Connecting and locking device for building templates

A locking device and construction formwork technology, which is applied to the connection parts of formwork/formwork/work frame, buildings, building structures, etc., can solve the problems of poor connection stability and inability to connect formwork with different angles, and achieve rotation stability , save connection time, and achieve precise connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

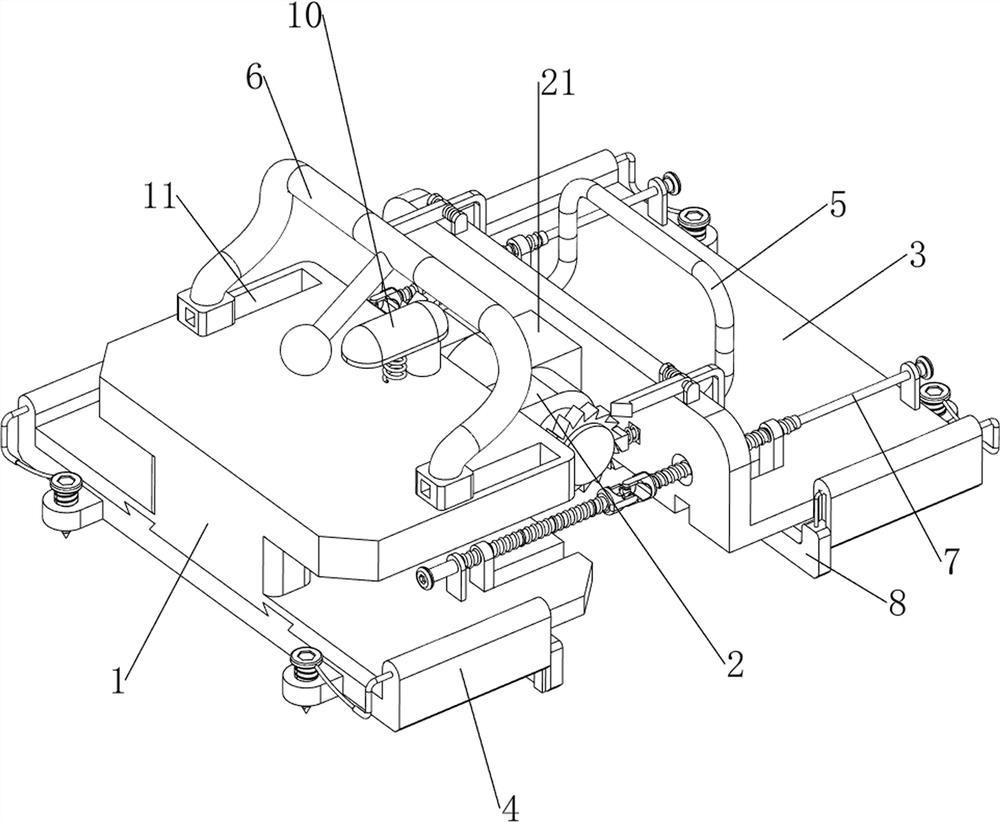

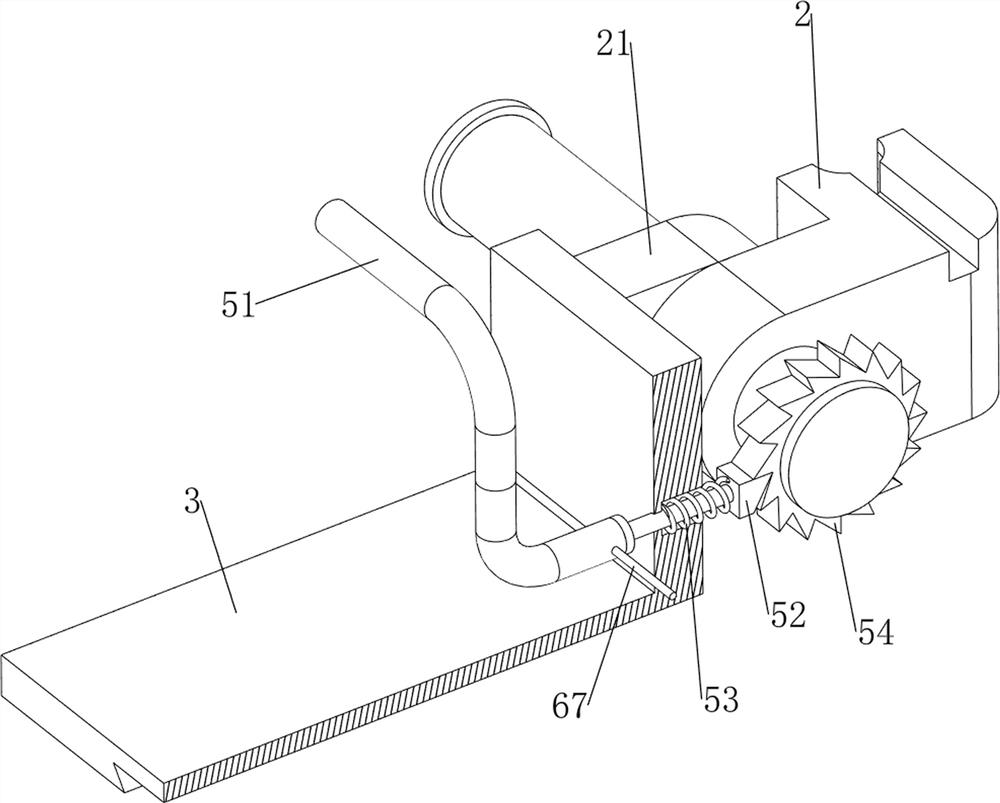

[0030] A locking device for building formwork connection, such as figure 1 , figure 2 , Image 6 , Figure 7 and Figure 9 As shown, it includes a T-shaped frame 1, a first connecting spring 12, a first hinge block 2, a second hinge block 21, an L-shaped plate 3, an installation mechanism 4, an adjustment mechanism 5 and a locking mechanism 6. The T-shaped frame 1 A cavity is opened on the right side, a first hinge block 2 is slidably arranged in the cavity, a first connecting spring 12 is connected between the first hinge block 2 and the T-shaped frame 1, and the right part of the first hinge block 2 rotates through There is a shaft, a second hinge block 21 is bolted on the shaft, an L-shaped plate 3 is bolted on the right side of the second hinge block 21, the top of the T-frame 1 is symmetrically opened with sliding grooves 11 on the front and rear sides, and the T-frame An installation mechanism 4 is arranged between the 1 and the L-shaped plate 3 , an adjustment mech...

Embodiment 2

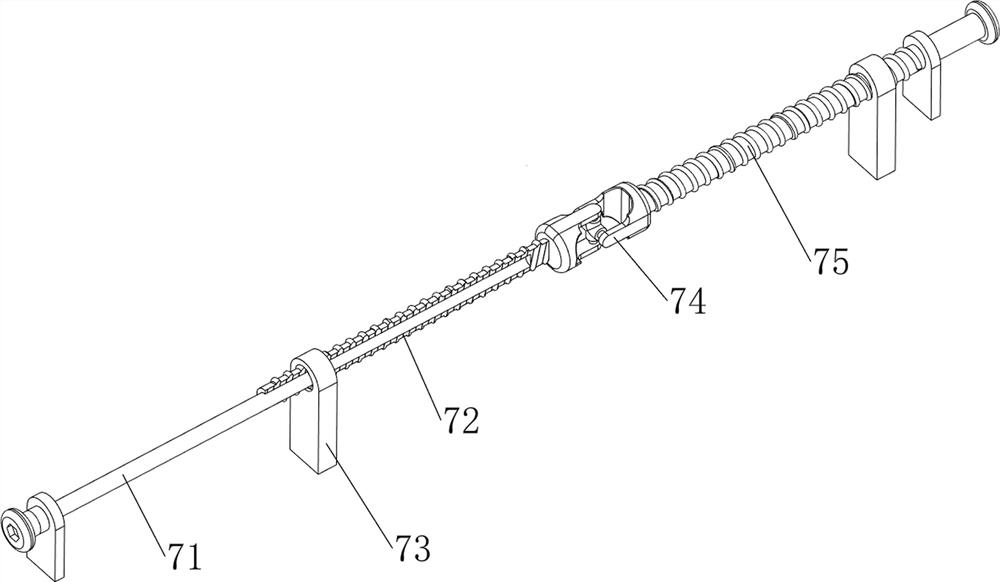

