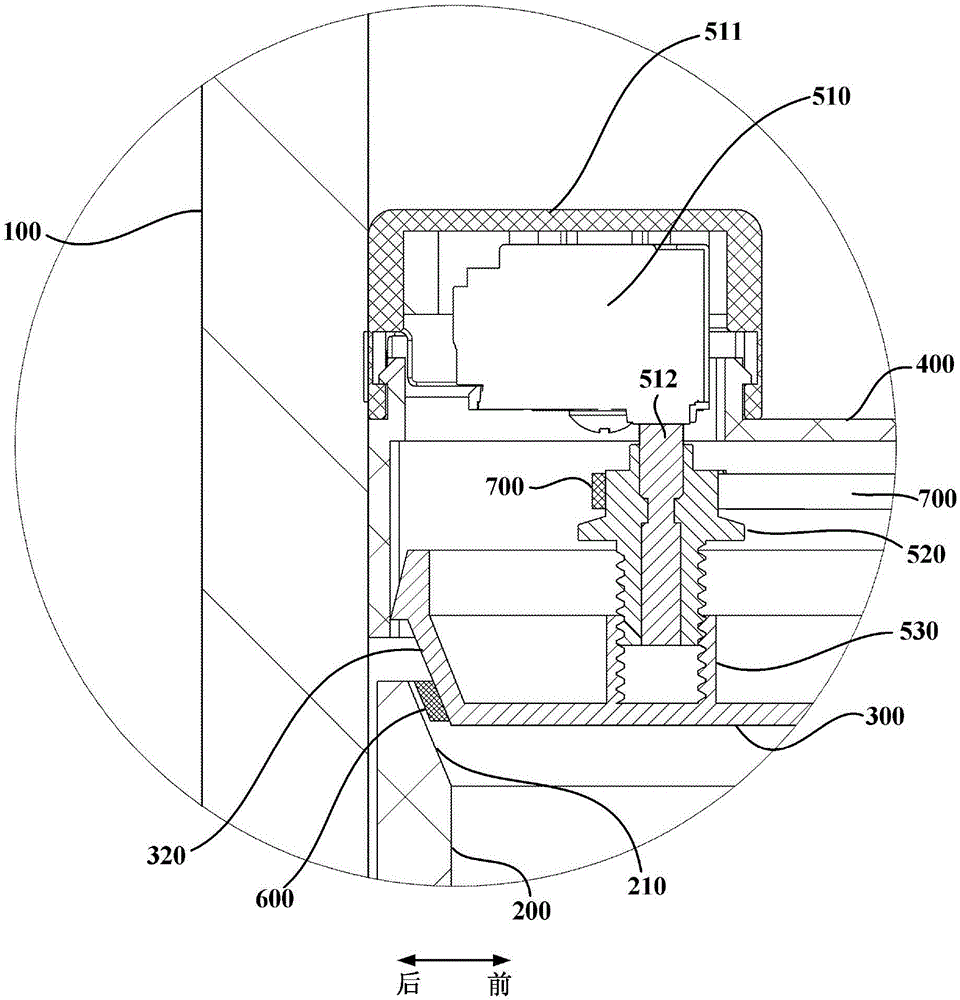

Refrigerator

ActiveCN106595167AImprove stabilityAchieve airtight storageLighting and heating apparatusDomestic refrigeratorsEngineeringMechanical engineering

The invention provides a refrigerator. The refrigerator comprises a refrigerator body with an opened front side, a drawer with an opened upper side and arranged in the refrigerator body in a front-back translation manner between a front limit position and a back limit position, a locking cover arranged above the drawer in an up-down translation manner and configured to be downwards moved to a closing position so as to close the opening at the upper side of the drawer and enable the drawer not to move forwards when the drawer is positioned in the back limit position or configured to be upwards moved to an opening position away from the opening at the upper side of the drawer so as to allow forward movement of the drawer, and a driving device configured to controllably drive up-down translation of the locking cover. The refrigerator can realize sealed storage of objects and automatic opening and closing of the locking cover.

