High-precision polishing equipment for graphite slices

A high-precision, slicing technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, surface polishing machine tools, etc., can solve the problem of inability to achieve the polishing accuracy of graphite slices, the rough position adjustment of the polishing device of the transmission device, and the inability to adapt to individual graphite materials Differences and other issues, to achieve the effect of strengthening the vacuum adsorption effect, avoiding excessive polishing, and improving the vacuum adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

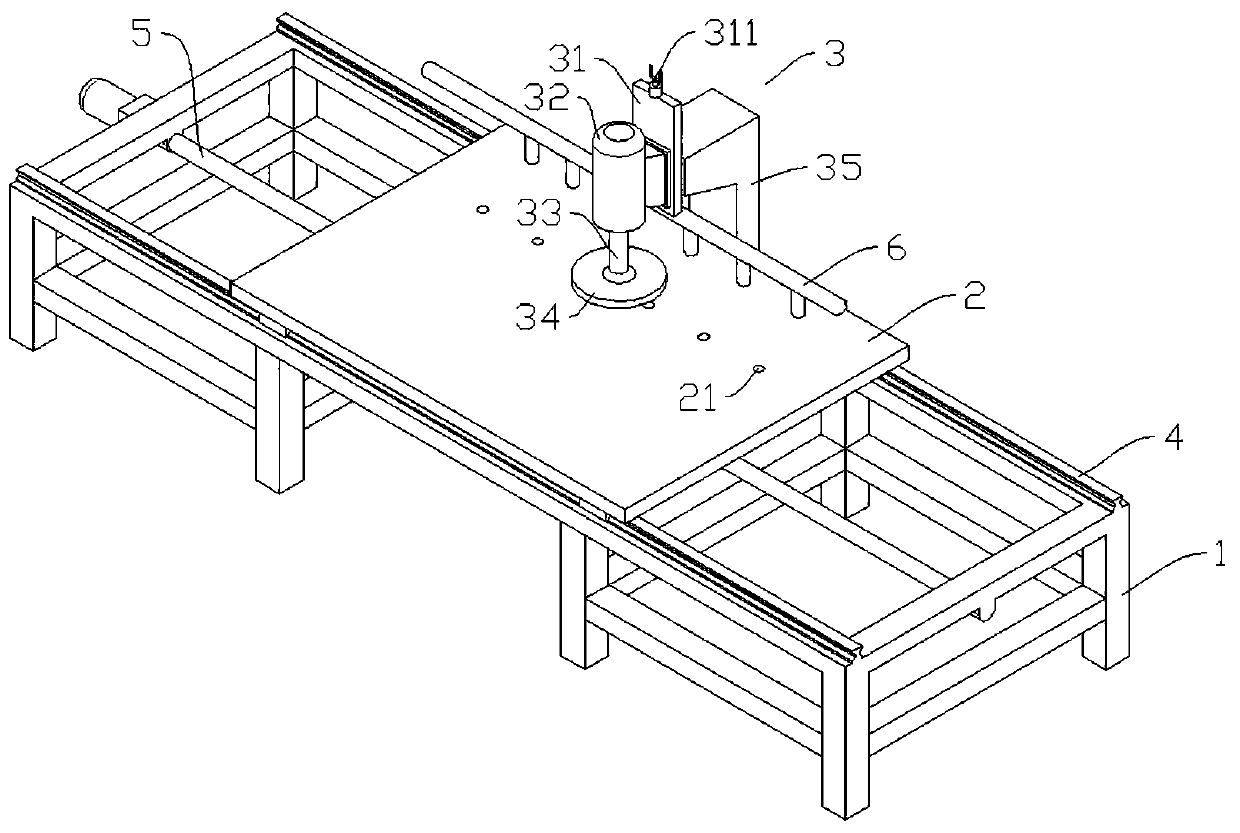

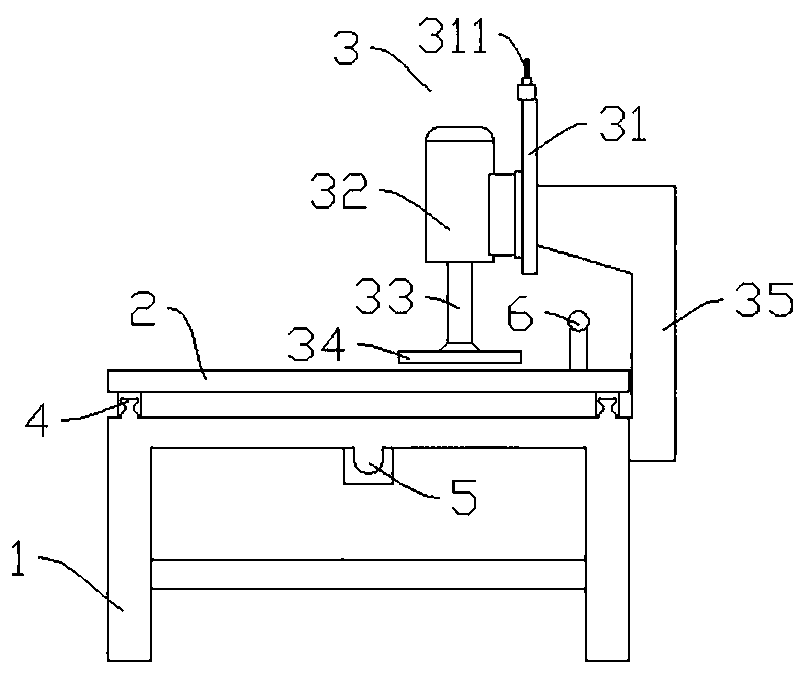

[0033] A high-precision polishing equipment for graphite slices, such as figure 1 and figure 2 shown, including:

[0034] - frame 1, said frame 1 is provided with two parallel slide rails 4;

[0035] - workbench 2, installed on the frame 1 through the slide rail 4; the upper surface of the workbench 2 is provided with some small holes 21 communicated with the vacuum pipeline 6, and the diameter of the small hole is 1.0cm; the vacuum pipeline 6 is connected to the vacuum generator; a lead screw 5 parallel to the slide rail 4 and installed on the frame 1 is provided under the workbench 2, and the supporting seat set on the lead screw 5 is connected with the working The table 2 is fixedly connected, and the lead screw 5 is driven to rotate by a motor;

