Automatic incasing machine

A cartoning machine and automatic technology, applied in packaging, bottle packaging, transportation and packaging, etc., can solve the problems affecting the quality of packaging and bottled products, high requirements for the professional technical level of operators, and unstable bottle movement. Ensure the quality of bottled products, ensure the quality of packaging, and the effect of smooth bottle movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

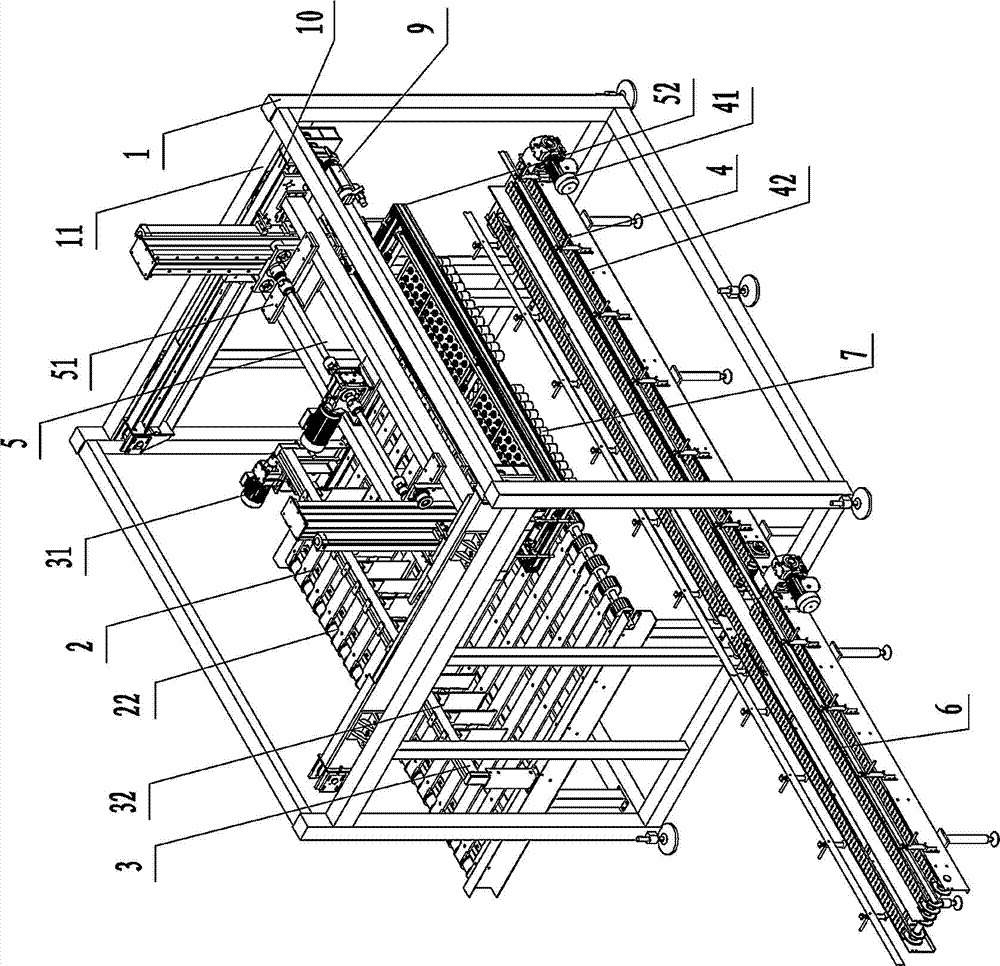

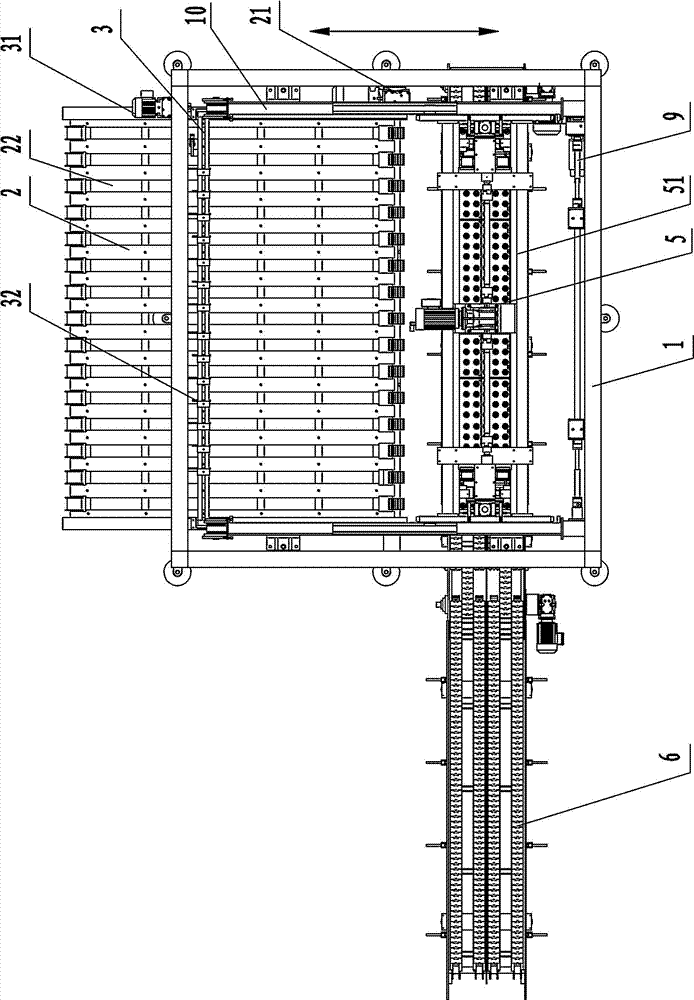

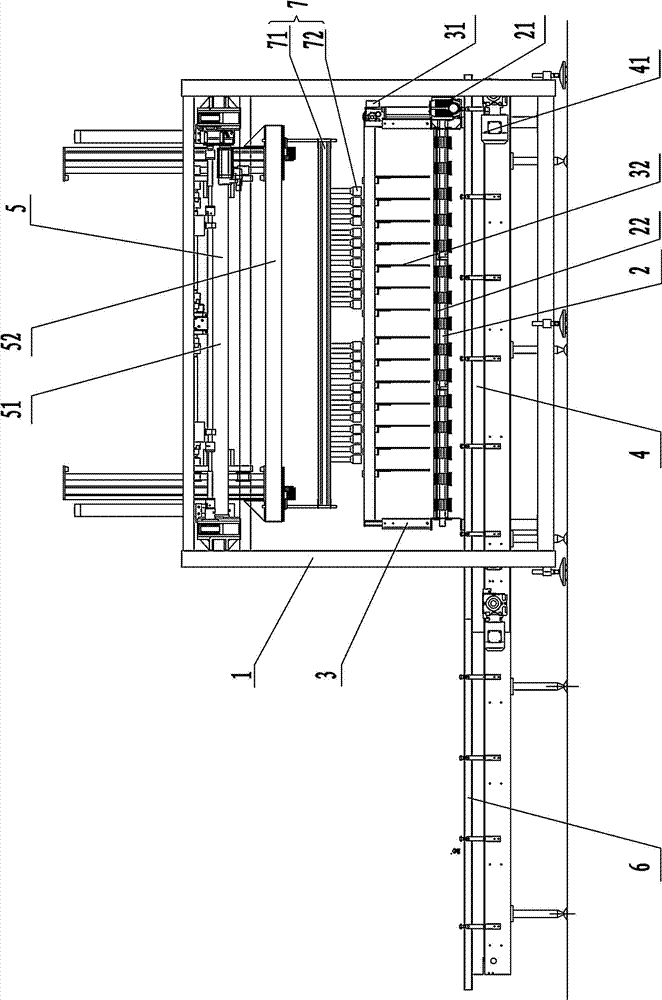

[0032] see figure 1 -4. In this embodiment, the automatic case packing machine includes a frame 1, a bottle feeding device 2, a bottle discharging device 3, a case feeding device 4 and a bottle moving device 5 (see figure 1 ).

[0033] The frame 1 is mainly used to install the relevant parts of the bottle feeding device 2, and can adopt a suitable frame structure formed by connecting multiple components according to the requirements of the equipment; the frame also includes other devices (such as a bottle shifting device) 5. Each base frame of the box feeding device 4, etc.), which at least includes a top frame 11 for supporting the bottle shifting device 5 and not hindering the translation and lifting functions of the bottle shifting device 5 (see figure 1 ). The rack 1 can be realized by means of existing technologies, which will not be described in detail here.

[0034] The bottle feeding device 2 is composed of a plurality of parallel conveyor belts driven by a motor, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com