Owner:HAIER SMART HOME CO LTD

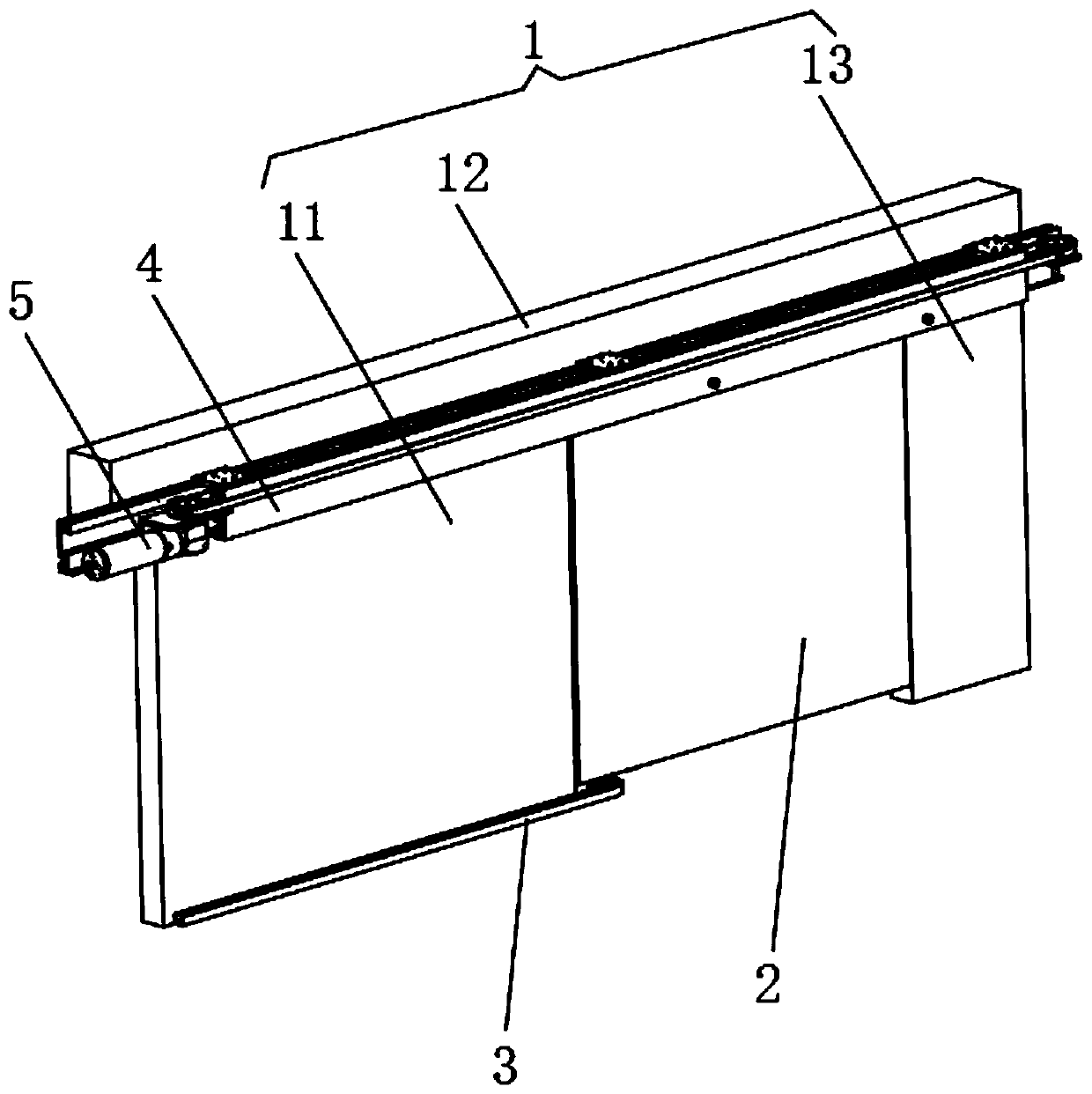

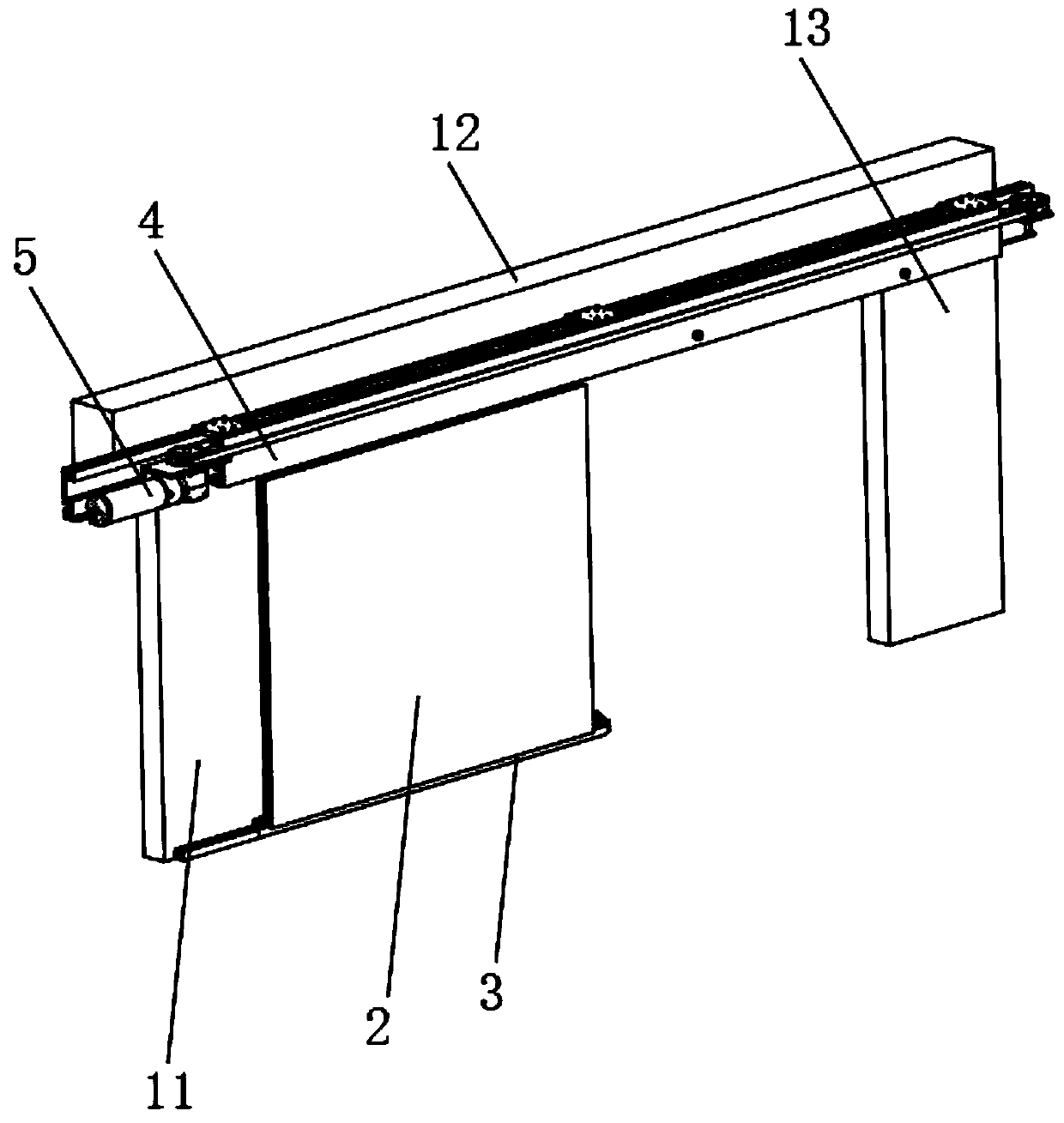

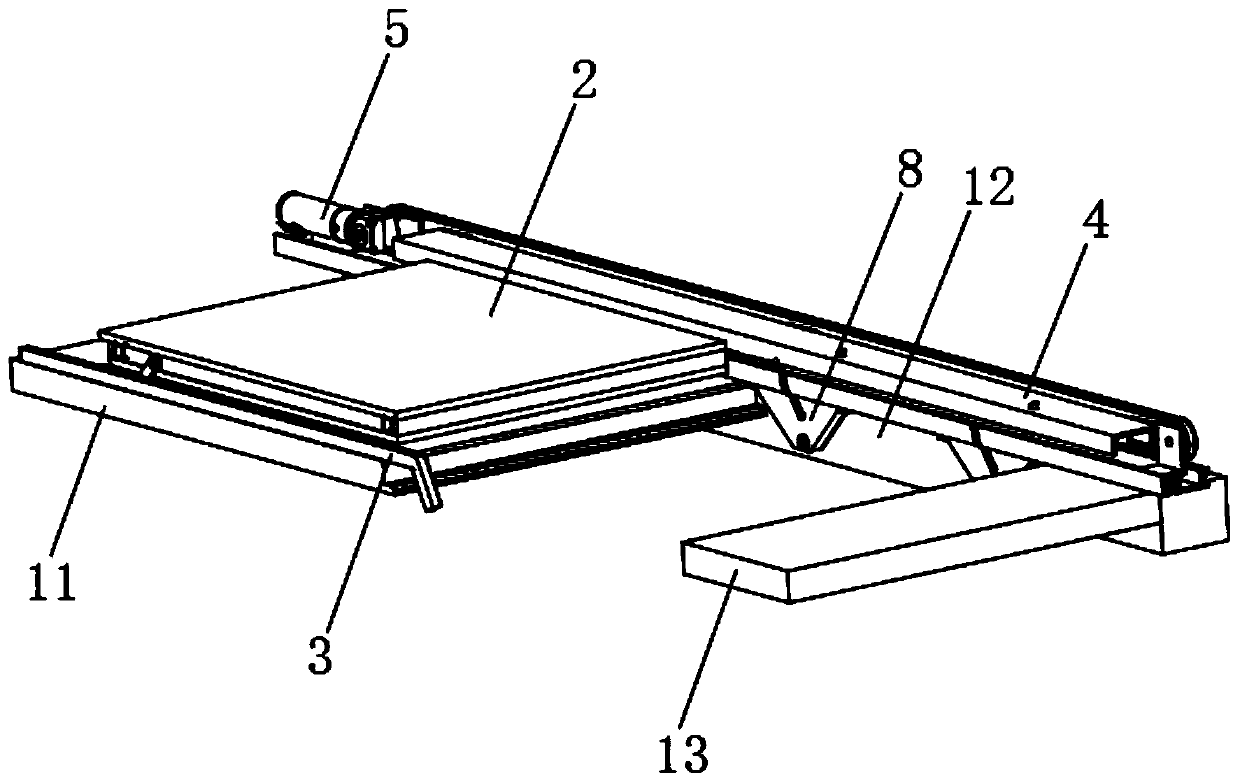

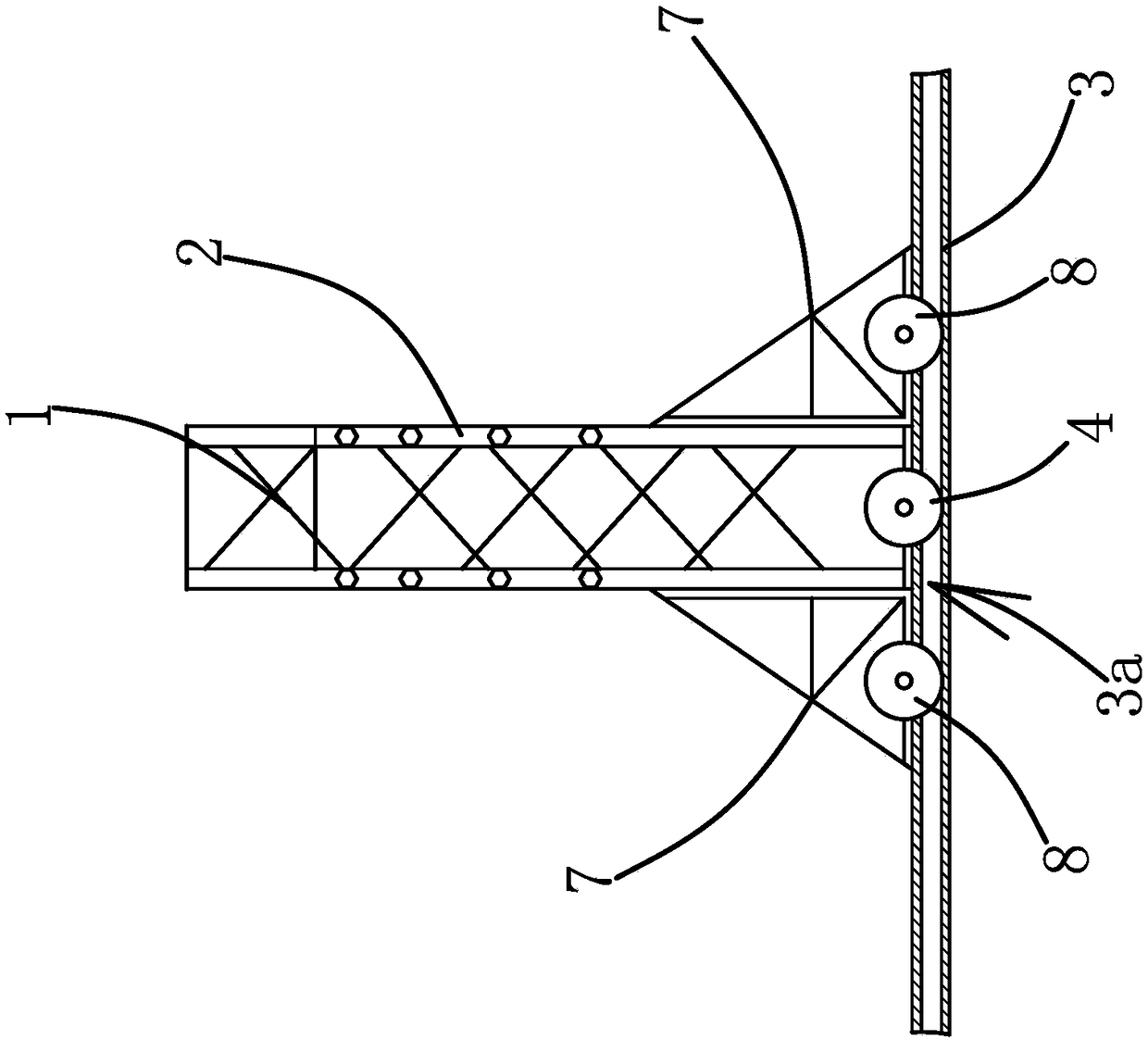

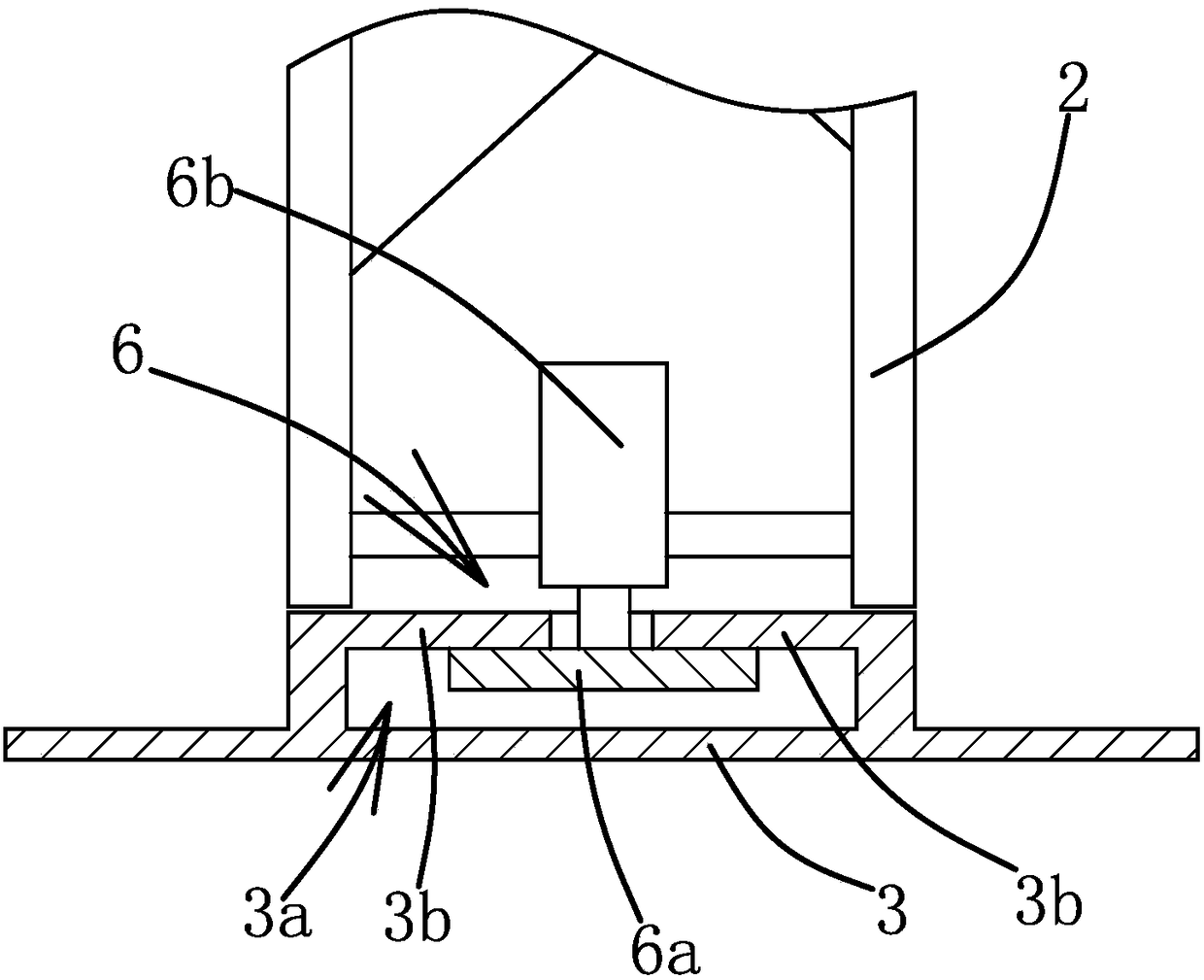

Translation blackboard

The invention provides a translation blackboard, belongs to the technical field of teaching equipment, and solves the problem of easiness in shaking of the blackboard due to excessive gap between the blackboard and a slide rail side wall in the sliding process in a traditional translation blackboard. The translation blackboard comprises a fame, and a slide rail 1 and a slide rail 2 arranged at two ends of the frame; a blackboard is arranged between the slide rail 1 and the slide rail 2; a control motor and a rack connected with the blackboard are arranged at the upper end of the blackboard; the control motor is connected with a gear engaged with the rack; the slide rail 2 is projected to form a slide plate; at least one pair of adjusting grooves formed in the thickness direction of the blackboard is respectively arranged at the upper end and the lower end of the blackboard; multiple pairs of adjusting blocks are arranged at the upper end and the lower end of the blackboard; each pair of adjusting blocks at the upper end of the blackboard can slide along the corresponding adjusting grooves, and can be butted against two side walls of the slide rail 1; and each pair of adjusting blocks at the lower end of the blackboard can slide along the corresponding adjusting grooves and can clamp the slide plate. The translation blackboard can be more stable in the use process.

Owner:台州市求展工贸有限公司

Connecting and locking device for building templates

ActiveCN114541752AFirmly connectedAccurate connectionAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

Owner:义乌建投巨匠建设有限公司

Electronic control plug-and-pull translation device

PendingCN110318628AAchieve closed door sealingImprove sealingPower-operated mechanismWing suspension devicesEngineeringMechanical engineering

The invention relates to the field of building component connection structures, and discloses an electronic control plug-and-pull translation device. The electronic control plug-and-pull translation device comprises a component frame and a moving component located on the inner side. The component frame comprises a fixing component in the same plane as the moving component, an upper