Material conveying system and laser processing equipment

A material transmission system and laser processing technology, applied in the field of material transmission system and laser processing equipment, can solve the problem of difficult to adapt to the standard of double-pipeline transmission and docking, and achieve the effect of reasonable structure design, reasonable layout and production capacity commission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

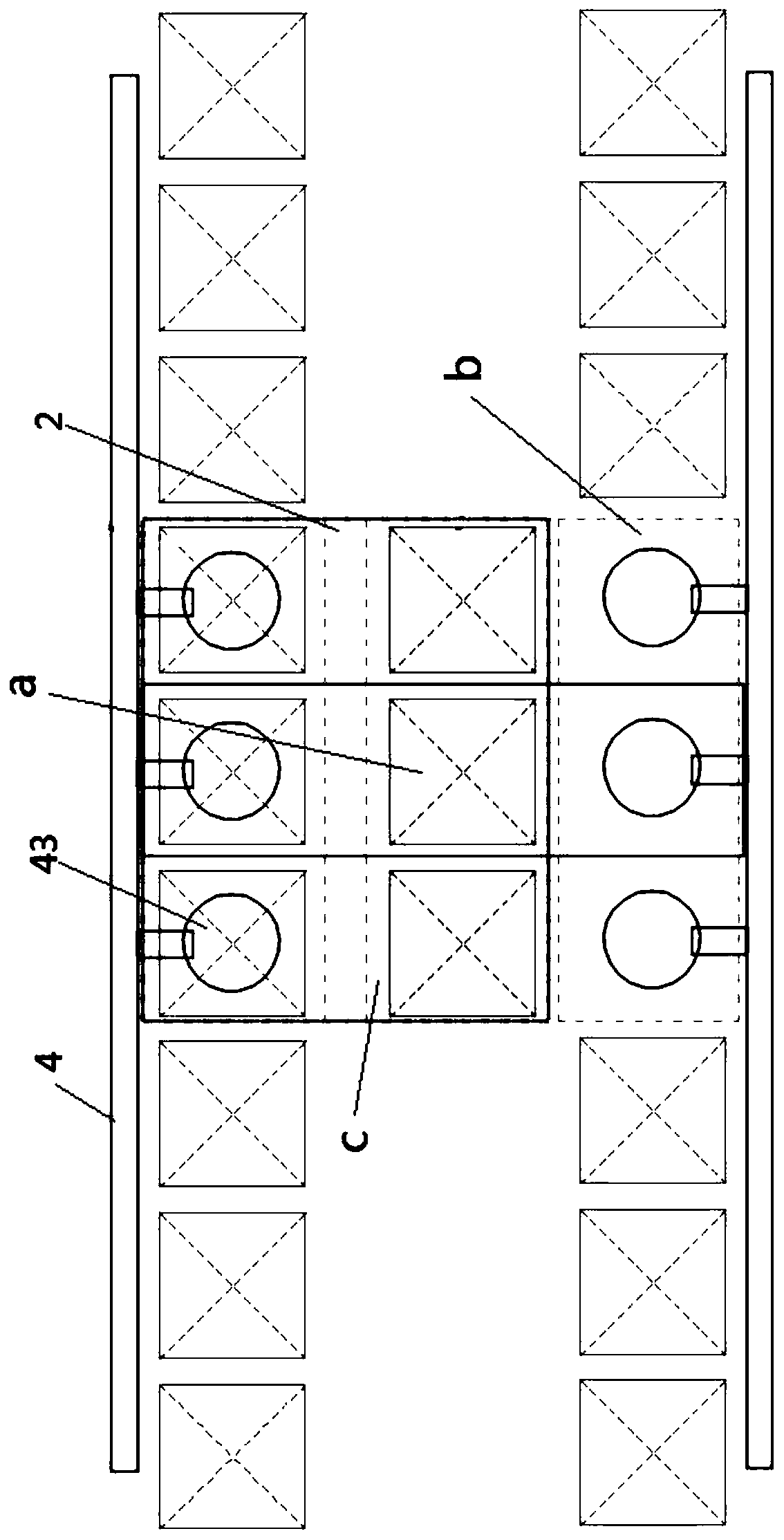

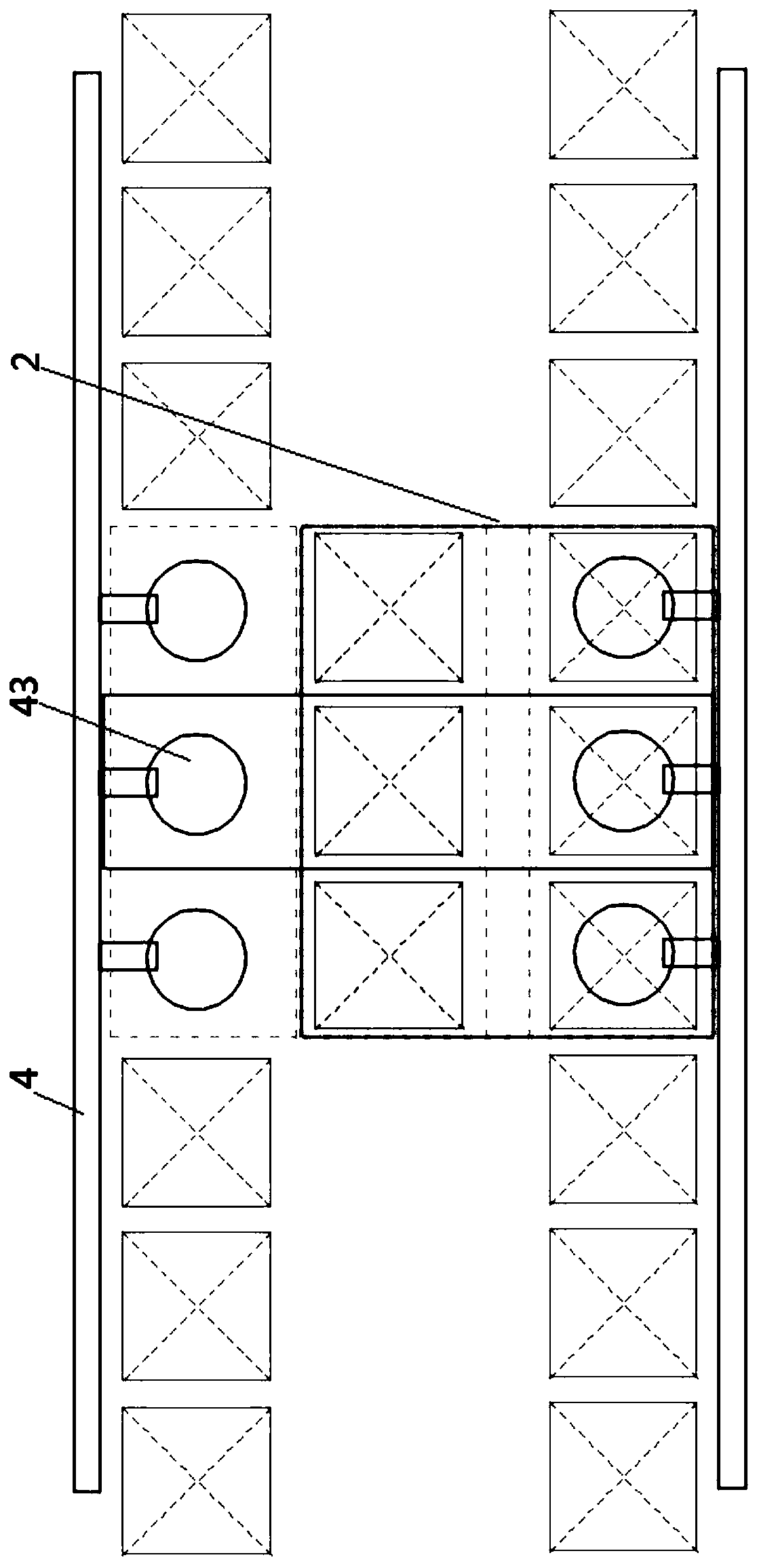

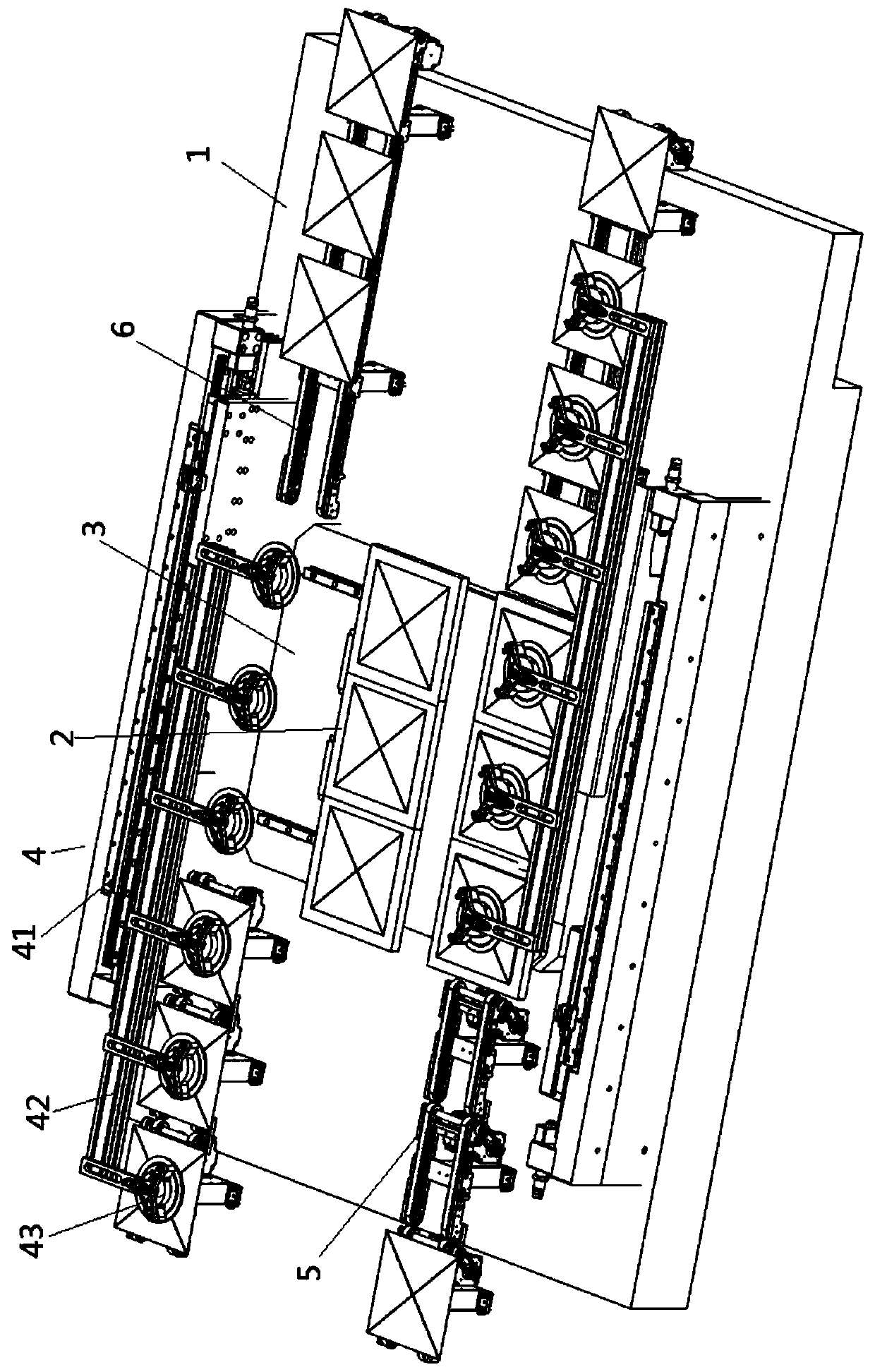

[0038] Embodiment one: if figure 1 , 2 , 3, and 4, the material transmission system of this embodiment includes a workbench 1, an object stage 2, a drive transmission assembly 3 and a loading and unloading mechanism; the above-mentioned object stage 2 is arranged on the upper end of the workbench 1, and is installed on The drive transmission assembly 3 on the workbench 1 is connected by transmission, and the above-mentioned object stage 2 is provided with two groups of discharge positions arranged side by side (a in the figure is the discharge position); the left and right sides above the above-mentioned workbench 