[0036] - The grinding assembly 3 includes a lifting base 31, the lifting base 31 is adjusted to lift through the rotating part 311 on its upper surface, and the outer circumference of the rotating part 311 is marked with scale...

Embodiment 2

[0040] This embodiment is a high-precision polishing equipment for graphite slices, the basic structure is the same as that of Embodiment 1, and on the basis of Embodiment 1, it also has the following structural features:

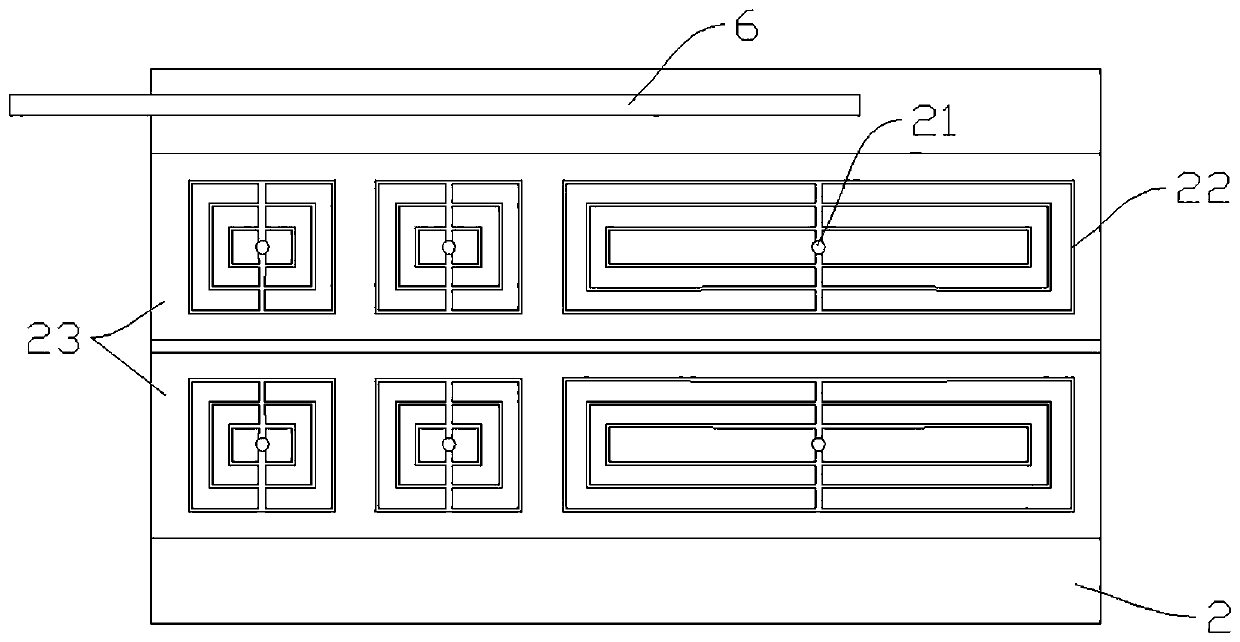

[0041] The mounting seat 35 is slidingly connected with the frame 1 . Specifically, the mounting base 35 is provided with a slider, and the sliding block cooperates with the electric guide rail provided on the frame to realize the mounting base 35 moving along the translational direction of the workbench 2, thereby realizing the translation of the polishing disc 34 in this direction, The equipment can not only realize the adjustment of the graphite slice polishing position through the translation of the workbench 2, but also realize the translation of the mounting seat 35, which has higher flexibility; the table structure of the workbench 2 is as follows: image 3 As shown, the surface of the workbench 2 is provided with two recessed areas 23 for placing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com