connecting beamand a side component. The moving component is movably clamped between the fixing component and the side component. A guide mechanism is arranged on the portion, close to the edge of the lower end, ofthe outer surface of the front end of the fixing component. A rail structure for providing a sliding rail for the moving component is fixedly arranged on the outer surface of the front end of the upper connecting beam. A driving device for driving the moving component to slide is arranged on the inner side of the rail structure. Rolling wheel structures and connecting rod structures which are used for sliding connection are arranged between the upper end of the moving component and the rail structure. Each rolling wheel structure comprises an upper plate and a lower plate. The electronic control plug-and-pull device has better sealed degree when closed and has small rail size, convenient installation, good bearing capacity and safe use.

Owner:孟大军

Production equipment of intelligent optical fiber preforming bar with recovery function

InactiveCN107804966AWith recycling functionImprove practicalityGlass making apparatusEngineeringRecovery function

The invention relates to production equipment of an intelligent optical fiber preforming bar with a recovery function. The production equipment comprises a shell; the shell is internally provided witha first motor, a target bar and a reaction chamber; the reaction chamber is internally provided with a cleaning mechanism and a moving mechanism; the moving mechanism comprises a lifting assembly anda moving assembly; and the lifting assembly comprises a blast lamp, a moving frame, a second motor, a semi-gear, a connecting rod and two racks. According to the intelligent optical fiber preformingbar with the recovery function, residues on the target bar are cleaned away by the cleaning mechanism, and compared with a traditional cleaning mechanism, the cleaning mechanism is wider in cleaning angle and better in cleaning effect; and a nonuniform part of a dust-like porous stock bar is filled by the moving mechanism, and compared with a traditional moving mechanism, the moving mechanism is more stable and precise during lifting and horizontal moving, so that the dust-like porous stock bar is more precisely filled by using the blast lamp, and the practicability of the production equipmentof the optical fiber preforming bar is greatly improved.