[0036] On the basis of Example 1, as figure 1 , Image 6 and Figure 8 As shown, an auxiliary mechanism 7 is also included. The auxiliary mechanism 7 includes a guide rod 71, a first screw rod 72, a second nut 73, a coupling 74 and a second screw rod 75. The sides are symmetrically welded with second nuts 73 in the front and rear, and the second nuts 73 on the left and right sides slide through the T-frame 1 and the L-shaped plate 3 respectively. The guide rods 71 of the two nuts 73, the guide rods 71 are hingedly sleeved with a first screw rod 72, the first screw rod 72 is threaded through the adjacent second nut 73, and both the front and rear sides of the top of the T-frame 1 are rotatable. A second screw rod 75 is provided, the second screw rod 75 is opposite to the thread on the first screw rod 72 , and a coupling 74 is bolted between the second screw rod 75 and the first screw rod 72 on the same side.

[0037] When the two templates are approached, the rightward m...

Embodiment 3

[0039] On the basis of Example 2, as figure 1 , Figure 5 and Image 6 As shown, it also includes a limiting mechanism 8. The limiting mechanism 8 includes a limiting silicone plate 81, a guide tube 82 and a second pulling rope 83. The opposite sides of the two sliding plates 41 are slidably provided with a limiting template. The limit silica gel plate 81, the two sliding plates 41 are separated from each other with a guide tube 82 running through the front and rear symmetrically, and the upper sides of the two limit silica gel plates 81 are symmetrically provided with a second pull rope for power transmission. 83. The tail end of the second pulling rope 83 is slidably penetrated through the adjacent guide tube 82 and connected with the adjacent screw 43.

[0040] The operator makes the opposite sides of the left and right templates contact the side of the left and right limit silica gel plates 81 away from each other, so that the template can be quickly aligned with the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com