1 are respectively Set a group of loading positions (place b in the figure is the material level), set a group of processing positions in the middle (place c in the figure is the processing position), and the above-mentioned drive transmission assembly 3 drives the above-mentioned carrier table 2 to reciprocate left and right, Drive the two sets of discharge positio...

Embodiment 2

[0059] Embodiment two: a kind of material transmission system, see Figure 5 , similar to Embodiment 1, the difference is that the loading and unloading mechanism is a loading and unloading belt conveyor 7 arranged before and after the discharge position, which can be one or a plurality of belt conveyors continuously arranged in the front and rear directions. Now, the discharge position of stage 2 is also arranged on the discharge belt conveyor 8 placed on stage 2, which can be one or a plurality of belt conveyors ( The conveying surfaces are flush with each other), on which one or more materials can be carried, corresponding to one or more discharge positions.

[0060] When used as a processing device for sheet materials, such as in the solar cell industry, the discharge belt conveyor 8 is a negative pressure adsorption belt conveyor.

[0061] At this time, the loading and unloading of materials can be transferred to the discharge position by means of belt conveyor transport...

Embodiment 3

[0063] Embodiment 3: A laser processing equipment, including a laser processing module and the material transmission system in Embodiment 1 or Embodiment 2. The above-mentioned laser processing module is installed on the above-mentioned workbench 1, and its laser scanning head is placed on the above-mentioned Above the processing position, the above-mentioned laser scanning head is used to send out the laser beam downward, and scan and process the materials at a group of the above-mentioned discharge positions that move to the above-mentioned processing position. This laser processing equipment can greatly increase the production capacity , and the laser scanning head is generally used for the scanning processing of the cells to be processed on the two discharge positions, and the layout and design are very reasonable.

[0064] As a preferred solution, there is one laser processing module or a plurality of the same amount as the material processing position, and the materials o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com