Owner:深圳市中科智诚科技有限公司

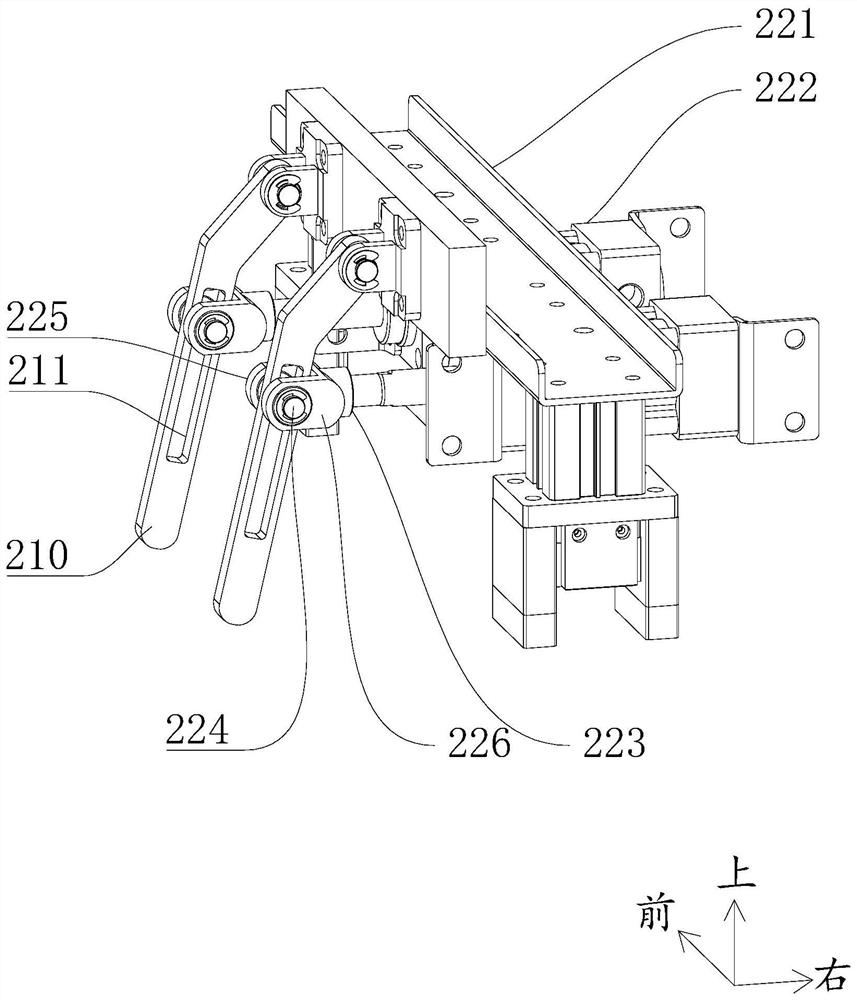

Plate attraction clamp

InactiveCN113291807AImprove gripImprove adsorption capacityConveyorsConveyor partsEngineeringStructural engineering

The invention discloses a plate attraction clamp comprising a main frame. The main frame is provided with a left anti-falling mechanism, a right anti-falling mechanism and magnetic attraction units, the left anti-falling mechanism comprises a rotary driving device and clamping rods, the rotary driving device is connected to the left side of the main frame, the rotary driving device is in driving connection with the clamping rods, and the bottom end of each clamping rod is an anti-falling end. Each magnetic attraction unit is located between the left anti-falling mechanism and the right anti-falling mechanism and comprises a base, a lifting driving part, a magnetic body, vertical plates and buffer pads, the bases are located on the main frame and relatively fixed to the main frame, at least the vertical plates are arranged on the bottom sides of the bases at intervals in the horizontal direction, and the buffer pads are arranged on the bottom sides of the vertical plates correspondingly. Each lifting driving part is connected to the corresponding base, each magnetic body is located between any two corresponding adjacent vertical plates, and the lifting driving parts are in driving connection with the vertical plates. According to the plate attraction clamp, stable grabbing and horizontal moving of metal plates can be achieved, the problem of falling of the metal plates is avoided, and the stability and safety of attraction and conveying of the metal plates are improved.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

Fabricated steel structure sliding frame

PendingCN108104484AAchieve lockingEasy to useBuilding material handlingLocking mechanismMaterials science

The invention provides a fabricated steel structure sliding frame, and belongs the technical field of steel structures. The fabricated steel structure sliding frame solves the problem that using of anexisting steel structure sliding frame is very inconvenient. The fabricated steel structure sliding frame comprises a supporting platform made of a steel structure, vertical columns are arranged on the lower sides of the two ends of the supporting platform, and the vertical columns are made of steel structures; the sliding frame comprises two parallel guiding rails used for being arranged on theground, and the upper end faces of the guiding rails are provided with guiding grooves; and the lower ends of the vertical columns are fixedly connected with pulleys and motors for driving the pulleysto rotate in the axial direction, the pulleys are embedded in the guiding grooves of the guiding rails, and the lower ends of the vertical columns are provided with locking mechanisms for locking thevertical columns. The fabricated steel structure sliding frame has the advantages that using is convenient and the application range is wide.

Owner:浙江钢泰钢结构(集团)有限公司

A carbon fiber gas cylinder detection line and detection method

InactiveCN105424489BSimple structureCompact structureDetection of fluid at leakage pointDrying using combination processesFiberCarbon fibers

The invention discloses a carbon fiber gas cylinder detection line and a carbon fiber gas cylinder detection method. The detection line includes, in a front-to-back arrangement manner, a water pressure test apparatus, a water pressure auxiliary test apparatus and an air tightness test apparatus. The water pressure test apparatus includes a test rack, a test operation bench, a pressurizing apparatus, a test case installed on the test rack, and test trolleys for stably placing a plurality of to-be-tested gas cylinders. The water pressure auxiliary test apparatus includes a gas cylinder fixture, a transporting trolley, and a gas cylinder water-pouring-away and drying device. The air tightness test apparatus includes an air tightness detection apparatus and a second air supply apparatus for supplying air to the to-be-tested gas cylinders. The air tightness test apparatus is in a cabinet structure or a ground trough structure. The detection method includes the steps of 1) water pressure test; 2) water pouring-away and drying treatment; and 3) air tightness test. The detection line is reasonable in design and simple in operations, is good in use effects, and can easily and quickly complete water pressure test and air tightness test for a plurality of carbon fiber gas cylinders.

