Battery shell automatic notching die

A technology of battery casing and slit die, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of poor production efficiency, low production efficiency, large product burrs, etc., so as to reduce production costs and improve work production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

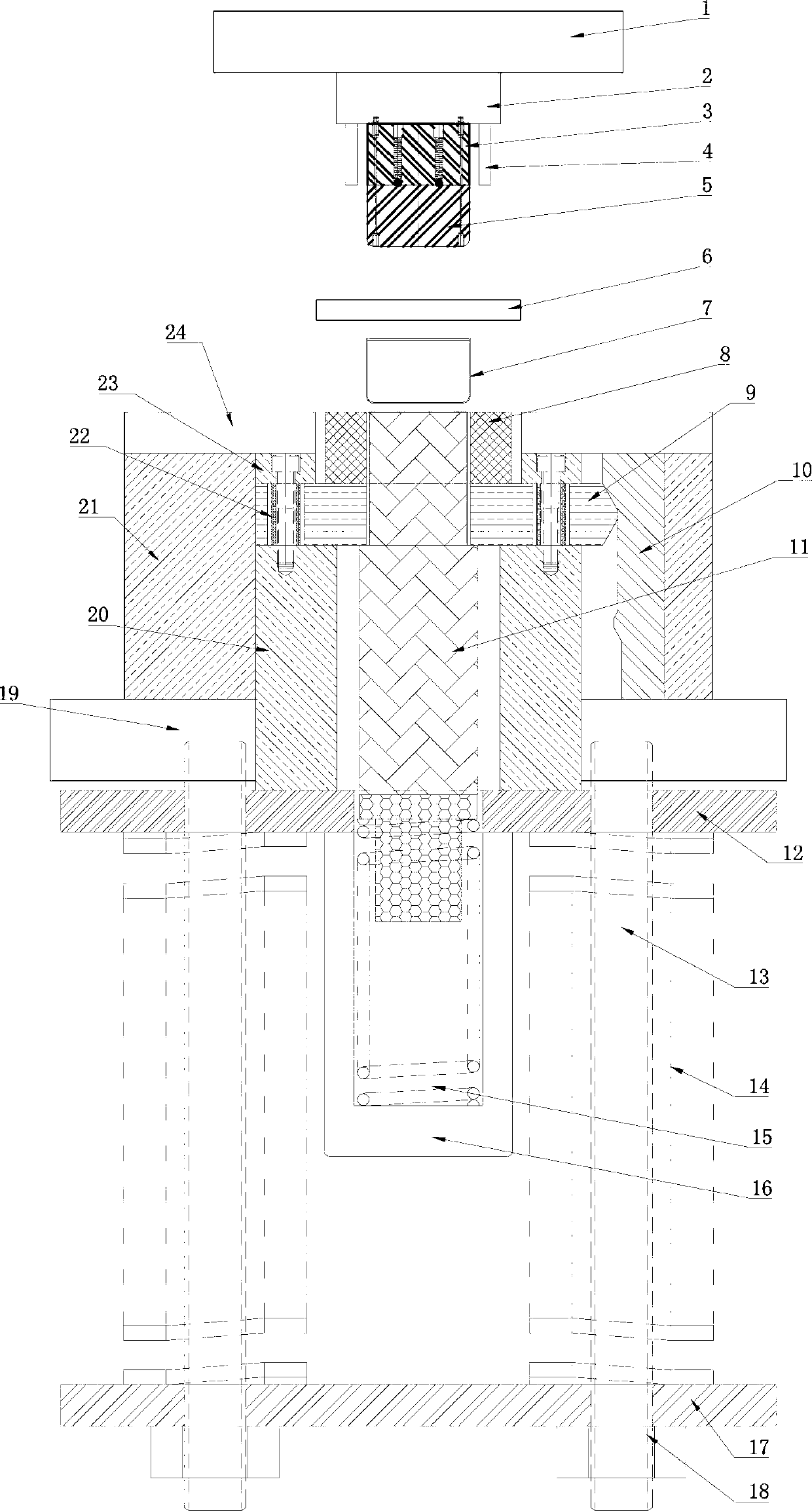

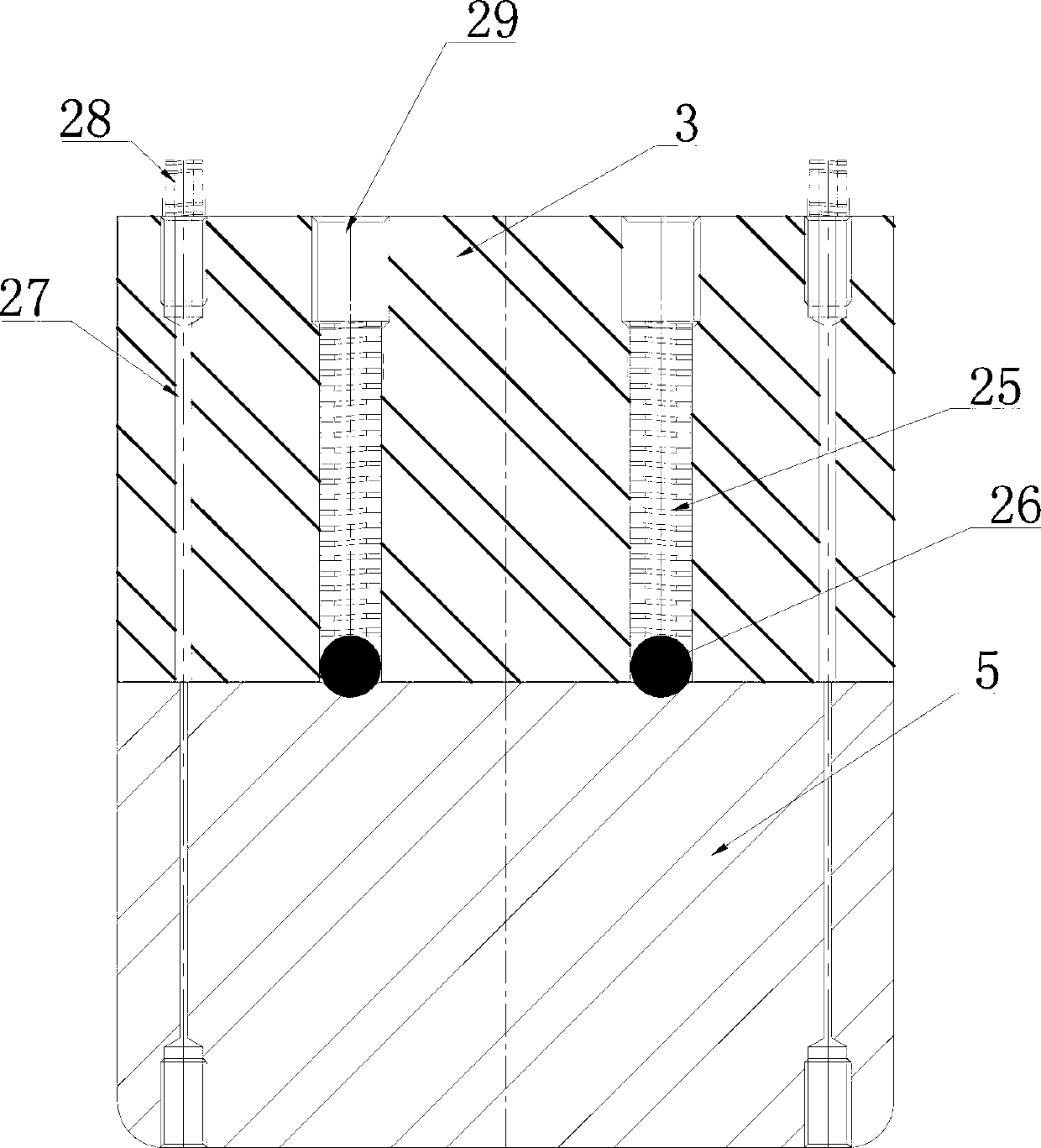

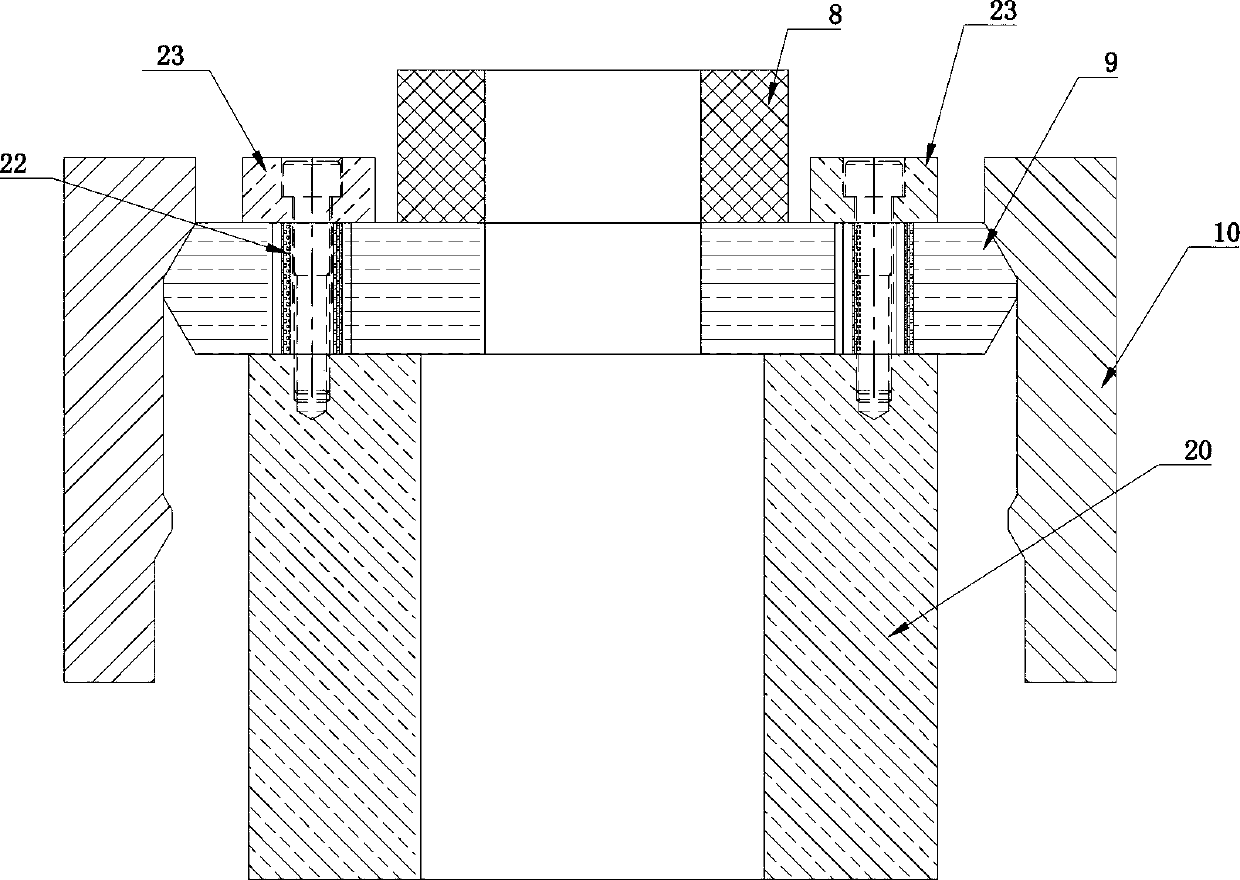

[0027] A kind of battery casing automatic cutting die, such as Figure 1 to Figure 7 As shown, it includes an upper mold and a lower mold. The upper mold includes an upper template 1, and the upper template 1 is fixedly connected with a slit punch fixing plate 2, and the slit punch fixing plate 2 is fixedly connected with a slit punch 3 and a positioning rod 4. The positioning rod 4 is located around the notch punch 3, and the front, rear, left, and right sides of the notch punch 3 are movably connected with a positioning core 5; There is a die cover plate 24, and a perforation is arranged in the middle of the die cover plate 24; a lower positioning seat 20 is movable up and down in the middle of the lower mold base 21 and the lower template 19, and a guide slider 9 is arranged on the lower positioning seat 20, and the guiding slider 9 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com