Owner:TECHN MONITORING CENT OF CHANGQING PETROLEUM EXPLORATION BUREAU

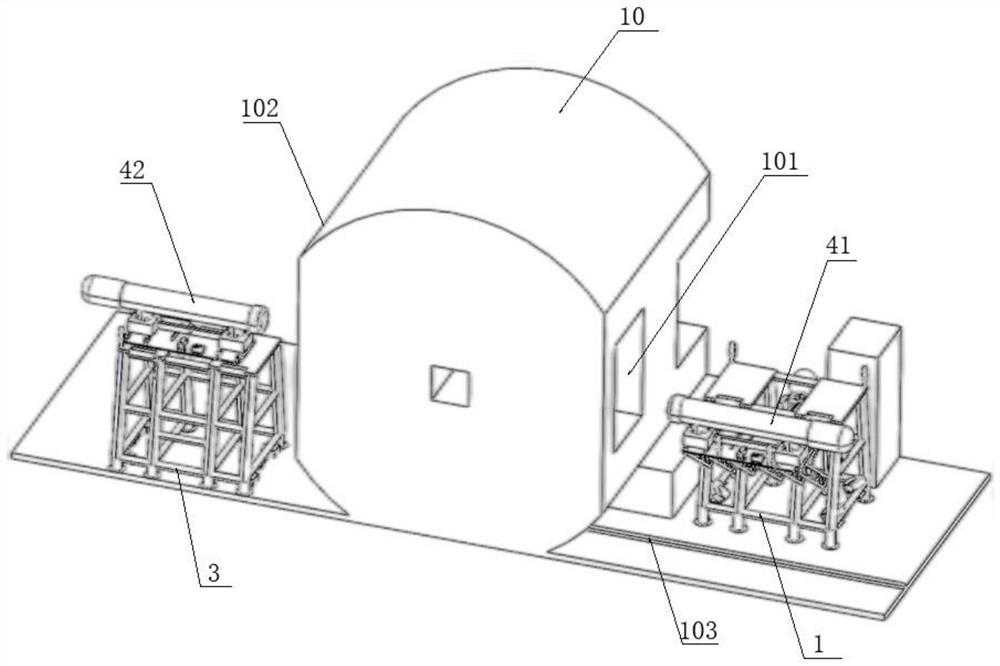

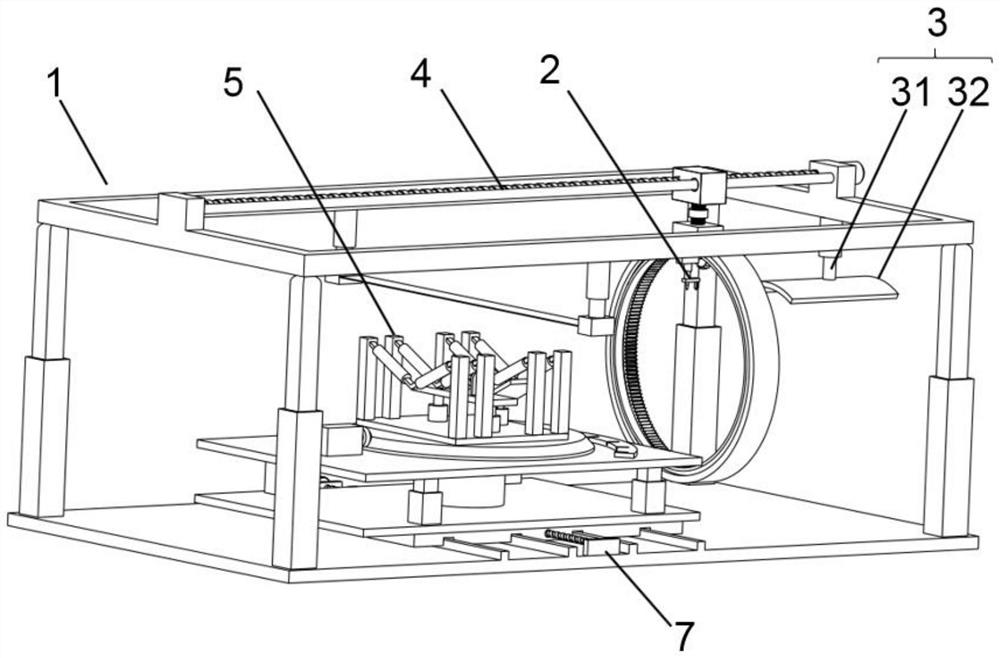

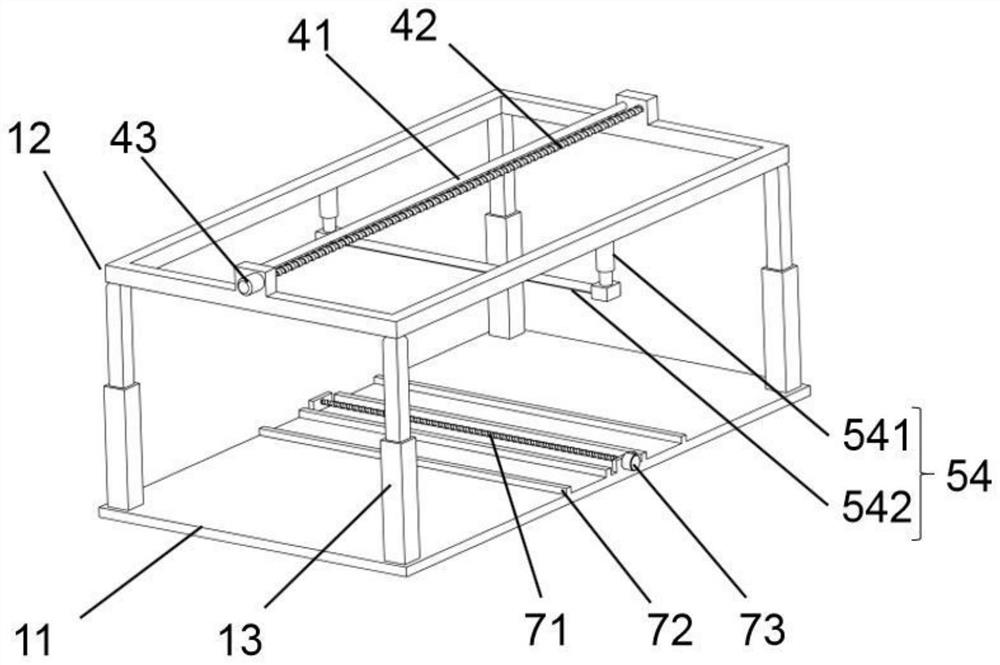

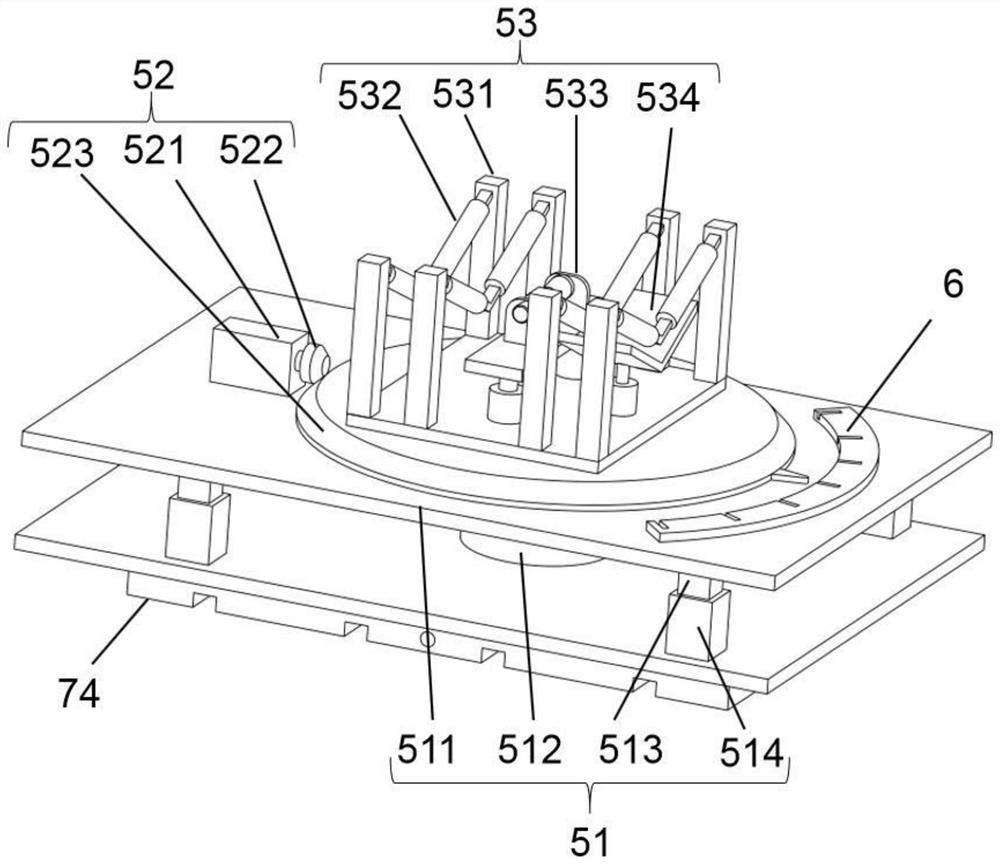

Schlieren instrument support system for wind tunnel test

ActiveCN113551867AImprove configuration efficiencyAchieve resilienceAerodynamic testingSupporting systemClassical mechanics

The invention discloses a schlieren instrument support system for a wind tunnel test, and the system comprises: a support frame I which is disposed at the outer side of a right observation port of a wind tunnel test section, wherein a turnover device is rotatably arranged at the upper end of the support frame I, and a collimation system of the schlieren instrument is arranged at the upper end of the turnover device in a sliding manner; and a support frame II which is arranged on the outer side of the left observation opening of the wind tunnel test section, wherein a viewing system of the schlieren instrument is arranged at the upper end of the support frame II in a sliding manner. The system is novel in structure, stable in operation and simple in operation, and the assembling and debugging efficiency of the schlieren instrument in a wind tunnel test can be remarkably improved through the overturning mechanism and the translation structure; the position detection system ensures the stability of displacement motion operation of each part of the device; the mobile device enables the device to have certain mobility; the control driving system enables the device to have good controllability; and the whole device is high in automation degree, and the labor intensity of operators is reduced while the working efficiency of the wind tunnel test is improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

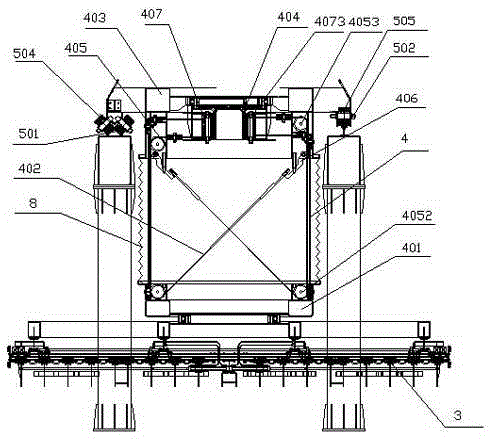

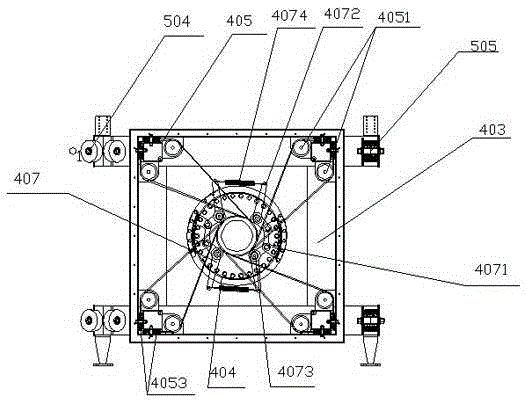

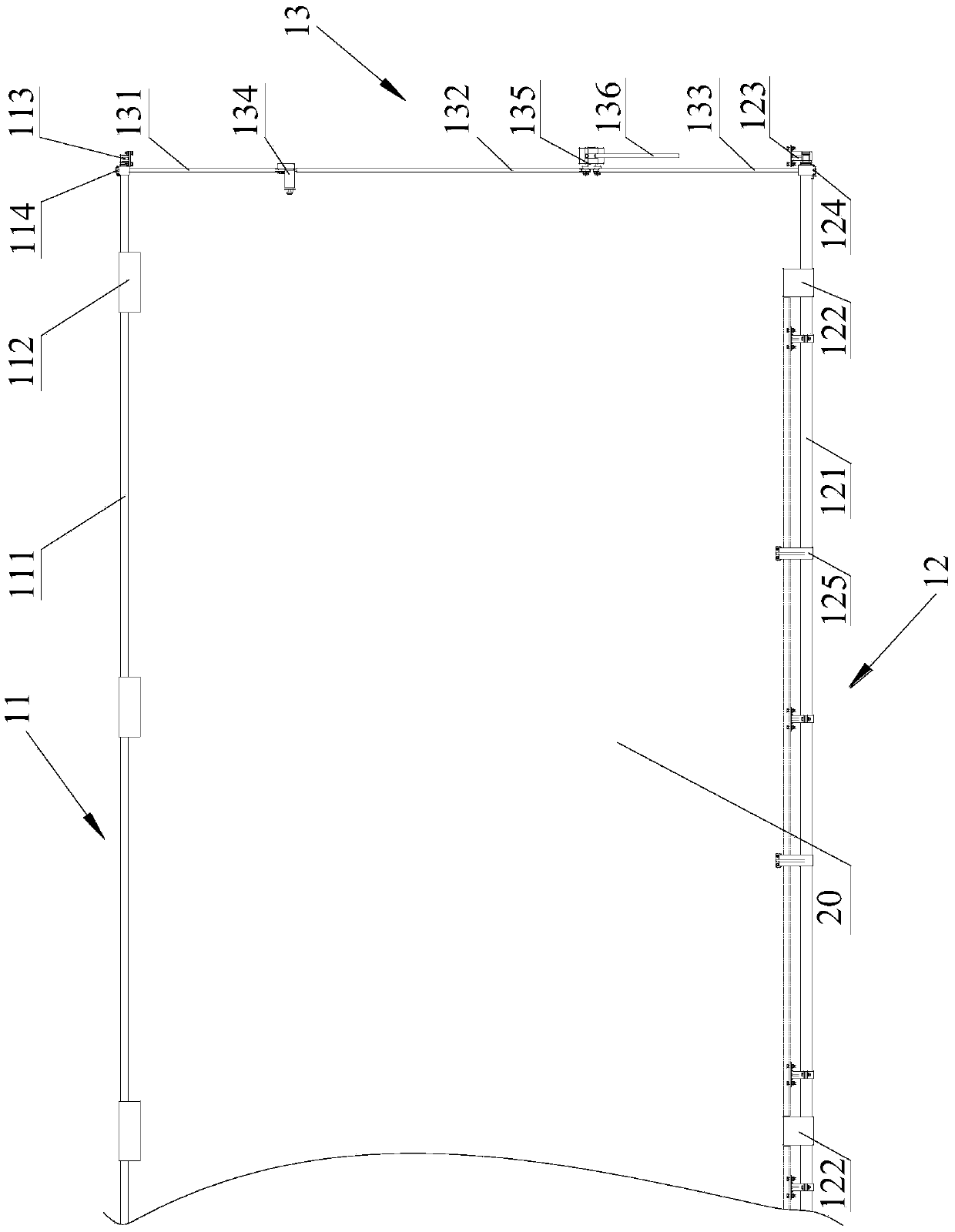

Auxiliary equipment for oil and gas long-distance pipeline construction and construction method thereof

PendingCN114505626ADoes not affect alignmentHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesPortal frameIndustrial engineering

The invention discloses auxiliary equipment for oil and gas long-distance pipeline construction and a construction method thereof, and belongs to the technical field of oil and gas long-distance pipeline construction.The auxiliary equipment comprises a main frame and a welding part, the main frame comprises a base and two portal frames, and a rail assembly is connected between the tops of the two portal frames; the welding part is movably mounted on the rail assembly; a pipeline feeding part and a translation assembly are arranged on the side, away from the positioning part, of the base. The pipeline feeding part comprises a lifting assembly, a rotating assembly is arranged on the lifting assembly, and a pipeline conveying assembly is arranged on the rotating assembly; a clamping assembly is arranged at the top of the pipeline conveying assembly; position adjustment of the to-be-welded pipeline in three directions can be achieved, the position of the to-be-welded pipeline is adjusted through a mechanical structure, the welding part can achieve automatic welding of the pipeline, and safety and reliability are higher.

Owner:刘展

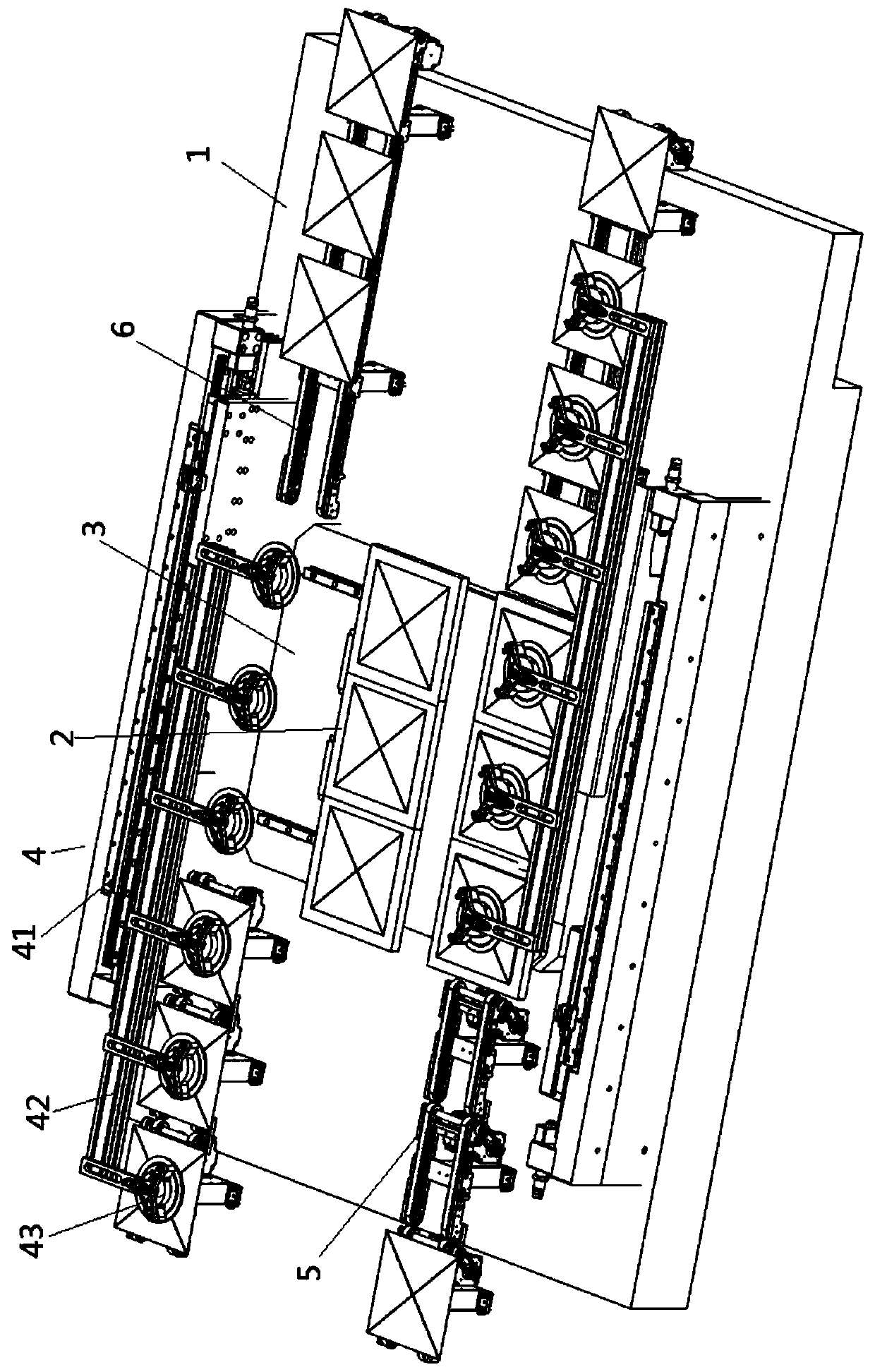

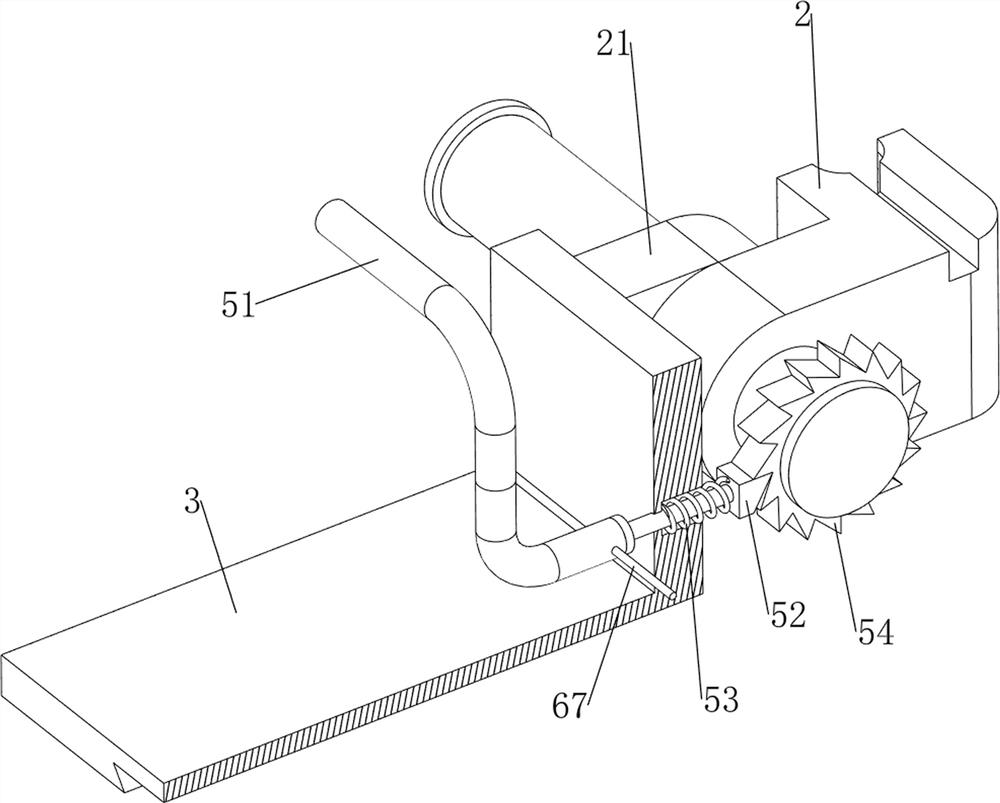

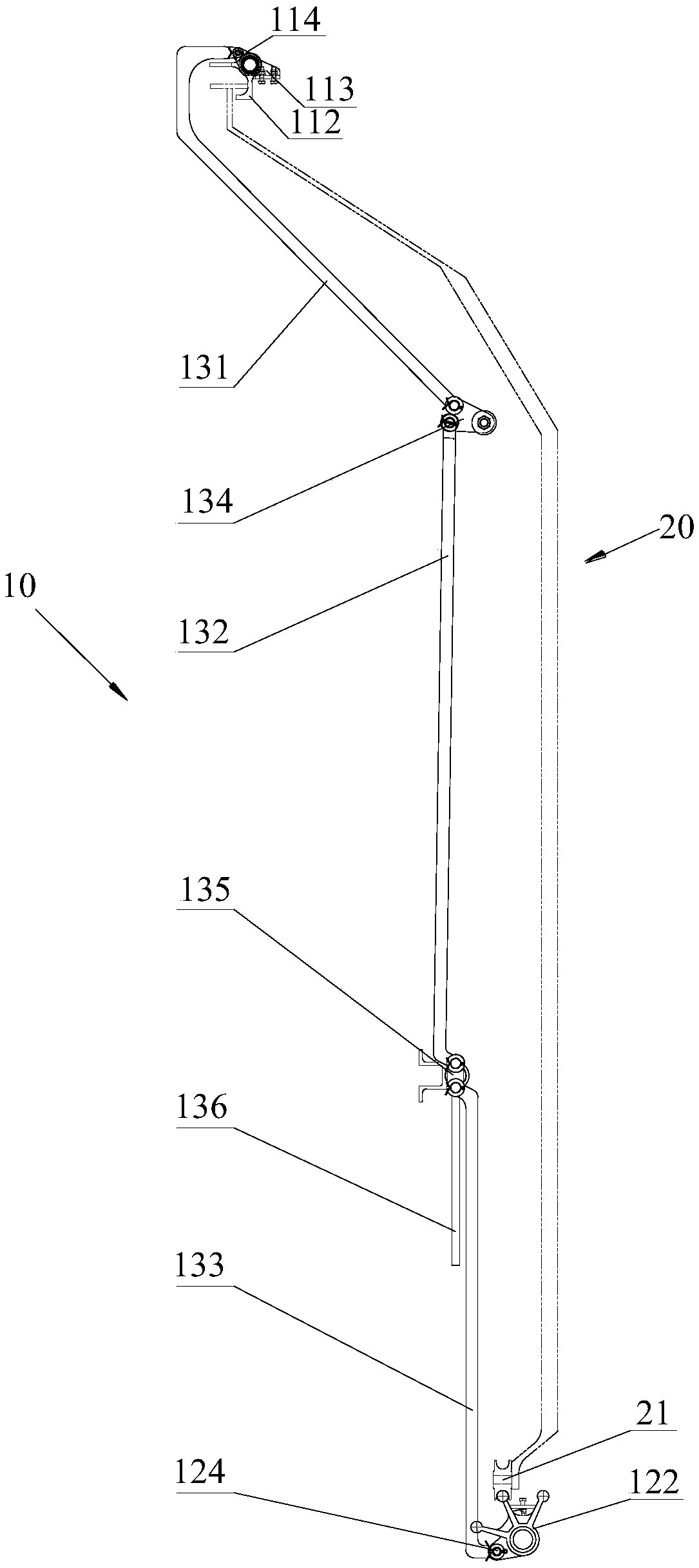

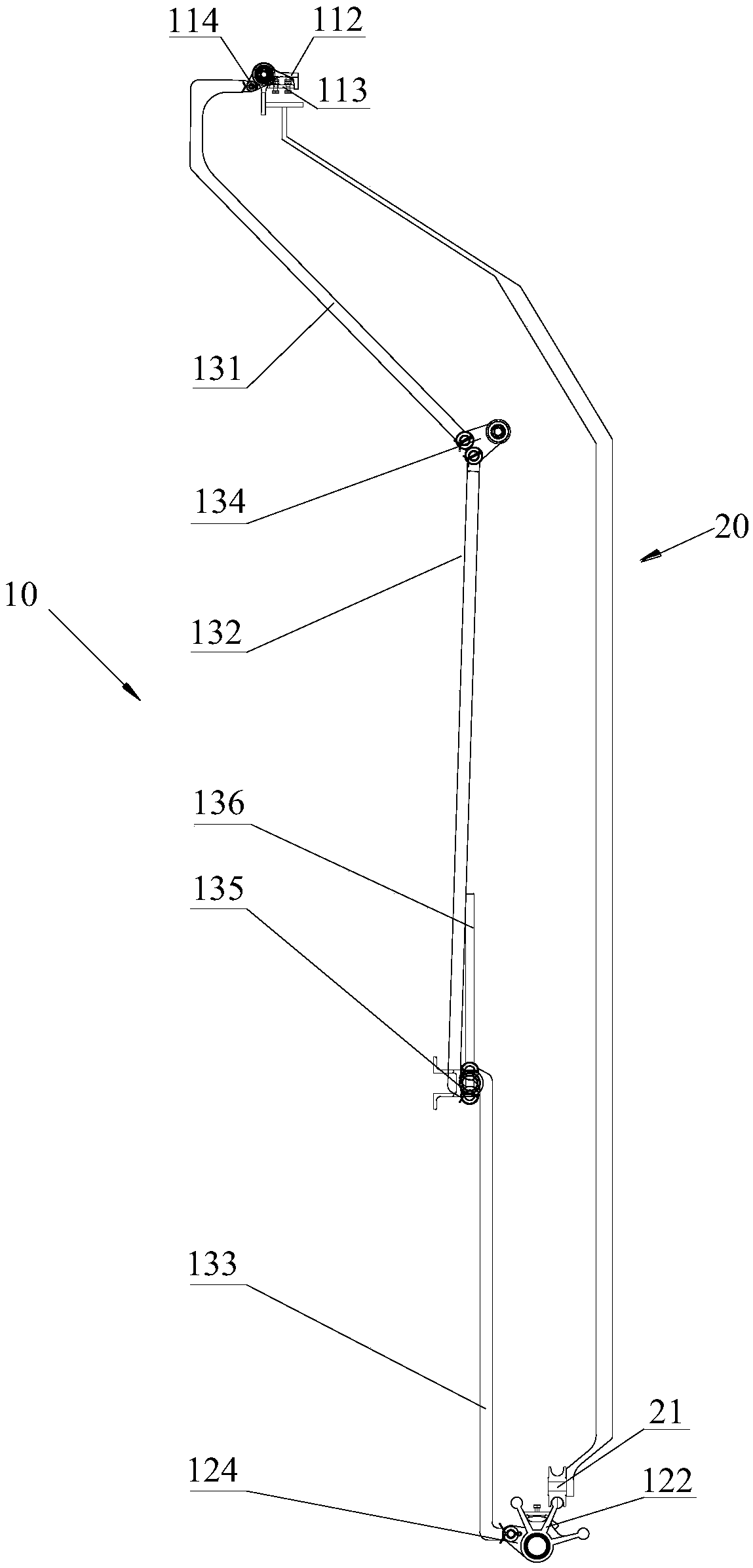

Railroad box car and car door opening and closing device thereof

ActiveCN105507723ATranslation stabilizationEasy to operatePower-operated mechanismPush and pullCar door

The invention discloses a railroad box car and a car door opening and closing device thereof. The car door opening and closing device is used for starting horizontal movement of a car door in inner and outer directions and comprises an upper driving mechanism, a lower driving mechanism and a middle driving mechanism, wherein the upper driving mechanism is arranged at the upper part of the car door and is used for pushing the upper part o the car door to horizontally move in the inner and outer directions; the lower driving mechanism is arranged at the lower part of the car door and is used for pushing the lower part of the car door to horizontally move in the inner and outer directions; one end of the middle driving mechanism is connected to the upper driving mechanism, and the other end of the middle driving mechanism is connected to the lower driving mechanism; the middle driving mechanism drives the upper driving mechanism and the lower driving mechanism to synchronously act so as to push the car door to horizontally move. Through the car door opening and closing device, the car door can be pushed and pulled along the car body direction; the horizontal movement of the car door in the inner and outer directions can be started so as to open and close the car door; the car door opening and closing device is simple and convenient to operate.

Owner:CHINA RAILWAYS CORPORATION +1

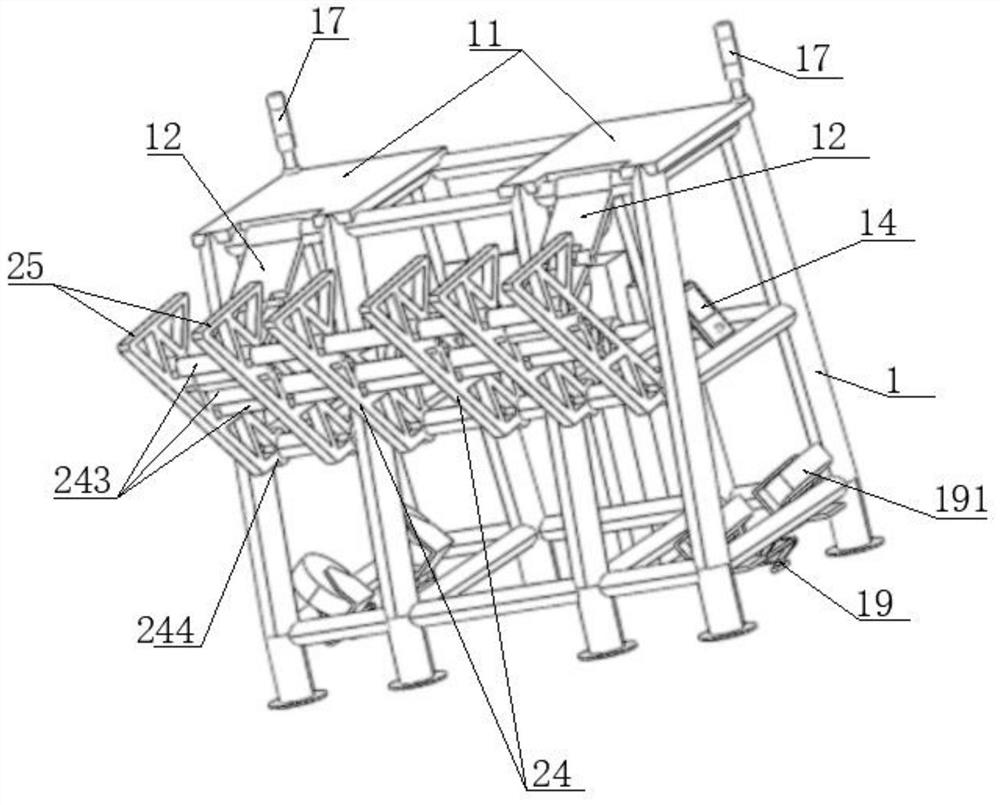

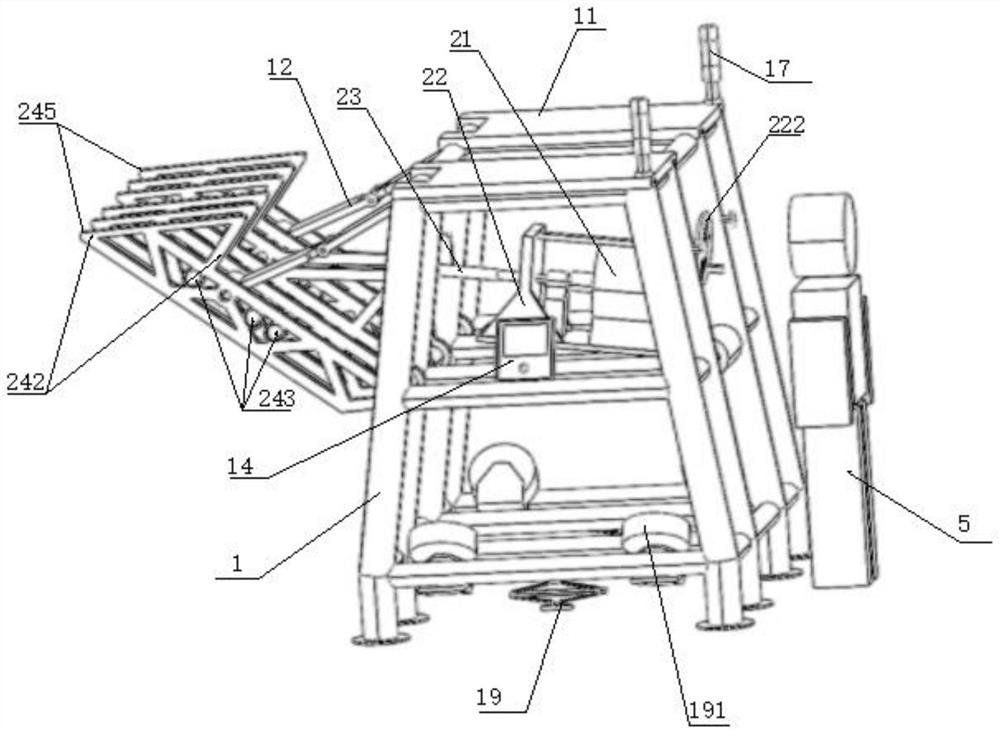

Locking Mechanism in Batch Grabbing Device for Special Gas Cylinders

ActiveCN109592552BAct as a backup bufferProper bufferingLoad-engaging elementsLocking mechanismEngineering

The invention provides a locking mechanism in a special gas steel bottle batch type grabbing device and belongs to the technical field of machinery. By means of the locking mechanism in the special gas steel bottle batch type grabbing device, the problem of poor stability existing in the prior art is solved. The locking mechanism in the special gas steel bottle batch type grabbing device is arranged between a fixed plate and a moving plate and comprises a locking hole concaved in the inner side of the fixed plate, the locking hole is internally provided with a spring and a locking pin, the spring and the inner end of the locking pin are both located inside the locking hole, the outer end of the locking pin stretches out of the locking hole, the side portion of the moving plate is providedwith an inclined force acting surface, and under the pushing squeezing effect of the locking pin, the moving plate has a tendency to move into the fixed plate and makes first positioning holes be in one-to-one correspondence with second positioning holes. The locking mechanism in the special gas steel bottle batch type grabbing device has high stability.

Owner:浙江英德赛半导体材料股份有限公司

Automatic tappet rod body machining device

The invention provides an automatic tappet rod body machining device, and belongs to the field of tappet rod body machining equipment. The automatic tappet rod body machining device comprises an automatic workpiece supply device, a clamping device and a machining device body. The clamping device comprises a rotatable clamp body and a clamping mechanism, wherein the clamping mechanism is arranged on the clamp body. The automatic workpiece supply device is used for pushing a tappet rod body to the clamp body. The clamping mechanism is used for tightly clamping the tail of the tappet rod body. A tool surface is arranged on the clamp body, and is the end surface of the portion, close to the head portion of the clamped tappet rod body, of the clamp body, and when the clamp body rotates, the tool surface faces the machining device body or the side of the tool surface faces the machining device body. By the adoption of the automatic tappet rod body machining device, the purpose that both the end surface of the head portion of the tappet rod body and the circumferential surface of the head portion of the tappet rod body can be machined can be achieved in the one-time clamping process, repeated clamping does not need to be conducted, the working time is shortened, the production efficiency is improved, the degree of automation is relatively high, and the production cost is reduced.

Owner:陈玲婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com